Axial load testing method of ball bearing

A technology of axial load and test method, applied in the direction of measuring device, force/torque/work measuring instrument, instrument, etc., can solve the problem that cannot fully meet the requirements of ball bearing test axial load, and achieve the method is simple and accurate. The effect of high degree and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

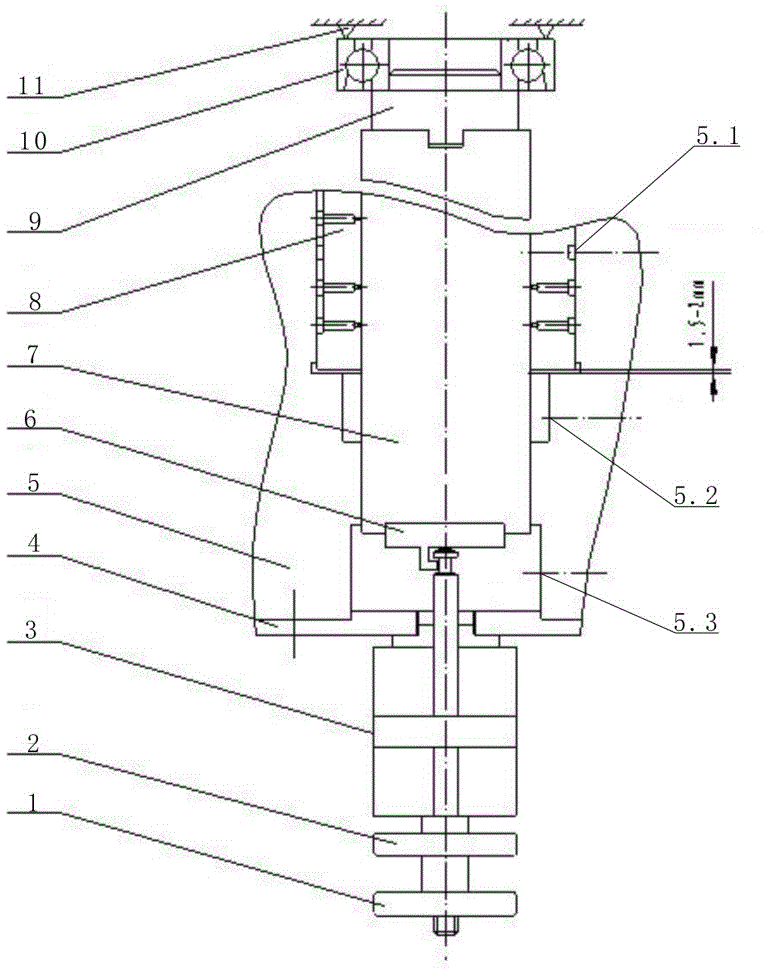

[0028]The invention relates to an axial load testing method of a ball bearing. The axial load testing method uses a set of testing devices to clamp and position the tested ball bearing at one time and realize the tested ball bearing. The pressure generated by compressed air exerts pressure on the tested ball bearing. The ball bearing exerts a stable and non-impact axial load. The compressed air in the airtight chamber can realize the uniform speed of the air spindle and make the tested ball bearing realize the stepless loading of the axial load. The axial load test method is reliable, easy to operate, The method is simple and convenient.

[0029] combine figure 1 , the test device includes a lock nut 1, an adjustment nut 2, a cylinder 3, an end cover 4, a base 5, an axial bracket 6, an air spindle 7, a bearing sleeve 8, a positioning centering seat 9, and a positioning support 11, wherein The effective cross-sectional area of the air main shaft 7 in the case of a given oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com