Screw nut, method of production thereof and corresponding tool

一种螺母、工具的技术,应用在金属材料制成的螺母领域,能够解决加工复杂性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

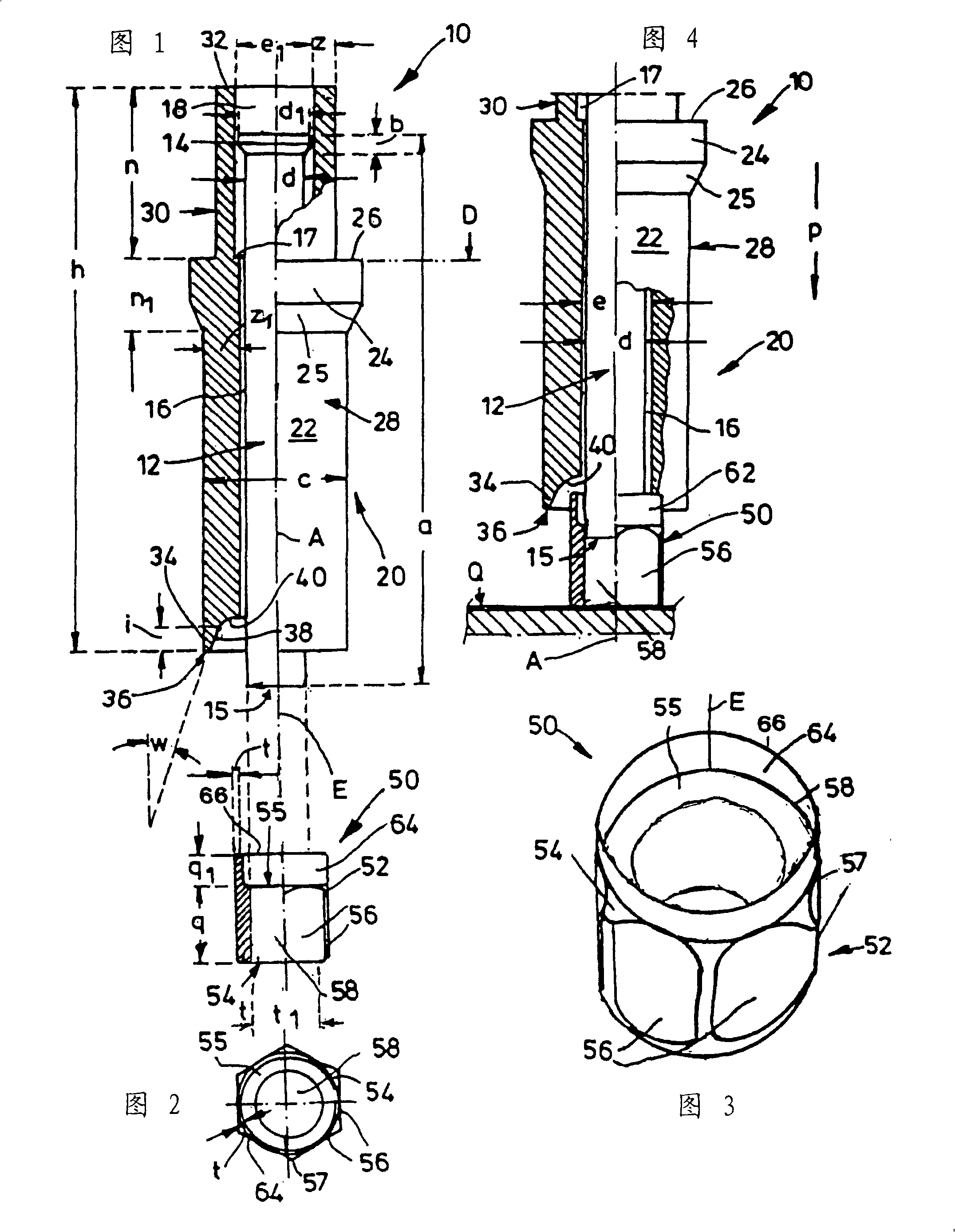

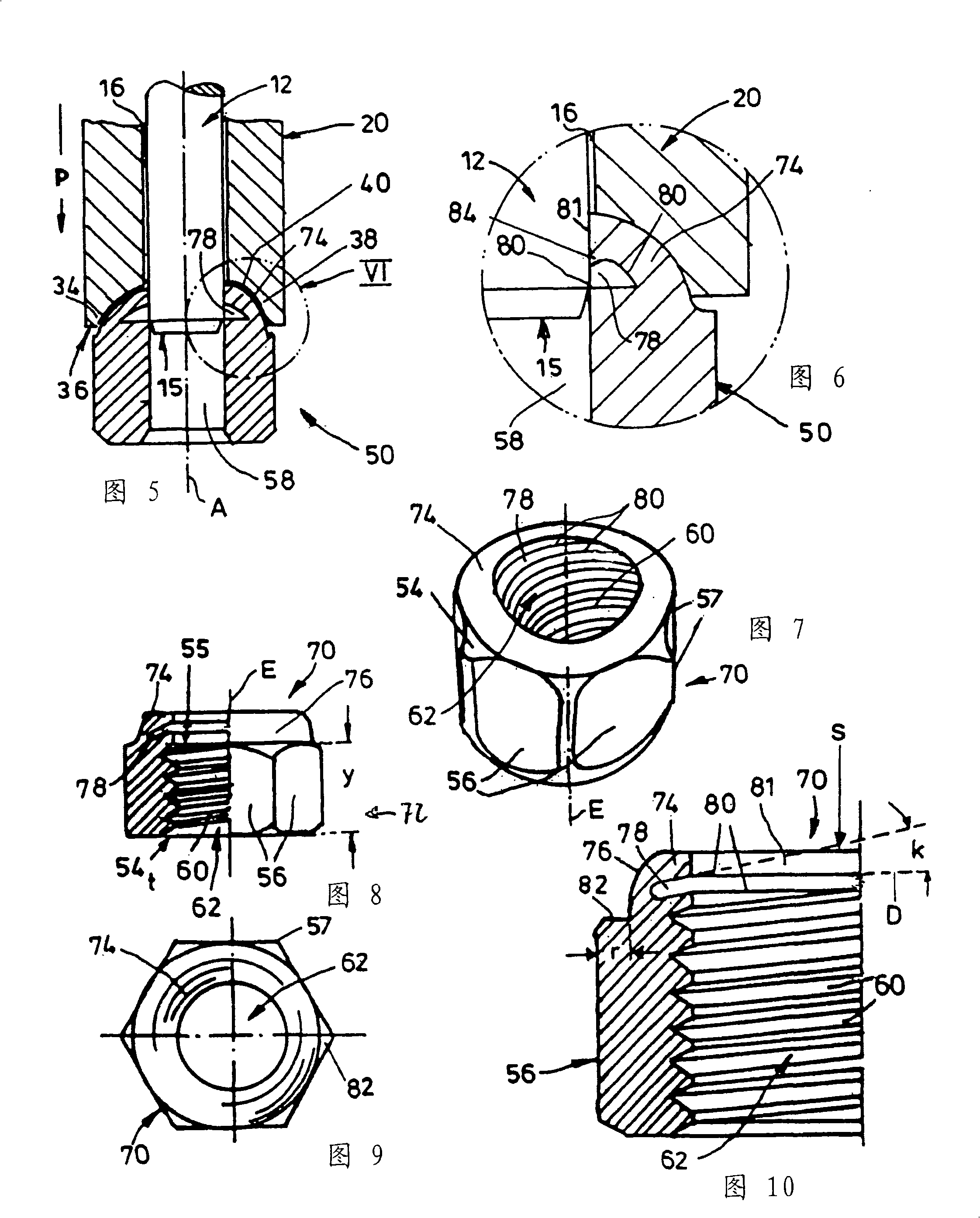

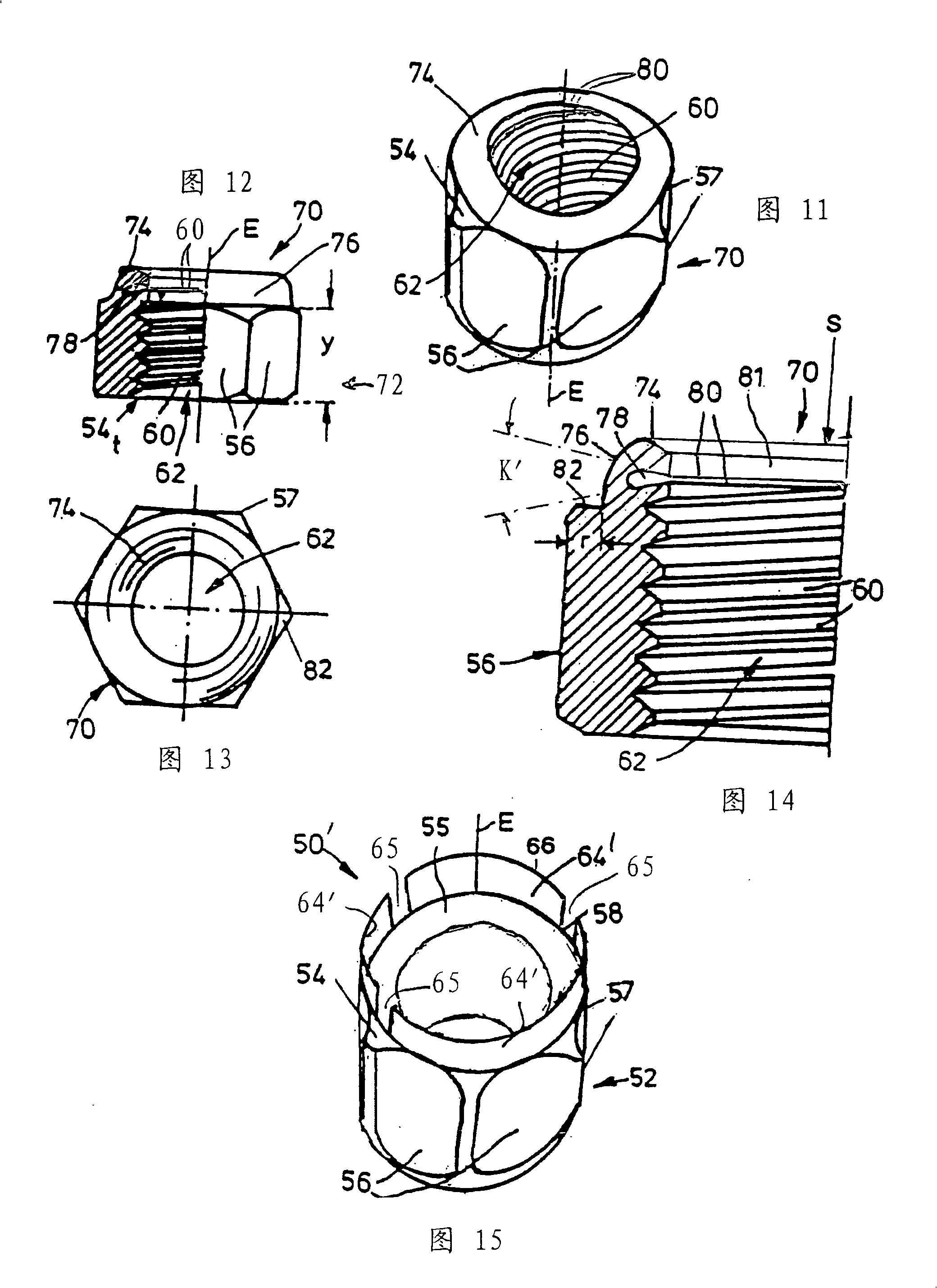

[0040] The metal tool 10 that is used to process an annular workpiece 50 has punch 12, and its length a here is 76mm and diameter d is about 10mm, forms a central stop disc 14 from its upper end in Fig. 1, stop disc diameter d 1 Here it is 12 mm and the axial thickness b is 3 mm. The dimensions of the punch 12 and thus the diameter d of its pressing end face 15 depend on the diameter of the bore of the nut blank 52 which will be described later. The punch 12 is movably accommodated in a guide channel 16 of a sleeve-shaped housing 20 whose axial length h is here 78 mm and whose outer diameter c is approximately 22 mm. The diameter e of the guide channel 16 extending along the longitudinal axis A of the housing is slightly larger than the diameter d of the punch 12 .

[0041] At an axial distance n of 23 mm from the upper lip 32 of the cylindrical housing 20, an annular flange 24 is formed on the outer surface 22 thereof. In a radial plane D defined by its upper annular edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com