Hot type member fetching machine

A technology for pick-up arms and components, which is applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems that thermal pick-up machines cannot be applied, and achieve the effect of small movement displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

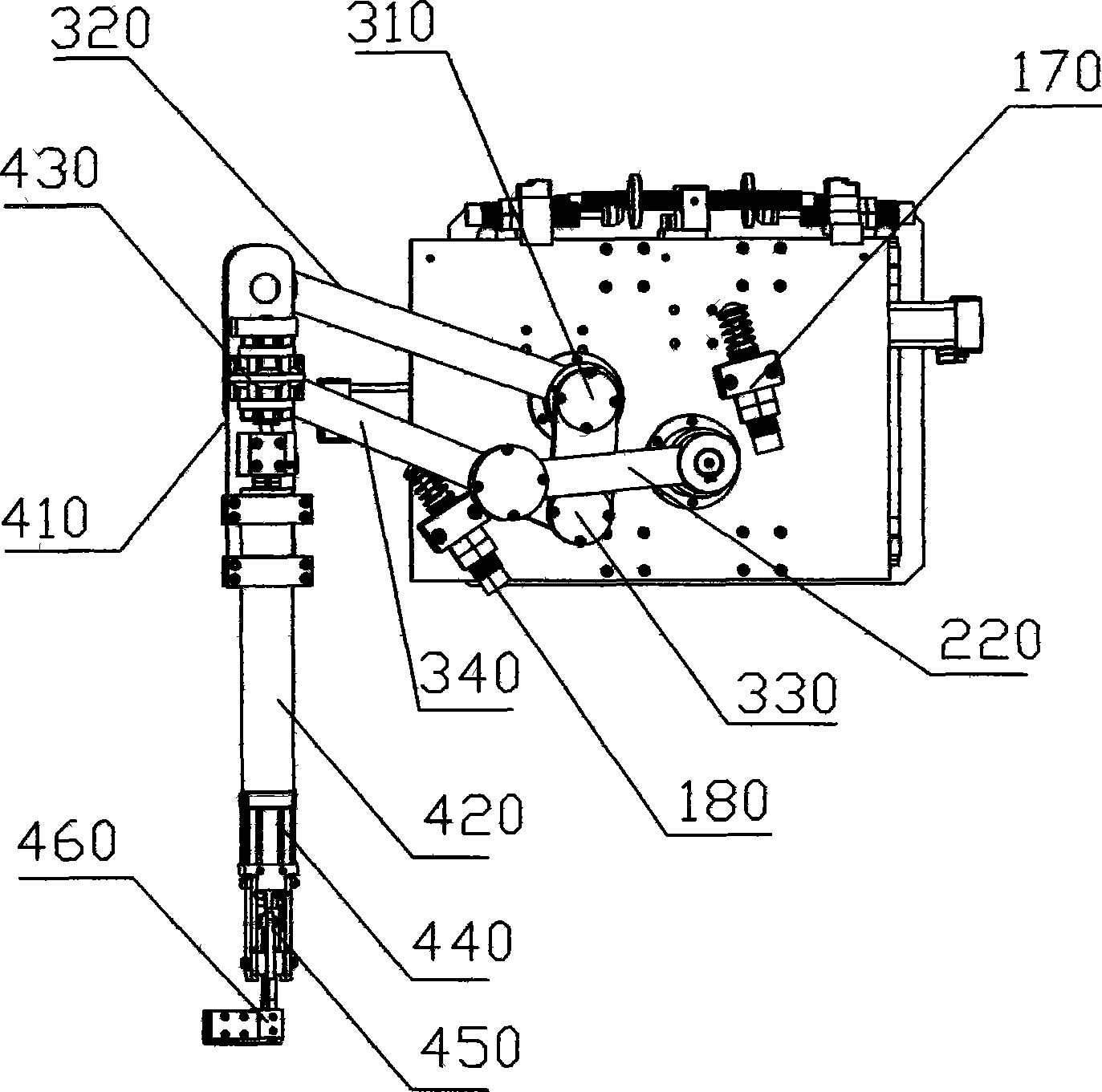

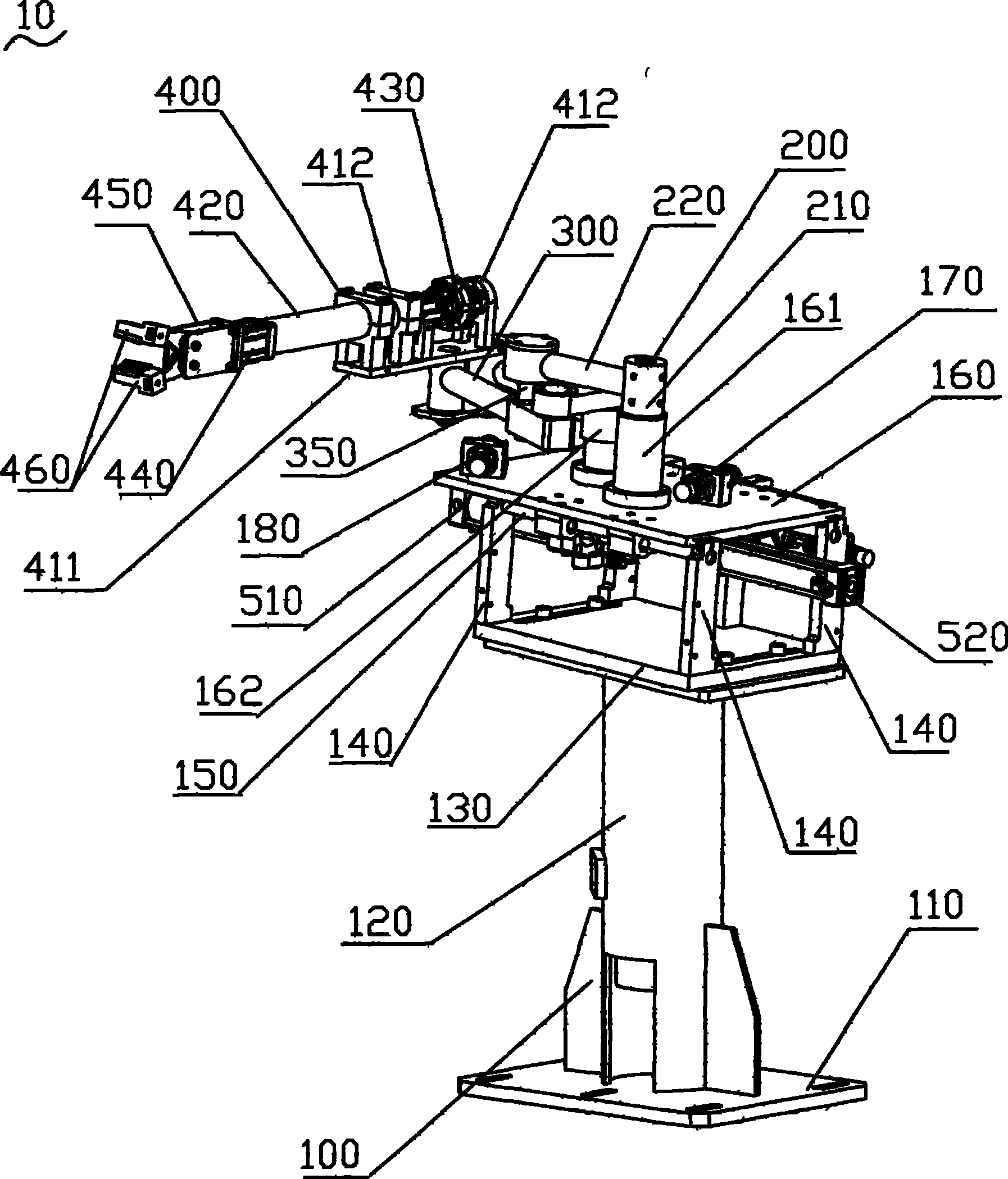

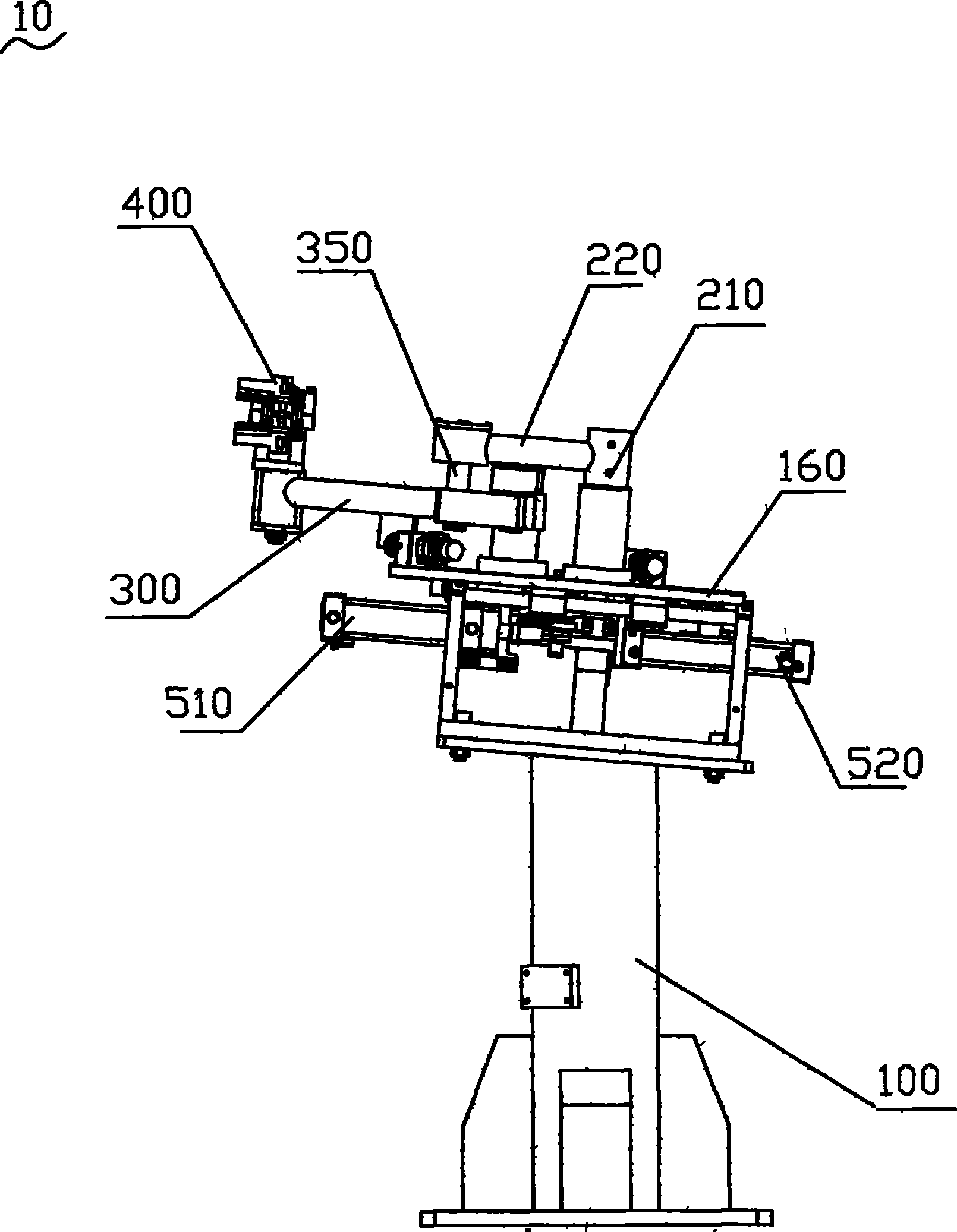

[0018] Please refer to Fig. 1 and Fig. 2, the thermal extractor 10 of the present invention cooperates with the hot chamber die casting machine, and is used to take out the die casting from between the male mold and the female mold of the hot chamber die casting machine. The thermal extractor 10 includes a base 100 , a driving rod assembly 200 , a driven rod assembly 300 , an extracting arm assembly 400 and a driving source group.

[0019] The machine base 100 has a square-shaped bottom plate 110 , and a cylindrical supporting post 120 extends from a middle portion of the bottom plate 110 . A square top plate 130 is fixed on the top of the bearing column 120 . A pillar 140 extends vertically upward from the four corners of the top plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com