AC mine winder rotor frequency modulation pressure regulating apparatus

A mine hoist, frequency modulation and voltage regulation technology, applied in AC motor control, lifting equipment in mines, motor/generator/inverter limiter, etc., can solve the problems of poor speed regulation performance, low reliability of equipment, Occupy a large area and other issues to achieve the effect of improving operational performance and safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

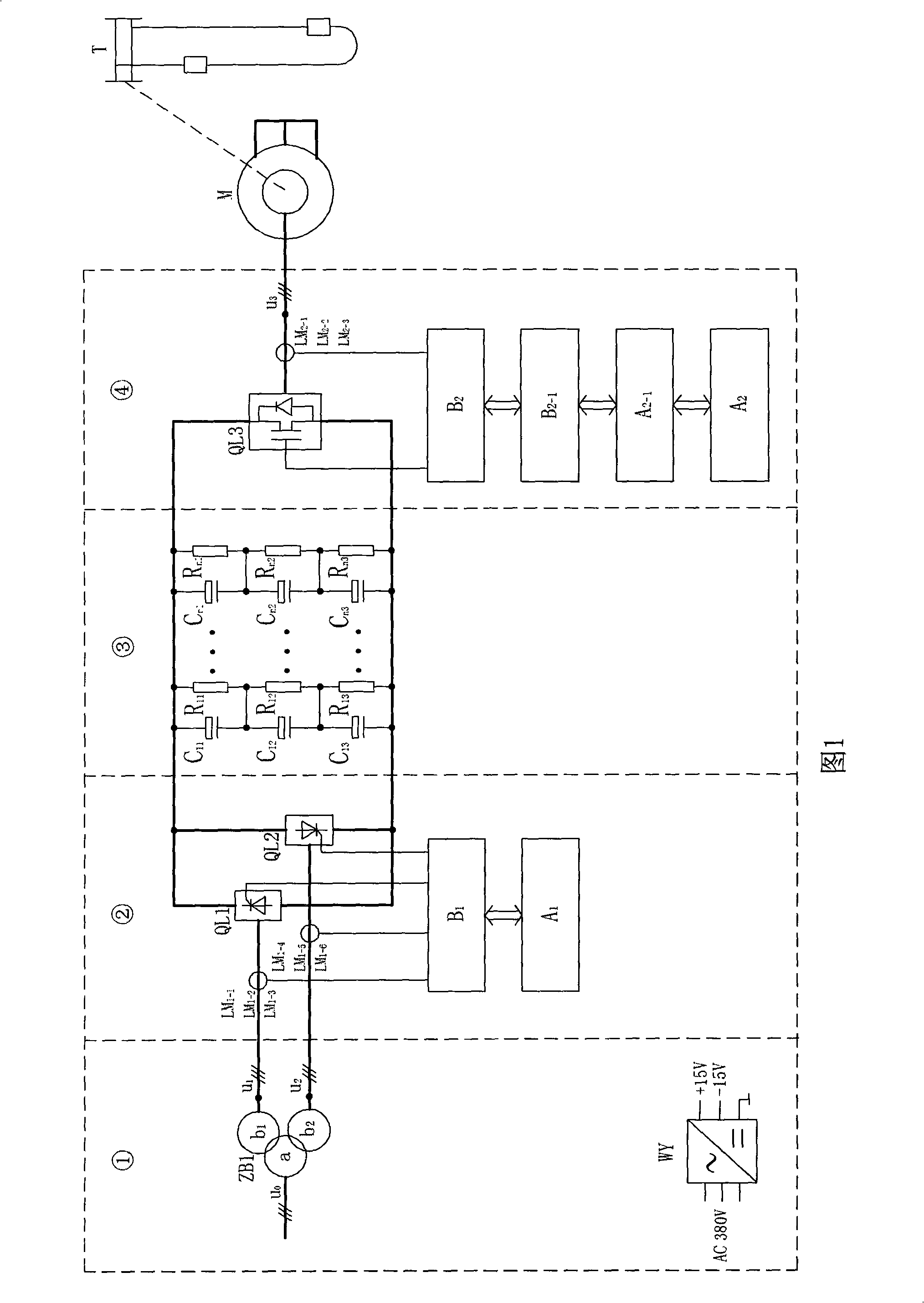

[0015] Embodiment of the present invention is described in conjunction with accompanying drawing:

[0016]As shown in Figure 1, the AC mine hoist rotor frequency modulation and voltage regulation device of the present invention is mainly composed of a power input part ①, a rectification / feedback part ②, a DC energy storage part ③, a voltage regulation and frequency modulation output part ④, etc.; the power supply part is divided into two parts First, the switching power supply WY converts the AC 380V power supply provided by the system into +15V, -15V DC power supply, which is provided to each unit A1, B1, A2, B2 and A2-1 in the frequency modulation and voltage regulation device , B2-1 is used to maintain the normal operation of the frequency and voltage regulating device; secondly, the rectifier transformer ZB1 can provide large-capacity AC power for the frequency and voltage regulating device, and the primary winding of ZB1 is designed to accept any standard voltage in China ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com