Novel hard aluminium alloy bar material hot-extrusion mold

A technology of hot extrusion die and hard aluminum alloy, applied in metal extrusion die and other directions, can solve the problems of poor fluidity of hard aluminum alloy, shrinking tail, difficult feeding of bar corners, etc., to eliminate shrinking tail and slub. effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

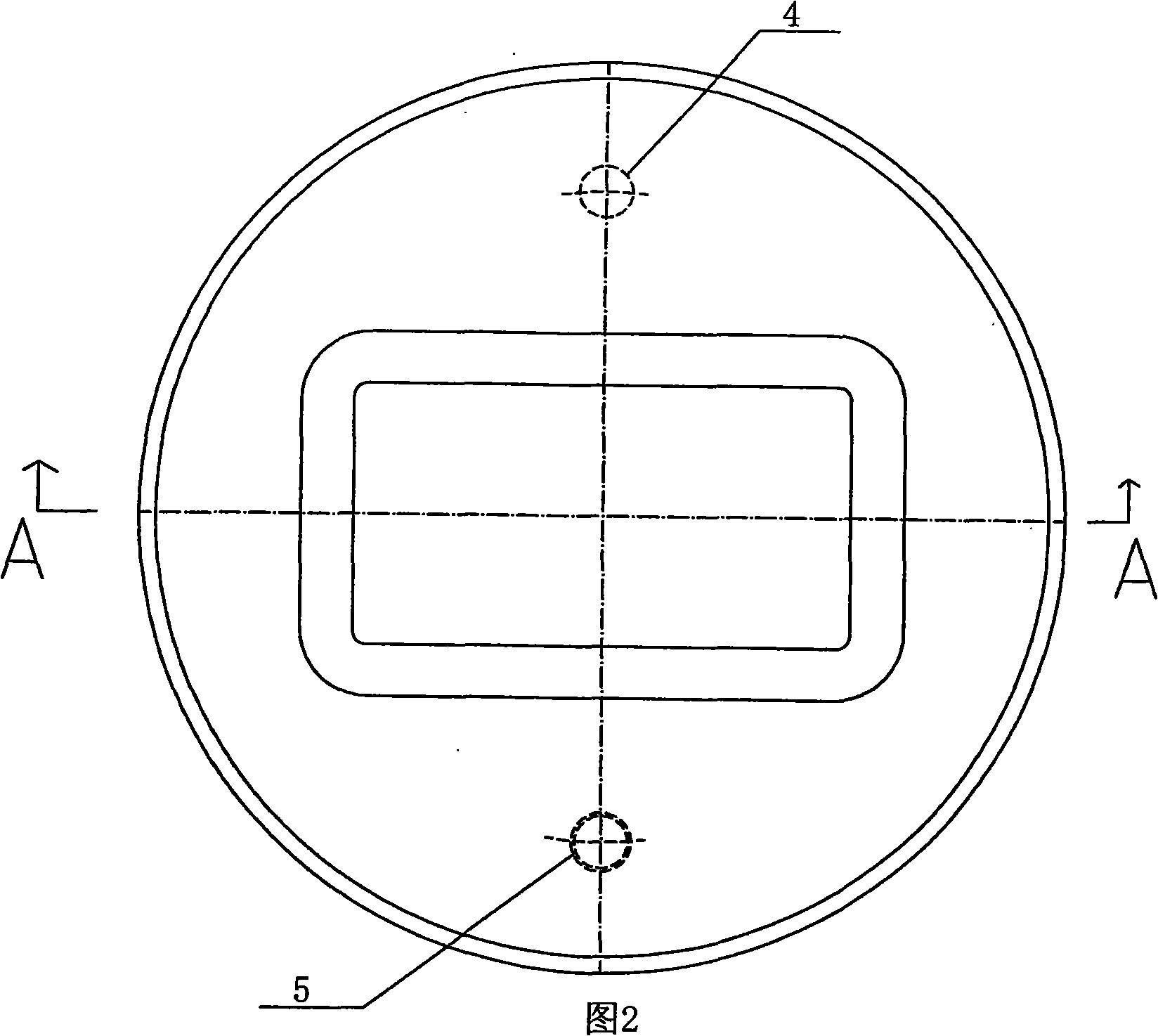

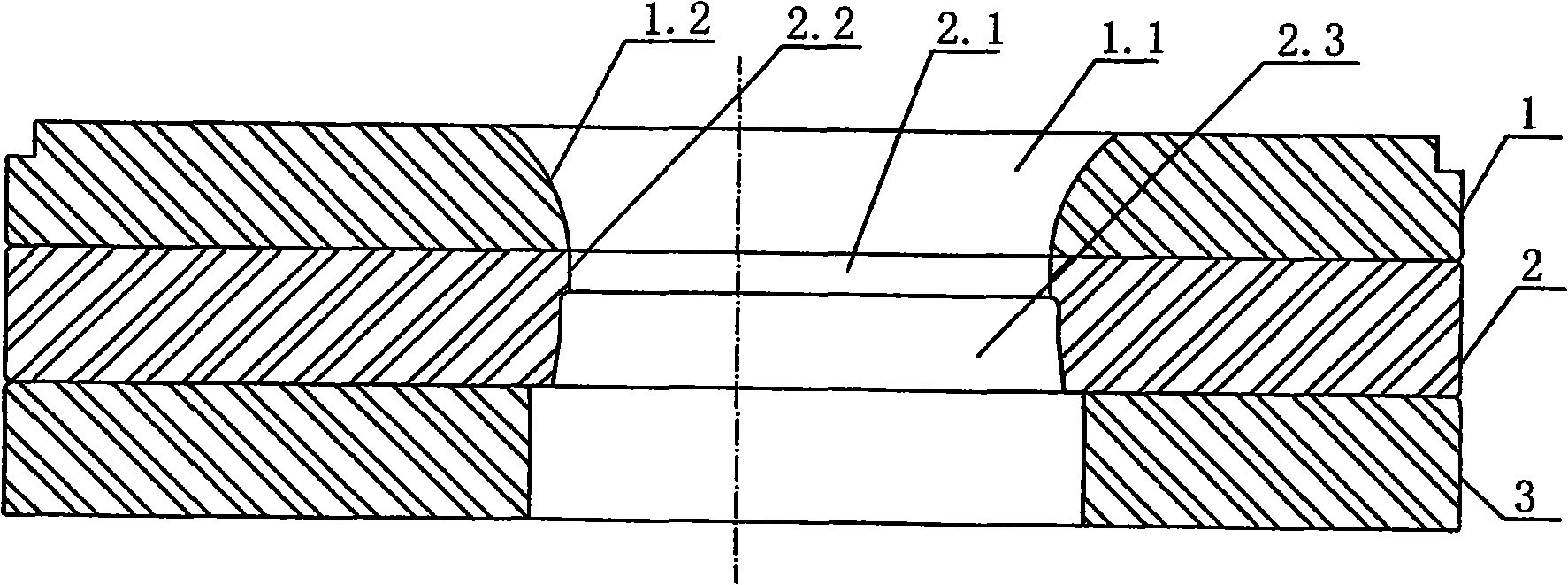

[0019] see figure 1 ~2, the novel duralumin alloy bar hot extrusion die that the present invention relates to, by pre-guiding mold 1 ( image 3 ), model 2 ( Figure 4 ) and Die Pad 3 ( Figure 5 ) is formed by assembling the pin 4 and the screw 5. The forward material welding chamber 1.1 of the front diversion mold 1 and the cavity working belt 2.2 of the mold 2 adopt a smooth transition of a circular arc 1.2, and the profile is extruded through the cavity working belt 2.2 of the mold 2. The discharge port 2.3 of the mold 2 and the mold pad 3 are sent out. The height of the front material welding chamber 1.1 is 40-50mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com