Single-driving and double-receiving four-arm well diameter, microsphere, microelectrode eccentering device

A pushing device and micro-electrode technology, which is applied in the direction of borehole/well components, measurement, earthwork drilling and production, etc., can solve the problems of long length, shortened plate life, and increased instrument cost, so as to improve the service life and reduce the cost of the well Cost of diameter measurement, effect of instrument length shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

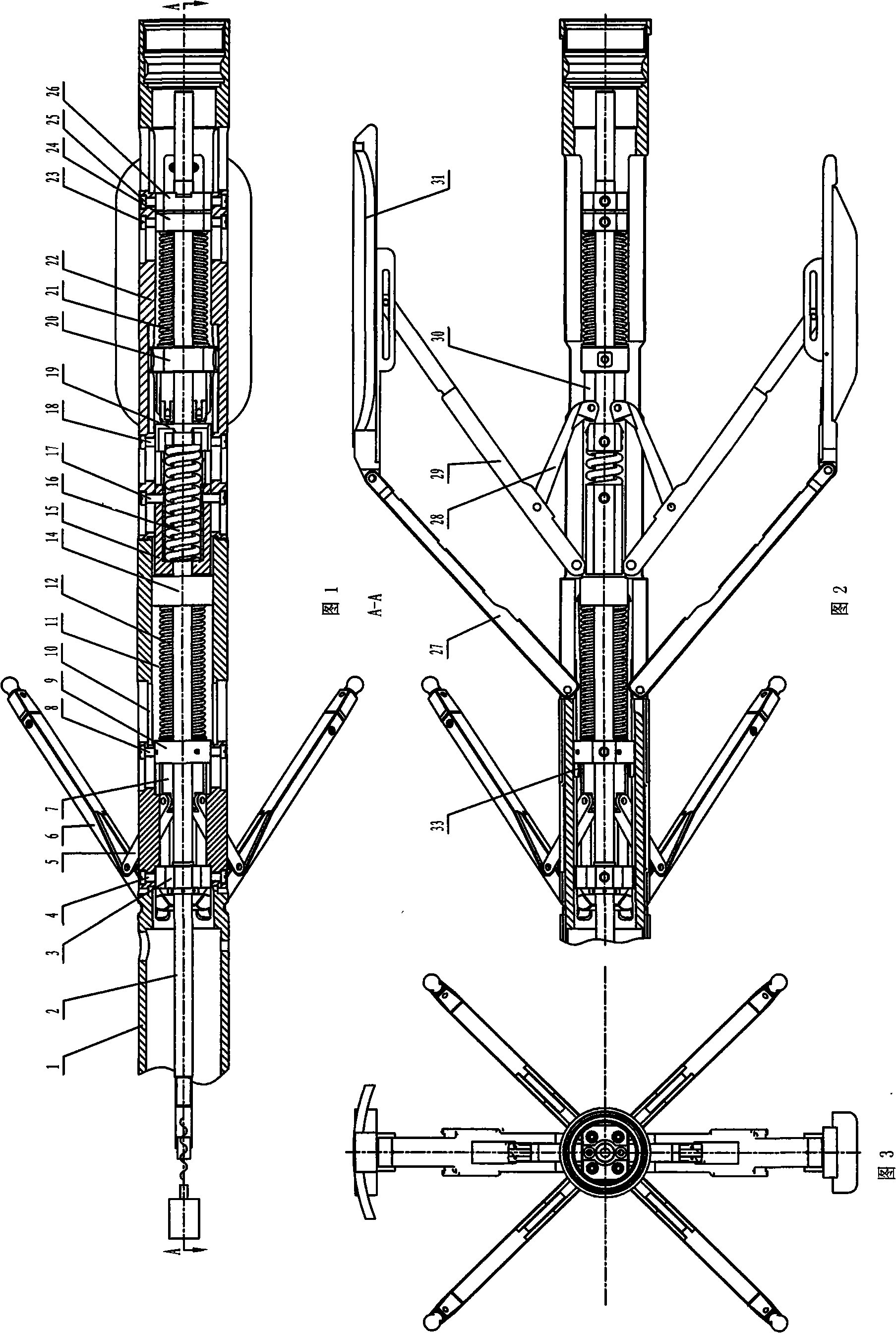

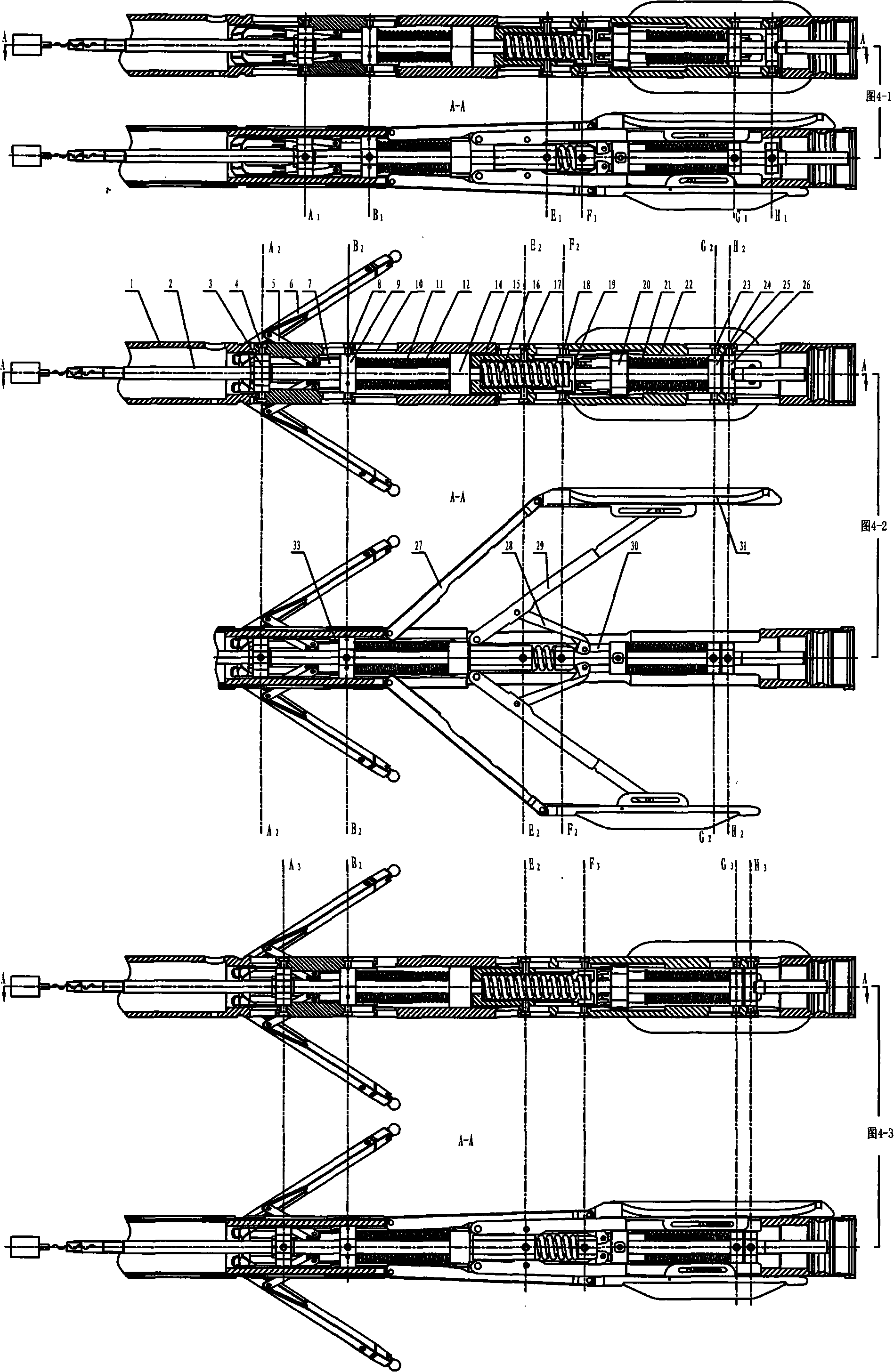

[0033] Embodiment 1: The present invention is described further in conjunction with accompanying drawing:

[0034] basic composition

[0035] The basic structure is shown in Figure 1-Figure 3. In the figure, the support tube 1 is the basic support of the entire pushing device, and the central tube 2 is driven by a motor through a ball screw to reciprocate along the axial direction of the supporting tube 1, which is the entire pushing device. Provide pushing power; well diameter sleeve 3, active sleeve 26 are axially fixedly connected with center pipe 2; well diameter sliding plate 9, well diameter support plate 14, pole plate retracting sleeve 15, pole plate closing plate 19, pole plate retracting spring 16. The driven disk 24 can slide axially along the support pipe 1 and the center pipe 2;

[0036] Borehole push mechanism: borehole push mechanism consists of borehole casing 3, borehole measuring arm 6, borehole connecting rod 5, borehole push rod 7, borehole sliding plate 9...

Embodiment 2

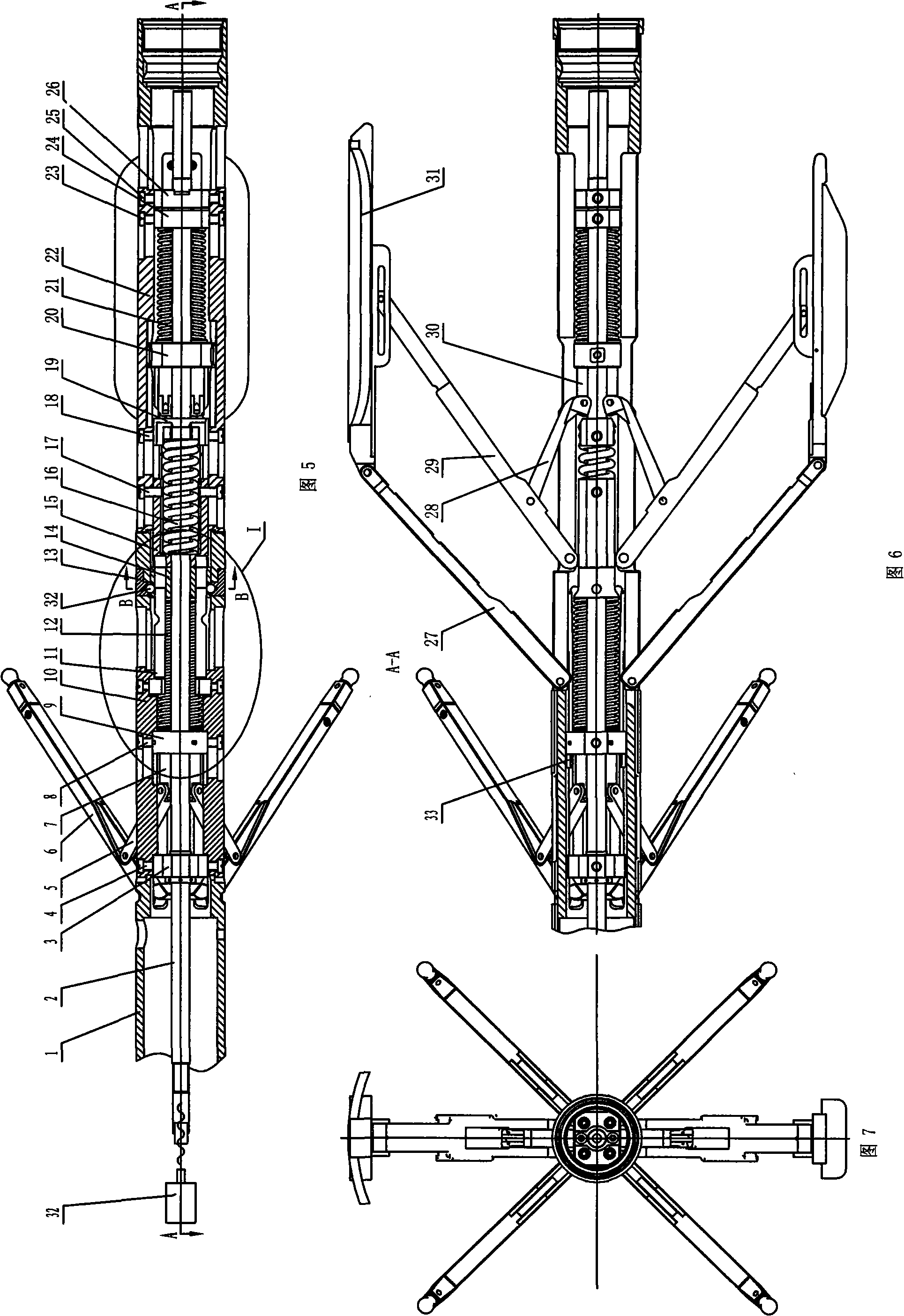

[0050] Embodiment 2: Referring to Fig. 5-Fig. 10, this embodiment is basically the same as Embodiment 1, and the similarities will not be repeated. The difference lies in: under the condition that the borehole spring 12 guarantees the required elastic force, the borehole diameter is supported The fixed connection between the sleeve 14 and the support pipe 1 is changed to that the borehole support sleeve 14 can slide in the support pipe 1 with the opening and closing of the borehole diameter measuring arm 6. Tight state, can improve the service life of diameter spring 12.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap