Process and device for processing granular material mixtures

A technology of granular materials and metering equipment, applied in the direction of volume metering, mixing methods, chemical instruments and methods, etc., can solve problems such as uneven mixture and damage to the physical and chemical properties of the final product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

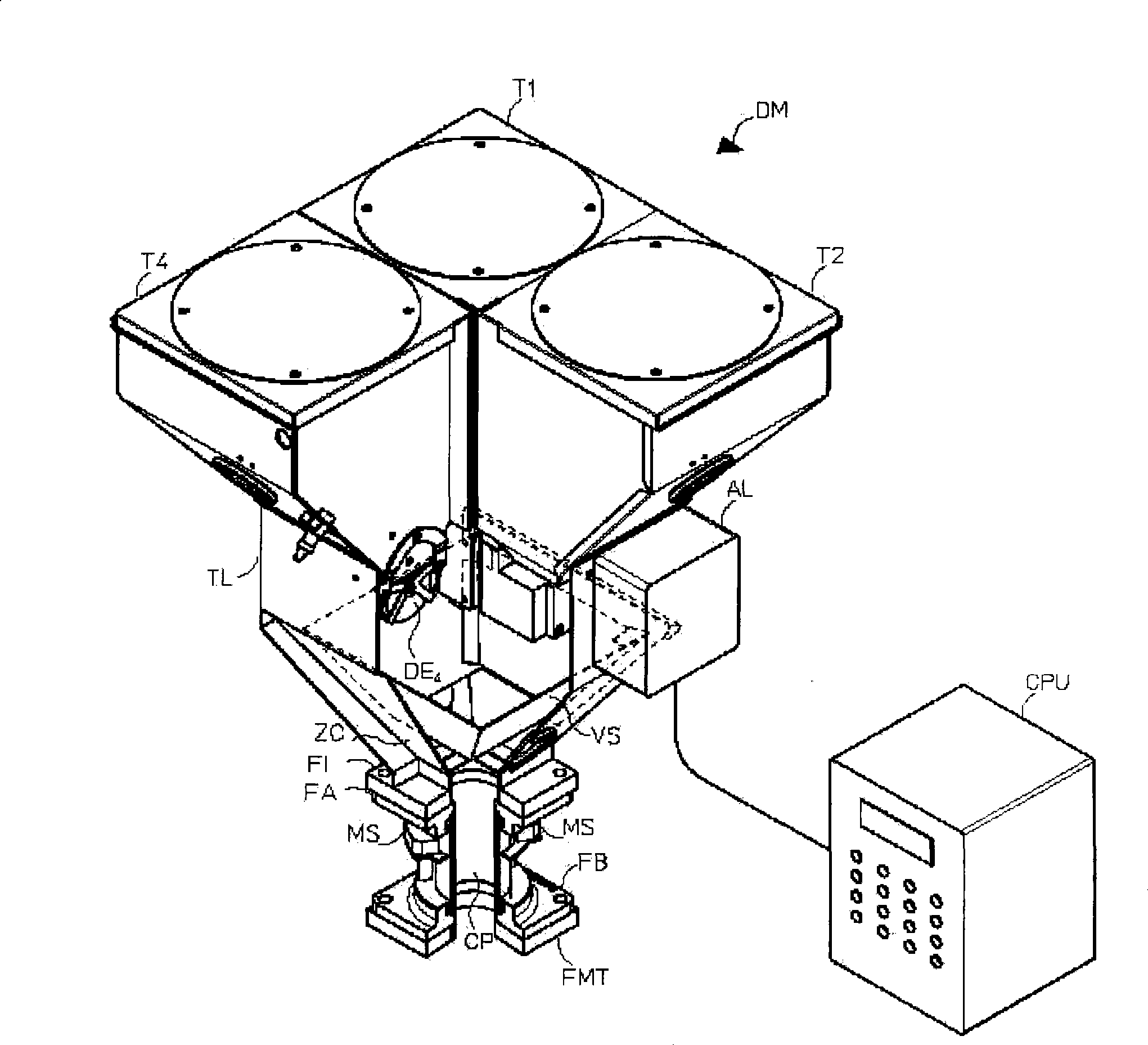

[0029] Referring to the above-mentioned drawings, it is known how to manufacture the granular material mixture of the present invention by a multi-metering device DM, wherein the multi-metering device DM is composed of a plurality of upper hoppers, which are detachably installed in the same number and consist of a In the housing seat defined by the fixed support frame TL. Three hoppers T1, T2 and T4 are shown in the accompanying drawing, wherein one hopper T3 is omitted, this is to better show the inside of the multi-metering device DM, obviously, the multi-metering device can also include four More or less than four hoppers.

[0030] Hoppers T1-T4 can be of the same or different sizes as required and are used to accommodate the various granular materials that need to be converted, usually raw plastic pellets, or scrap or slag in the form of coarse material, or colorants And / or another particulate additive that needs to be metered into another or other particulate material. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap