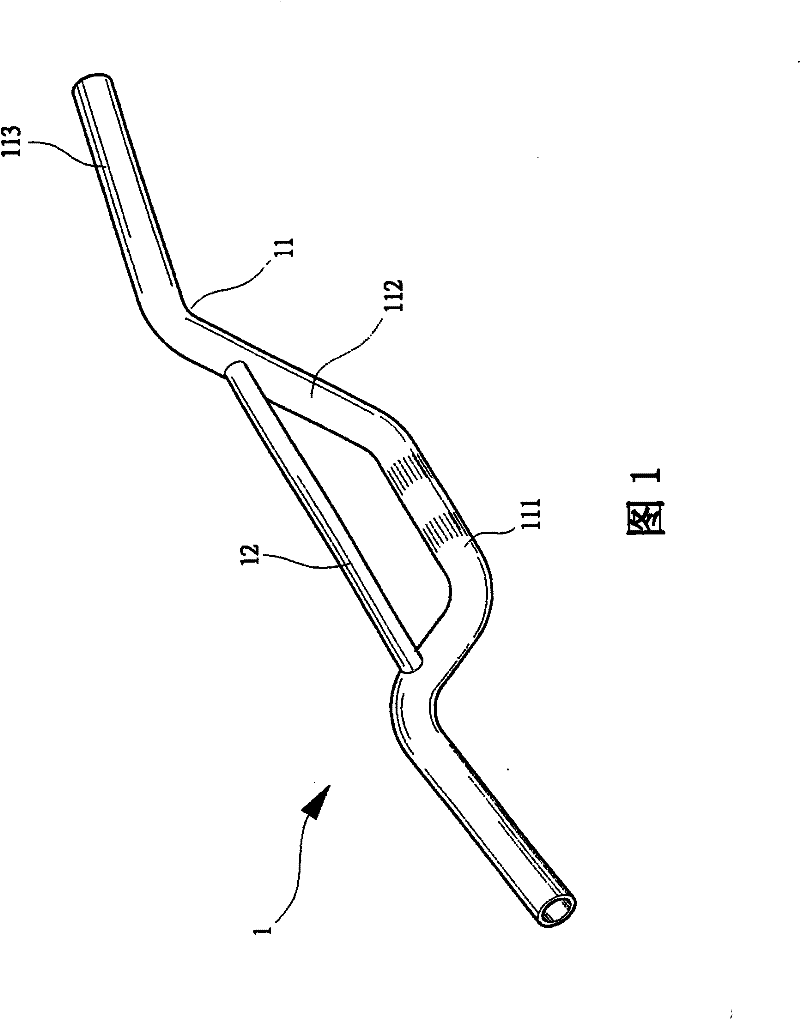

Vehicle steering handle structure

A technology for handlebars and vehicles, which is applied to steering mechanisms, bicycle accessories, transportation and packaging, and can solve problems such as inability to reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make it easier to understand the structure of the present invention and the effects that can be achieved, it is described as follows in conjunction with the drawings:

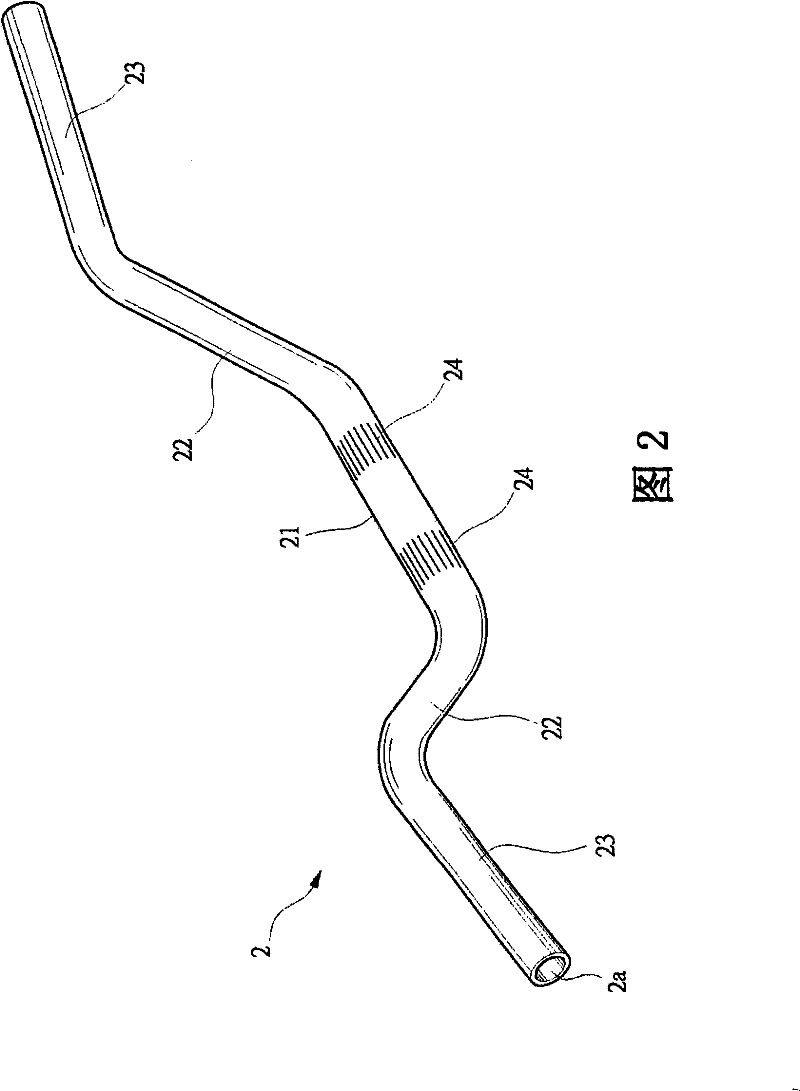

[0012] First, see figure 2 As shown, the steering handle 2 of the present invention is composed of a hollow body tube 2a. The body tube 2a is recessed in the middle to form a connecting portion 21, and the two ends of the connecting portion 21 extend obliquely upward to form a rising part 22, and at the end of the rising part 22, a section of gripping part 23 is extended in a substantially horizontal direction. In addition, a joint area 24 with two intervals and a rough surface is provided near the center of the connecting part 21. .

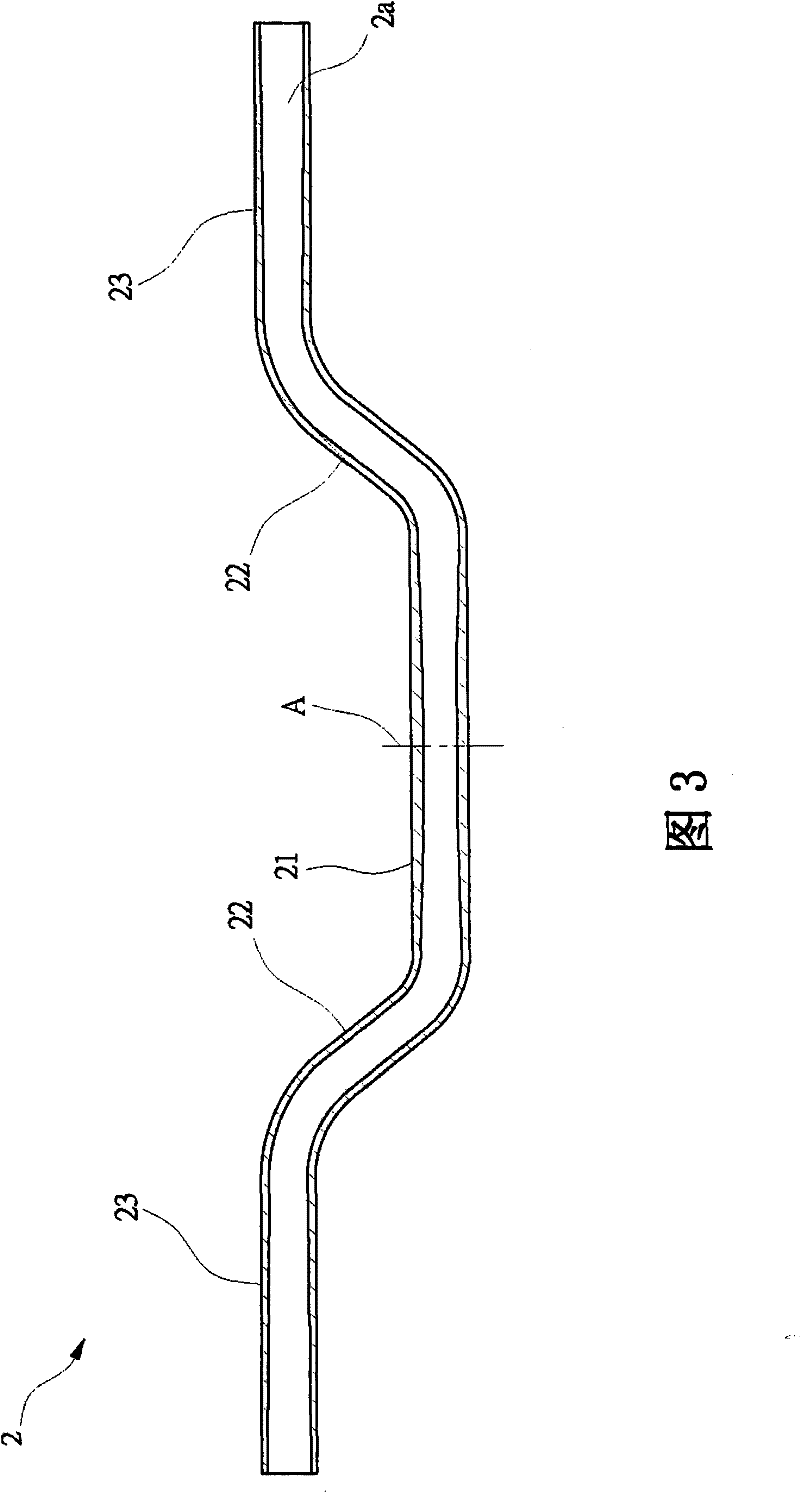

[0013] please cooperate image 3 , 4 For reference, since the steering handle 2 is left-right symmetrical with the center line A, the structure of the tubular body 2a will be described with one side below. The steering handle 2 of the present invention main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com