Patents

Literature

48results about How to "Achieve lightweight effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

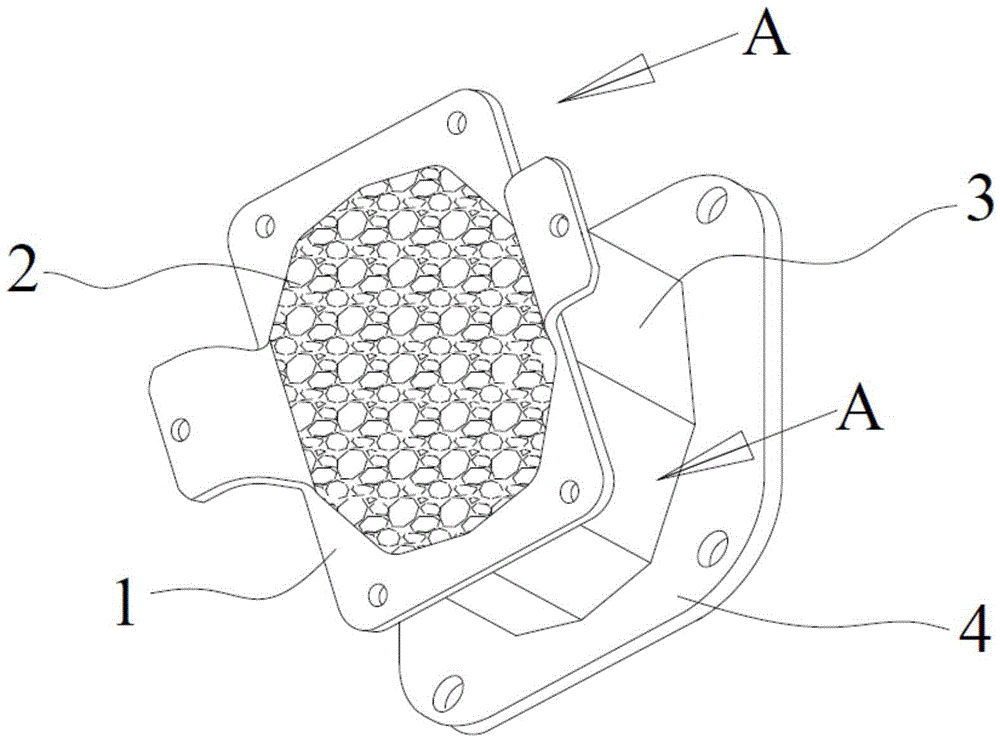

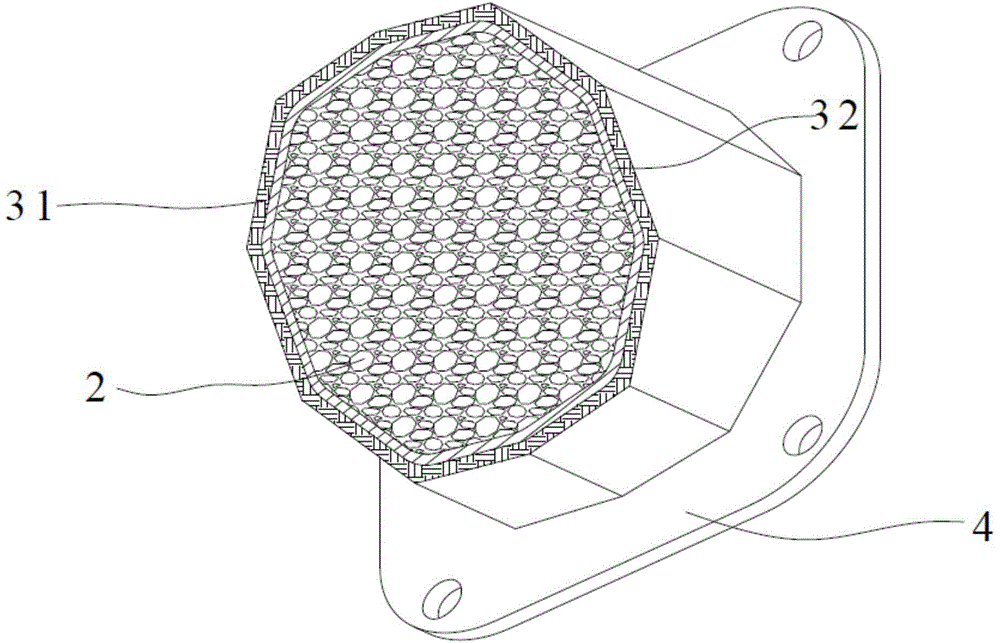

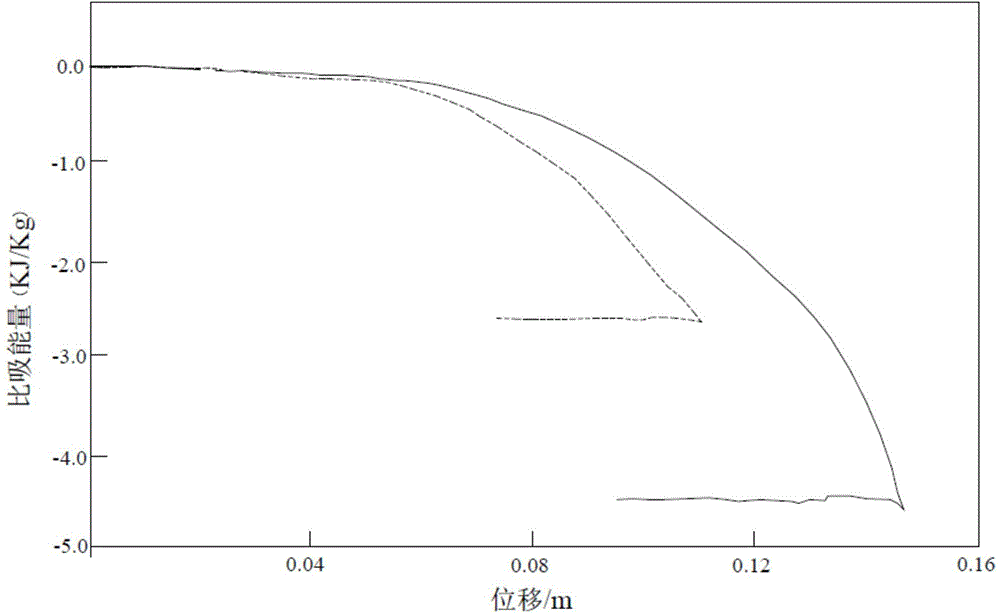

Automobile energy absorption box

InactiveCN104590178AImprove the impact energy absorption effectAchieve lightweight effectBumpersCarbon fiber compositeAbsorbed energy

The invention discloses an automobile energy absorption box. The automobile energy absorption box comprises an energy absorption box body. The energy absorption box body is made of carbon fiber composite materials and is filled with foam aluminum alloy ingots. According to the automobile energy absorption box, as the energy absorption box body is made of the carbon fiber composite materials, the light weight effect is achieved; compared with a common metal energy absorption box, the weight of the energy absorption box which is filled with the foam aluminum alloy ingots and made of the carbon fiber composite materials is reduced by 25% to 40%, the absorbed energy is 1.5 times to 3 times that of the common metal energy absorption box, the collision energy absorption effect can be accordingly improved, and the light weight effect is achieved.

Owner:WUHU LION AUTOMOTIVE TECH CO LTD

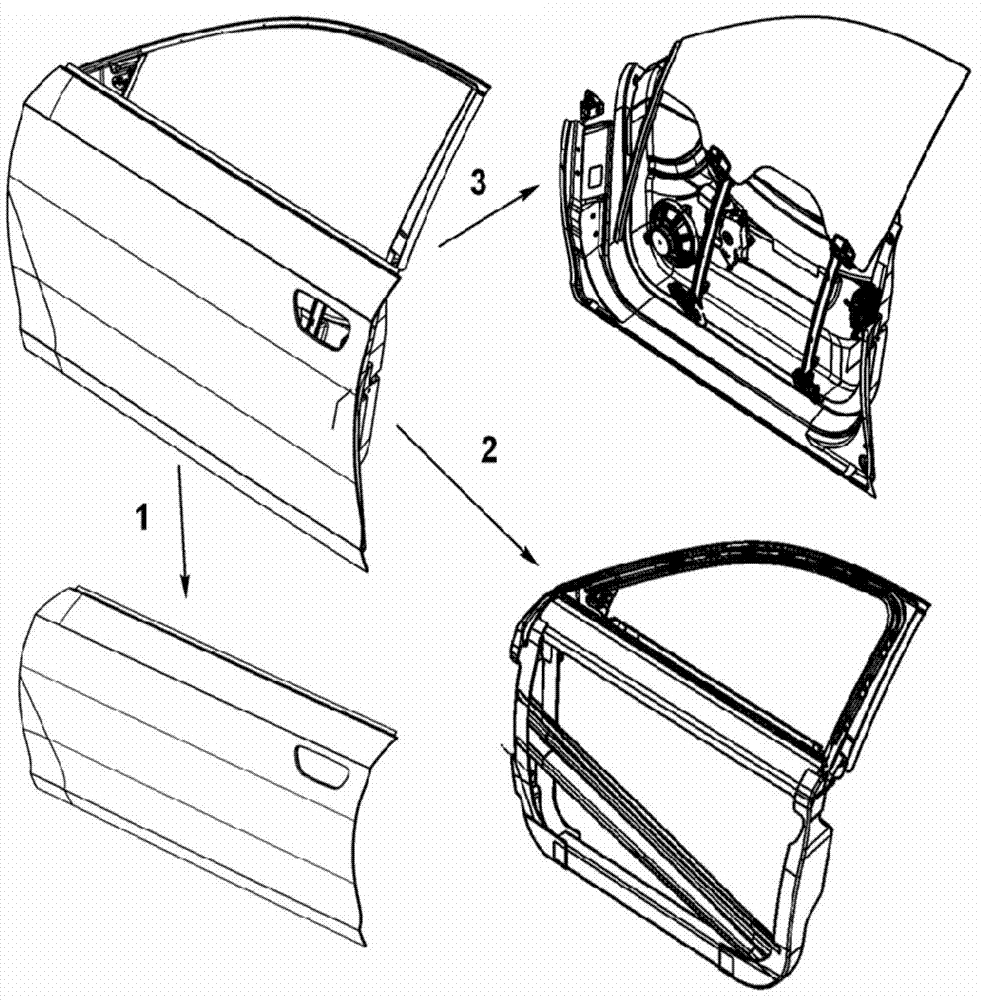

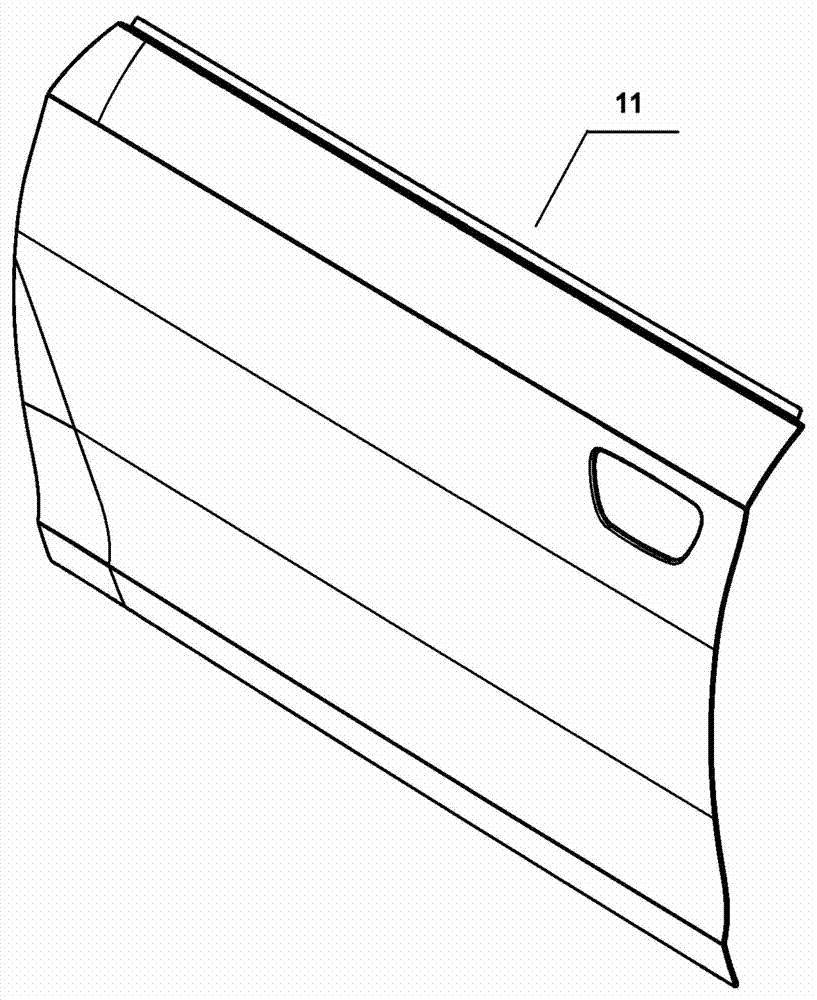

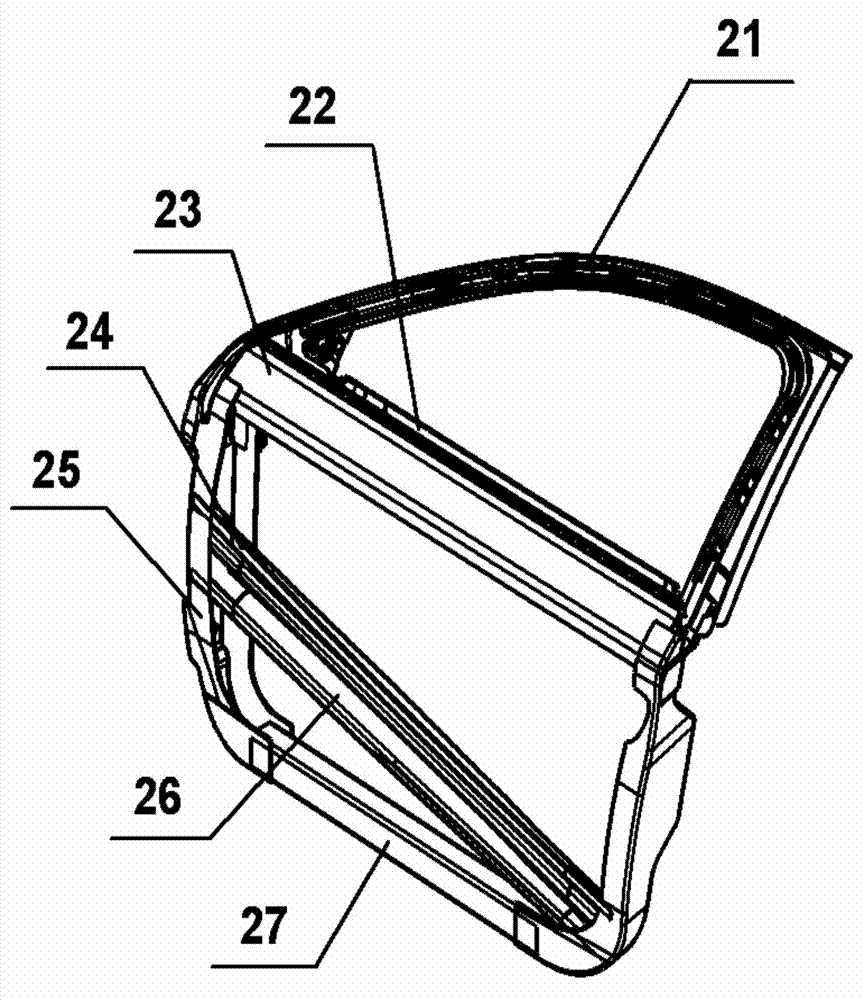

Modularized vehicle door with steel, aluminum and plastic mixed

The invention relates to a modularized vehicle door with steel, aluminum and plastic mixed. Compared with a total complex structure of a traditional vehicle door, according to the modularized vehicle door with steel, aluminum and plastic mixed, the original complex vehicle door structure is modularized, and the vehicle door structure is divided into three functional modules which include a vehicle door outer plate, a vehicle door frame, a vehicle door inner plate and an accessory module. According to the functionality of all parts of the vehicle door, traditional vehicle door modules are functionalized, and good vehicle door manufacturing and assembling manufacturability is achieved. The modularized vehicle door with steel, aluminum and plastic mixed is specifically characterized in that the vehicle door outer plate is not a main stressed part in the vehicle door structure, the strength and rigidity requirements are moderate, and the purpose generally lies in the effect that the functional requirements for meeting external shapes are improved; the vehicle door inner plate is not a main stressed part, either, and can be made of composite materials or plastic. According to the modularized vehicle door with steel, aluminum and plastic mixed, factors in all the aspects of strength, rigidity, appearance and weight are taken into comprehensive consideration, the vehicle door outer plate can be made of thinner metal material plates and aluminum alloy materials, and the aluminum alloy materials are light, small in specific gravity, high in strength, good in ductility, and high in corrosion resistance and meanwhile has good forming performance, machinability and the like.

Owner:HUNAN UNIV

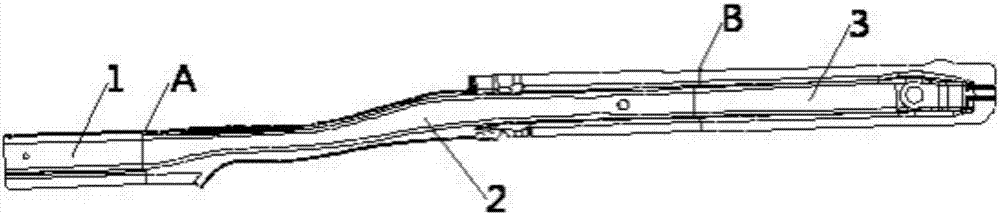

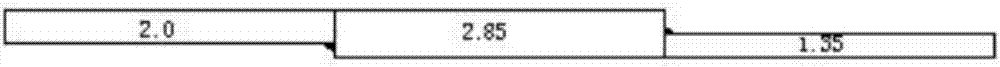

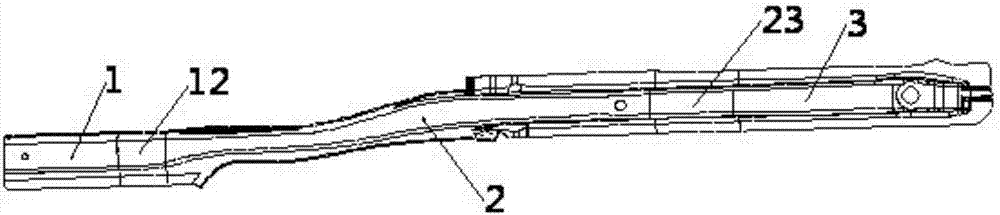

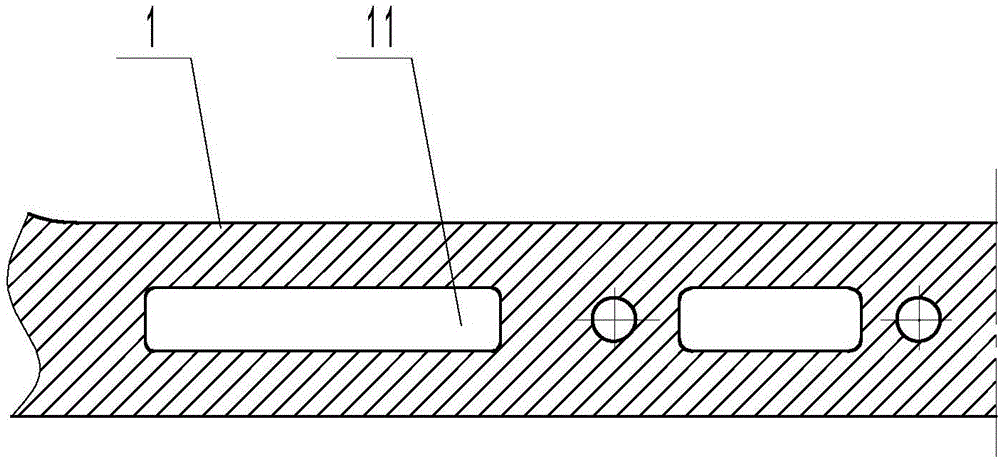

Continuous variable-thickness automobile front longitudinal beam inner plate and manufacturing method thereof

InactiveCN106891996AGuaranteed forward collision safety performanceAchieve lightweight effectUnderstructuresVariable thicknessEnergy absorption

The invention discloses a continuous variable-thickness automobile front longitudinal beam inner plate and a manufacturing method thereof. The continuous variable-thickness automobile front longitudinal beam inner plate comprises a front longitudinal beam inner plate body of a beam structure, wherein the automobile front longitudinal beam inner plate body is integrally rolled and formed by a whole piece of metal material; the automobile front longitudinal beam inner plate body comprises a body front section, a front transition section, a body middle section, a rear transition section and a body rear section; the body front section, the body middle section and the body rear section are constant-thickness structures, and the front transition section and the rear transition section are variable-thickness structures; the thickness of the body middle section is greater than the thickness of the body front section, and the thickness of the body front section is greater than the thickness of the body rear section; and the thickness of the front transition section and the rear transition section respectively increases gradually from the body front section and the body rear section which are thin to the body middle section. Compared with the prior art, the continuous variable-thickness automobile front longitudinal beam inner plate has the advantages of forming a reasonable combination of flexibility and strength of the beam structure by virtue of the continuous change of the thickness of partial structures, changing the negative effect of the thickness transition and the strength transition at weld positions while ensuring the lightweight, increasing the energy absorption value and improving the formability.

Owner:CHINA FIRST AUTOMOBILE

Automobile energy absorption box

ActiveCN104590177AAchieve lightweight effectImprove impact resistanceBumpersEnergy absorptionEngineering

The invention discloses an automobile energy absorption box. The automobile energy absorption box comprises an energy absorption box body made of carbon fiber composite, and chamfer angles are formed in the margin of the energy absorption box body ends. The automobile energy absorption box has the advantages that lightweight effect is achieved with the adoption of carbon fiber composite, the weight of the energy absorption box with carbon fiber composite is 52% to 69% less than the common metal energy absorption box, and the comprehensive impact resistance ability and energy absorption effect are high.

Owner:WUHU LION AUTOMOTIVE TECH CO LTD

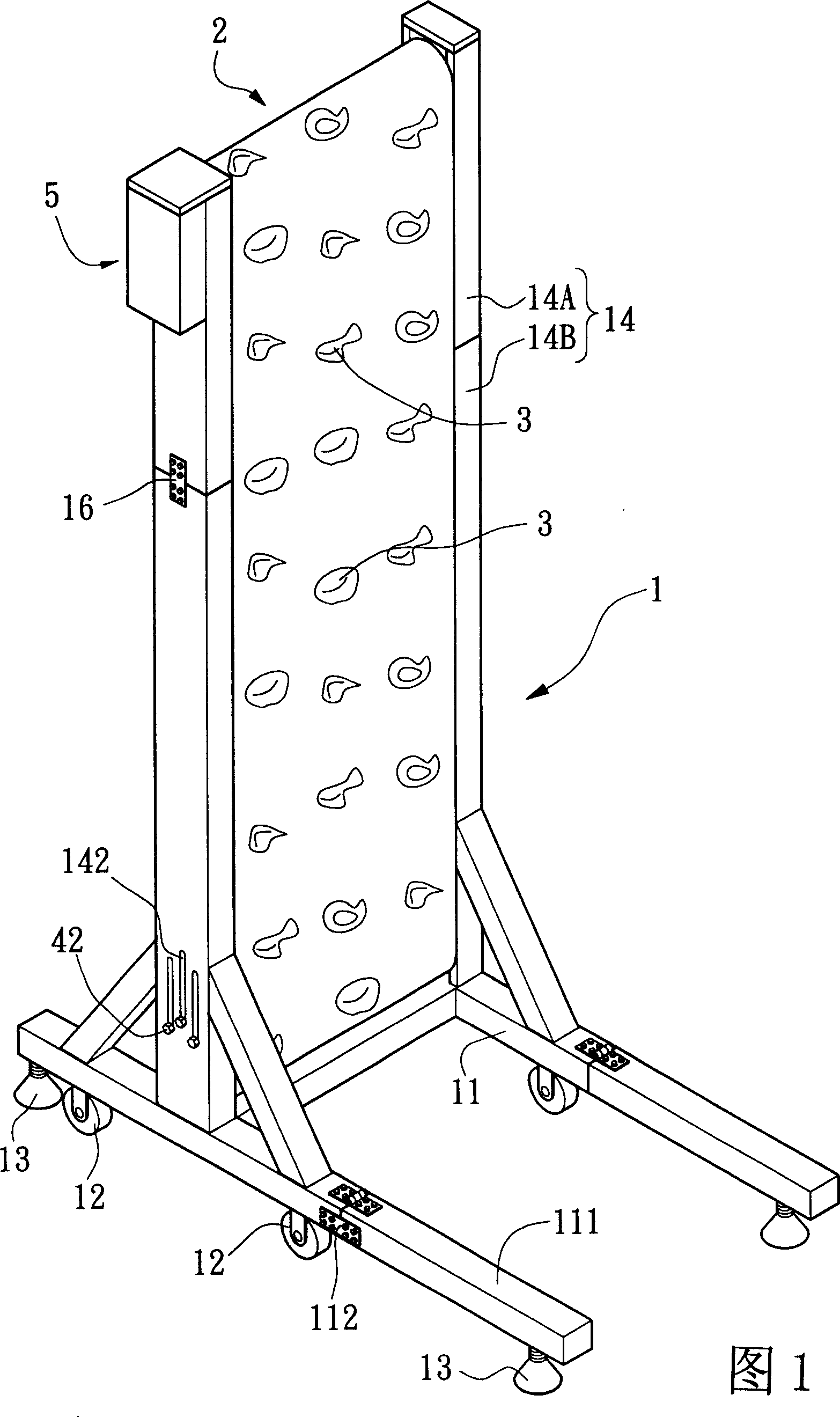

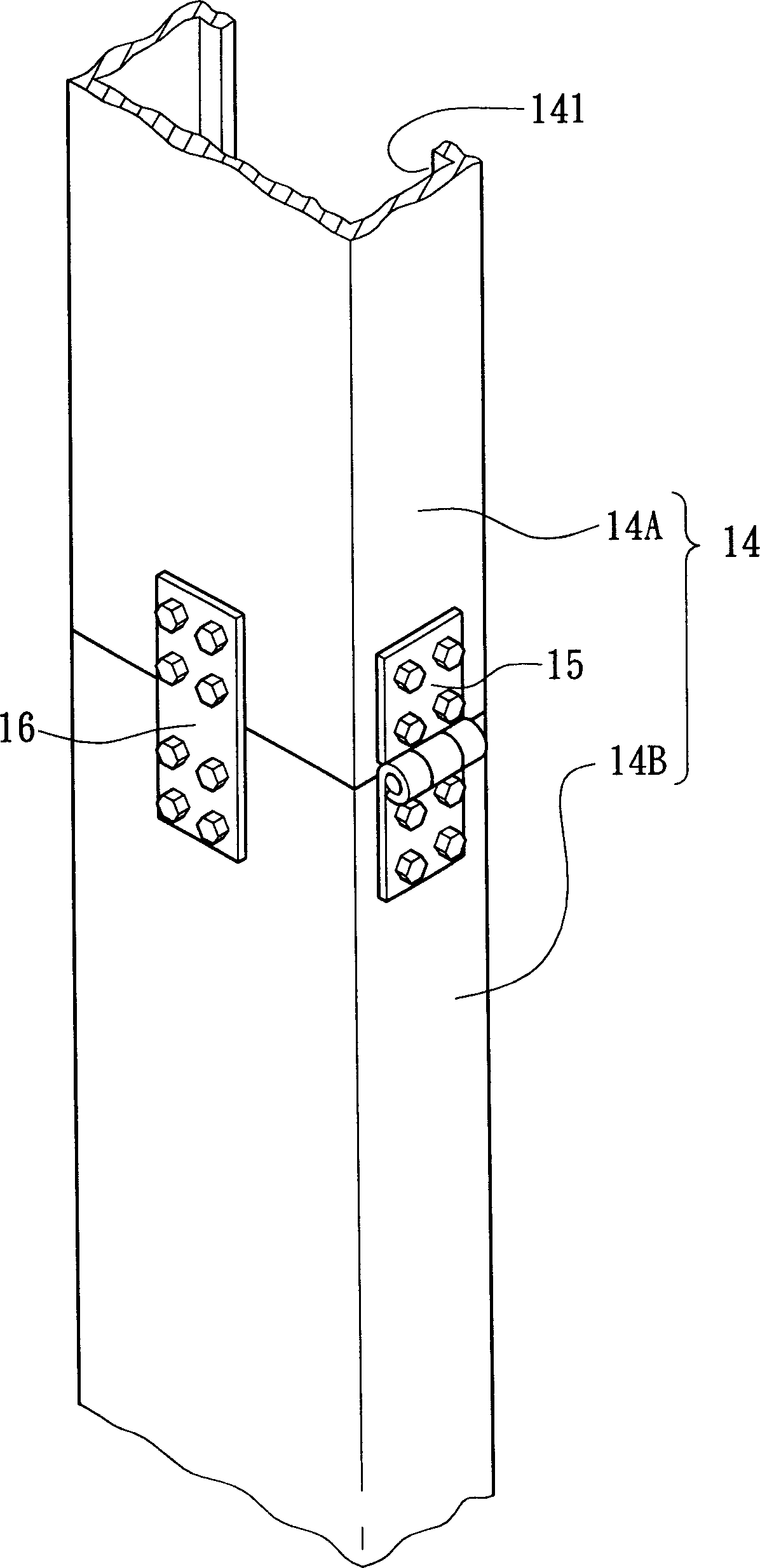

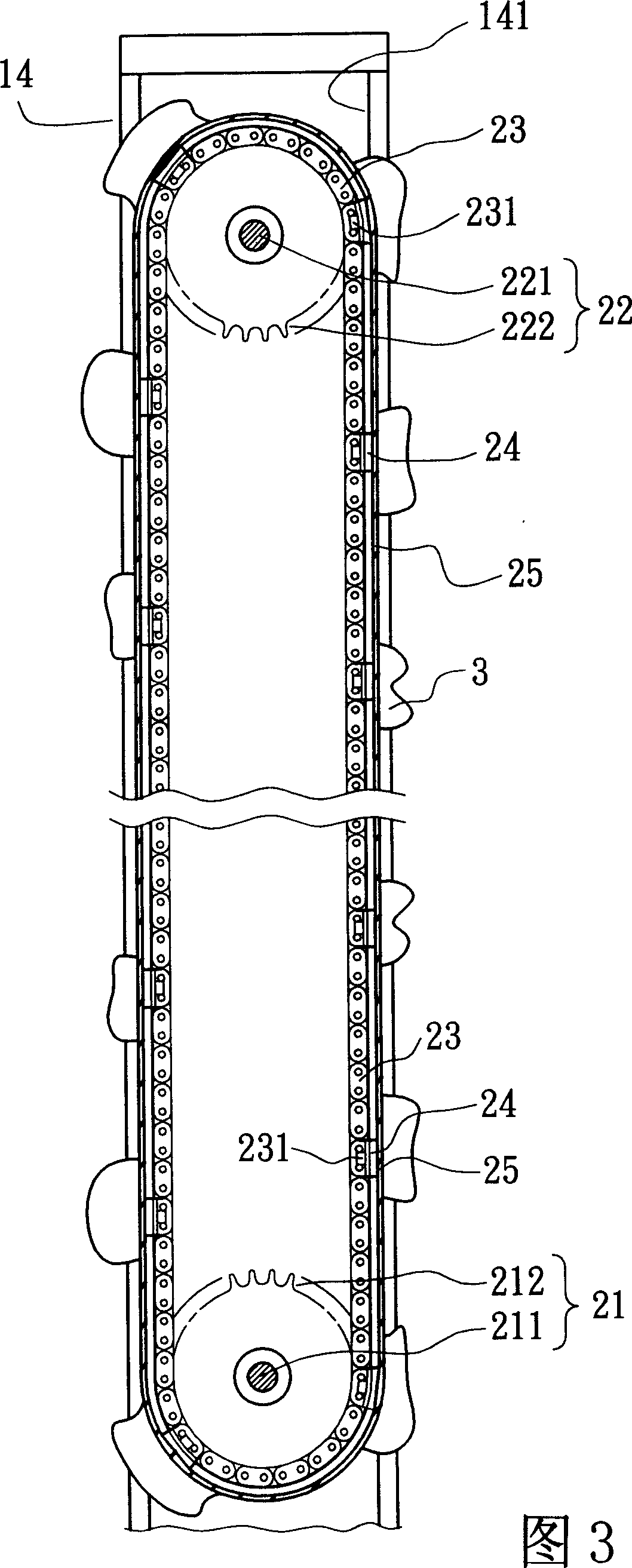

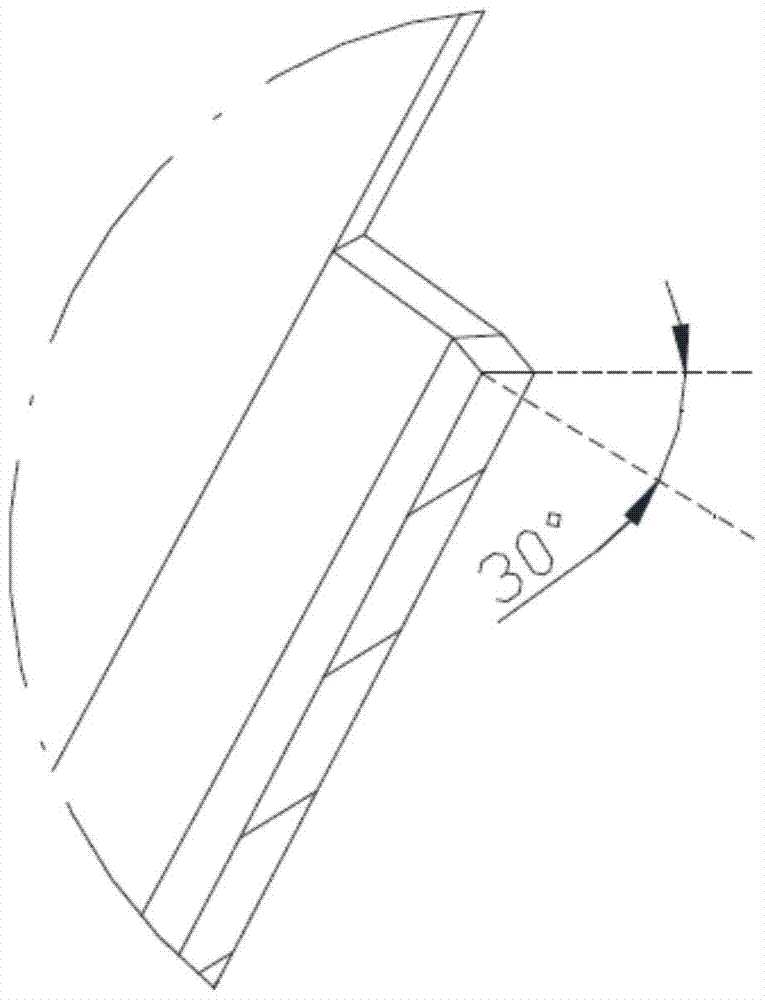

Machine for climbing rock

InactiveCN1623617ASimple structureAchieve lightweight effectMovement coordination devicesCardiovascular exercising devicesHorizontal forceEngineering

An apparatus for simulating the climbing along cliff is composed of a base, a vertical frame on said base, and a circulating rotation mechanism consisting of the endless chains, the grasping blocks arranged on said chains, several transverse bars and barrier for bearing the horizontal force applied to chains, and an endless soft pad covering on said chains.

Owner:巫佑丰

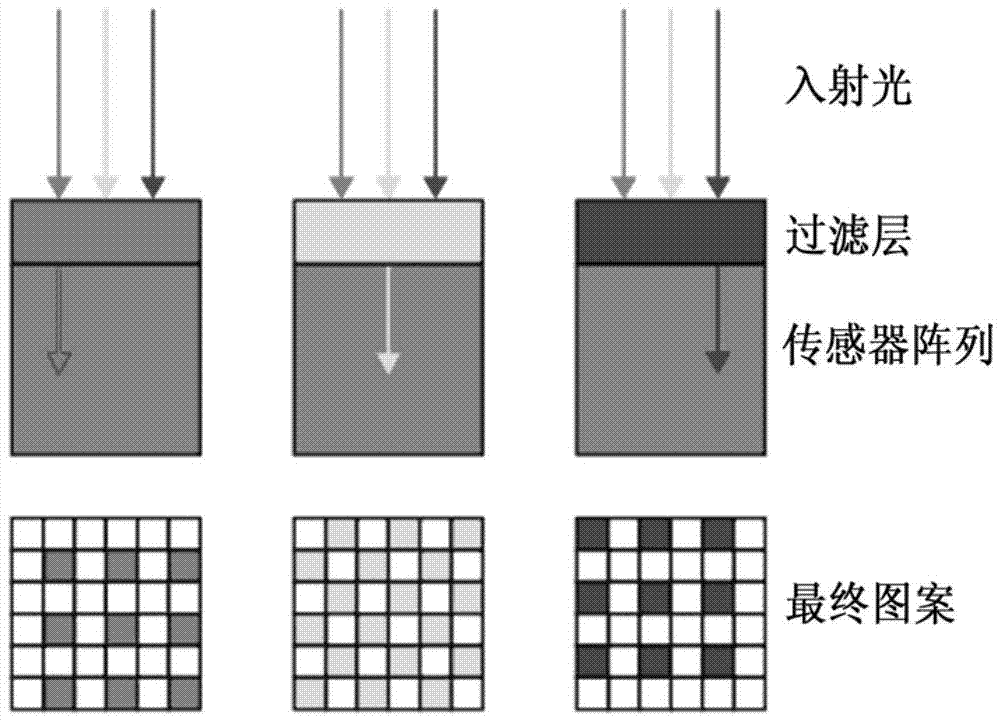

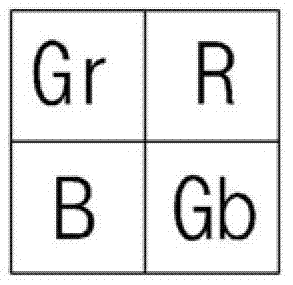

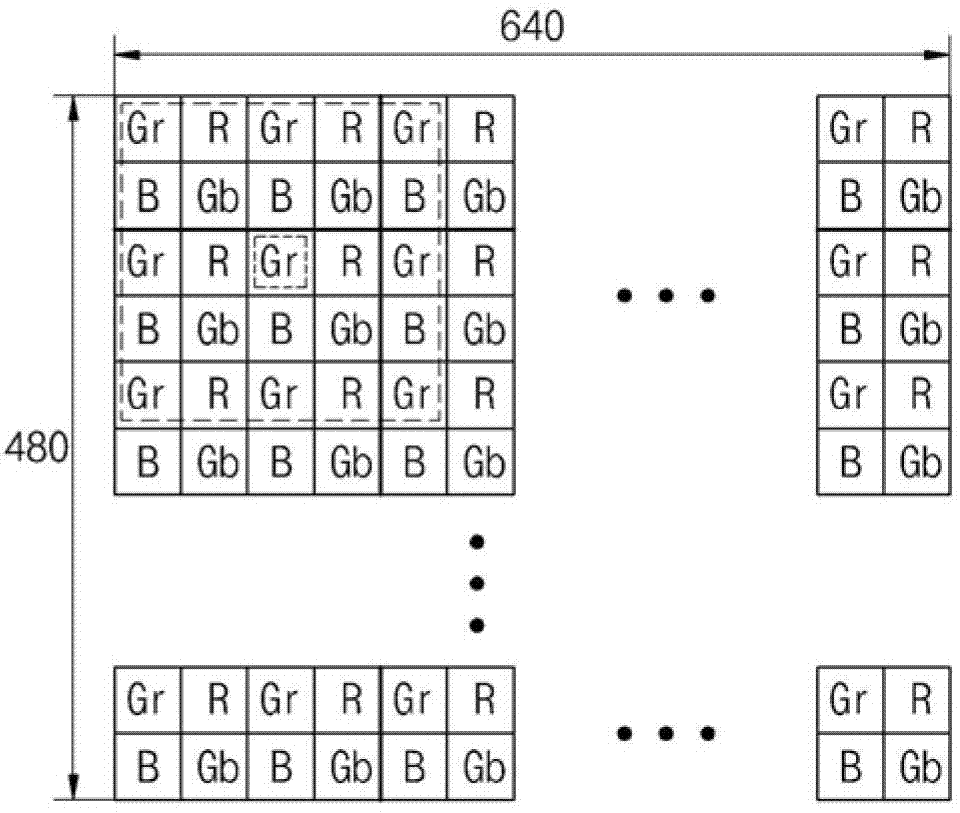

Device for correcting offset correction between pixels of image sensor and correction method thereof

InactiveCN102957879AImprove poor qualityEasy wiringTelevision system detailsImage analysisCorrection methodImage sensor

Owner:HYUNDAI MOBIS CO LTD

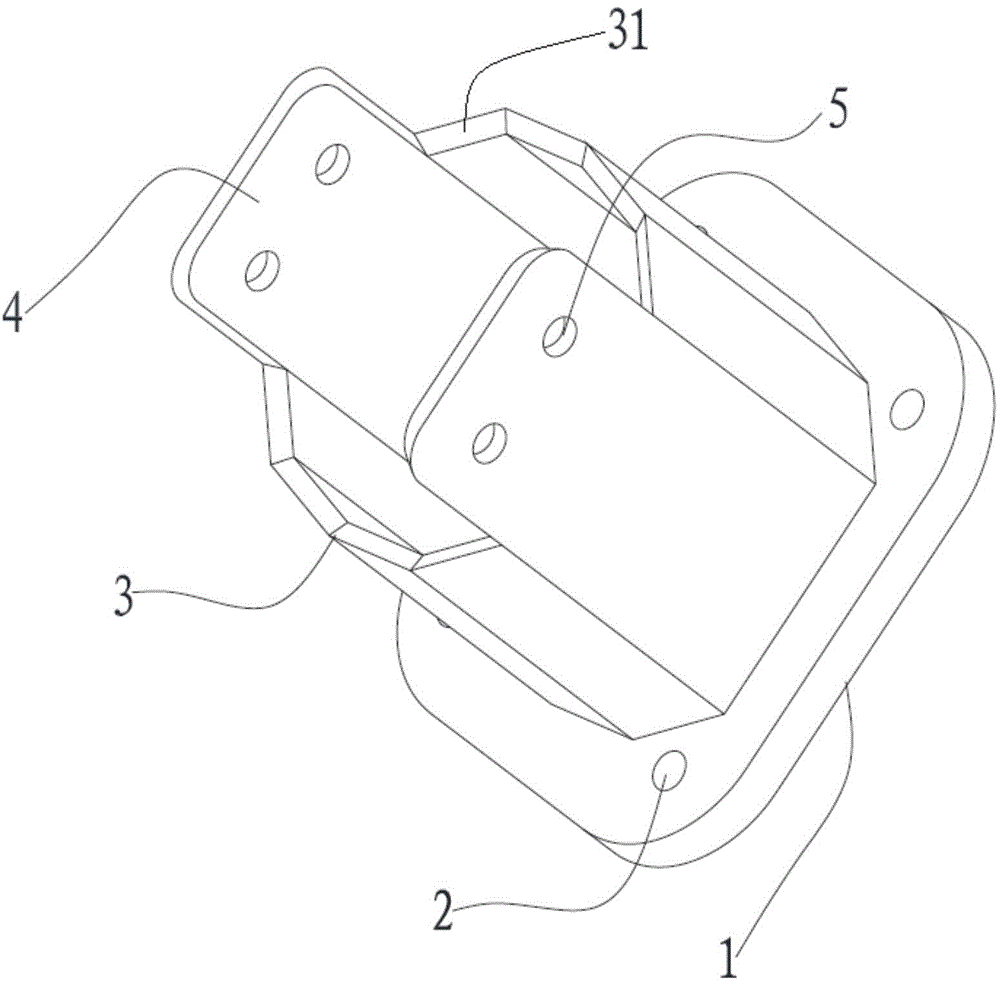

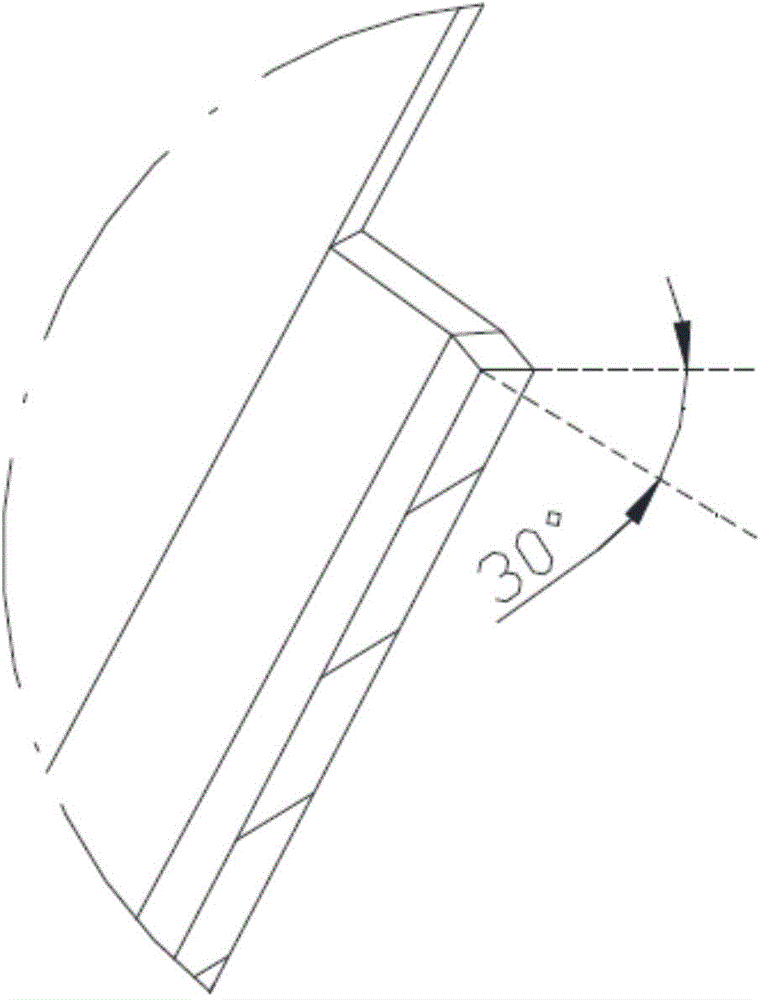

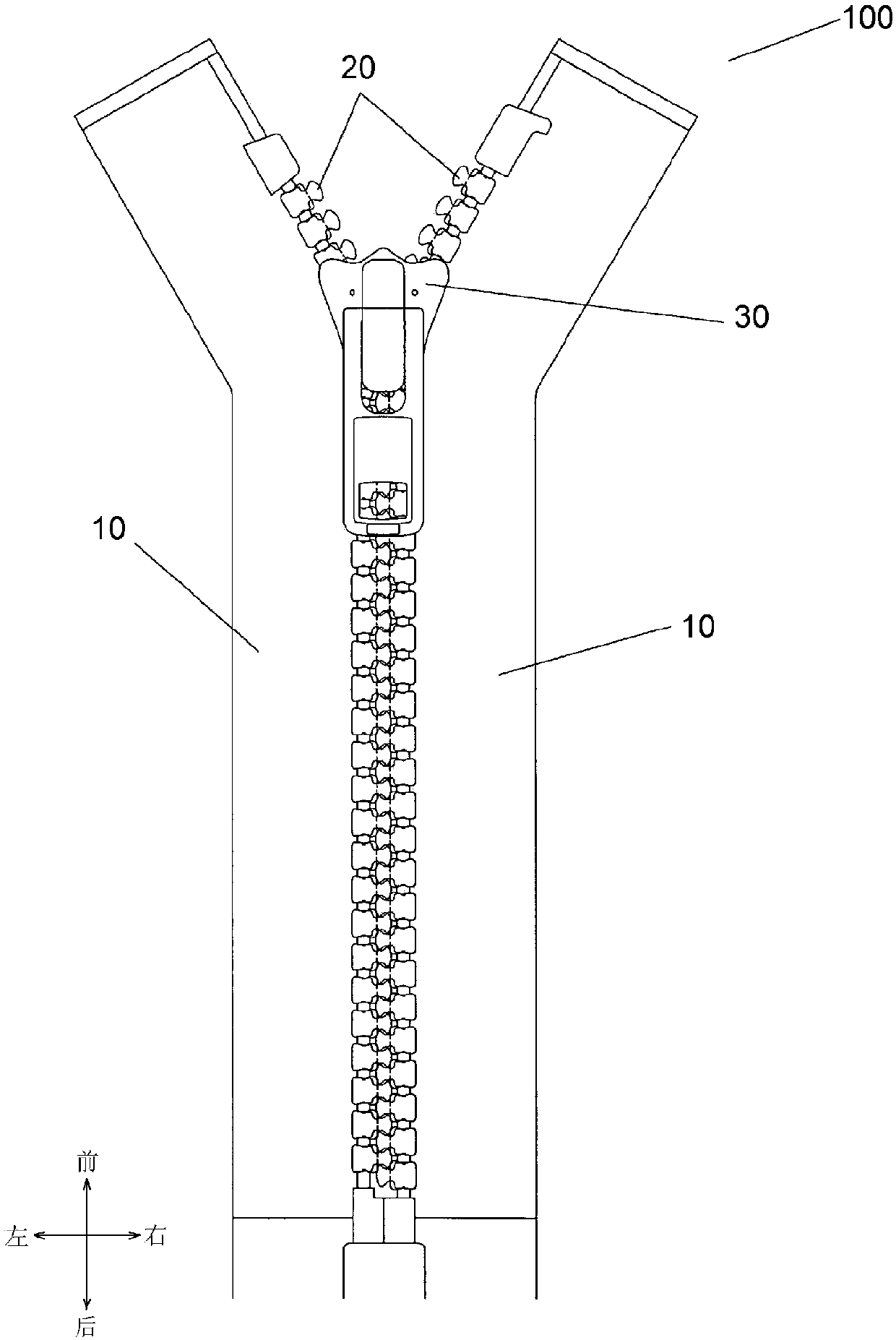

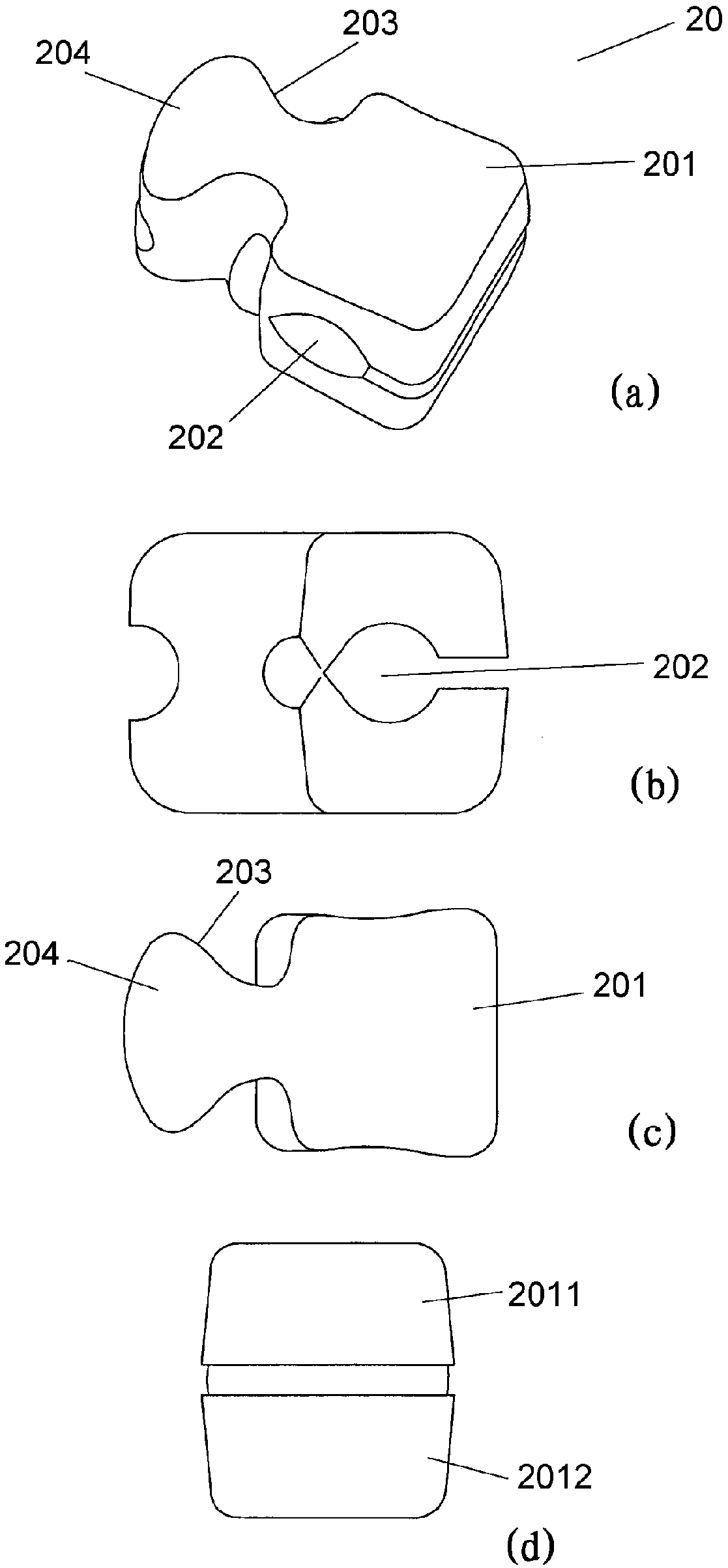

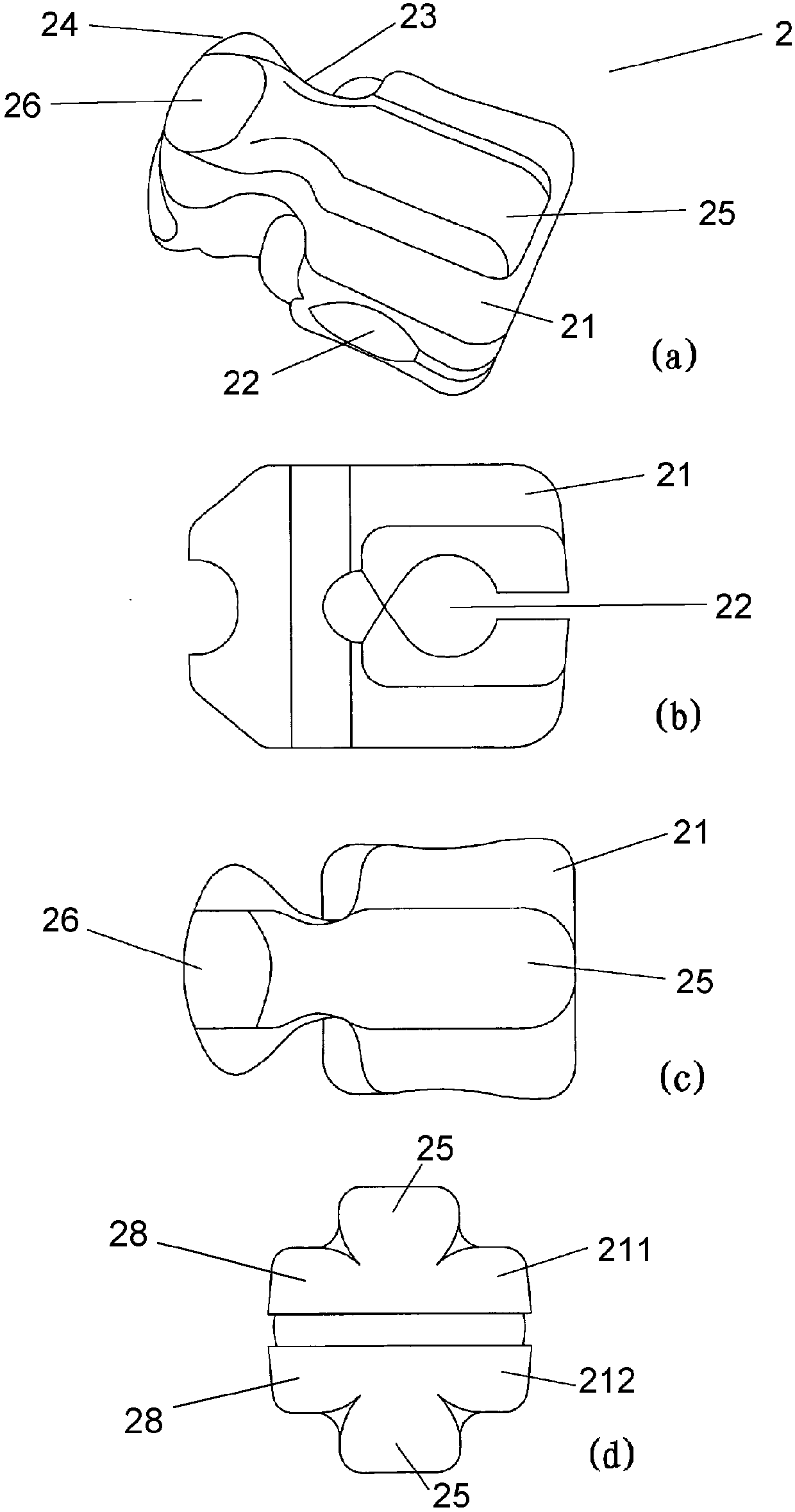

Chain tooth, chain strap and zipper

The invention provides a chain tooth, a chain strap and a zipper. The chain tooth and a strap are arranged together to form the chain strap, and the chain tooth comprises a body part, a mounting part,a neck part and a head part. The body part and the head part are connected through the neck part, the mounting part is used for mounting of the strap, the body part comprises an upper body part and alower body part, and at least one of the upper body part and the lower body part comprises a protruding part and a base part. The protruding part extends out of the base part, is located in the middle in the front-back direction and extends in the left-right direction. Furthermore, an inclined part inclined downwards in the left-right direction is formed on at least one side, in the vertical direction, of the head part, and convex parts extending in the front-back direction are formed on the two sides of the protruding part. According to the chain tooth, the chain strap and the zipper, weightreduction can be achieved, and strength and use reliability can be guaranteed.

Owner:YKK CORP

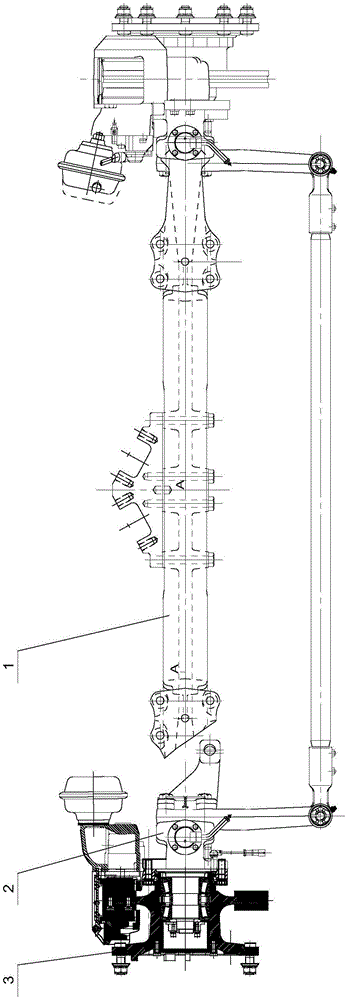

Automobile front axle assembly

InactiveCN106739808AReduce manufacturing costSave processing costBraking element arrangementsAxle unitsBearing capacityAutomotive engineering

The invention provides an automobile front axle assembly, and relates to automobile accessories. The automobile front axle assembly comprises a front axle, a brake assembly and a hub assembly which are respectively arranged at two ends of the front axle, wherein the hub assembly comprises a hub body, an outer bearing and an inner bearing which are arranged in the hub body; a brake boss is arranged on the hub body instead of a brake disc; friction plates are connected with left and right end faces of the brake boss, and thermal baffles are arranged between the friction plates and the brake boss; the outer bearing and the inner bearing are connected into a whole to form an integral unit bearing; and one or a plurality of through holes are formed in the front axle to realize light weight. According to the automobile front axle assembly, the brake disc is canceled in the hub assembly, and the friction plates and thermal baffles which are connected together with the hub body are adopted to replace the brake disc, so that the aims of production cost conservation, facilitated after-sale replacement and low maintenance cost can be achieved; and the whole axle has the characteristics of light weight, long service life, front axle bearing capacity guarantee, and is easy for popularization and application.

Owner:FANGSHENG AXLE LIUZHOU

Lightweight and high strength and ductility automotive steel using silicon instead of aluminum and preparation method of the steel

The invention relates to lightweight and high strength and ductility automotive steel using silicon instead of aluminum. An alloy comprises, by weight percentage, 0.1-0.4 wt% of C, 3.5-5.5 wt% of Si,4.0-6.0 wt% of Mn, 0.5-1.0 wt% of Ni, 0.01-0.1 wt% of Ti and the balance Fe. The invention further relates to a preparation method of the lightweight and high strength and ductility automotive steel using silicon instead of aluminum. The preparation method includes the alloy component weighing and taking, smelting, casting and hot rolling procedure. The lightweight and high strength and ductilityautomotive steel using silicon instead of aluminum and the preparation method of the steel are provided. The material has excellent mechanical performance, and is low in production cost and simple inprocess, a series of problems caused by lightweight aluminum are compensated very well, and great application prospects are achieved.

Owner:DONGGUAN UNIV OF TECH

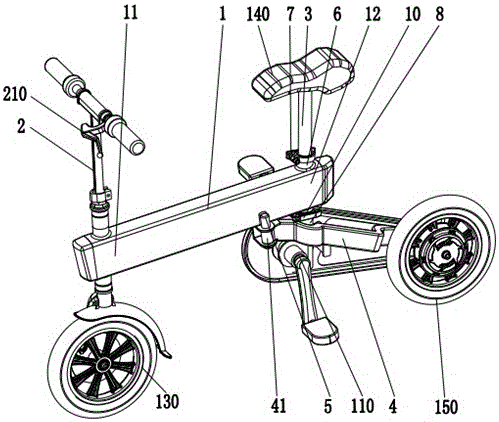

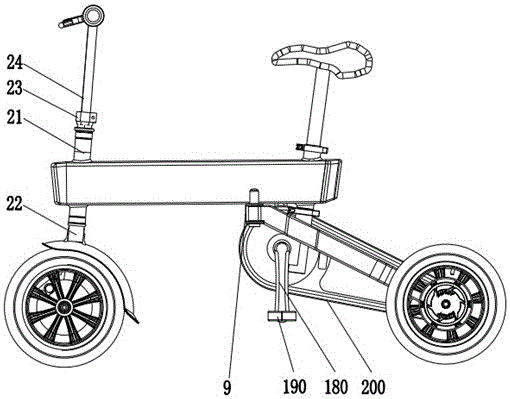

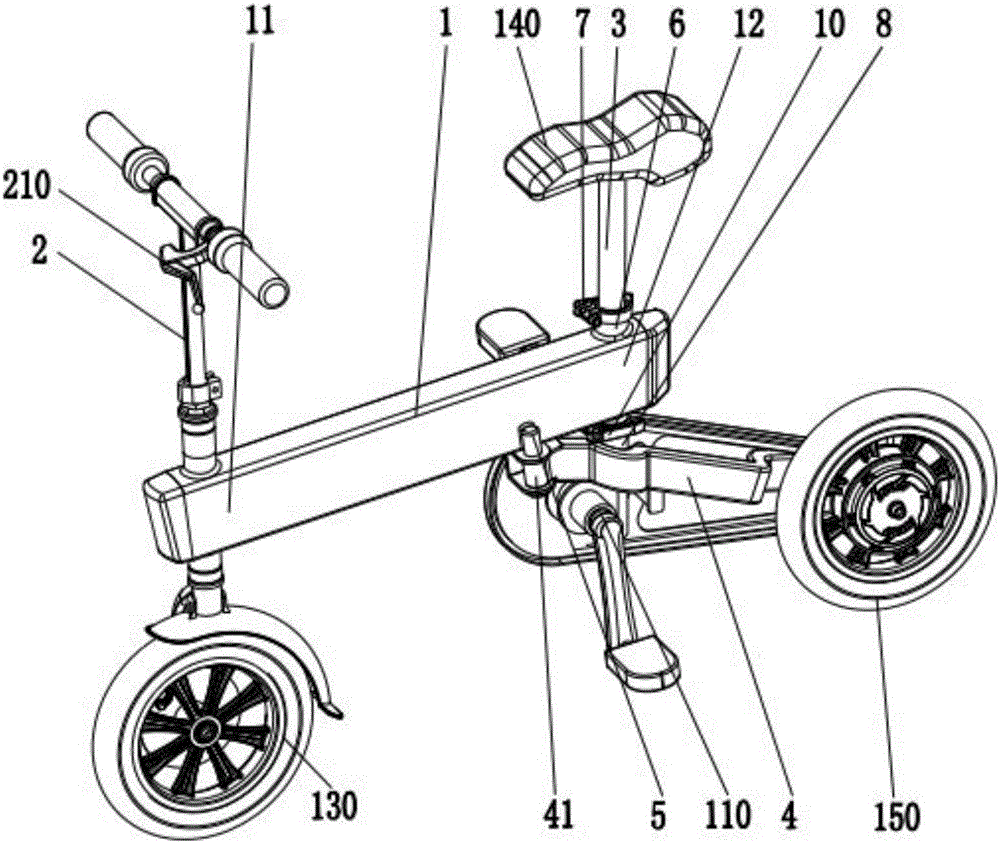

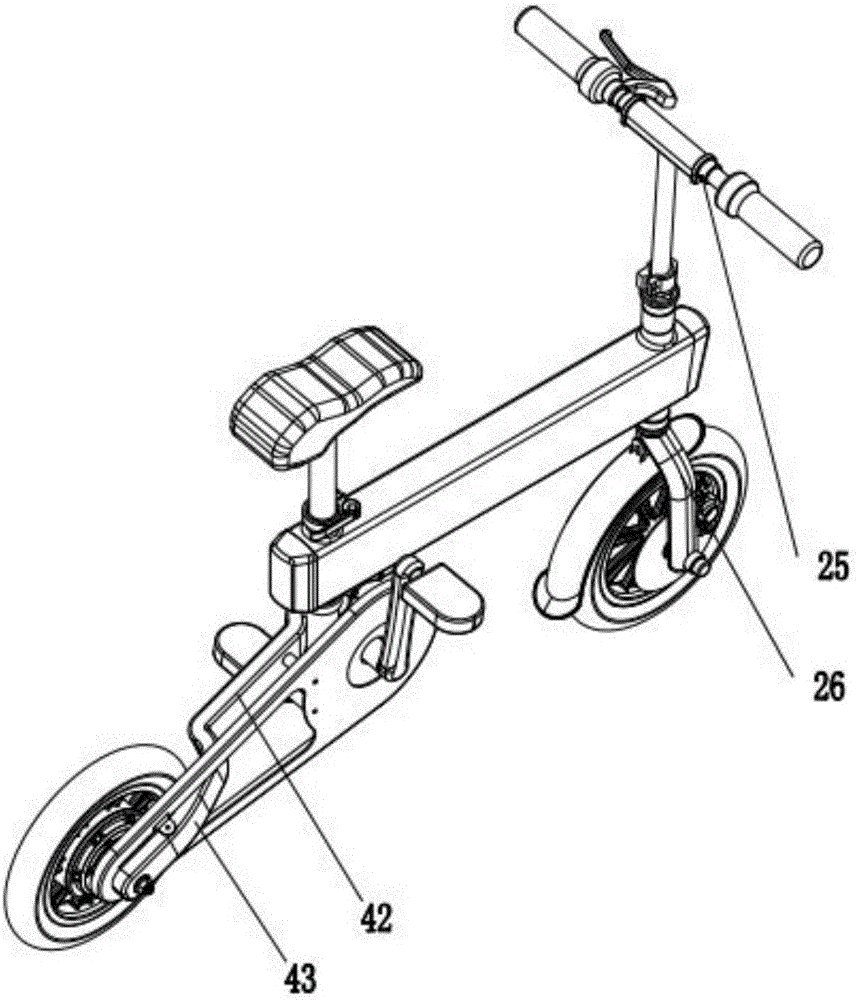

Folding electric bicycle frame and folding electric bicycle

InactiveCN106585818AAchieve foldingAchieve stabilitySteering deviceFoldable cyclesVehicle frameEngineering

The invention relates to a folding electric bicycle frame. The folding electric bicycle comprises a main crossbeam, wherein a front wheel steering mechanism is arranged at the first end of the main crossbeam, a cushion support pipe is in flexible inserting connection to the second end of the main crossbeam, the main crossbeam is also pivoted to one end of a rear electric bicycle frame, and one of the main crossbeam and the rear electric bicycle frame can rotate around a rotating shaft connected with the main crossbeam and the rear electric bicycle frame relative to the other of the main crossbeam and the rear electric bicycle frame in a horizontal direction; the rotating shaft is located between the front wheel steering mechanism and the cushion support pipe, and the rear electric bicycle frame is locked through the matching of the rotating shaft and the cushion support pipe under an unfolded state. The folding electric bicycle frame disclosed by the invention is exquisite in design and simple in structure, and an original structure of a conventional folding electric bicycle is broken through; and the rear electric bicycle frame and the main crossbeam can rotate relative to each other, so that folding an electric bicycle body can be realized. Though the matching of a support casing pipe and the rotating shaft connected with the rear electric bicycle frame and the main crossbeam, the stability of the electric bicycle body under the unfolded state can be effectively realized. A whole folding structure and an unfolded locking structure are succinct, and compared with a conventional folding electric bicycle body, the folding electric bicycle frame has the advantage that the number of desired parts and components is greatly reduced.

Owner:苏州速蝶科技有限公司

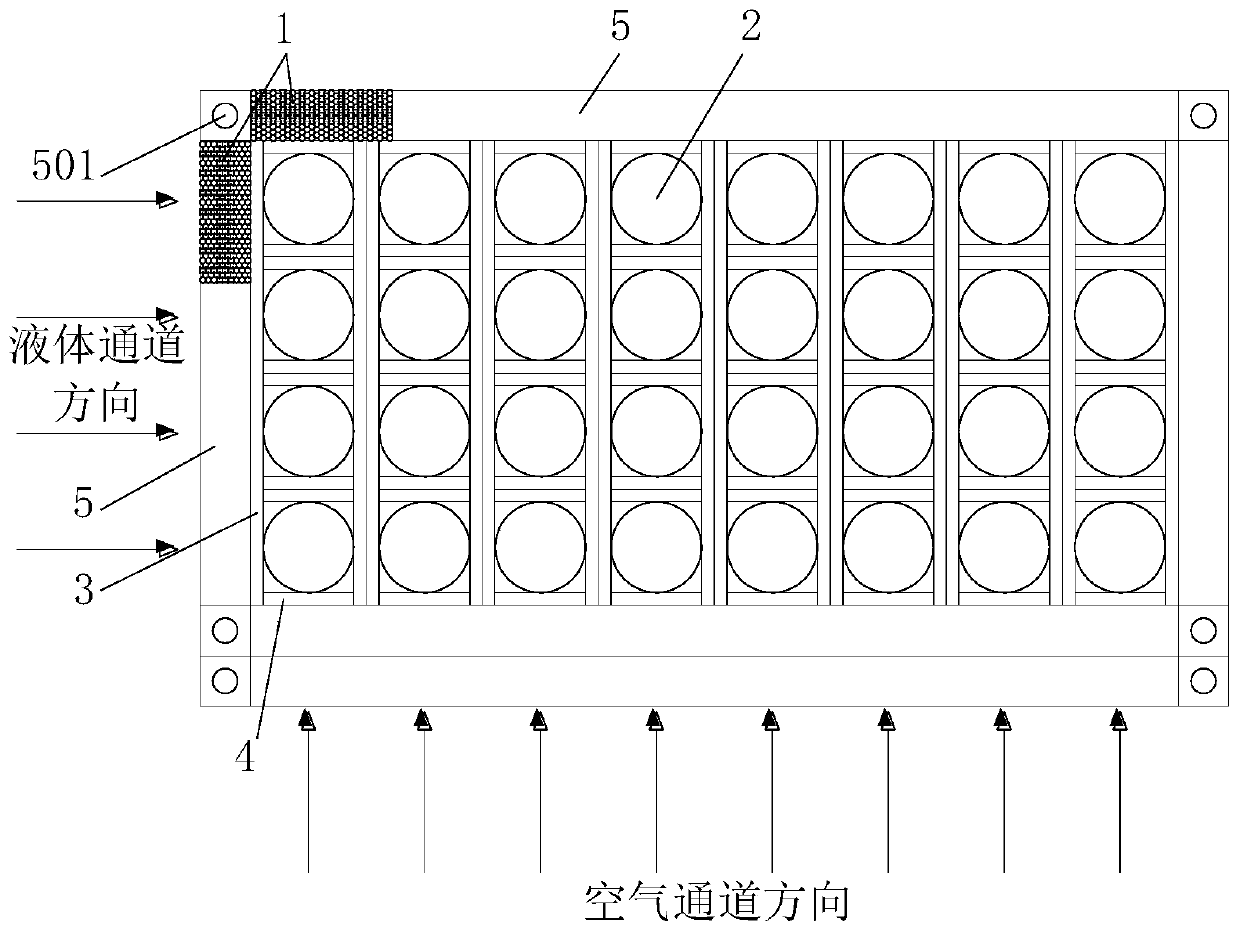

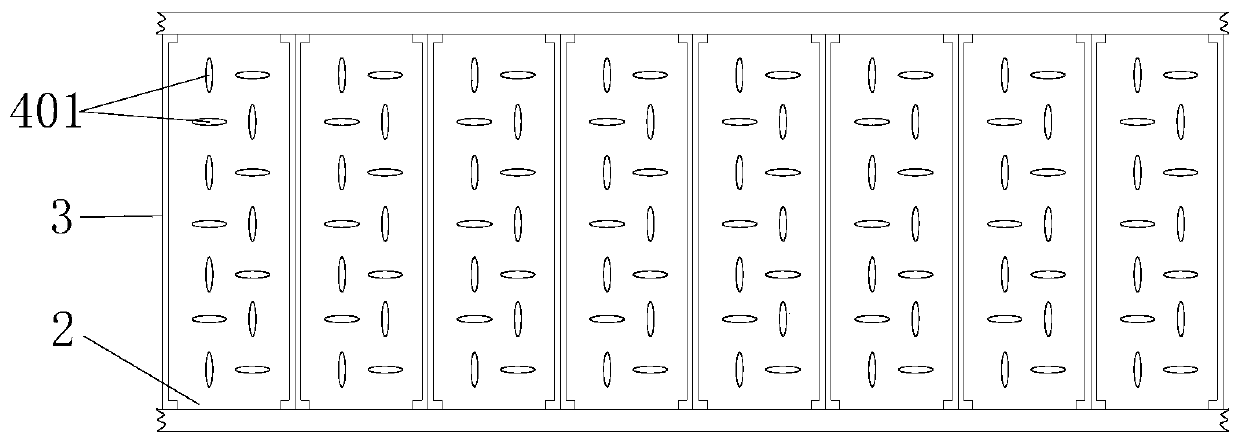

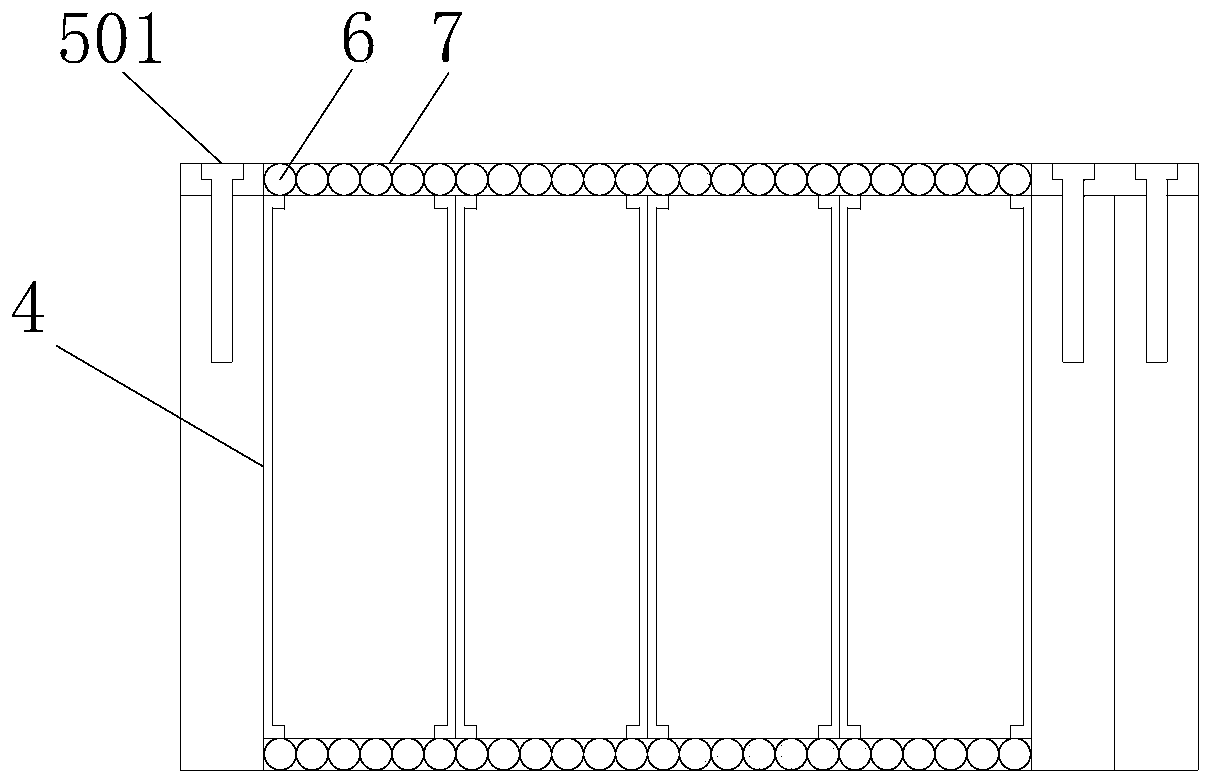

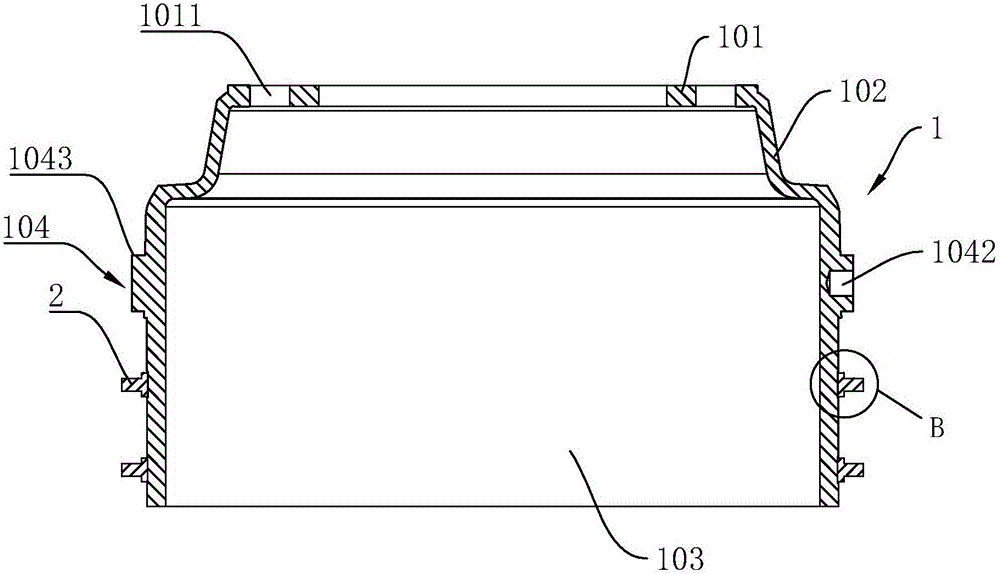

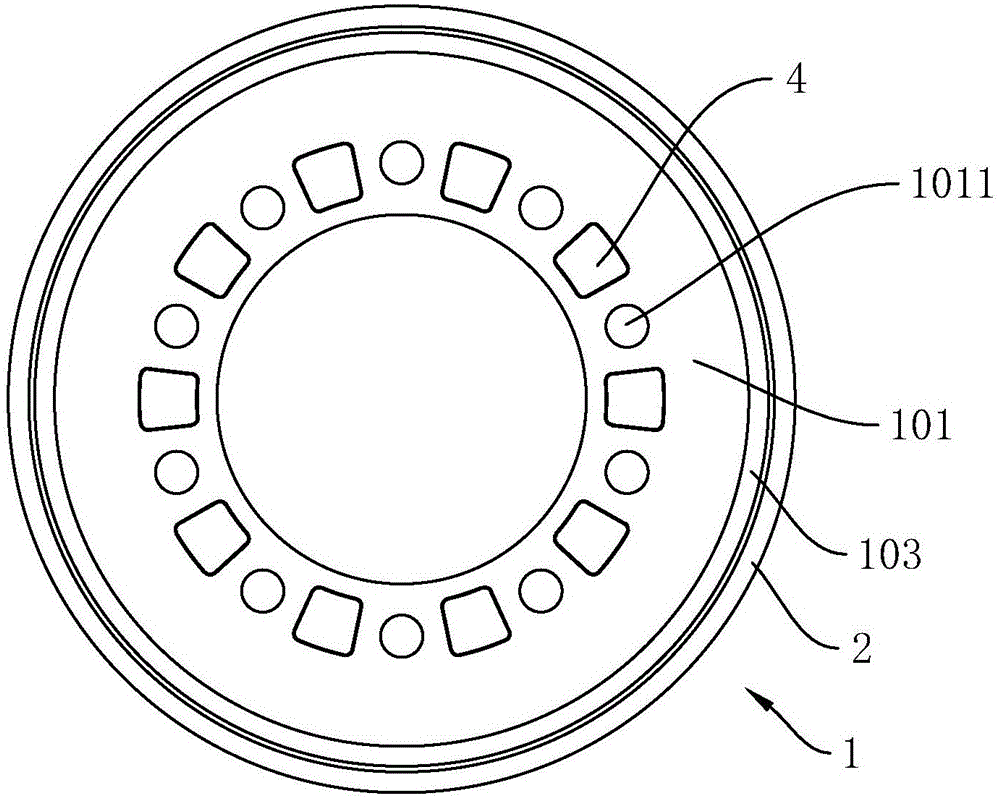

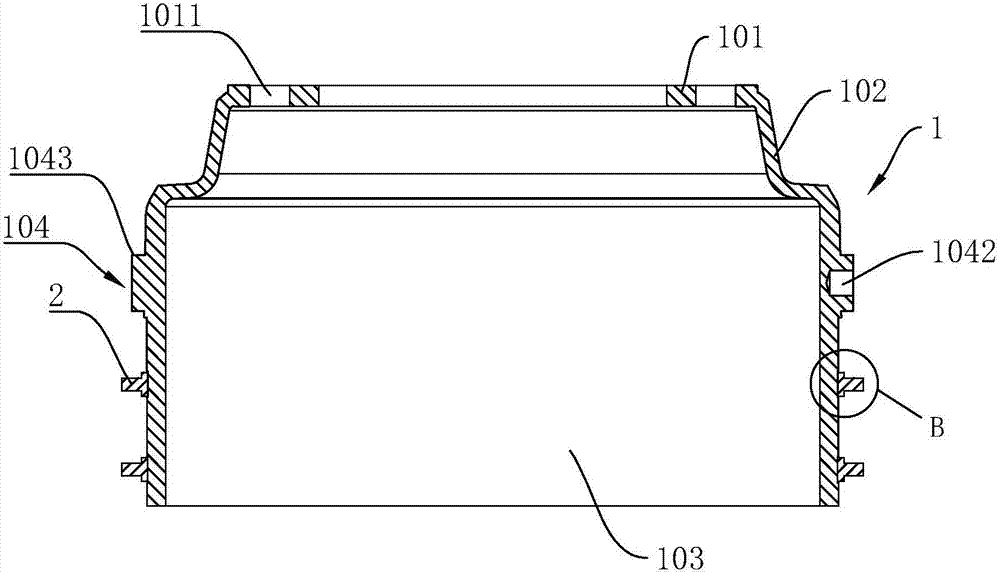

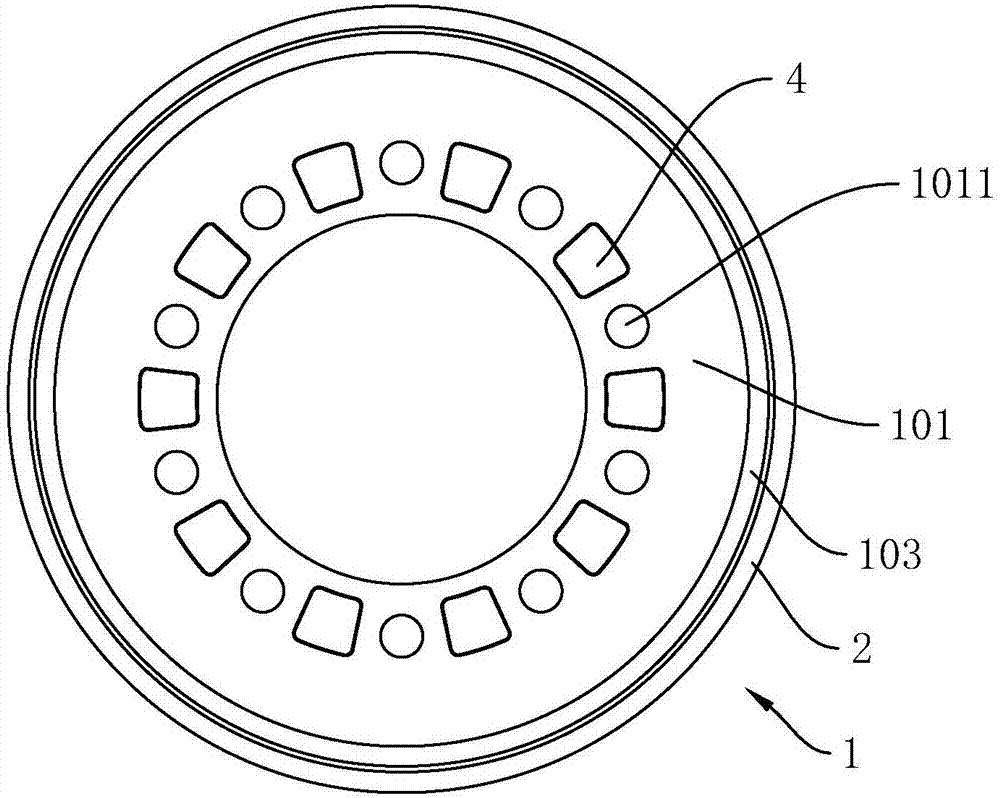

Anti-collision temperature control integrated battery module structure, processing device and method

ActiveCN111509161AHigh strengthImprove securityBattery isolationSecondary cellsStructural engineeringMechanical engineering

The invention relates to an anti-collision temperature control integrated battery module structure, a processing device and a processing method. The anti-collision temperature control integrated battery module structure comprises a battery module box body serving as a carrier, an isolation wall I and an isolation wall II are arranged in the battery module box body; an isolation wall I and the isolation wall II form a square fence and form a hollow-square-shaped structure with the battery module box body; a battery jar for placing a battery is placed in the square fence; a sandwich empty layerfor forming a channel is arranged between the square fence and the battery module box body, an anti-collision strip is arranged in the sandwich empty layer, and a battery module end cover is arrangedon the battery module box body; protective structure inner cores in honeycomb gradient arrangement with different poisson ratios are embedded into the anti-collision strips; the anti-collision temperature control integrated battery module structure is reasonable in design, compact in structure and convenient to use.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

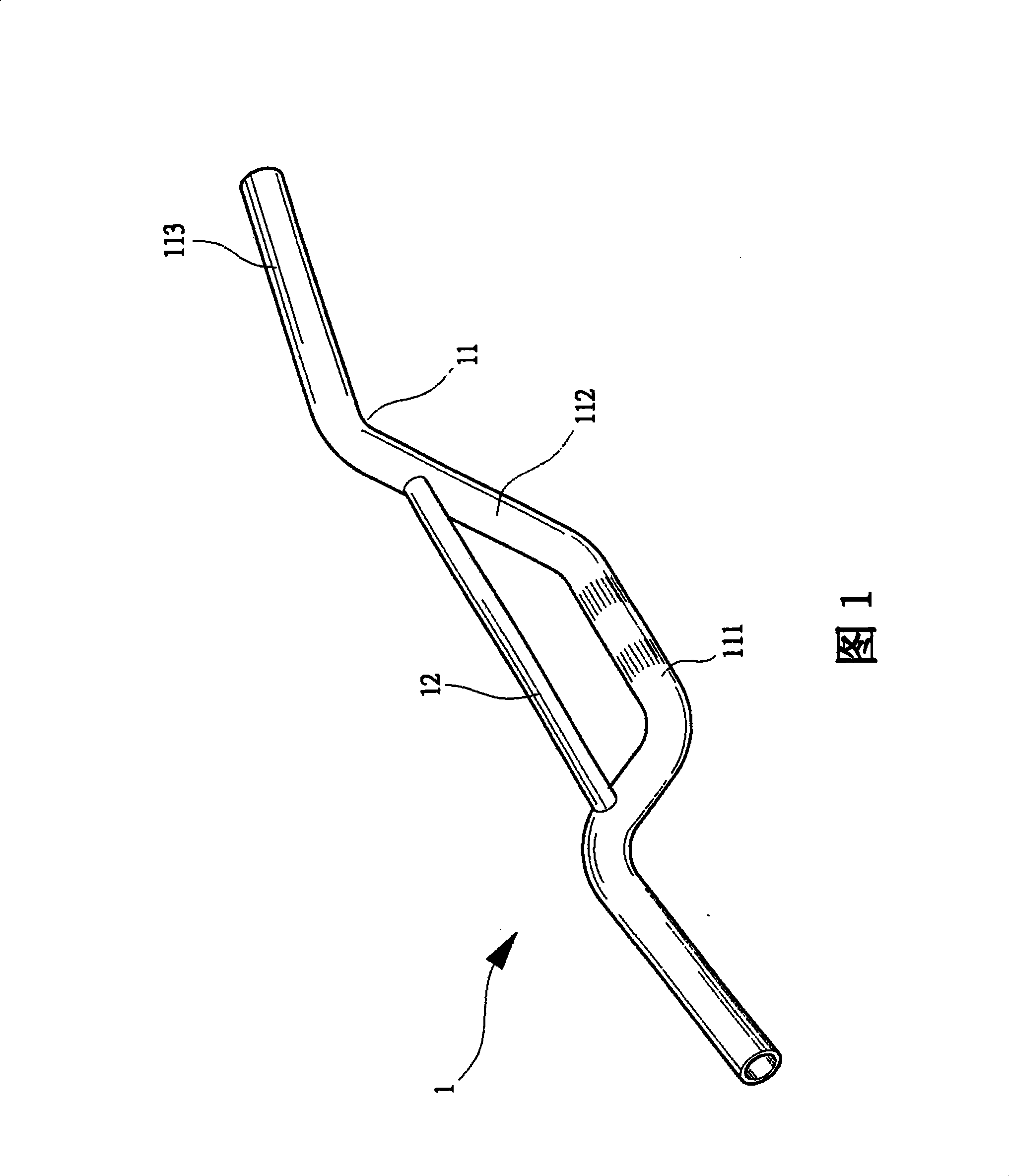

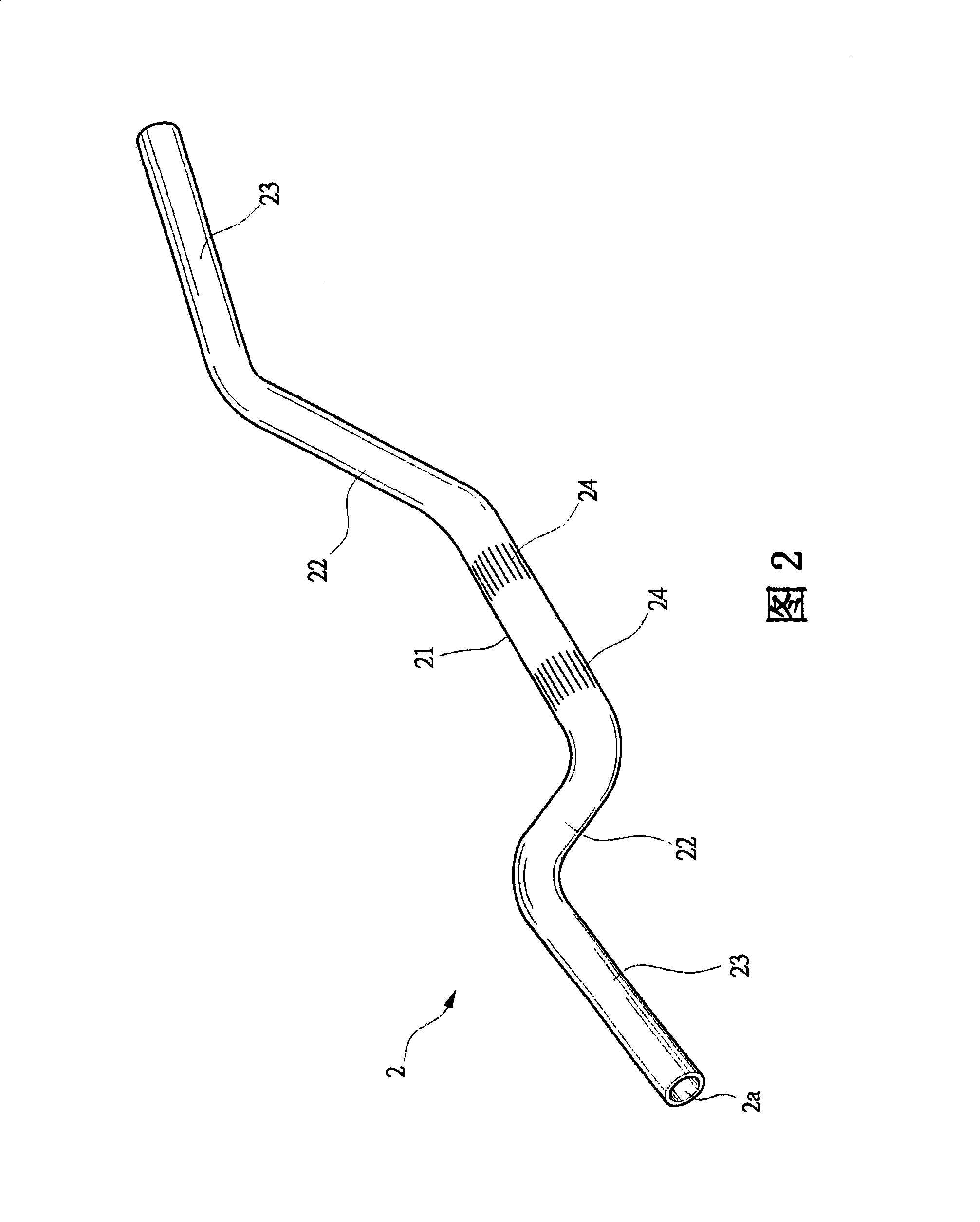

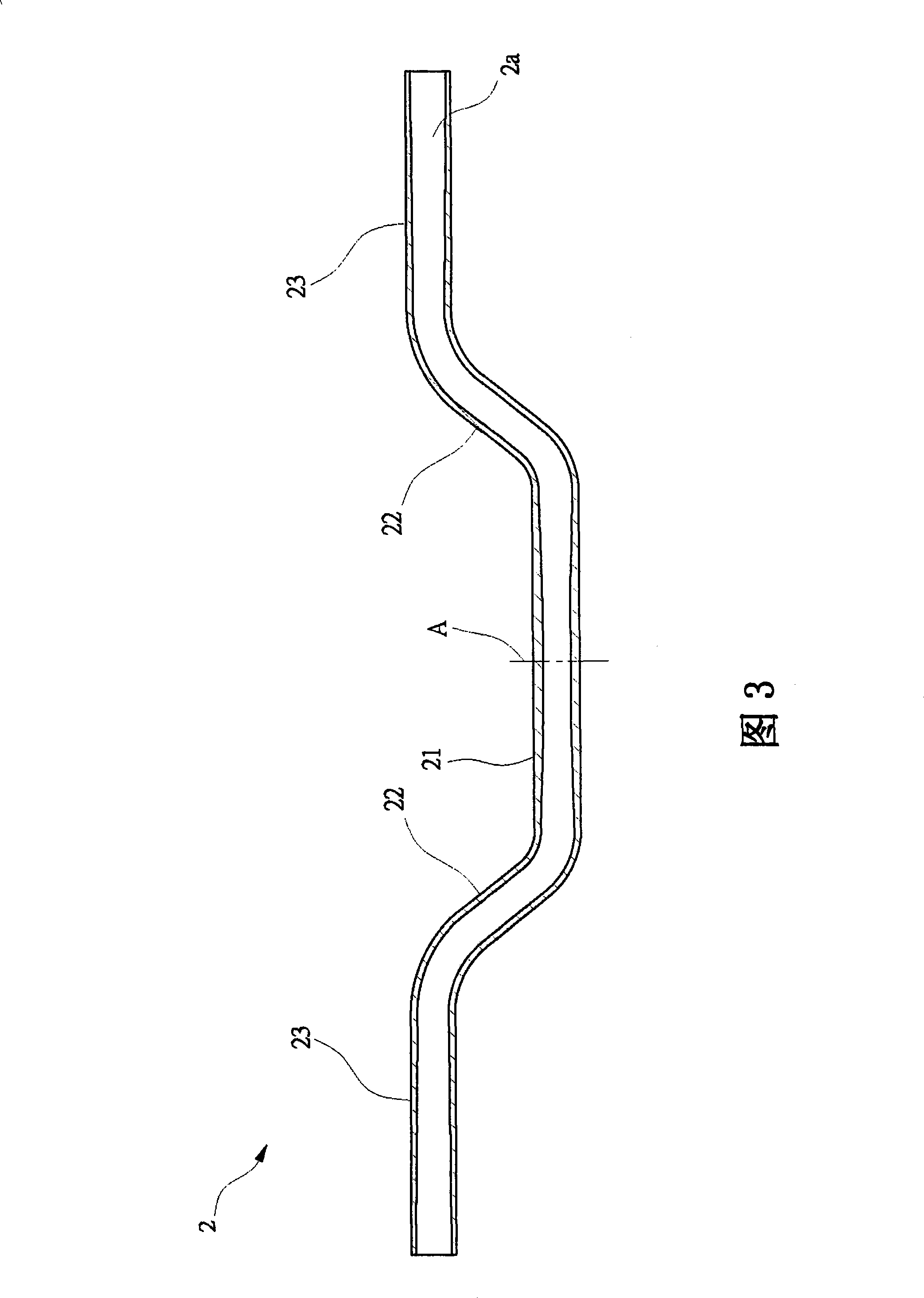

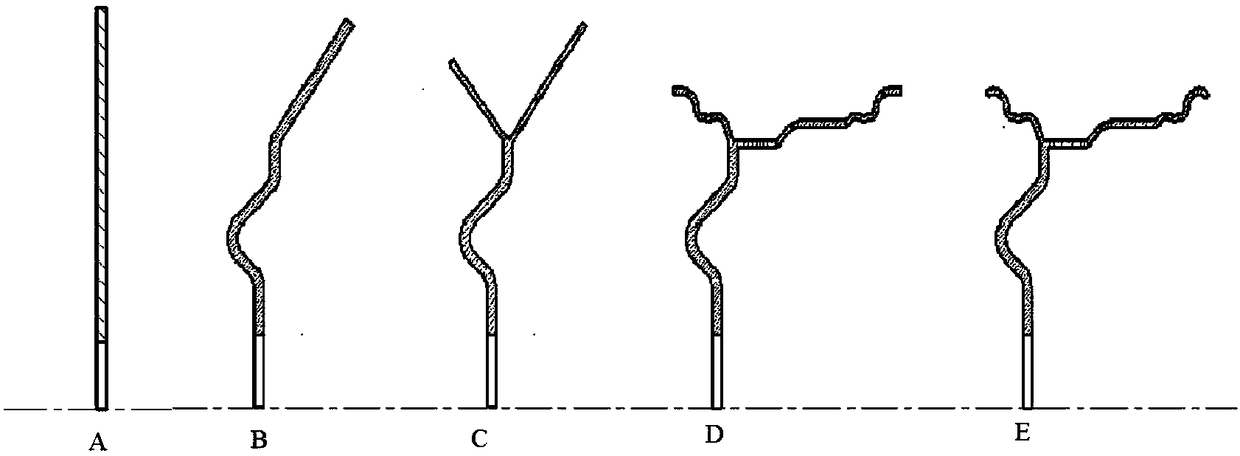

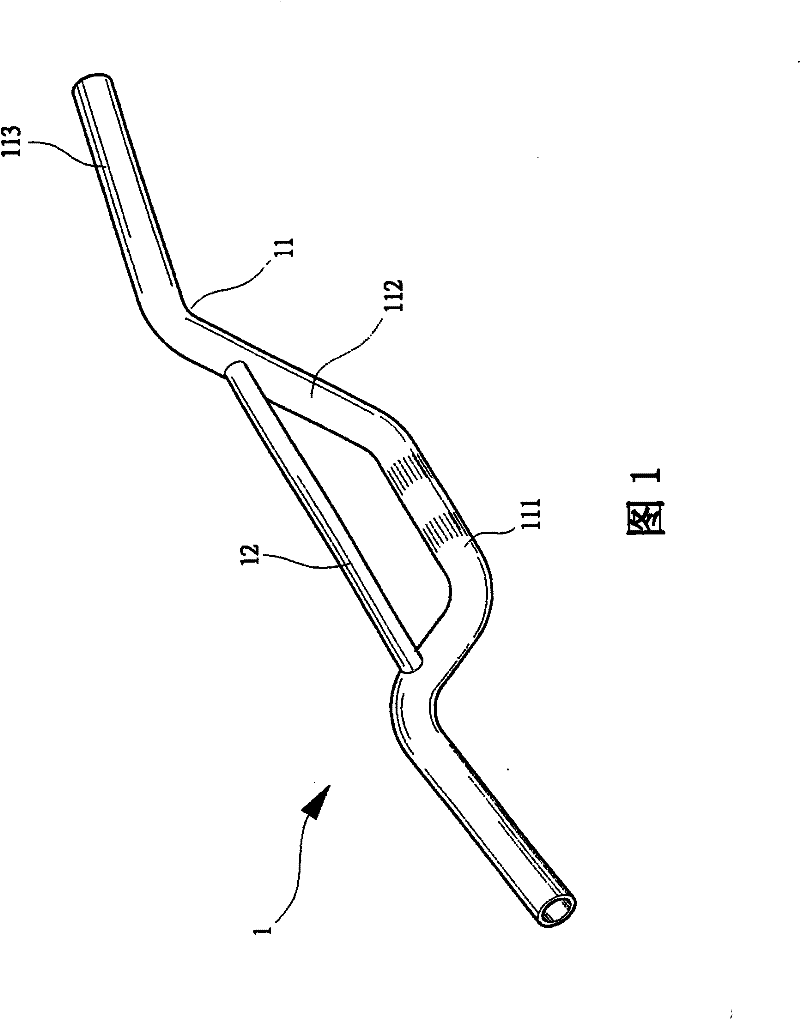

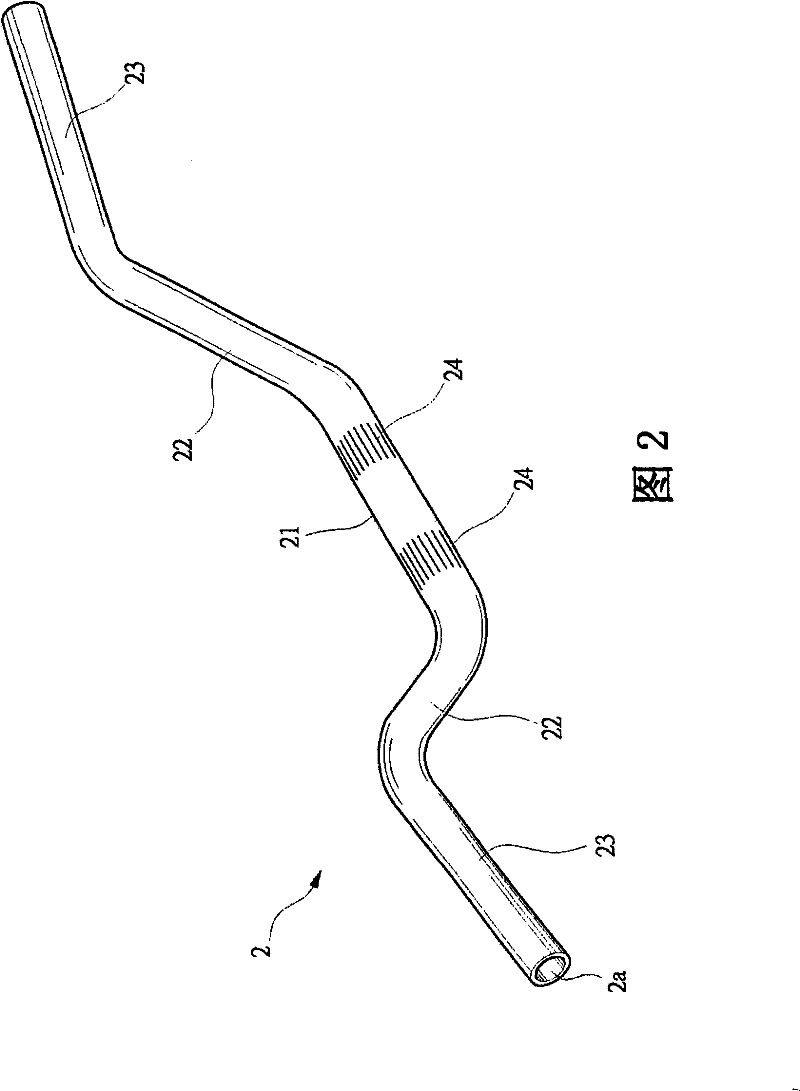

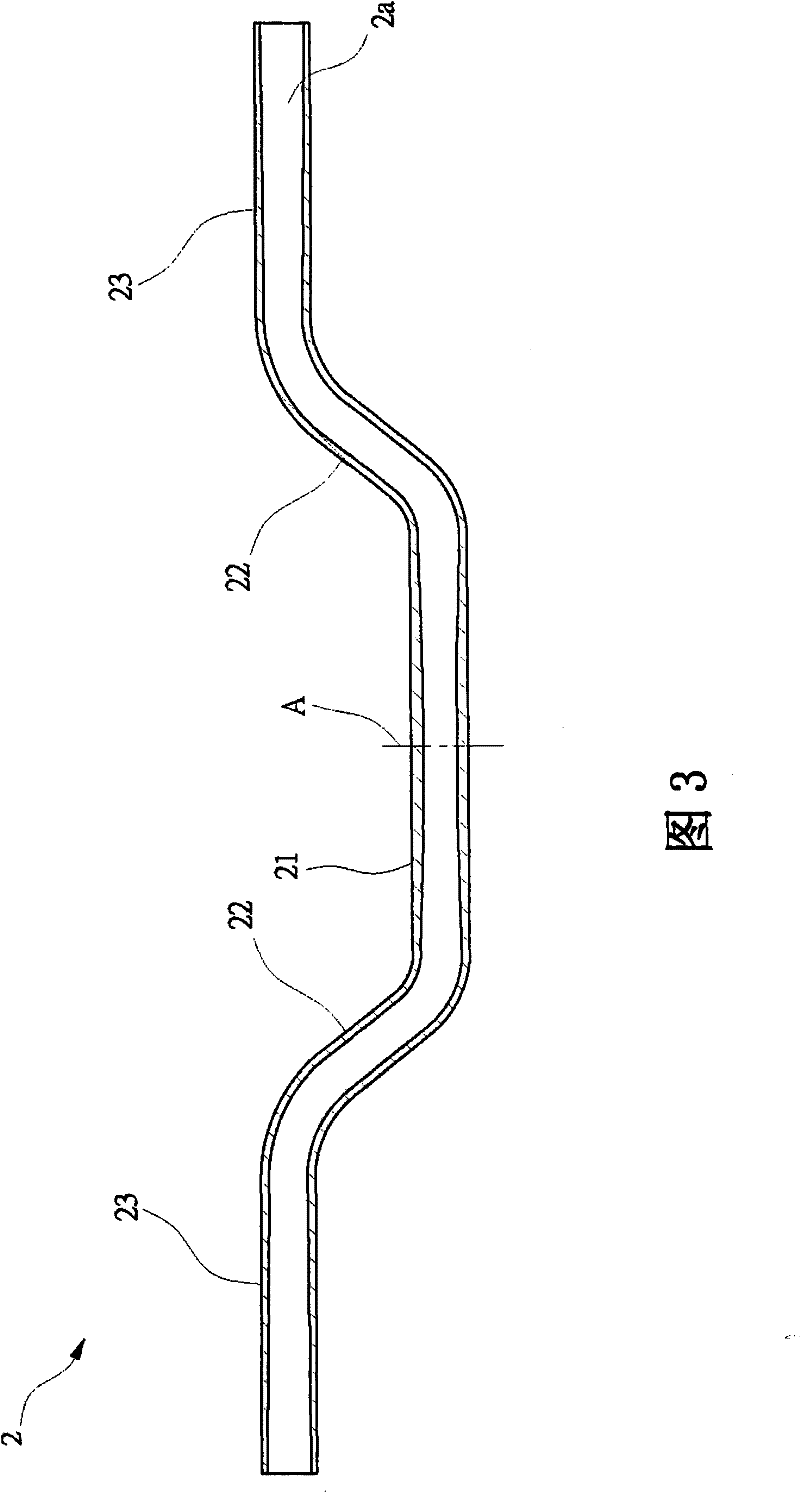

Vehicle steering handle structure

InactiveCN101362493AAchieve lightweight effectSteering deviceTube diameterElectrical and Electronics engineering

The invention relates to a vehicle steering handle structure, which is composed of a ducted body tube. A connecting part is concavely arranged at the middle part of the tube, raising parts are formed by extending upwards and slanchways from the both ends of the connecting part, a holding part is also formed by extending in the slightly horizontal direction from the end of the raising part, and a bonding zone between two coarse surfaces is also arranged on the connecting part. The vehicle steering handle structure is mainly characterized in that the tube diameter of the connecting part is larger than that of the raising part, the tube diameter of the raising part is larger than that of the holding part, and the connecting part comprises at least one inner tube wall which is linearly and gradually diffused and the inner tube wall of the holding part is also linearly and gradually diffused, therefore, the steering handle can reach high rigidity strength requirement, and simultaneously can also reach the effect of light weight.

Owner:KYMCO

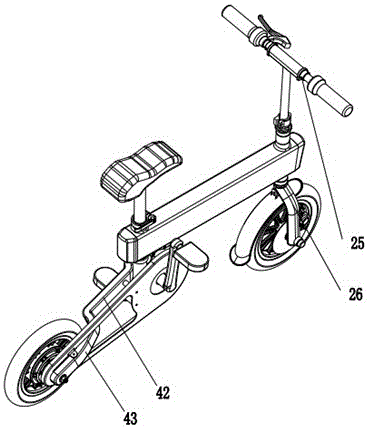

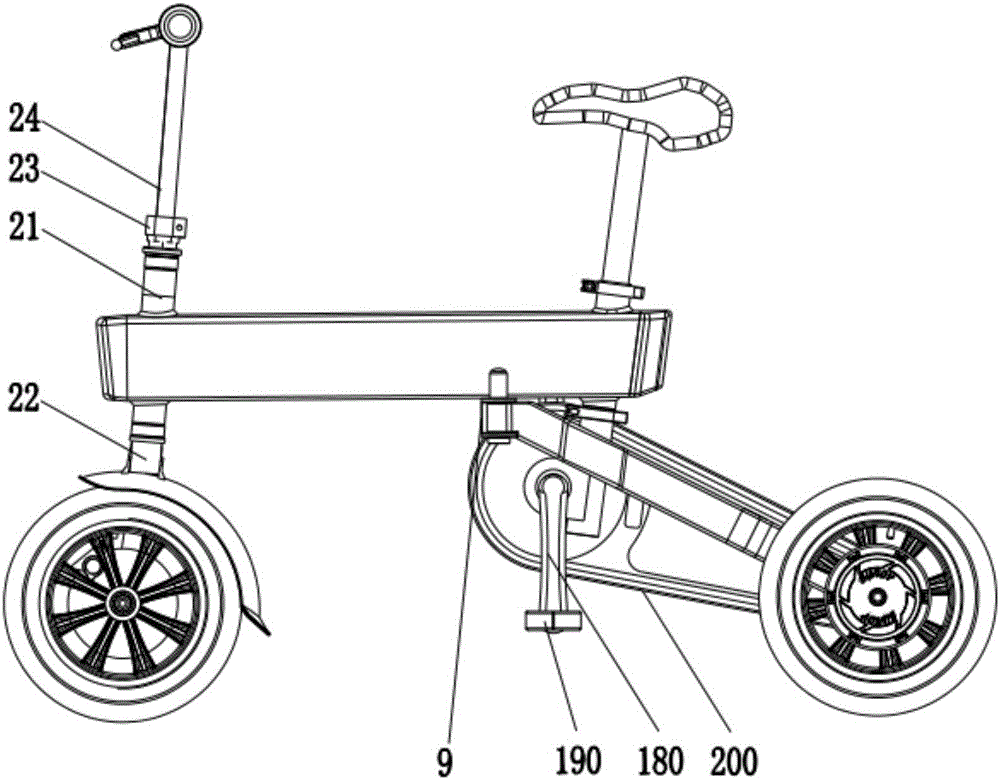

Folding electric scooter or bicycle

InactiveCN106585816AExquisite designSimple structureSteering deviceFoldable cyclesHeight differenceMechanical engineering

The invention discloses a folding electric scooter or bicycle. The folding electric scooter or bicycle comprises a folding electric scooter or bicycle frame, a front wheel located at the front end of the folding electric scooter or bicycle frame and a rear wheel located at the rear end of the folding electric scooter or bicycle frame. Under an unfolded state, the top arc of the front wheel and the top arc of the rear wheel are in the same plane, and under a folded state, the top arc of the front wheel and the top arc of the rear wheel are in parallel; the projection of the front wheel and the projection of the rear wheel are coincided with each other on the same plane in parallel to the top arc of the front wheel and the top arc of the rear wheel. The folding electric scooter or bicycle is exquisite in design, and simple in structure. After the folding electric scooter or bicycle is folded, the front wheel is parallel to the rear wheel, and height differences do not exist, so that after being folded, the folding electric scooter or bicycle can also be pushed wholly through the rolling of the front wheel and the rear wheel, and conditions are created for carrying the complete folding electric scooter or bicycle. After the folding electric scooter or bicycle is folded, the front wheel and the rear wheel can be integrally connected, and a pushing handle arranged on a cushion is used, so that the folding electric scooter or bicycle is convenient to carry, time-saving and effortless.

Owner:苏州速蝶科技有限公司

Integral wheel stamping and spinning manufacturing method

InactiveCN108655245AAchieve lightweight effectTo achieve the effect of lightweightRimsMetal-working apparatusEngineeringFlange

The invention discloses an integral wheel stamping and spinning manufacturing method. The method comprises the following steps that (1) stamping is carried out, specifically, stamping is carried out on a blank so as to form a spoke part; (2) pre-spinning is carried out on a rim, specifically, the blank is clamped by adopting an upper pre-spinning mandrel and a lower pre-spinning mandrel, the upperpre-spinning mandrel and the lower pre-spinning mandrel drive the blank to rotate synchronously, and meanwhile, lateral extrusion force is applied to the outer edge of the blank by adopting an autorotation and radial feed type spinning wheel so as to form the outer edge of the blank into the V-shaped rim with an outward opening; (3) spinning forming is carried out on the rim, specifically, the blank is clamped by adopting an upper rim forming mandrel and a lower rim forming mandrel, the upper rim forming mandrel and the lower rim forming mandrel drive the blank to synchronously rotate, and meanwhile, pressure is applied to the two sides of the V-shaped rim by adopting an autorotation and radial feed type forming spinning wheel so as to enable the two sides of the V-shaped rim to be attached to the upper rim forming mandrel and the lower rim forming mandrel respectively; and (4) spinning is carried out on a wheel flange.

Owner:BAOSHAN IRON & STEEL CO LTD

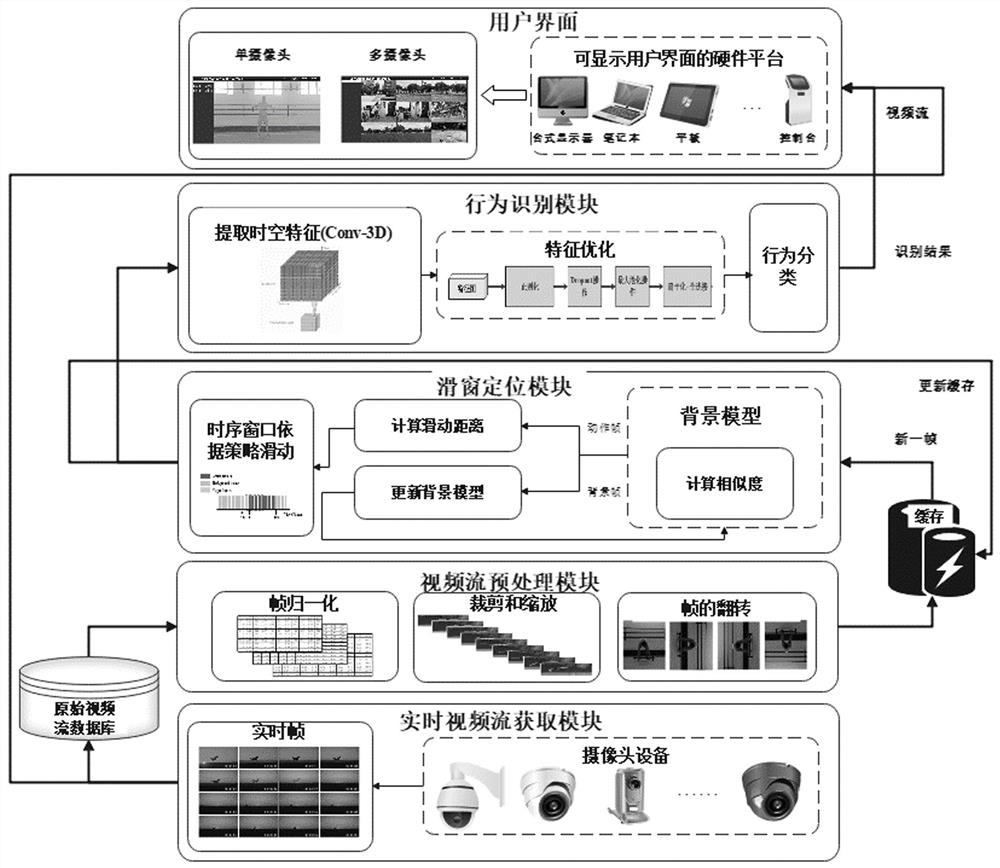

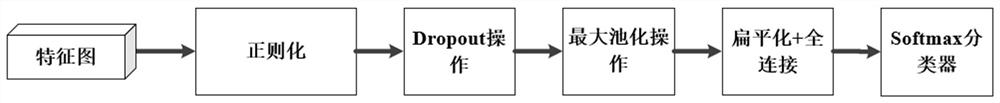

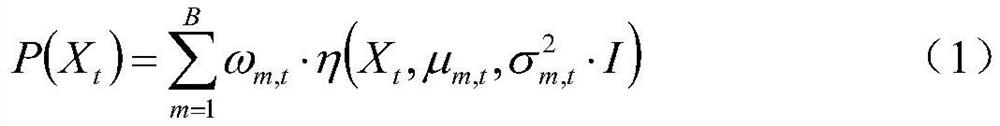

Real-time video stream-oriented edge environment behavior recognition system

PendingCN113591674ASave computing resourcesAchieve lightweight effectCharacter and pattern recognitionTransmissionVideo streamingDetection performance

The invention discloses a real-time video stream-oriented edge environment behavior recognition system, which comprises a video stream acquisition module, a video stream storage module, a video stream preprocessing module, a cache module, a sliding window positioning module, a behavior recognition module and a user interface module; the sliding window positioning module starts an online detection method based on the action of the elastic jumping sliding window, a large amount of computing resources are saved by positioning the position of the action, and meanwhile, large loss of the detection performance of an original model with excellent performance due to the fact that frame-by-frame sliding of the sliding window is abandoned is avoided; a model lightweight effect is realized to a certain extent, a large amount of invalid data is prevented from being sent to a behavior identification module, the behavior identification efficiency is improved, the identification real-time performance is improved, and the privacy security problem of data acquired by edge equipment in a sensitive scene is better protected through data localization processing; and compared with a behavior identification service generally based on a cloud center, the system is more beneficial to the use of edge devices with limited resources.

Owner:GUILIN UNIV OF ELECTRONIC TECH

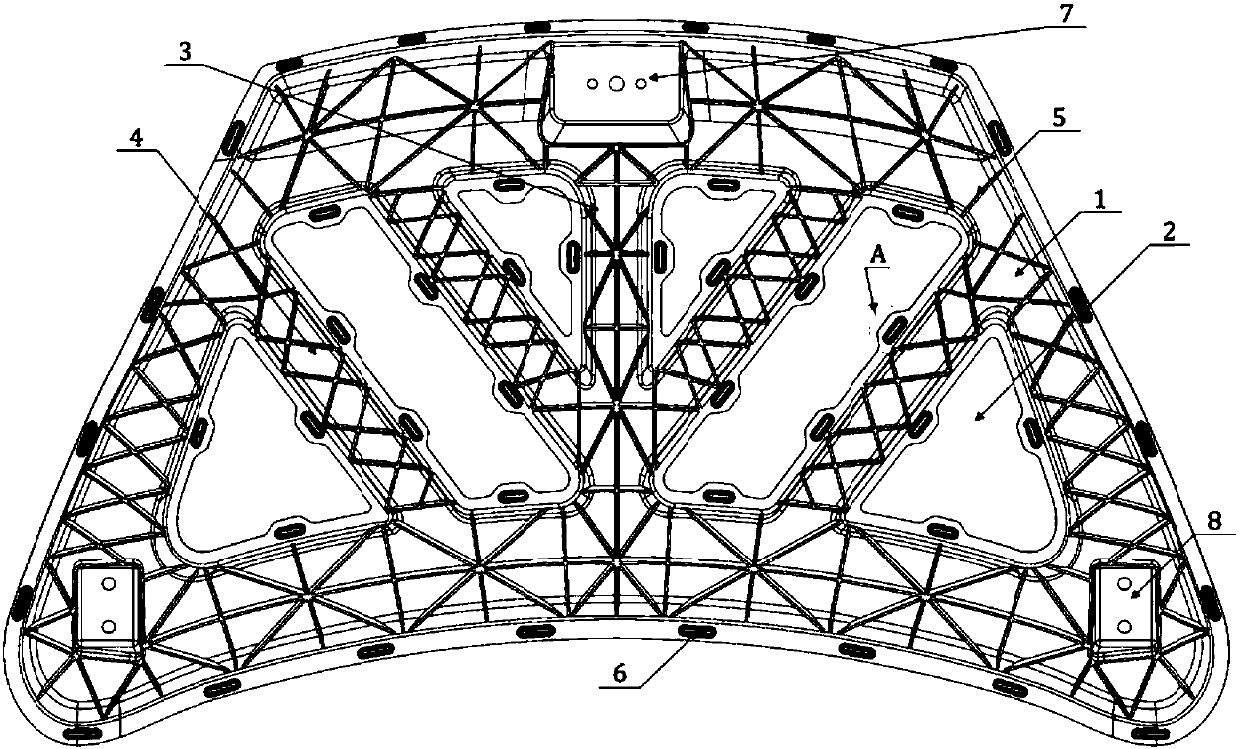

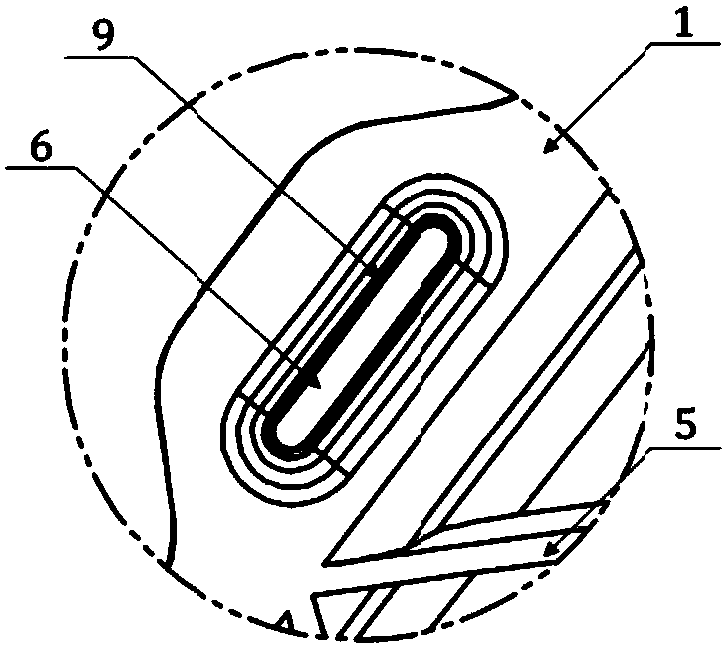

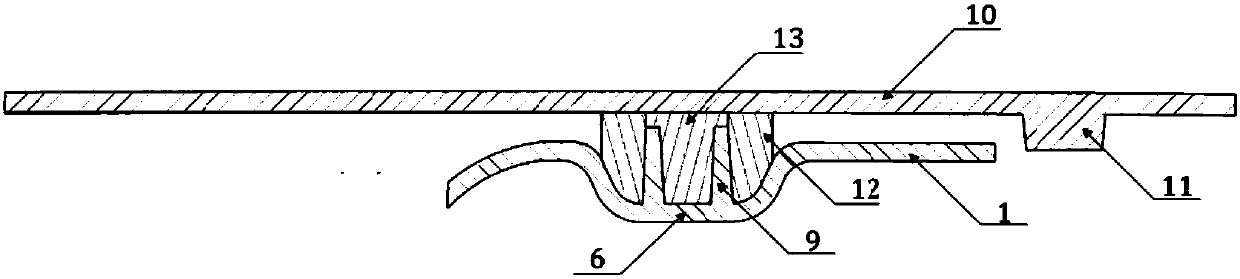

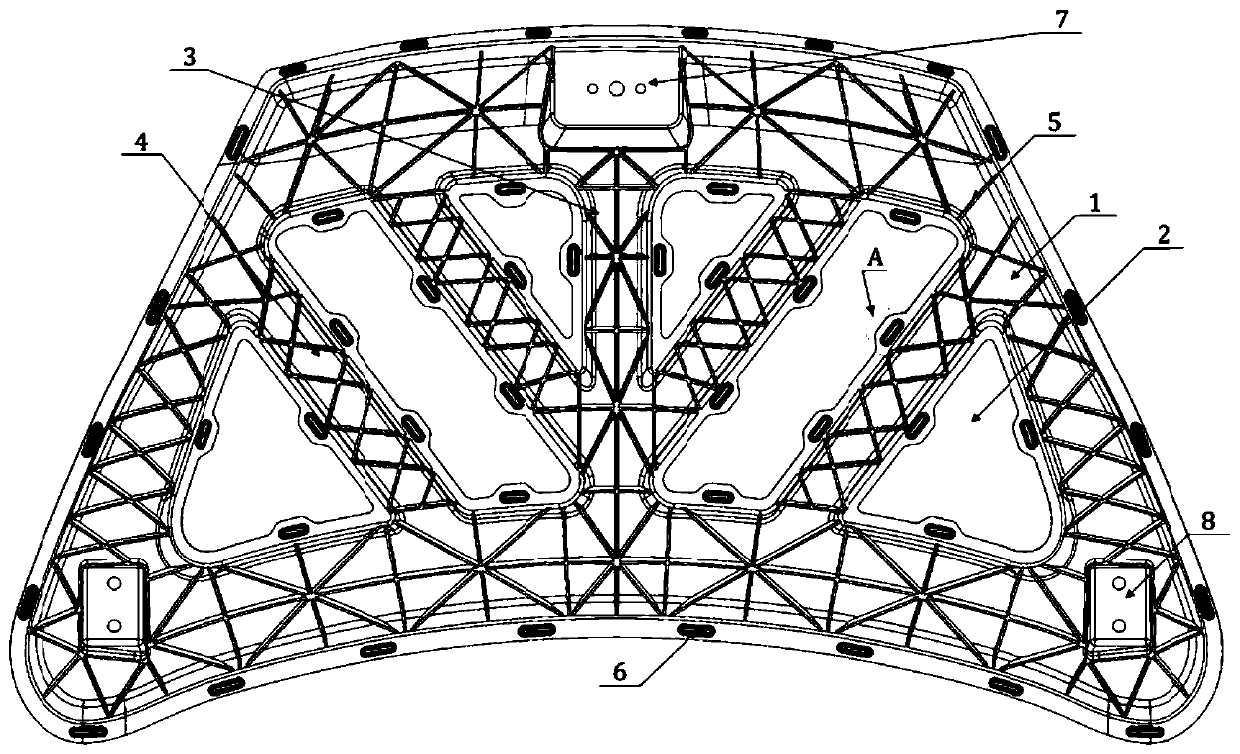

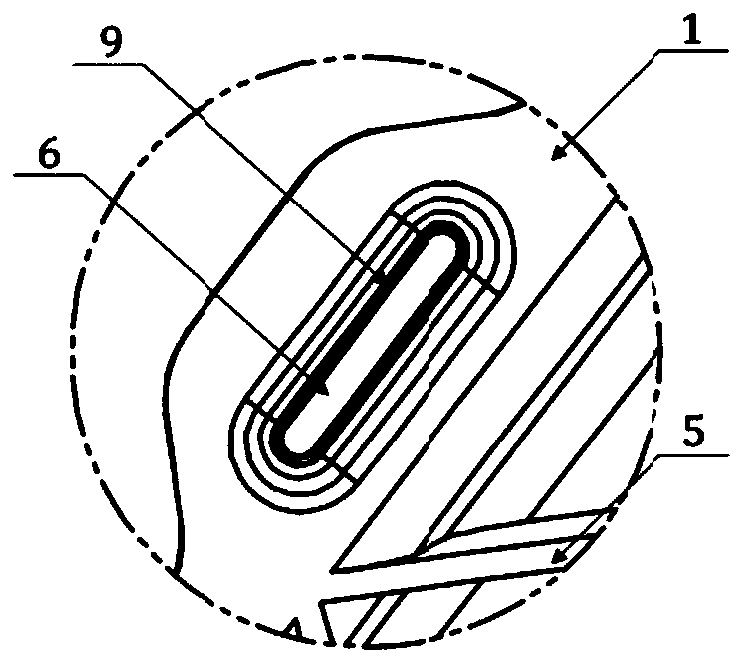

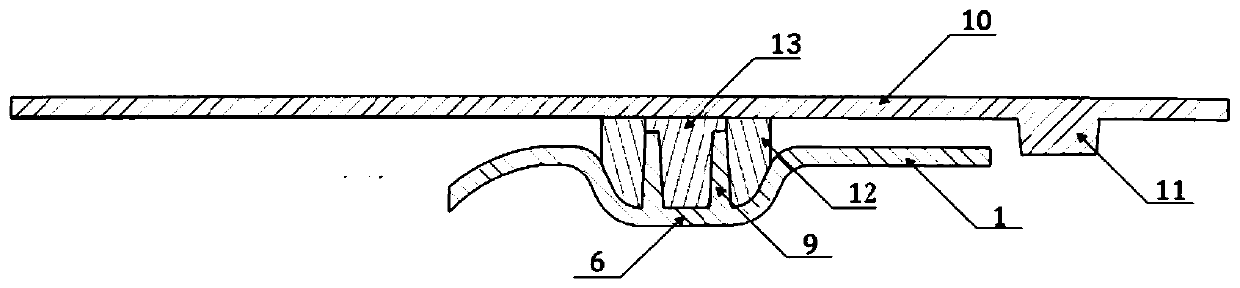

Composite engine hood inner panel of electric vehicle

ActiveCN107554620ALimit spacingGuaranteed thicknessSuperstructure subunitsStress concentrationAdhesive

The invention relates to a composite engine hood inner panel of an electric vehicle. An engine hood inner panel and an engine hood outer panel are connected in a gluing manner through an adhesive; theengine hood inner panel is provided with a flange; the gluing connection structure comprises a plurality of hoppers, stop blocks and a spill-proof block; the hoppers are respectively arranged on theflange of the engine hood inner panel; the stop blocks are arranged on the side near the outer panel, in the hoppers; the shape of each of the stop blocks is matched with that of the corresponding hopper; the stop blocks are higher than the plane of the inner panel; two kinds of adhesive with different properties can be separated by the stop blocks to achieve hybridization gluing; the spill-proofblock is located on the side near the inner panel, of the outer panel; the shape of the spill-proof block is determined according to the shape of the edge of the inner panel; the spill-proof block ishigher than the plane of the inner panel to prevent the adhesive form spilling; the composite-material engine hood inner panel disclosed by the invention is formed by adopting integrated injection molding of composites, and is low in the mold opening cost and high in the production efficiency; and through adoption of the hybridization connection, mechanical properties of different cohesive glue layers are reasonably utilized, the stress concentration at end heads is reduced, better adhesive properties are achieved, beautiful appearance of gluing is guaranteed, and the cost is saved.

Owner:GUANGXI AISHENG CHUANGZHI SCI & TECH CO LTD

Brake drum

ActiveCN105736609AImprove structural strengthImprove mechanical propertiesBraking drumsSlack adjustersUltimate tensile strengthMechanical engineering

The invention discloses a brake drum, which comprises a brake drum body provided with an installing part, a transition connecting part and a brake part, wherein one end, far away from the transition connecting part, on the brake part is tightly matched with a hoop ring; an annular reinforcing rib is arranged on the brake part positioned between the hoop ring and the transition connecting part; the annular reinforcing rib is projected out of the outer surface of the brake part and is made into a whole with the brake part; a plurality of first weight reducing grooves are formed in one side surface or two side surfaces of the annular reinforcing rib. Through the matching of the reinforcing rib and the hoop ring, the structure strength and the mechanical property are ensured; the heat radiation effect is good; the occurrence of longitudinal tiny crack and craze crack of the inner wall of the brake drum is avoided; the radial expansion deformation can also be counteracted; the fatigue resistance of the brake drum is improved; meanwhile, the tight holding force of the hoop ring on the brake drum body is realized; the disk of brake drum flying due to fracture is avoided; the service life is prolonged; the use safety is improved; through the first weight reducing grooves, the effect of the annular reinforcing rib is not influenced, the weight of the brake drum can also be reduced, and the light weight of the brake drum is realized.

Owner:SHANDONG HAOXIN MACHINERY

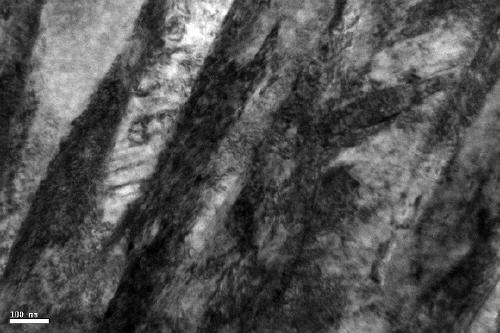

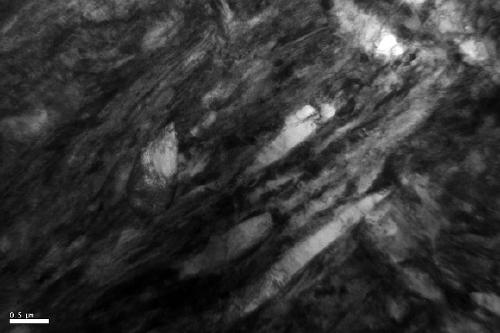

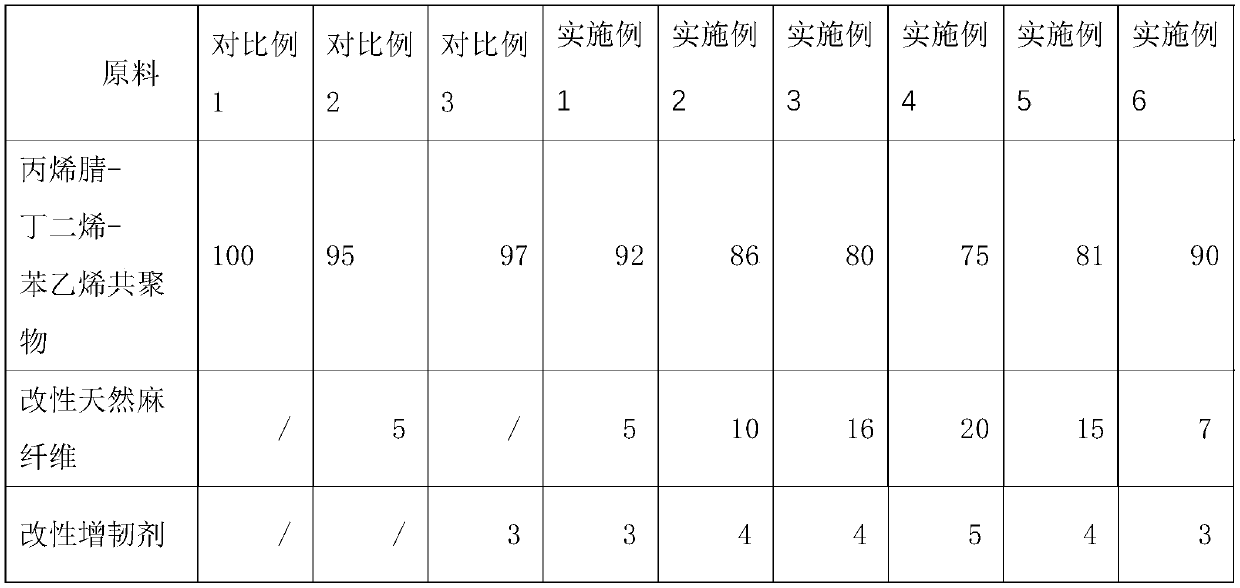

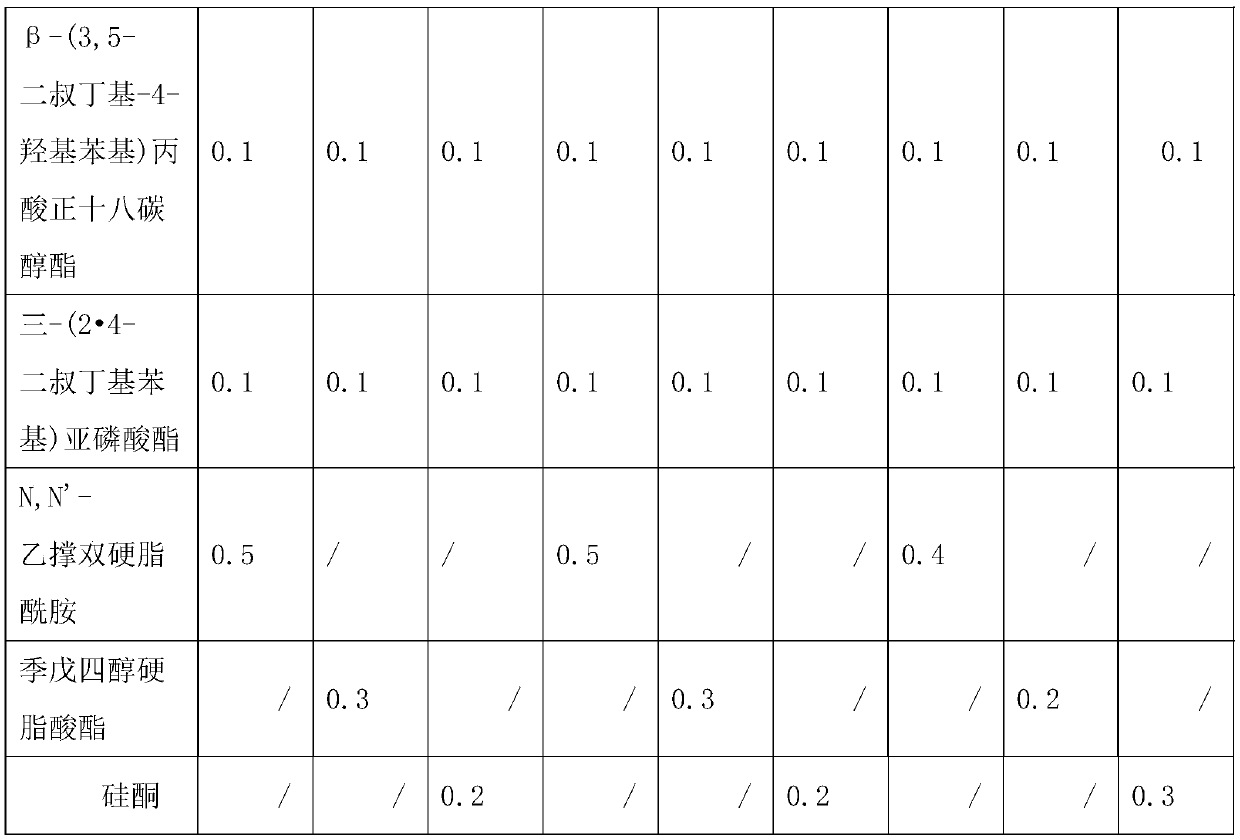

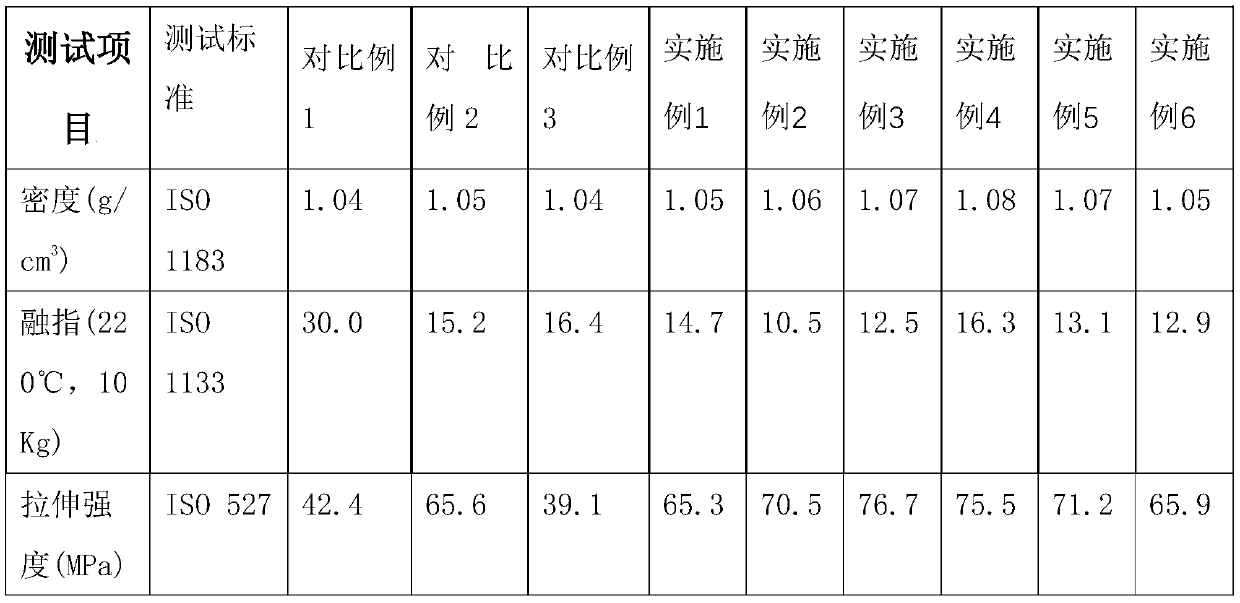

Natural fiber reinforced ABS composite material and preparation method thereof

The invention discloses a natural fiber reinforced ABS composite material and a preparation method thereof. The composite material comprises a main material and an auxiliary material, wherein the mainmaterial is prepared by, by weight, 75-92 parts acrylonitrile-butadiene-styrene copolymer, 5-20 parts of modified natural bast fiber and 3-5 parts of modified toughening agent; the auxiliary materialis prepared by, based on the fact that the total weight of the main material is 100 parts, 0.2 part of antioxidant and 0.2-0.5 part of lubricant. The prepared natural fiber reinforced ABS composite material is excellent in mechanical performance, low in density and lightweight.

Owner:ORINKO NEW MATERIAL CO LTD

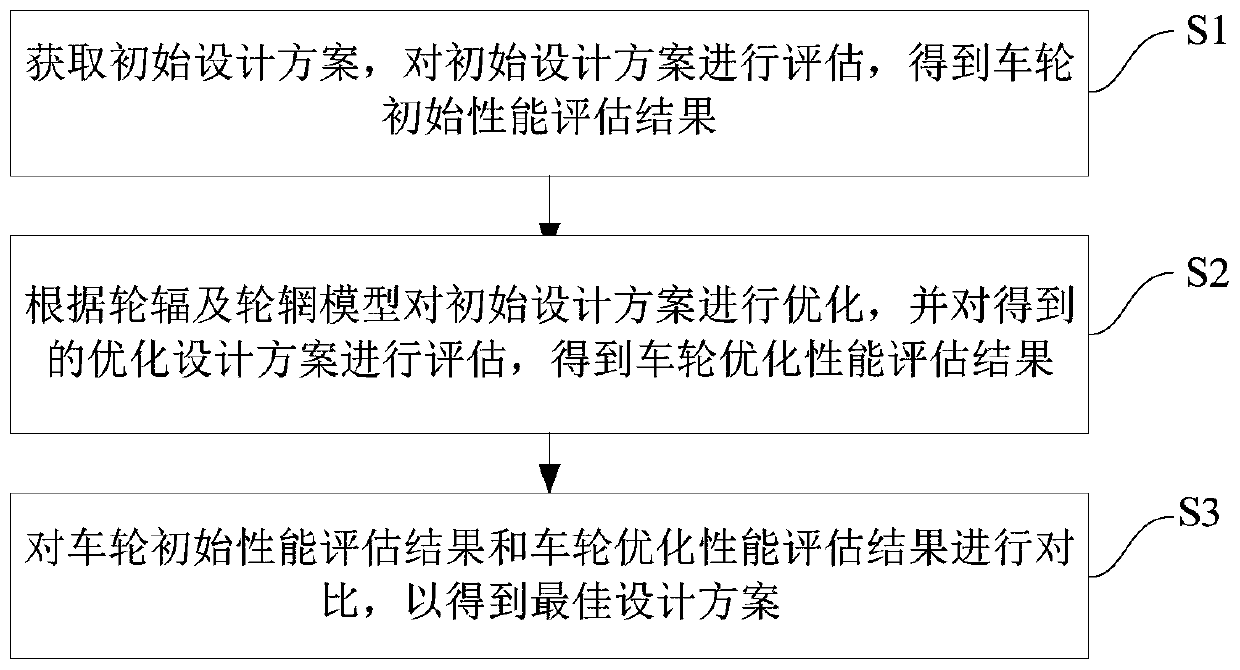

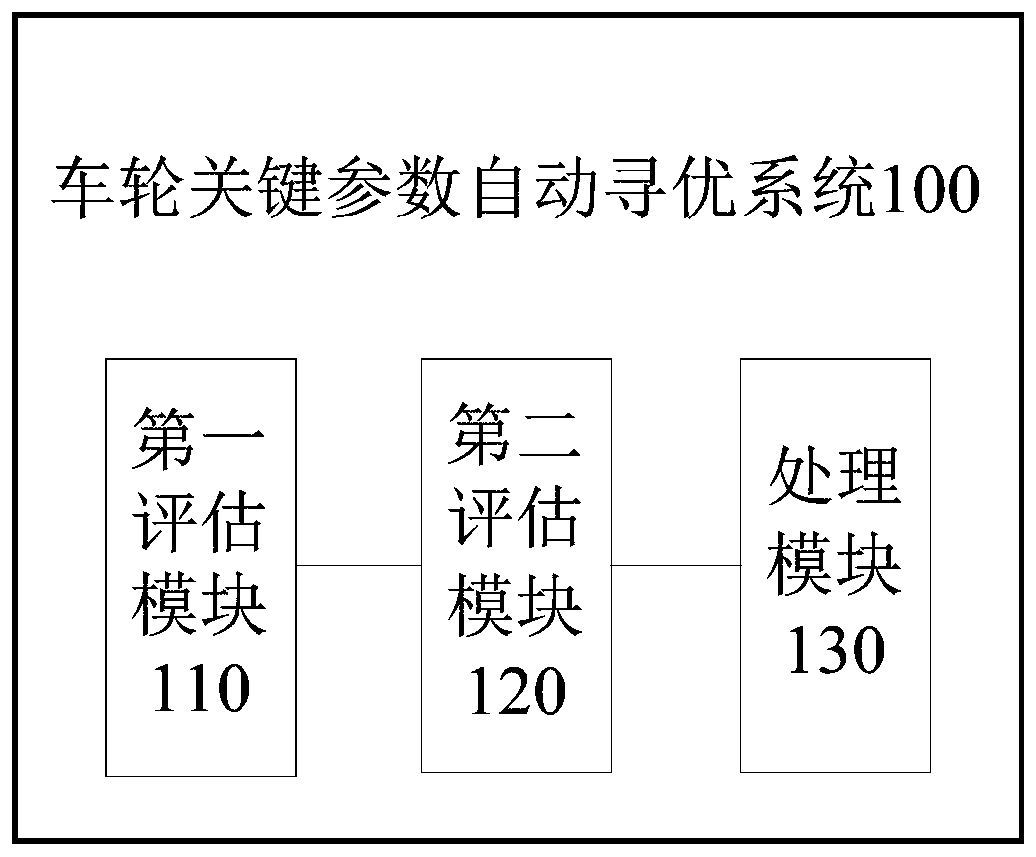

Wheel key parameter automatic optimization method and system

InactiveCN110555238AIncrease productionLow costSpecial data processing applicationsOptimal designEngineering

The invention provides a wheel key parameter automatic optimization method and system, and the method comprises the following steps: obtaining an initial design scheme, evaluating the initial design scheme, and obtaining a wheel initial performance evaluation result; optimizing the initial design scheme according to the spoke and rim model, and evaluating the obtained optimization design scheme toobtain a wheel optimization performance evaluation result; and comparing the wheel initial performance evaluation result with the wheel optimization performance evaluation result to obtain an optimaldesign scheme. According to the invention, design is carried out from wheel angles; an automatic optimization algorithm is adopted; based on an optimization design theory and method, the optimal scheme is automatically, quickly and optimally selected by using a numerical method, so that the product development period can be shortened, the experimental cost can be saved by the optimal scheme, thetransmission of acoustic cavity resonance energy can be inhibited on the premise of not increasing a new structure or material, the riding comfort is improved, and a light weight effect can be achieved.

Owner:BEIHANG UNIV

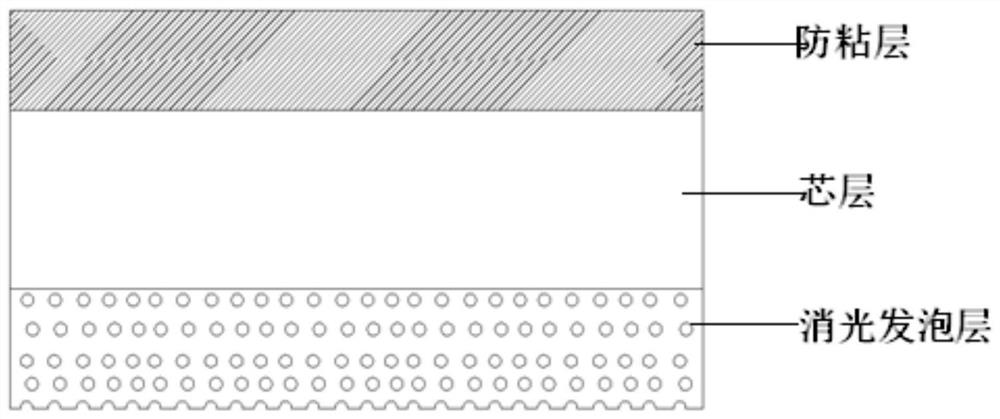

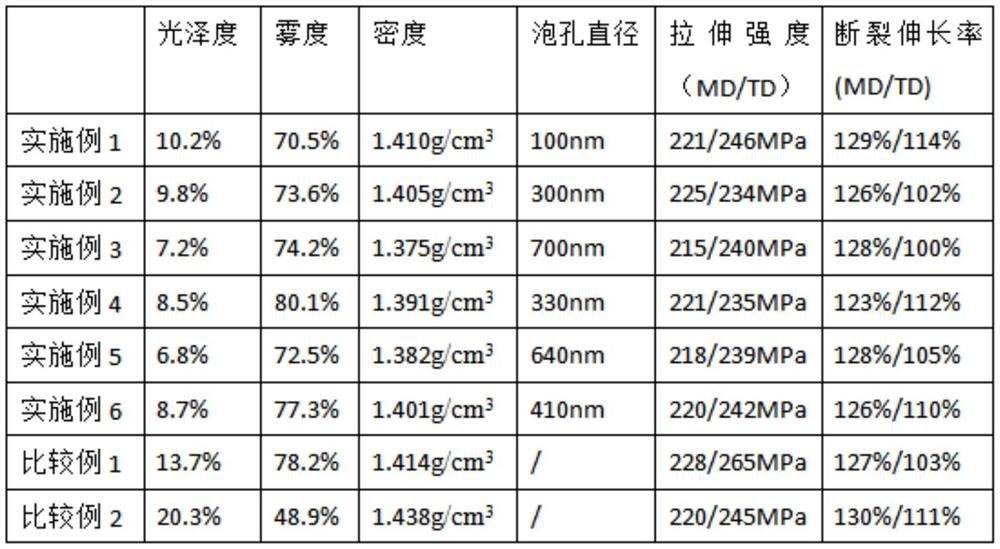

A kind of dull nylon film and preparation method thereof

ActiveCN109517372BReduce glossGood mattingSynthetic resin layered productsFlat articlesPolymer scienceFoaming agent

The invention provides a matte nylon film, comprising a release layer, a core layer and a matt foaming layer; the release layer comprises 97 to 99 parts by weight of nylon resin, 0.5 to 2 parts by weight of a release agent, 0.5 to 1 Slipping agent in parts by weight; the core layer includes nylon resin; the matting foam layer includes 91 to 97 parts by weight of nylon resin, 2 to 5 parts by weight of foaming agent, and 0.5 to 2 parts by weight of foaming initiator agent, 0.5 to 2 parts by weight of matting powder. The invention also provides a preparation method of the matte nylon film, which can effectively improve the matting effect and reduce the production cost.

Owner:HUNAN UNIV OF TECH

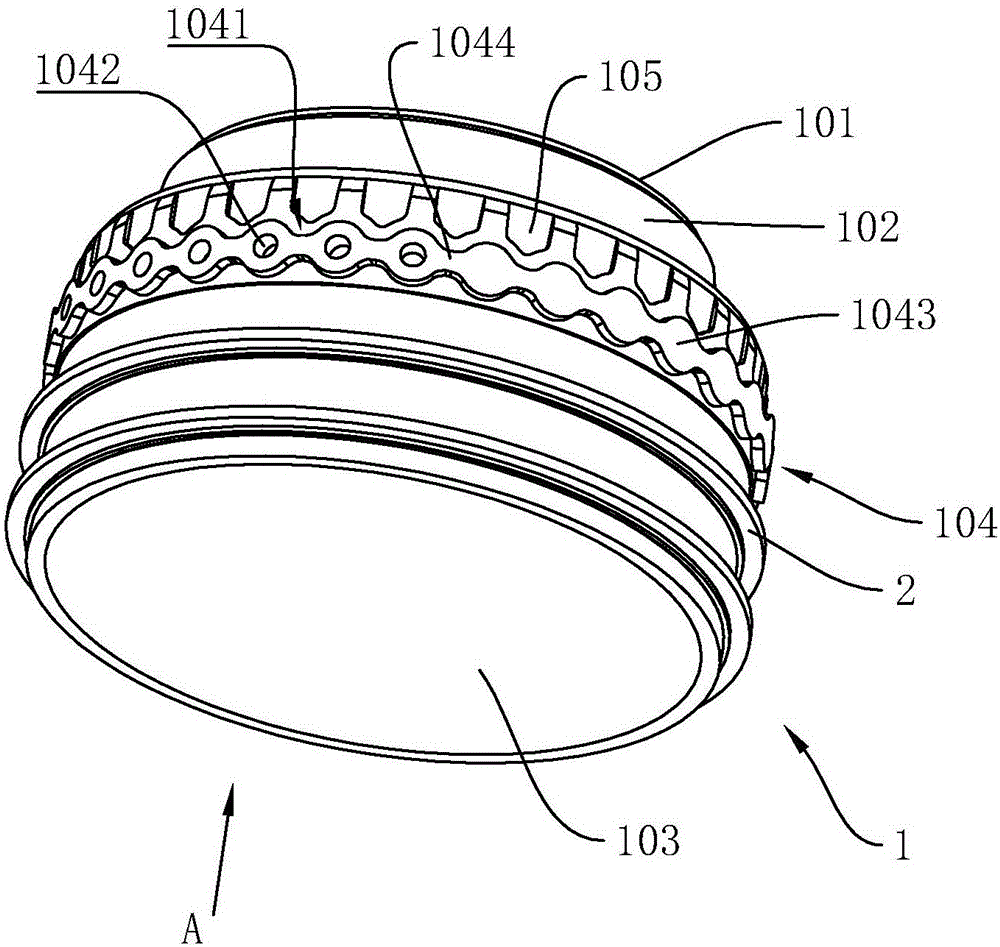

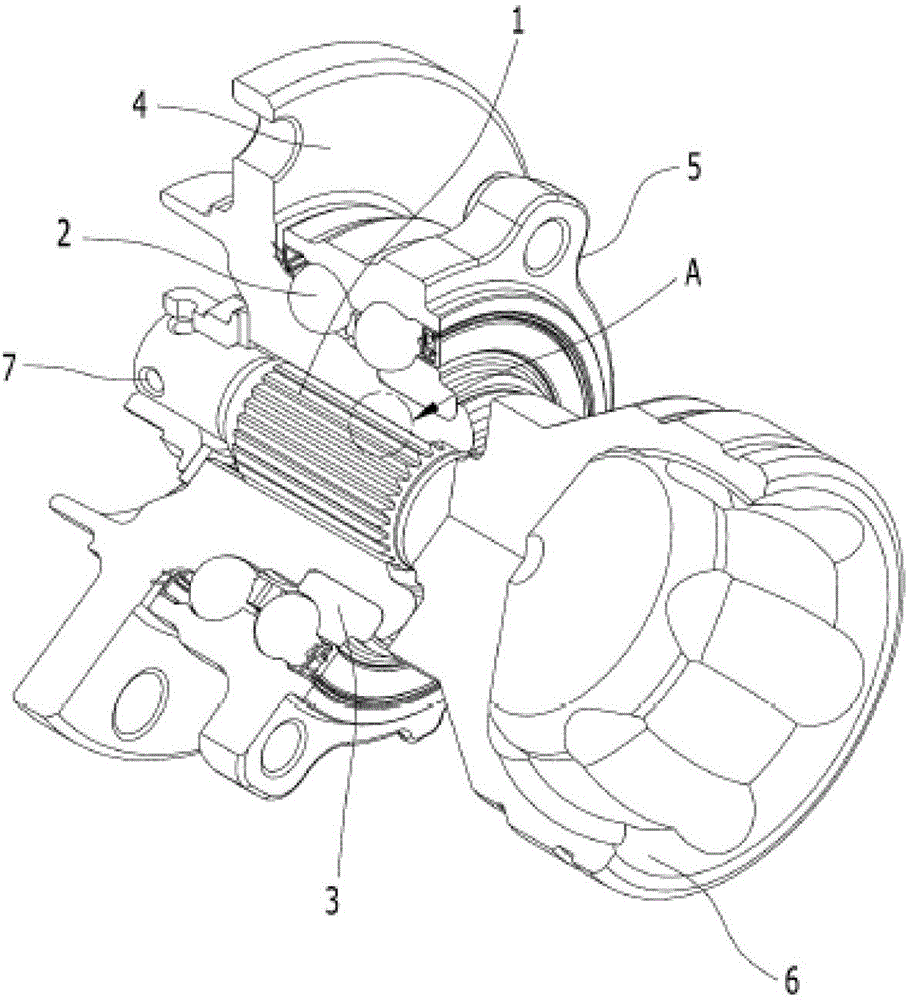

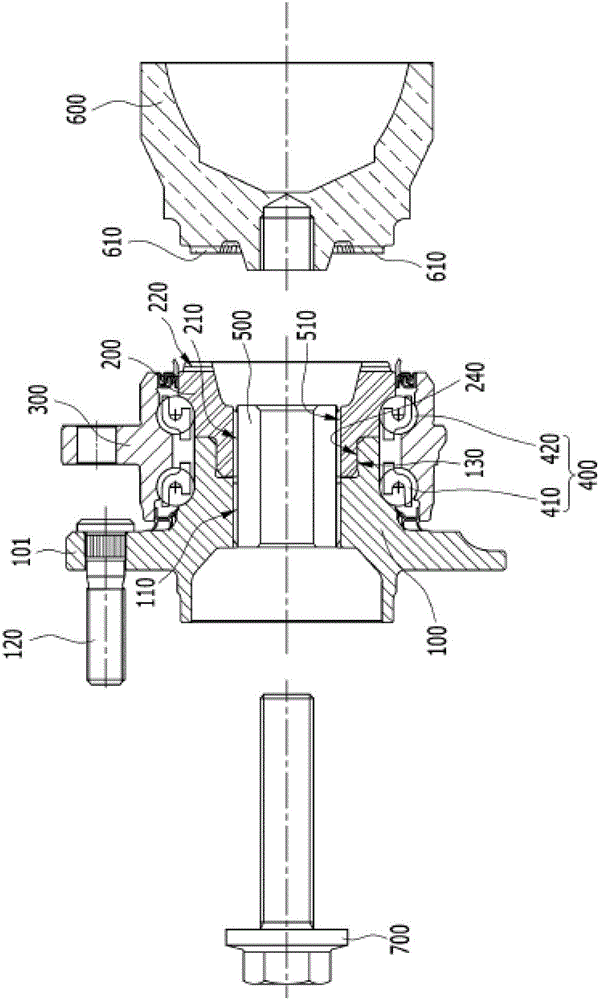

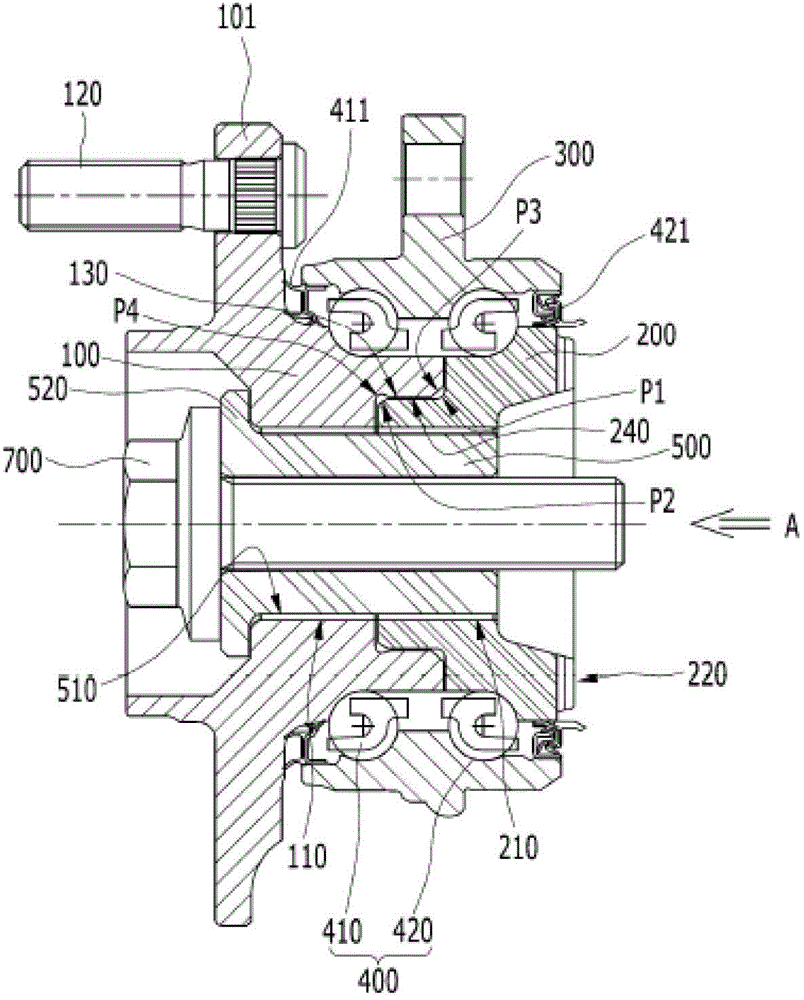

Wheel bearing combination structure and combination method

The invention provides a wheel hub combination structure and a wheel hub combination method, which can solve the problems of the wheel hub and constant-speed connector combination structure that the drive force is unstable to transmit, the noise exist, the endurance is poor and the service life is shortened. The wheel bearing combination structure comprises a wheel hub for installing a wheel, a middle hole inner wheel which is pressed into one side of the wheel hub, a ring-shaped outer wheel which is installed on the wheel hub and on the outer side of the inner wheel and a vibration body which is arranged between the wheel hub or the inner wheel and the outer wheel. The wheel bearing combination structure and the combination method is characterized in that the wheel hub is combined with the inner wheel through a spline, the inner wheel is combined with a connector component through a facial spline. Due to the adoption of the wheel bearing combination structure and the wheel bearing combination method, the drive force of a constant-speed connector is stably transmitted to a wheel bearing, and a silencing effect can be realized.

Owner:天津日进汽车系统有限公司

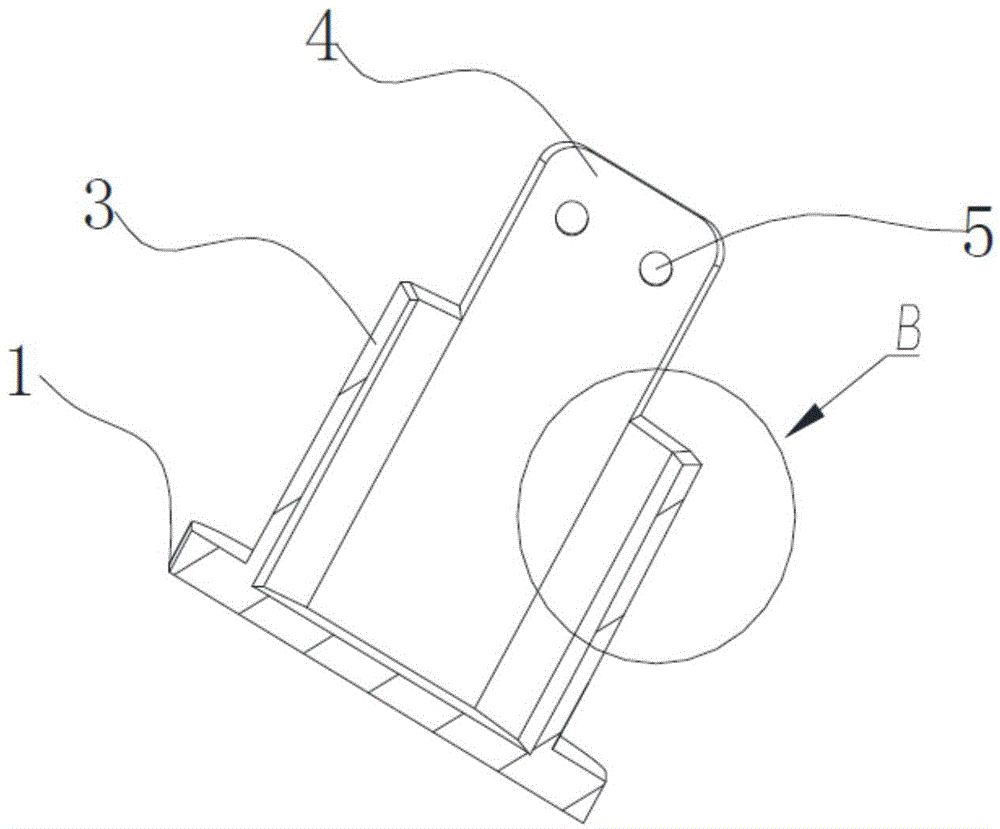

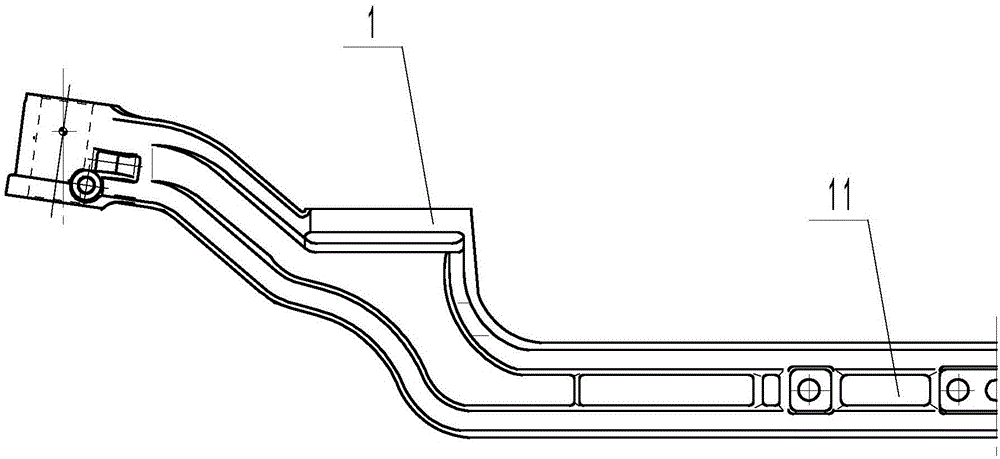

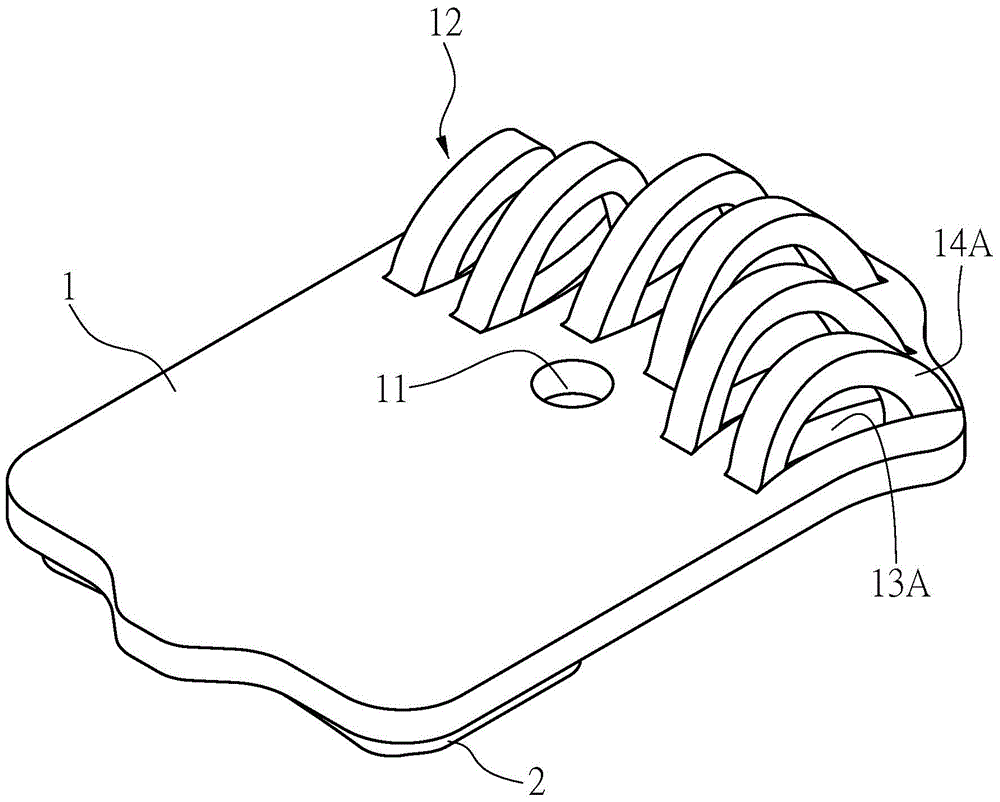

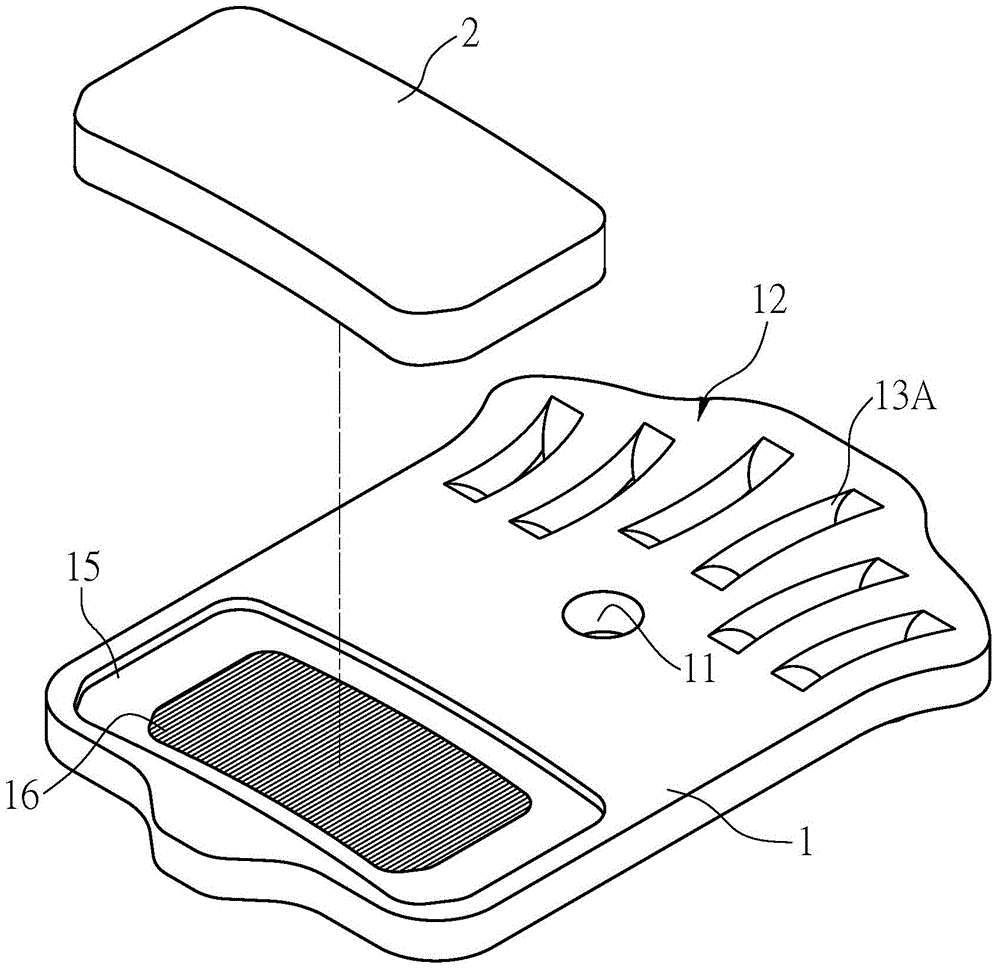

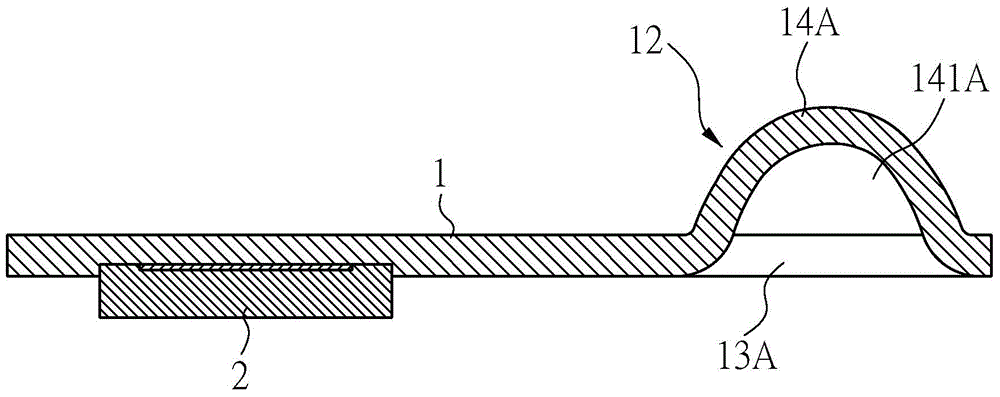

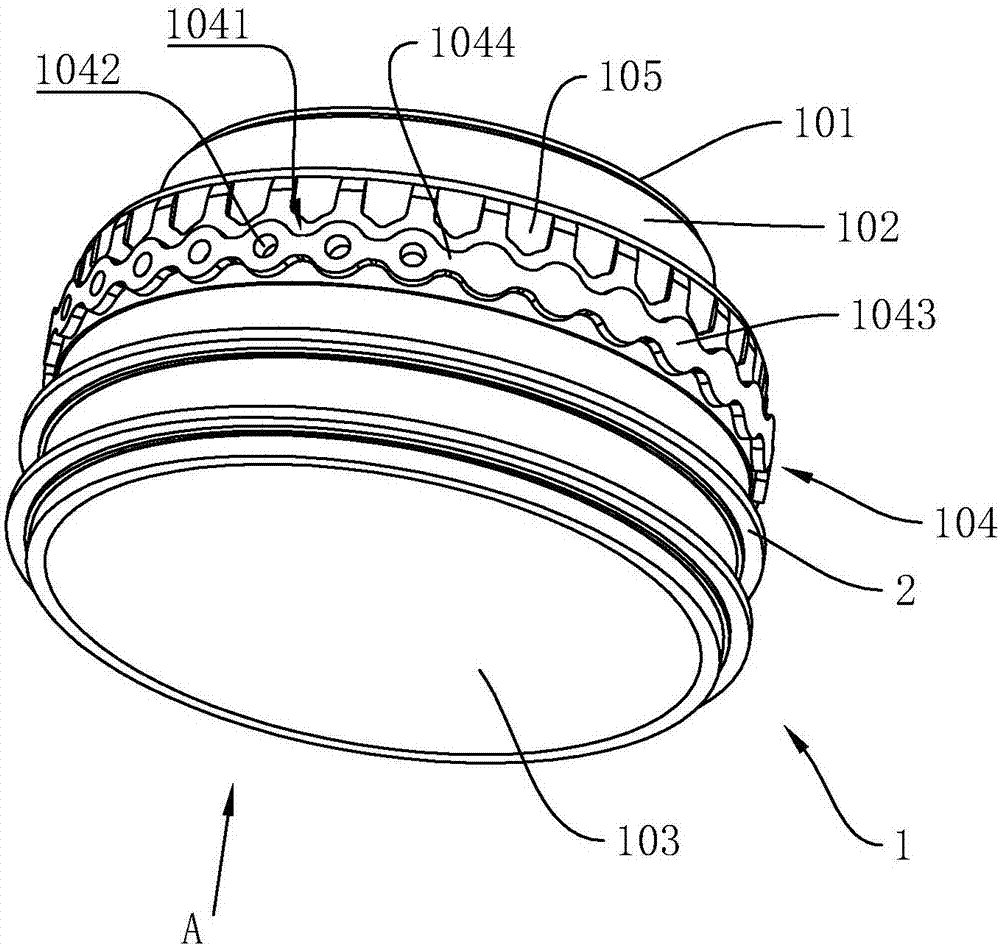

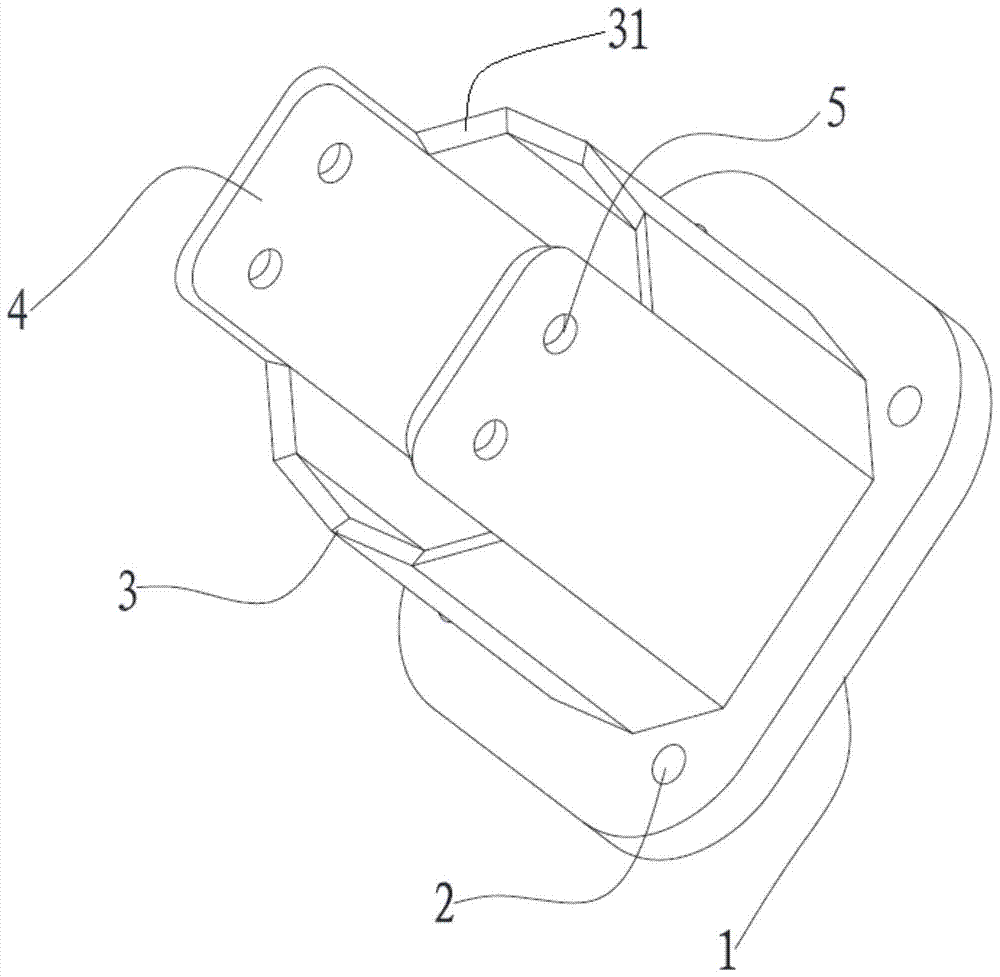

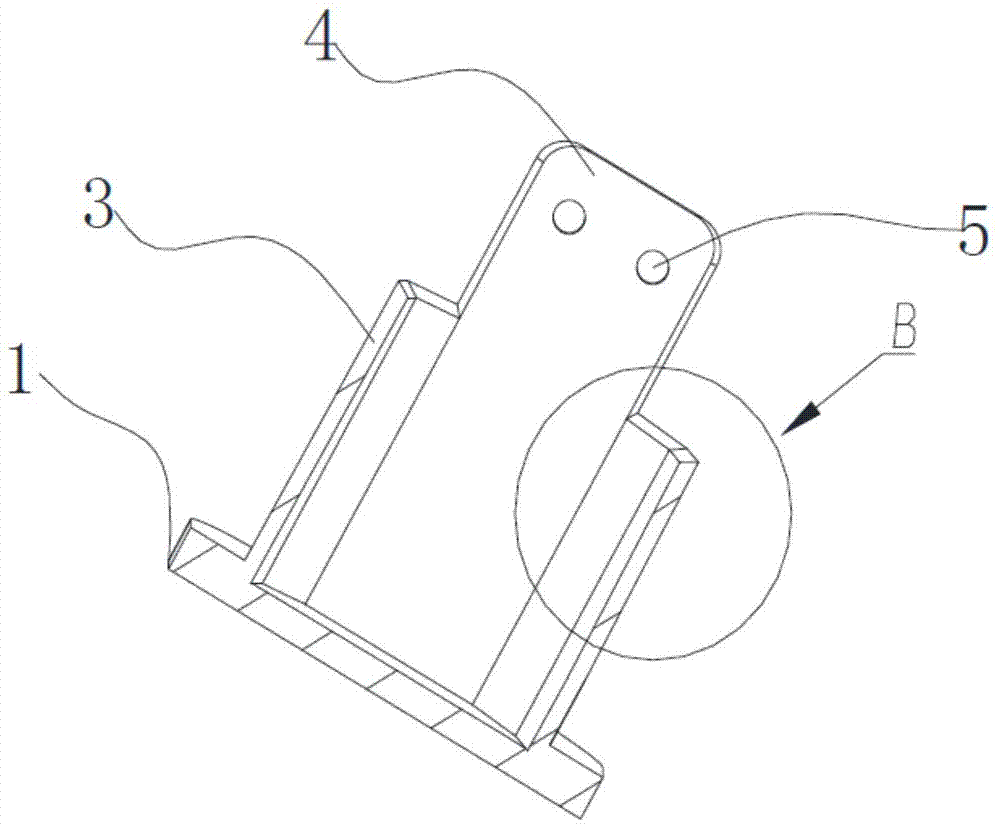

Brake pad heat-dissipating structure

InactiveCN104806670AImprove securityAchieve lightweight effectSlack adjustersFriction liningEngineeringBrake shoe

A brake pad heat-dissipating structure includes a main body (1) having a heat-dissipating portion (12) and a connecting portion for installing a brake shoe (2), and the heat-dissipating portion (12) includes plural penetrating holes (13A) penetrating through the main body (1) and arranged side by side with each other, and each penetrating hole (13A) is connected to a fin (14A) extending towards the outside of the main body (1) to provide a heat dissipating effect.

Owner:曾建融 +1

Vehicle steering handle structure

The invention relates to a vehicle steering handle structure, which is composed of a ducted body tube. A connecting part is concavely arranged at the middle part of the tube, raising parts are formed by extending upwards and slanchways from the both ends of the connecting part, a holding part is also formed by extending in the slightly horizontal direction from the end of the raising part, and a bonding zone between two coarse surfaces is also arranged on the connecting part. The vehicle steering handle structure is mainly characterized in that the tube diameter of the connecting part is larger than that of the raising part, the tube diameter of the raising part is larger than that of the holding part, and the connecting part comprises at least one inner tube wall which is linearly and gradually diffused and the inner tube wall of the holding part is also linearly and gradually diffused, therefore, the steering handle can reach high rigidity strength requirement, and simultaneously can also reach the effect of light weight.

Owner:KYMCO

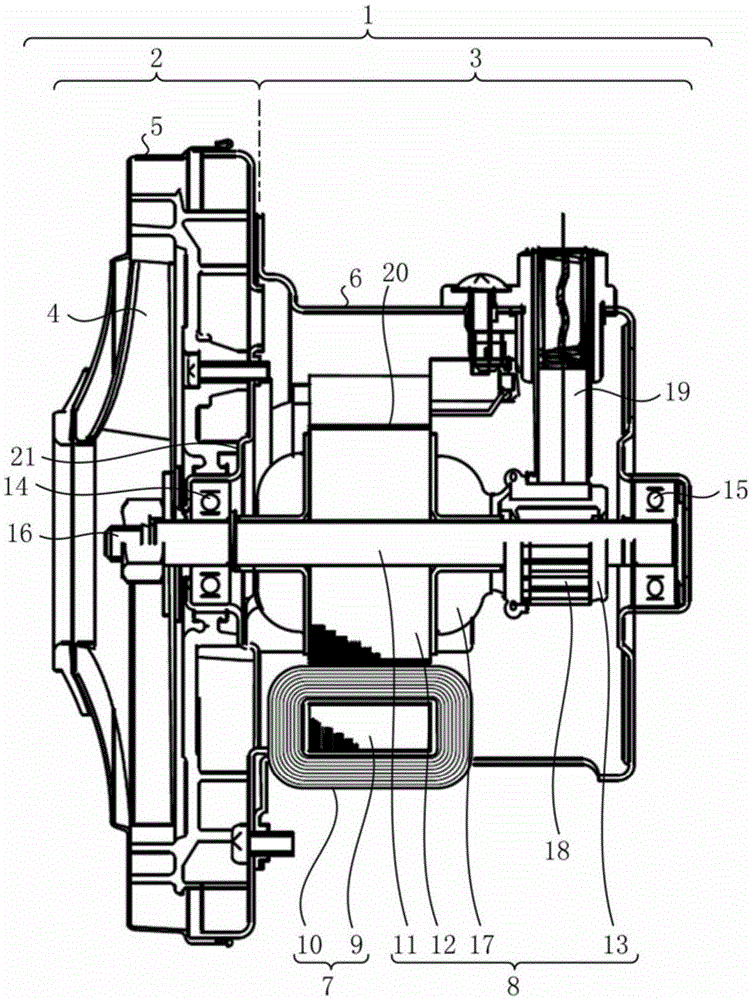

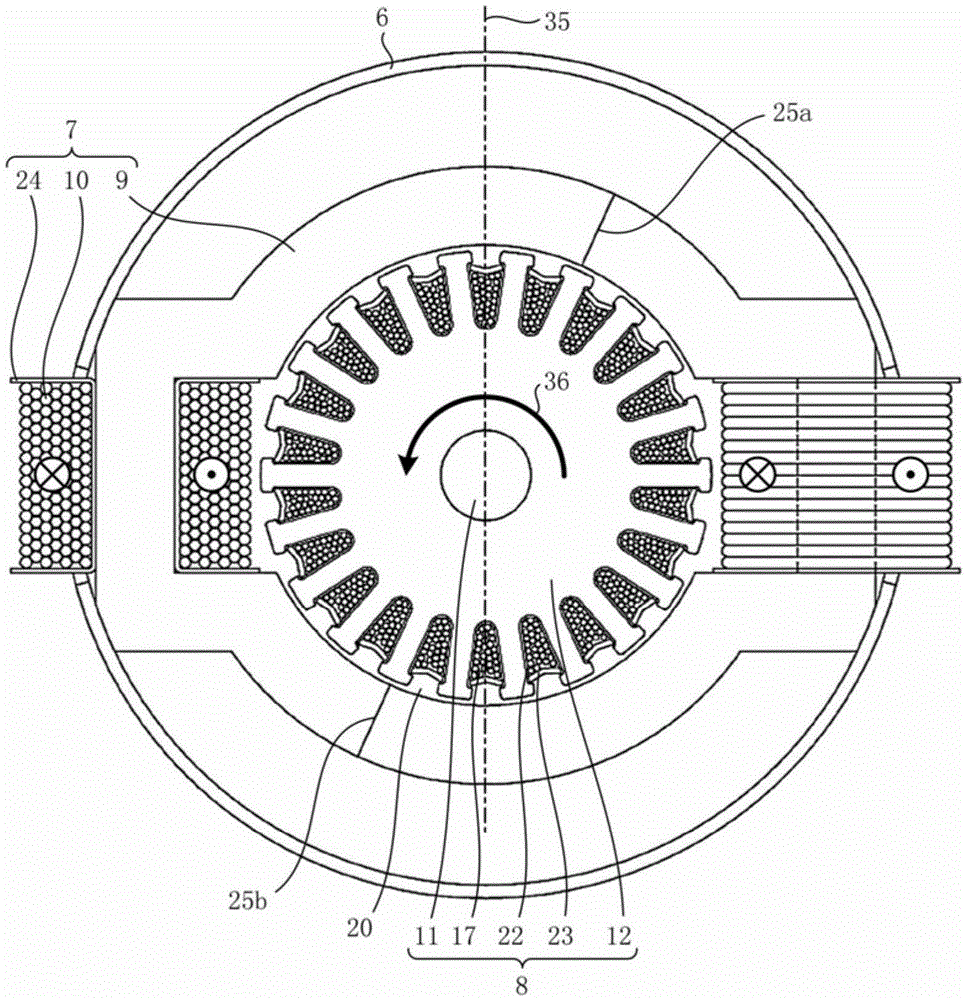

Electric fan and electric vacuum cleaner

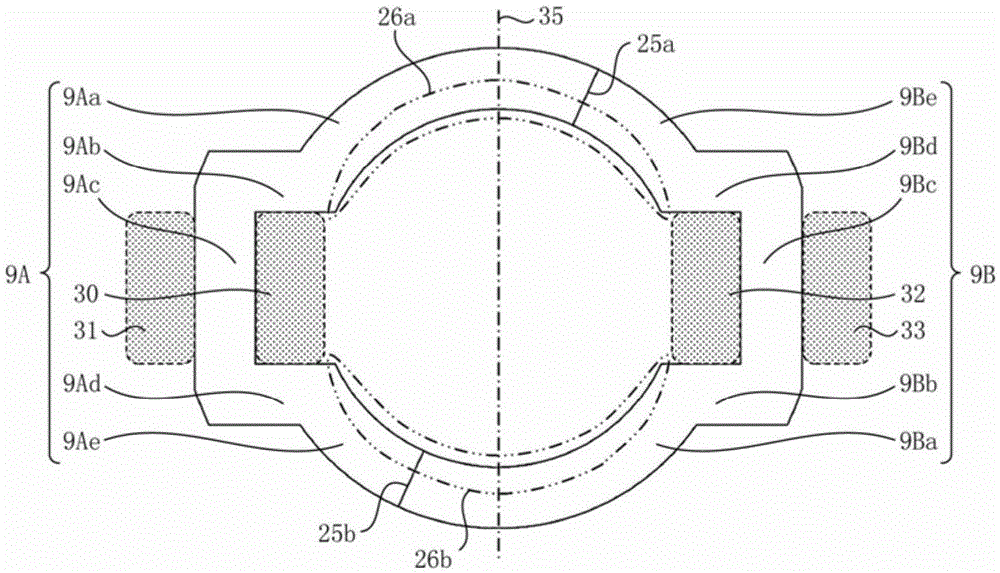

InactiveCN105324579AOrderly rowsImprove efficiencyPositive displacement pump componentsMagnetic circuit stationary partsMagnetic polesConductor Coil

Provided is an electric fan, comprising a stator provided with a stator core and a field winding and a rotor disposed on the inner side of the stator, wherein: the stator core is divided into two C-shaped sections (9A, 9B) at two core division positions (25a, 25b) offset from a magnetic pole axis in the reverse of the direction of rotation; the C-shaped sections (9A, 9B) are shaped so that a core portion in a position in a direction perpendicular to the magnetic pole axis (35) is shaped so as to bulge outward in a straight U shape at three straight sections; a region for winding the field winding is created using spaces formed between the outwardly bulging U shape and the outer periphery of the rotor, and spaces formed in positions that are symmetrical to the former spaces and sandwich arm sections (9Ac, 9Bc) of the straight sections in the center; and the radial widths of the portions that face the rotor become smaller as they draw closer to the core division positions (25a, 25b).

Owner:MITSUBISHI ELECTRIC CORP +1

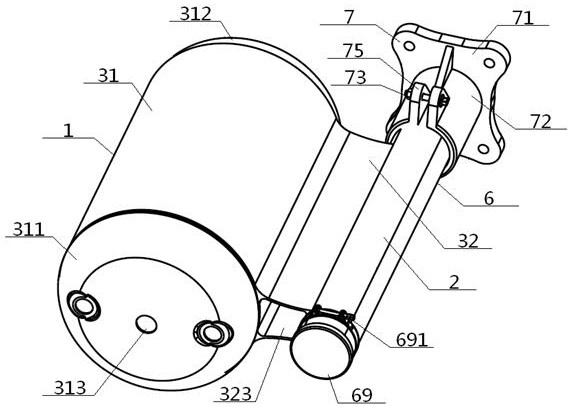

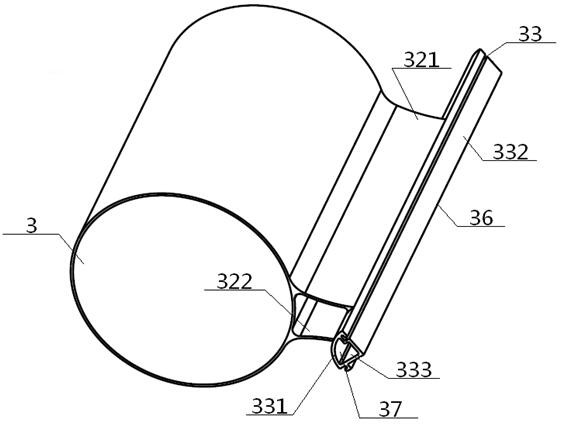

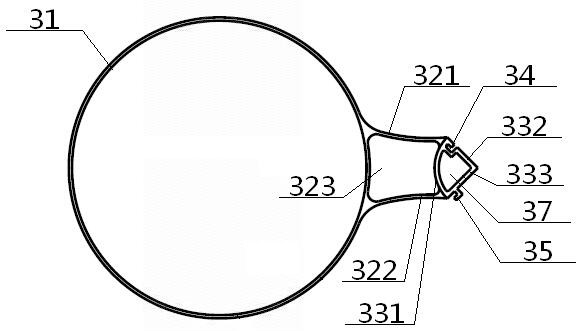

An interlocking aluminum alloy air storage cylinder assembly and manufacturing method thereof

ActiveCN110435616BEasy to operateReduce installation difficultyFluid braking transmissionStructural engineeringMechanical engineering

An interlocking type aluminum alloy air storage cylinder assembly comprises a cylinder unit and a fixing device. A rod A locking convex strip and a rod B locking groove are arranged in a supporting rod in the fixing device, the cylinder unit at least comprises an air storage cylinder, the first air storage cylinder comprises a first cylinder body, a first connecting part and a first interlocking part, the first interlocking part comprises a first inner connecting plate, a first upper inclined plate and a first lower inclined plate, the first upper inclined plate is provided with a first locking groove, the first lower inclined plate is connected with a first locking convex strip, one end of the first connecting part is connected with the side wall of the first cylinder body, the other endof the first connecting part is connected with the inner side surfaces of the upper end and the lower end of the first inner connecting plate, the outer side surface of the upper end of the first inner connecting plate is connected with the higher end of the first upper inclined plate, and the outer side surface of the lower end of the first inner connecting plate is connected with the lower end of the first lower inclined plate. Any single locking groove is in interlocking connection fit with any single locking convex strip. By means of the design, the installation effect is good, and the light weight effect is good.

Owner:DONGFENG COMML VEHICLE CO LTD

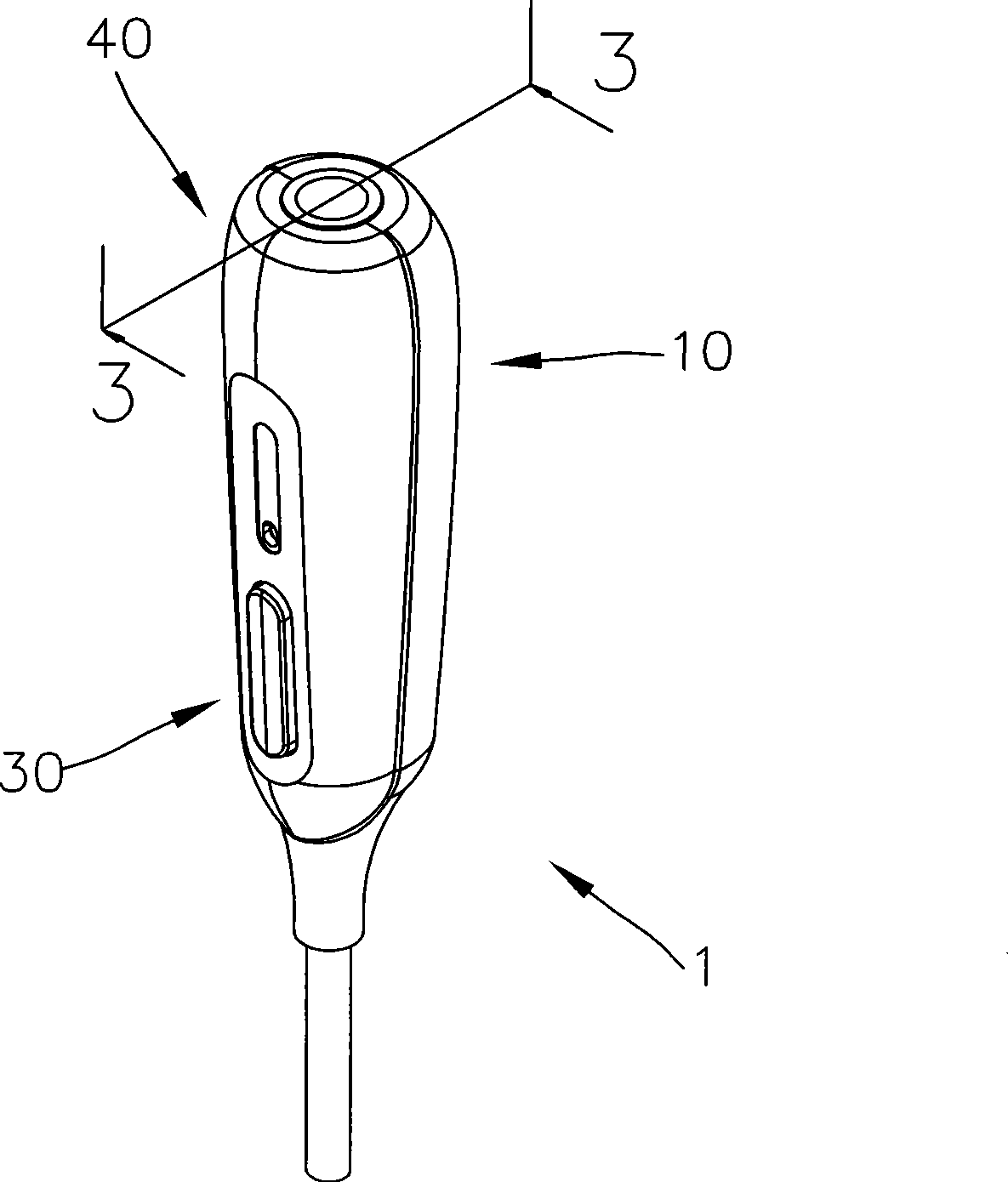

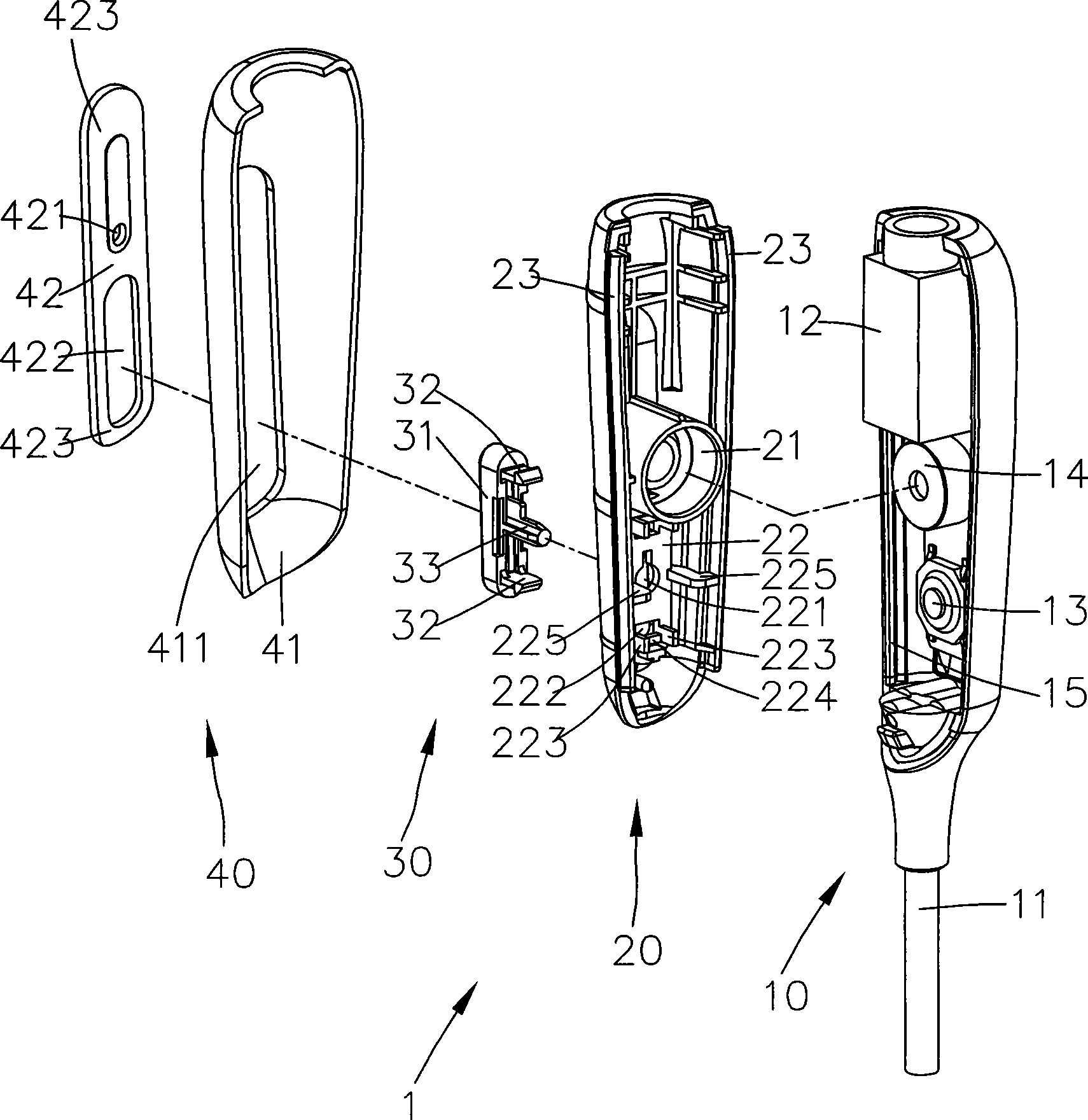

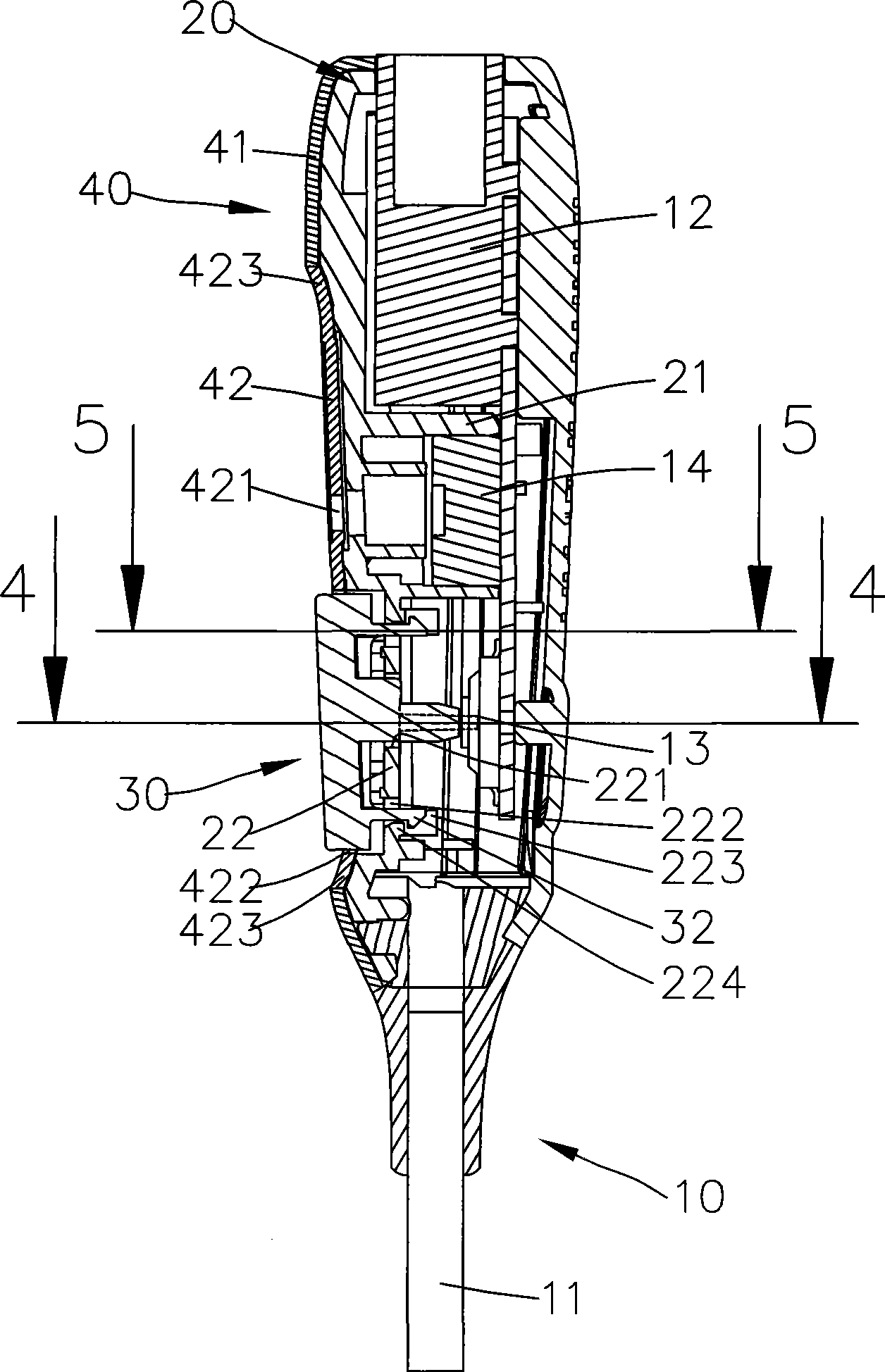

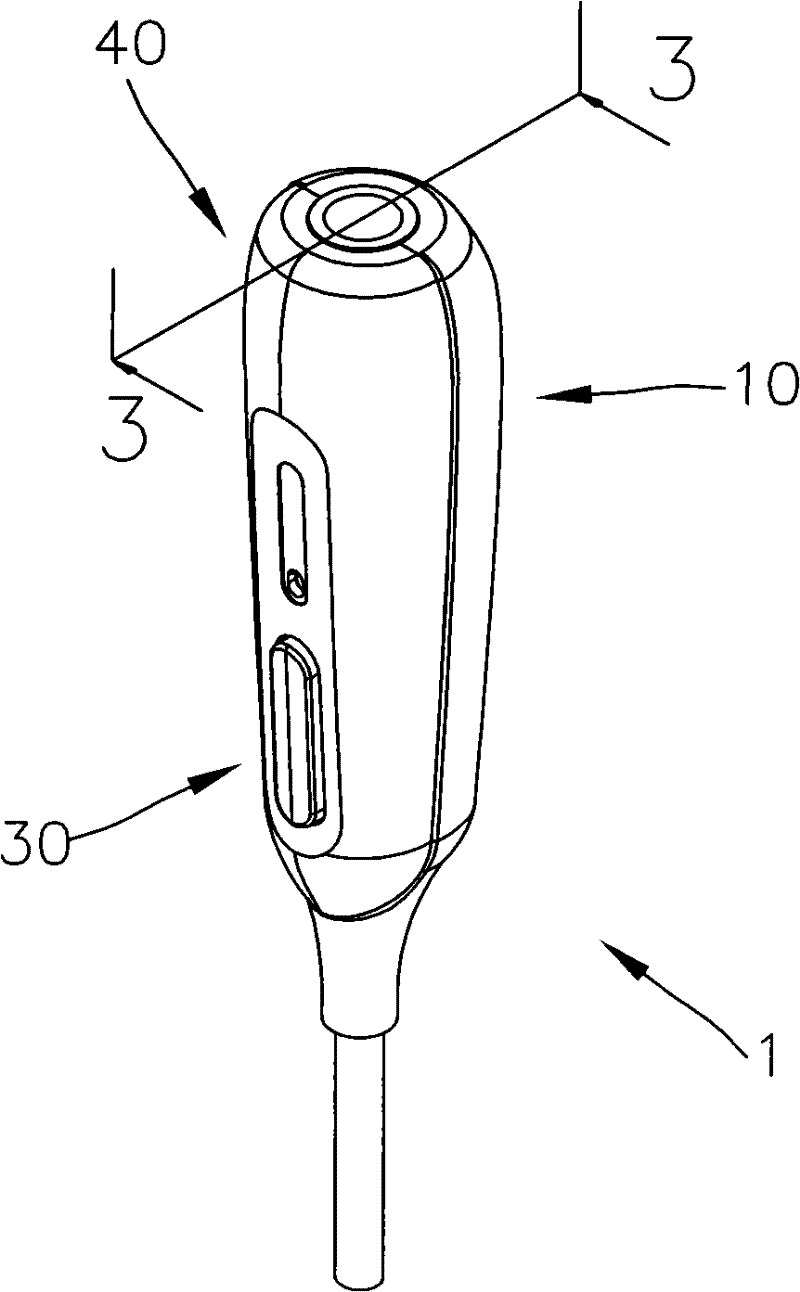

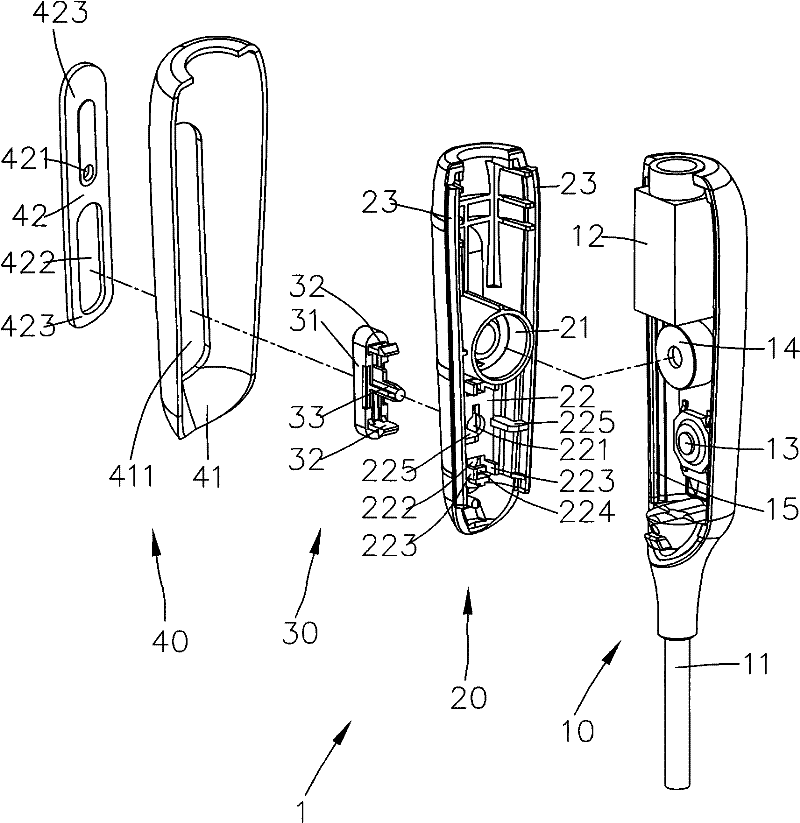

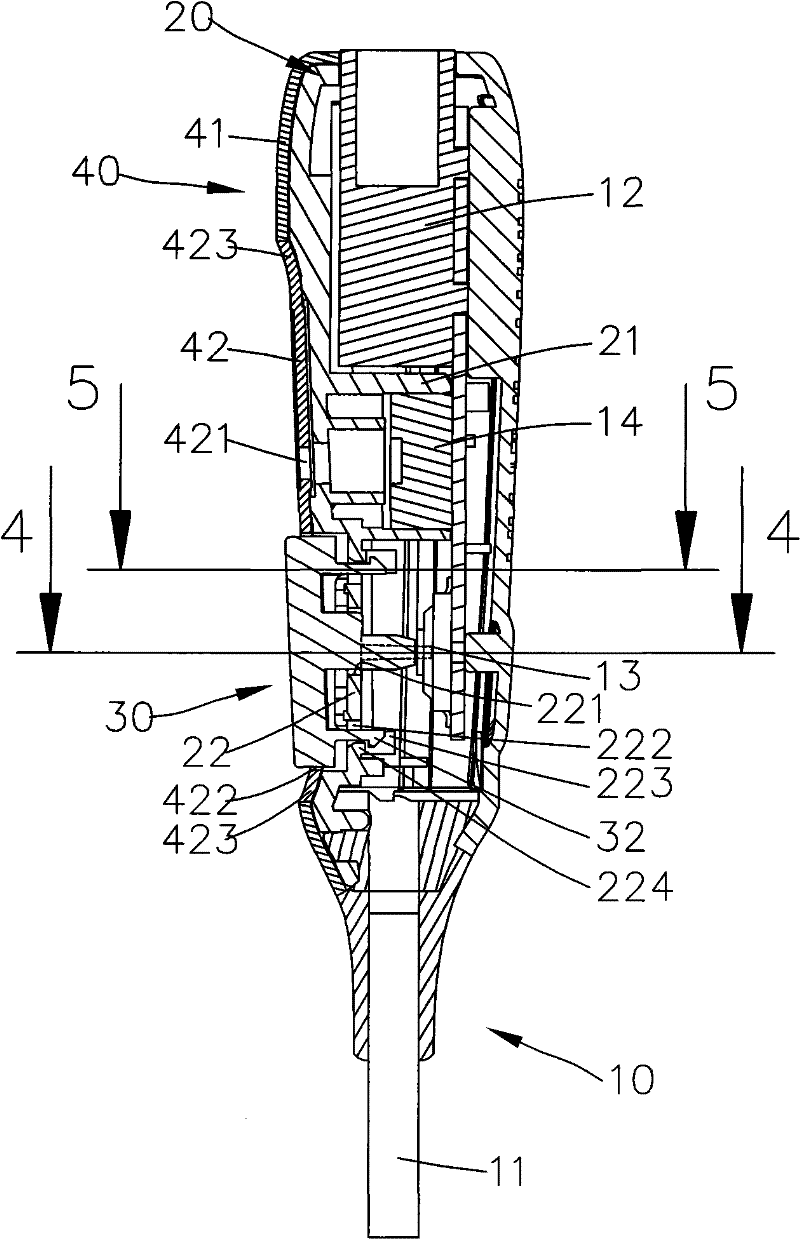

Fixed device for microphone

InactiveCN101374361ADoes not affect the structureThin and short in appearanceMicrophone structural associationMouthpiece/microphone attachmentsBiomedical engineeringMicrophone

The invention is a microphone fixing device, which includes a body, a fixing base and a press button, wherein a PCB and a radio device are equipped in the body. The fixing device is equipped in the body, at the same time a touch hole is formed on the corresponding PCB, and each fixing rib is projected from each of the double-side of the fixing base wall surface, for pressing the PCB and limiting shakes between the body and the fixing base; and the press button passes through the touch hole and selectively presses the PCB, thereby controlling the open / close of the radio device.

Owner:MERRY ELECTRONICS CO LTD

a brake drum

ActiveCN105736609BImprove structural strengthImprove mechanical propertiesBraking drumsSlack adjustersEngineeringUltimate tensile strength

Owner:SHANDONG HAOXIN MACHINERY

car crash box

ActiveCN104590177BAchieve lightweight effectImprove impact resistanceBumpersEnergy absorptionEngineering

The invention discloses an automobile energy absorption box. The automobile energy absorption box comprises an energy absorption box body made of carbon fiber composite, and chamfer angles are formed in the margin of the energy absorption box body ends. The automobile energy absorption box has the advantages that lightweight effect is achieved with the adoption of carbon fiber composite, the weight of the energy absorption box with carbon fiber composite is 52% to 69% less than the common metal energy absorption box, and the comprehensive impact resistance ability and energy absorption effect are high.

Owner:WUHU LION AUTOMOTIVE TECH CO LTD

microphone mount

InactiveCN101374361BDoes not affect the structureThin and short in appearanceMicrophone structural associationMouthpiece/microphone attachmentsEngineeringMicrophone

The invention is a microphone fixing device, which includes a body, a fixing seat and a button, wherein a PCB and a sound receiving device are arranged in the body. The fixing seat is clamped on the body, and a touch hole is formed at the corresponding PCB, and a fixing rib is protruded on both sides of the wall of the fixing seat, which presses against the PCB to limit the PCB from shaking between the body and the fixing seat. At the same time, the above-mentioned buttons are installed in the touch holes to selectively press the PCB, so as to control the opening / closing of the radio device.

Owner:MERRY ELECTRONICS CO LTD

An electric vehicle composite material hair cover inner panel

ActiveCN107554620BReduce vehicle qualitySimplify component compositionSuperstructure subunitsAdhesiveElectric vehicle

Owner:GUANGXI AISHENG CHUANGZHI SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com