Automobile energy absorption box

A technology of energy-absorbing boxes and automobiles, which is applied to bumpers and other directions, can solve the problems of low specific energy absorption and high weight, and achieve the effect of improving the effect of collision energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following describes the specific implementation of the present invention in further detail through the description of the embodiments with reference to the accompanying drawings. The purpose is to help those skilled in the art have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and Contribute to its implementation.

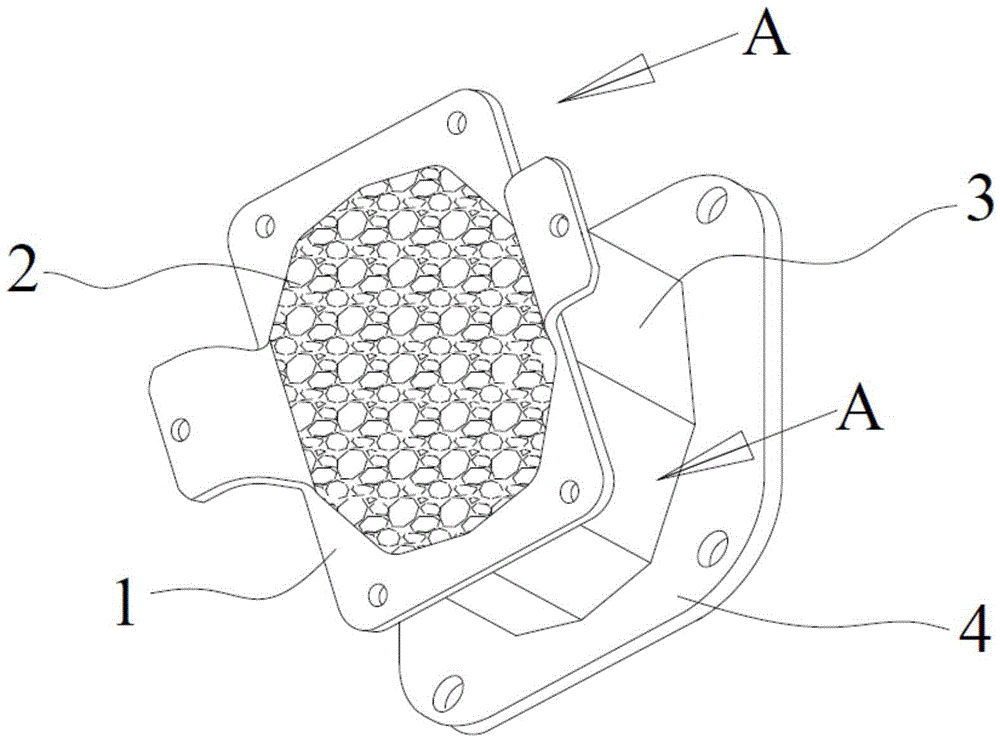

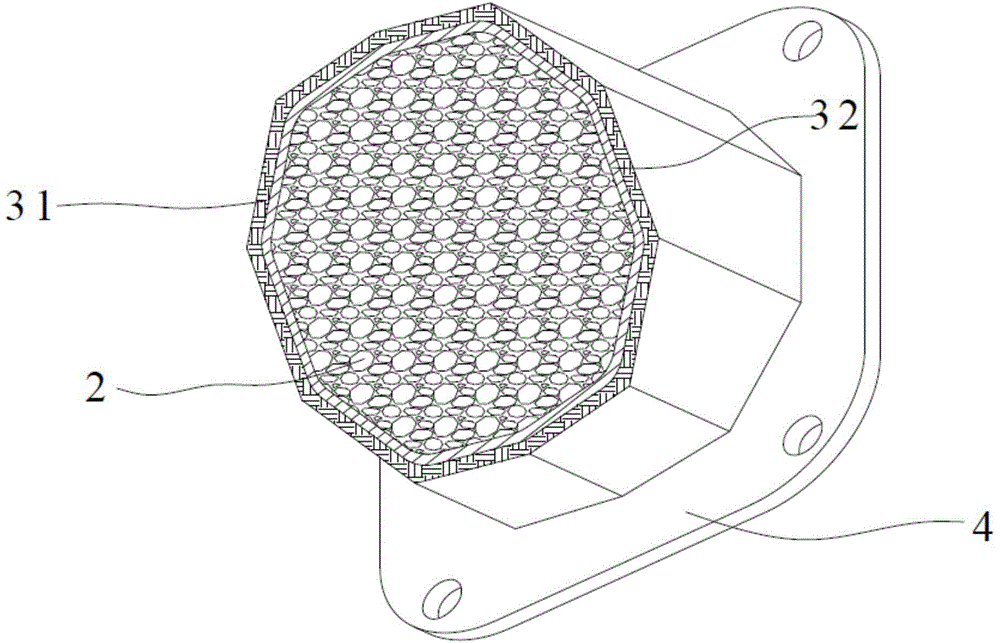

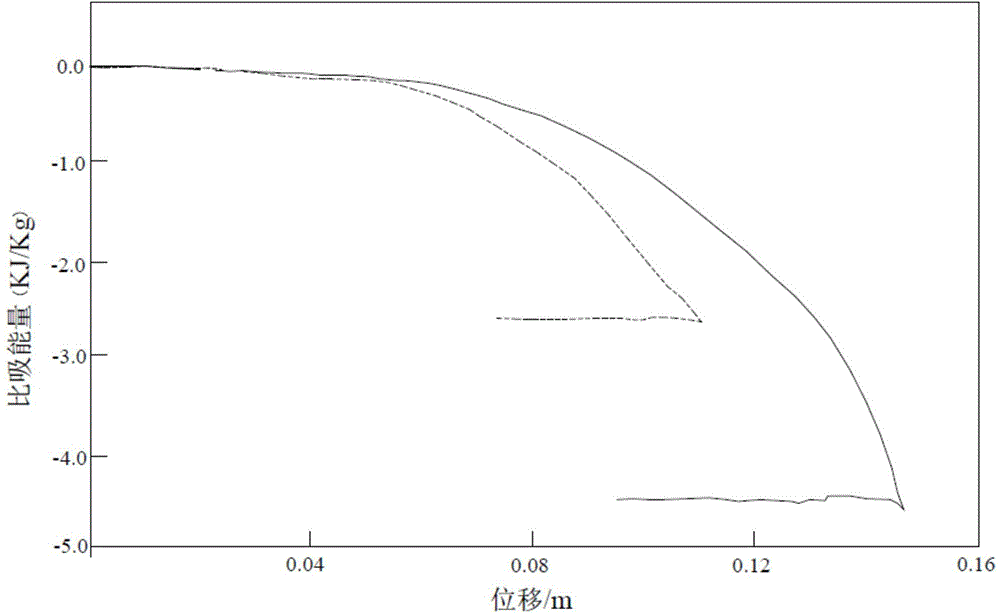

[0019] Such as figure 1 with figure 2 As shown, the present invention provides an automobile energy absorbing box, which includes an energy absorbing box body 3, a front beam connecting flange 1 and a front longitudinal beam connecting flange 4. The energy absorbing box body 3 of the energy absorbing box of the automobile is made of carbon fiber composite material, and the energy absorbing box body 3 is filled with foamed aluminum alloy ingots 2. The foamed aluminum alloy ingot 2 has good impact resistance and energy absorption characteristics, and can absorb a large amount of energy w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com