Patents

Literature

39results about How to "To achieve the effect of lightweight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

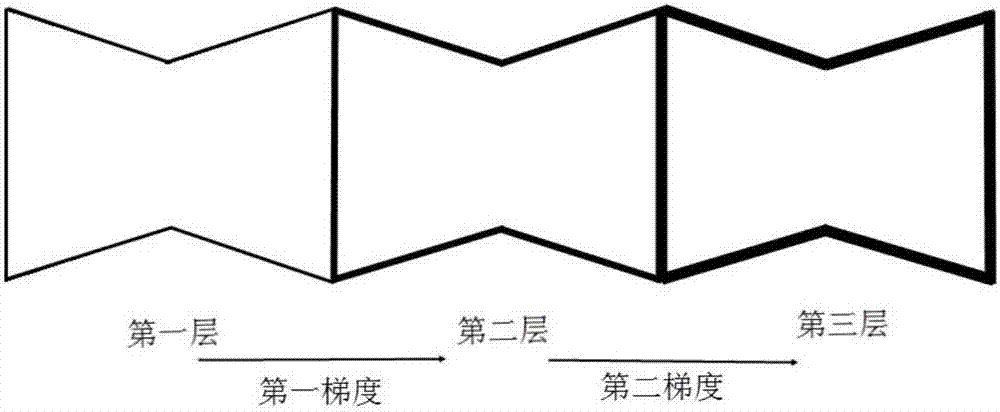

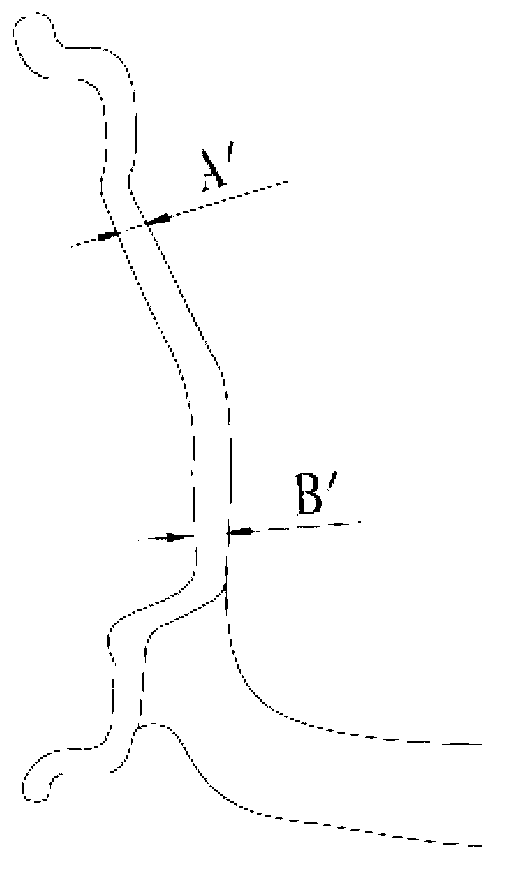

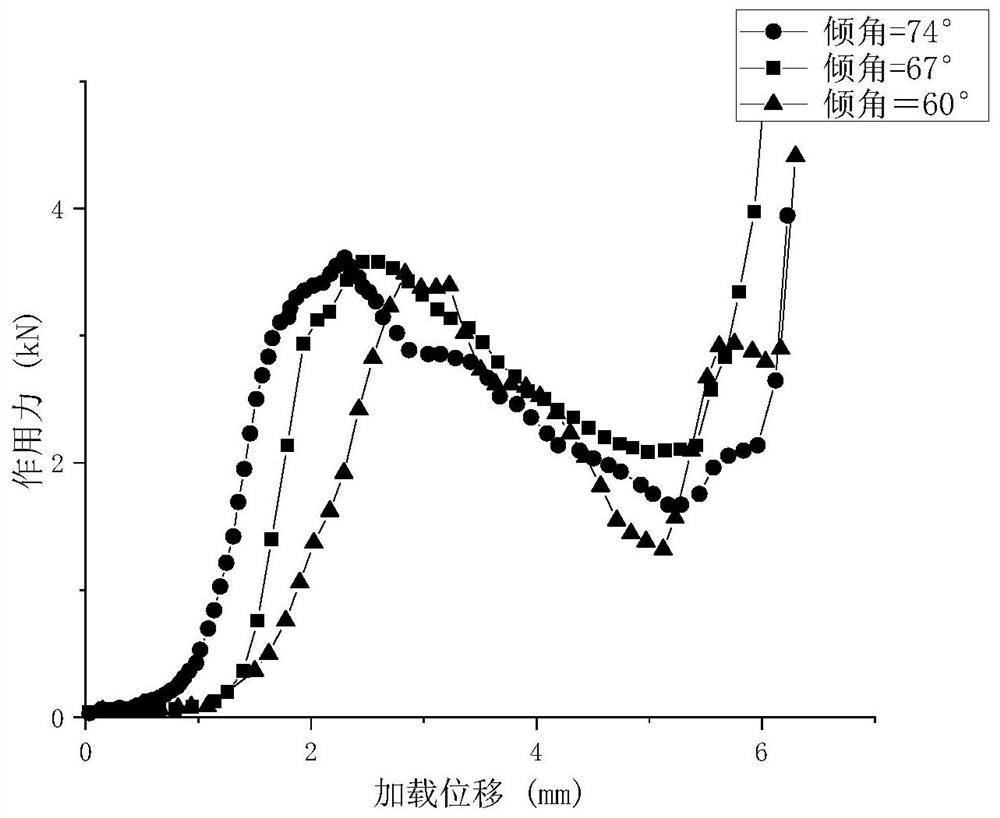

Variable-thickness-gradient negative poisson ratio automobile buffering and energy-absorbing structure and optimization method thereof

ActiveCN107235024ATaking care of protectionSolve conflictsDesign optimisation/simulationBumpersEnergy absorbingDesign objective

The invention discloses a variable-thickness-gradient negative poisson ratio automobile buffering and energy-absorbing structure and an optimization method thereof. The automobile buffering and energy-absorbing structure is formed by a variable-thickness-gradient negative poisson ratio structure, and the negative poisson ratio structure is formed by three-dimensional inwardly-sunken hexagon unit-cells in an array mode; in the longitudinal direction of an automobile, and three layers of unit-cells are distributed, the thickness gradients among the layers are different; and the variable-thickness-gradient negative poisson ratio automobile buffering and energy-absorbing structure is located between a bumper outer skin and a bumper cross beam, and mounted on the automobile bumper cross beam through mounting clamping holes, and mainly when the automobile is collided, the variable-thickness-gradient negative poisson ratio automobile buffering and energy-absorbing structure plays the role of energy absorbing and buffering. The invention further discloses a design method of the automobile buffering and energy-absorbing structure of the variable-thickness-gradient negative poisson ratio structure, the variable-thickness-gradient distribution character of the negative poisson ratio structure can be designed according to design objectives and requirements through a multi-subject and multi-objective cooperative optimization method, and the positive effects on protection to legs of goers outside the automobile and the crashworthiness of an automobile body are achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

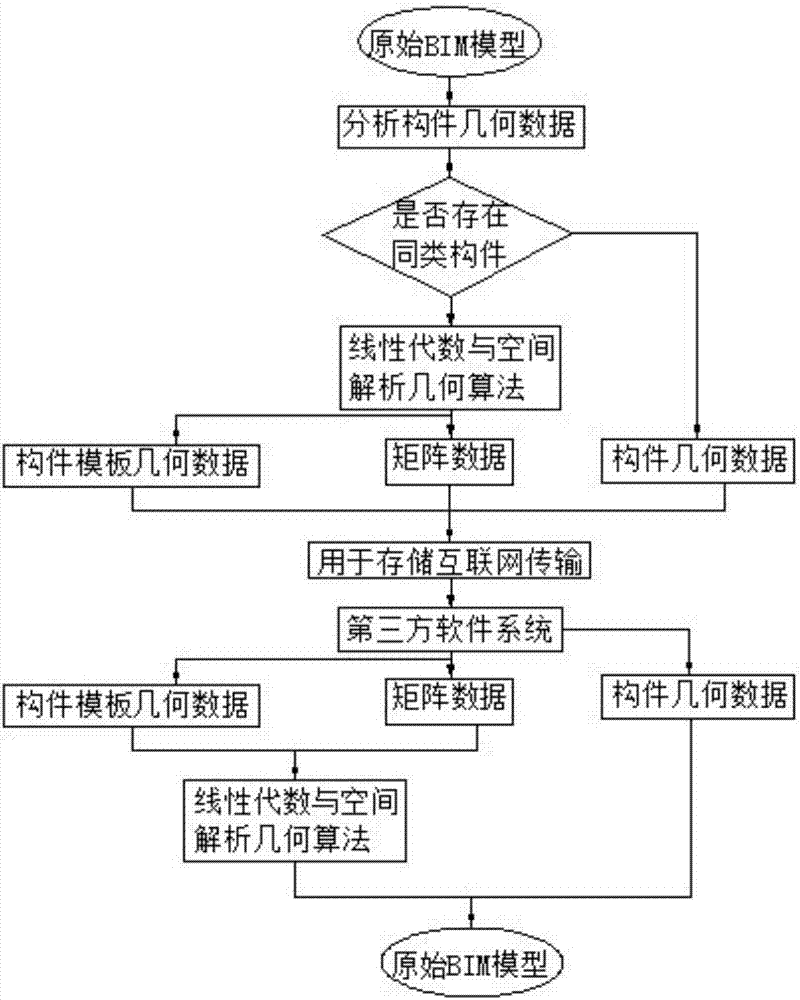

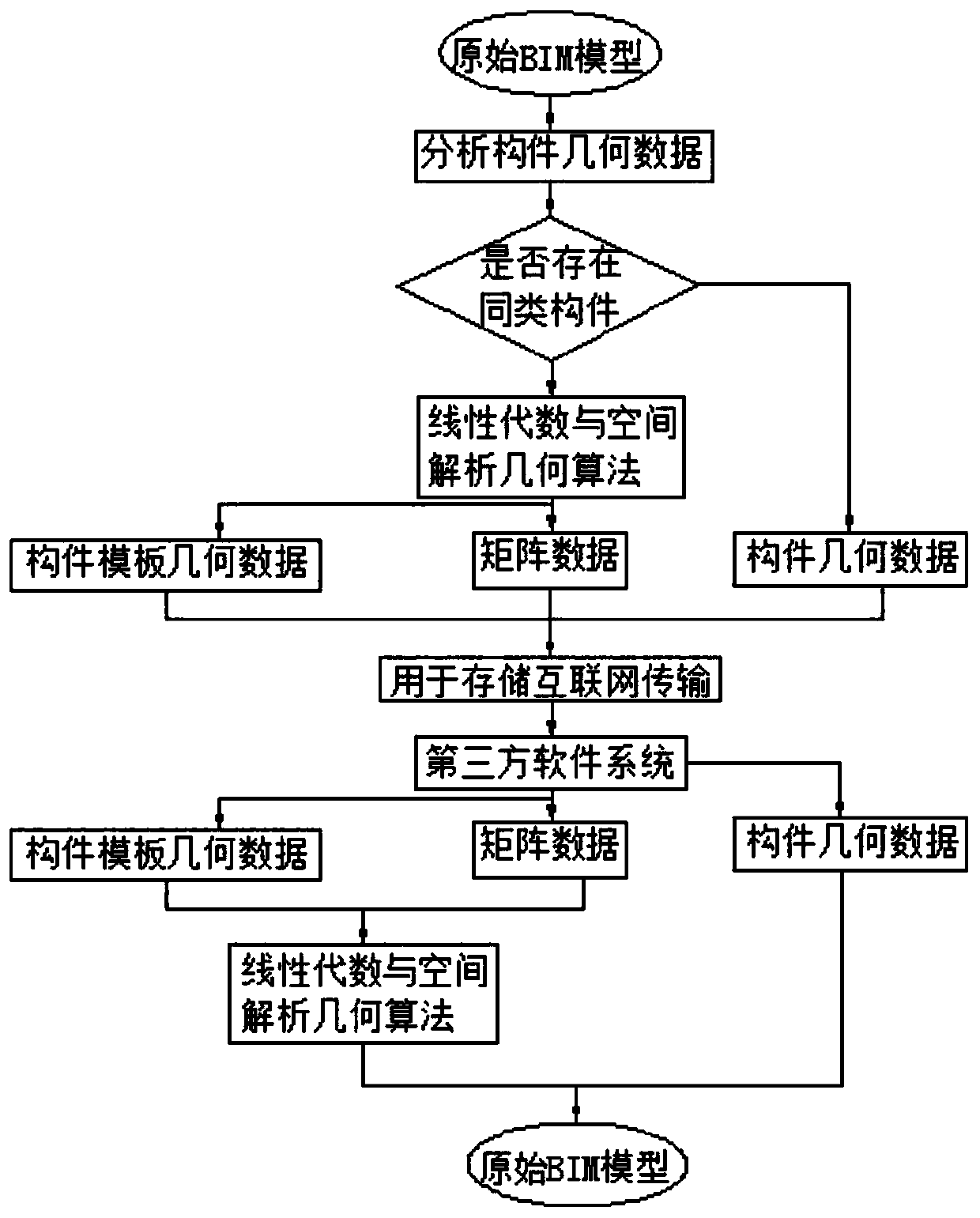

Method for lightening of BIM

ActiveCN107247822AReduce the amount of large dataTo achieve the effect of lightweightGeometric CADDesign optimisation/simulationTheoretical computer scienceGlobal coordinate system

The invention discloses a method for lightening of a BIM. The method comprises the steps that information data is extracted; in BIM engineering modeling under an existing system, model information data is extracted from an original BIM through use of legal and compliant technical manners; with regard to all the extracted component lists as well as race information data used by each component list, math methods of linear algebra and space analytic geometry will be used to analyze components of the same type in the BIM; and component template data formed by a reusable technologies and global coordinate system matrix data in the BIM are obtained through analysis. According to the invention, the ultra-large data size of the BIM is reduced; bottlenecks of the BIM in storage and transfer are solved; and the BIM is lightened.

Owner:南京戎光软件科技有限公司

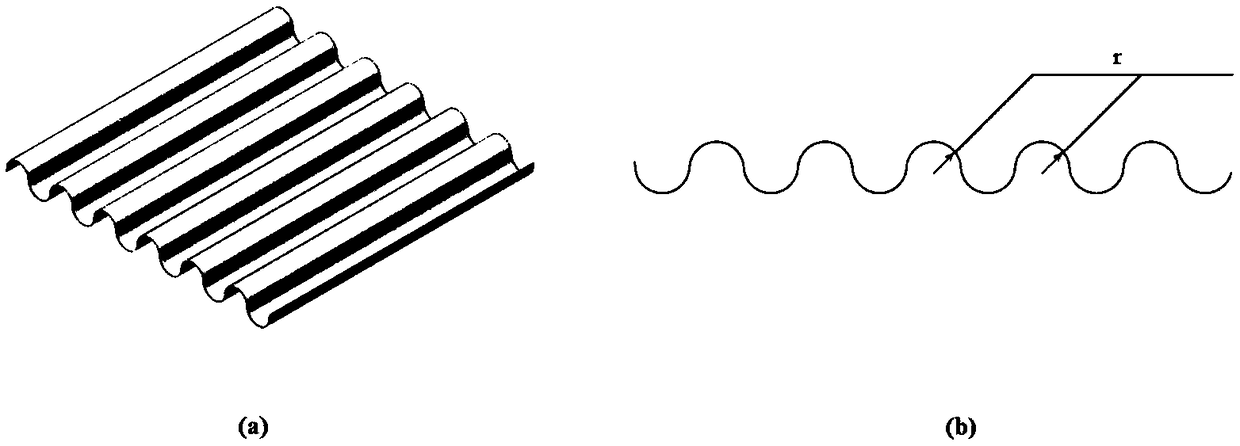

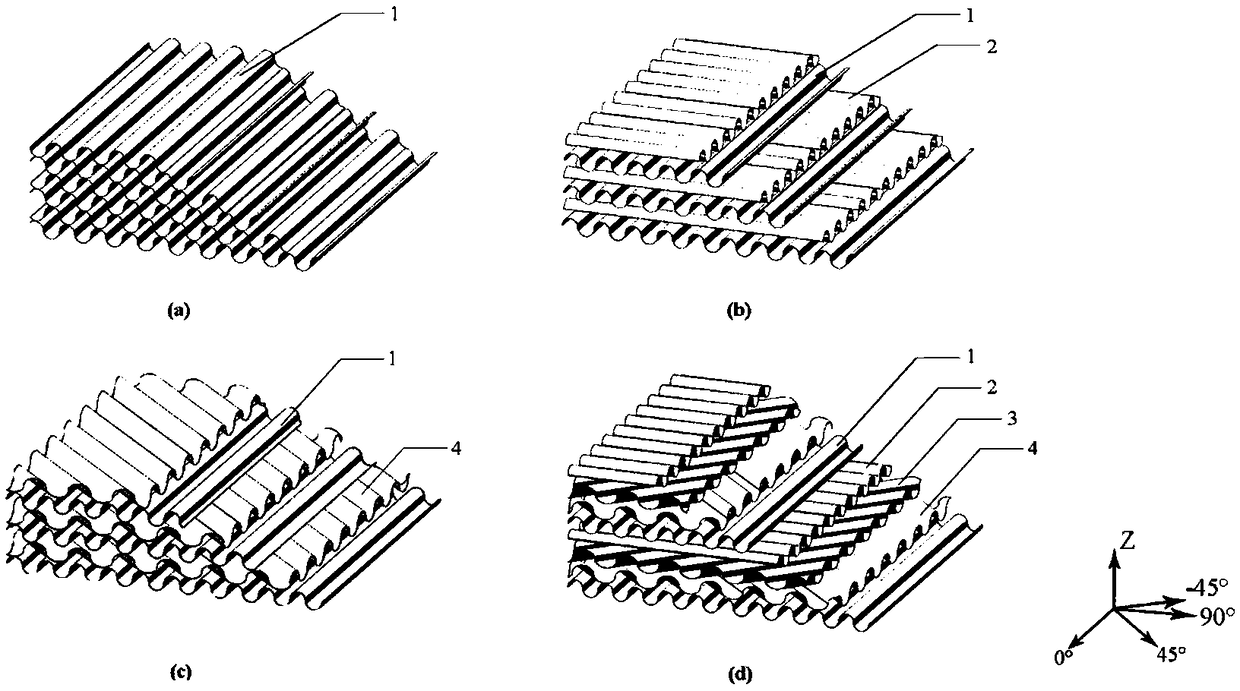

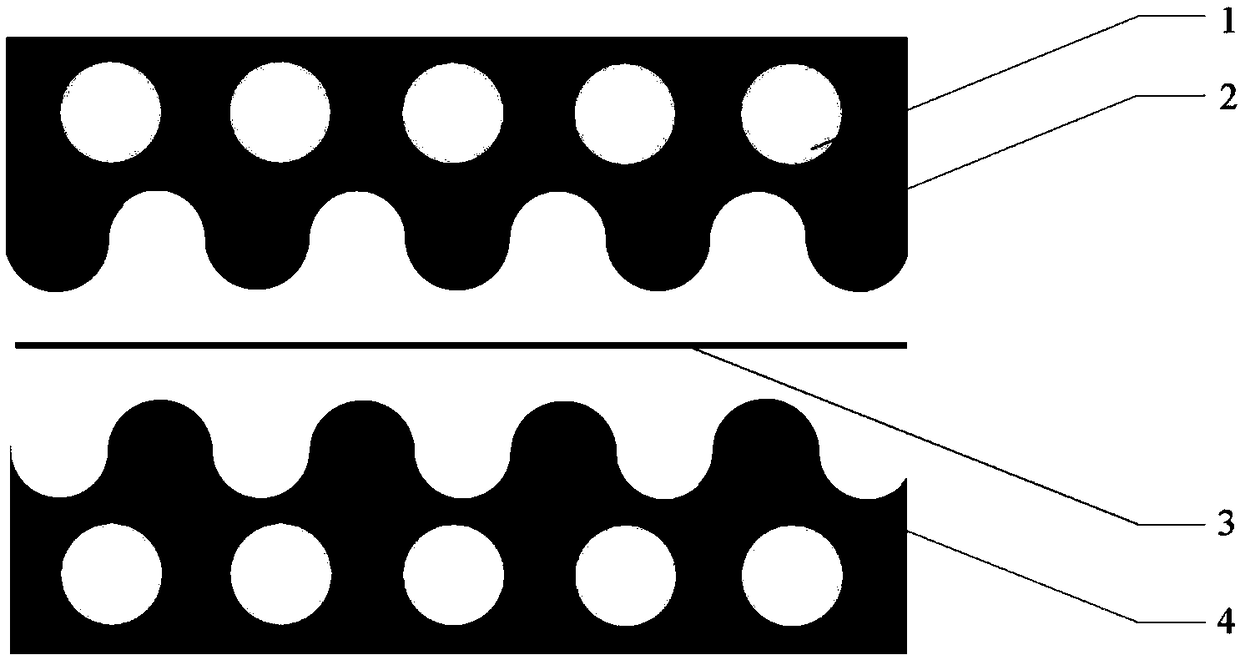

Wave type carbon felt electromagnetic shielding structural body and preparation method thereof

ActiveCN109263172ALow densityHigh shielding factorMagnetic/electric field screeningSynthetic resin layered productsFiberCarbon fibers

The invention discloses a wave type carbon felt electromagnetic shielding structural body and a preparation method thereof. The structural body is combined by adopting multi-layer wave type carbon felts according to certain angles. The multi-layer wave type carbon felts are adhesively connected by adopting adhesives, the wave type carbon felts adopt resin as base bodies, and carbon fiber felts arefunctional bodies. The electromagnetic shielding structural body has the large internal surface area, after electromagnetic waves transmit the surface layer carbon felts, the hook faces of the innerlayer carbon felts can perform repeated reflection, by mans of the multiple electromagnetic wave scattering effect of carbon fiber inside the carbon felts, and therefore the electromagnetic wave consumption and absorption of the carbon felt structural body are remarkably enhanced, the electromagnetic shielding effect is improved, the surface layer wave type carbon felt can remarkably lower the reflecting effect for emission electromagnetic waves, the influence of electromagnetic waves for peripherals and workers is lowered, and the invisibility effect can be achieved in some application fields.

Owner:BEIHANG UNIV

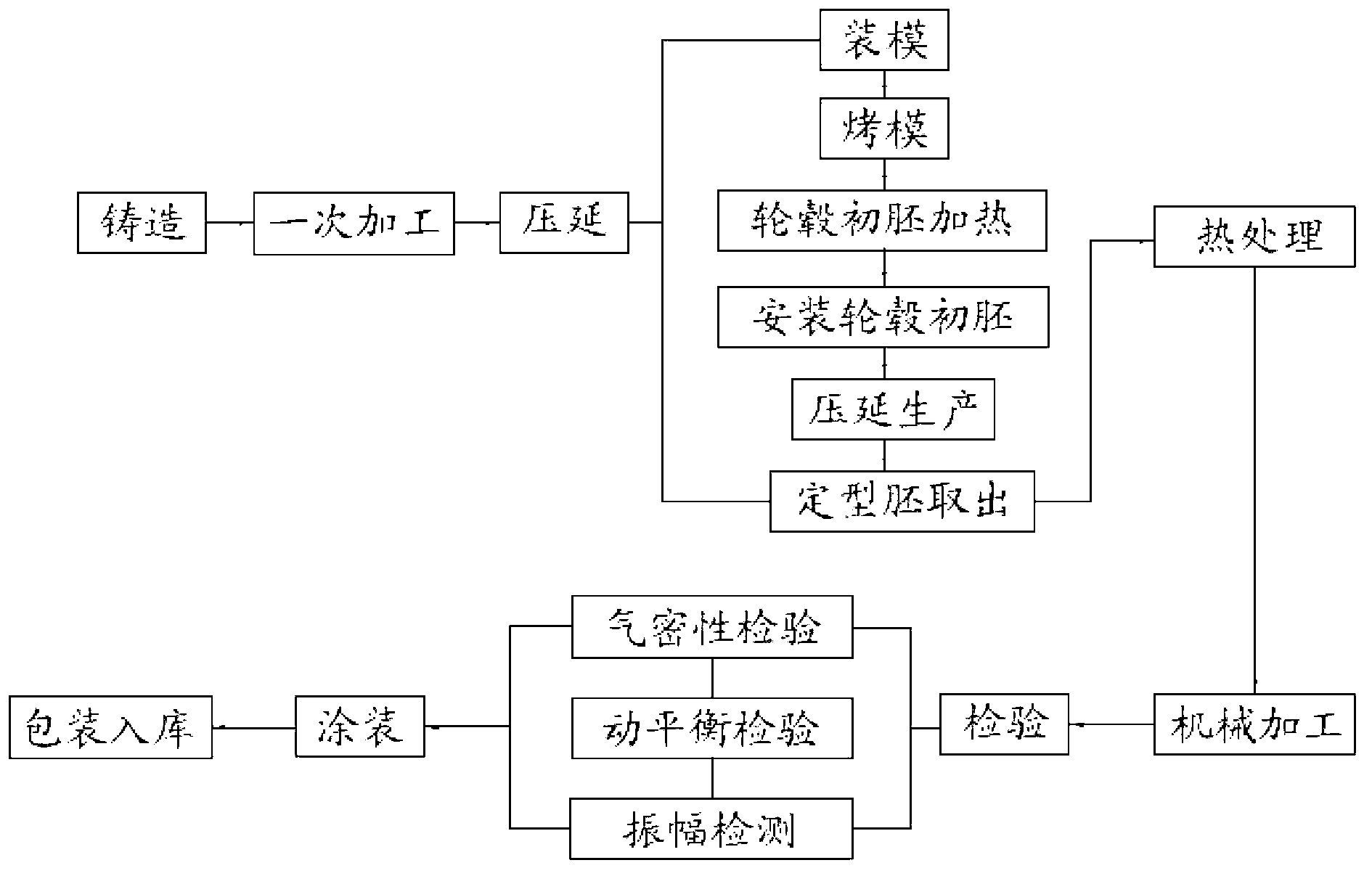

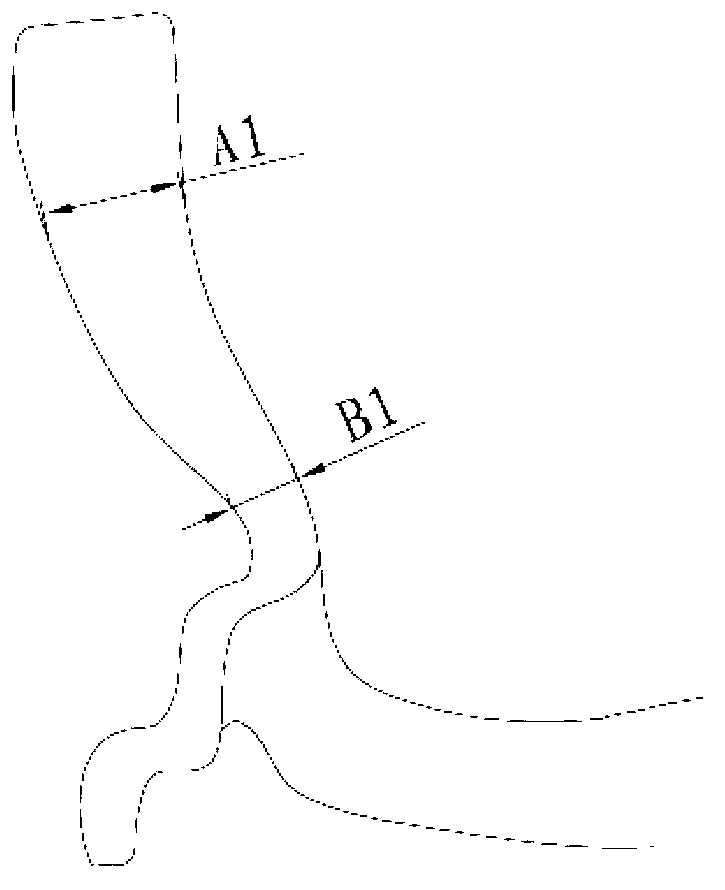

Forming method for aluminum alloy hub

The invention discloses a forming method for an aluminum alloy hub, which comprises the following forming steps: casting, calendering, heat treating, machining, testing, coating, and packing and storing. According to the forming method, feeding for a rib tail arc angle and a mounting face is improved during foundry manufacturing; the castability is good; the strength is effectively improved; and the thickness of a finished rim is thinner than that of a normal rim, so as to achieve the effect that the hub is light in weight, and is convenient to use and transport.

Owner:厦门民兴工业有限公司

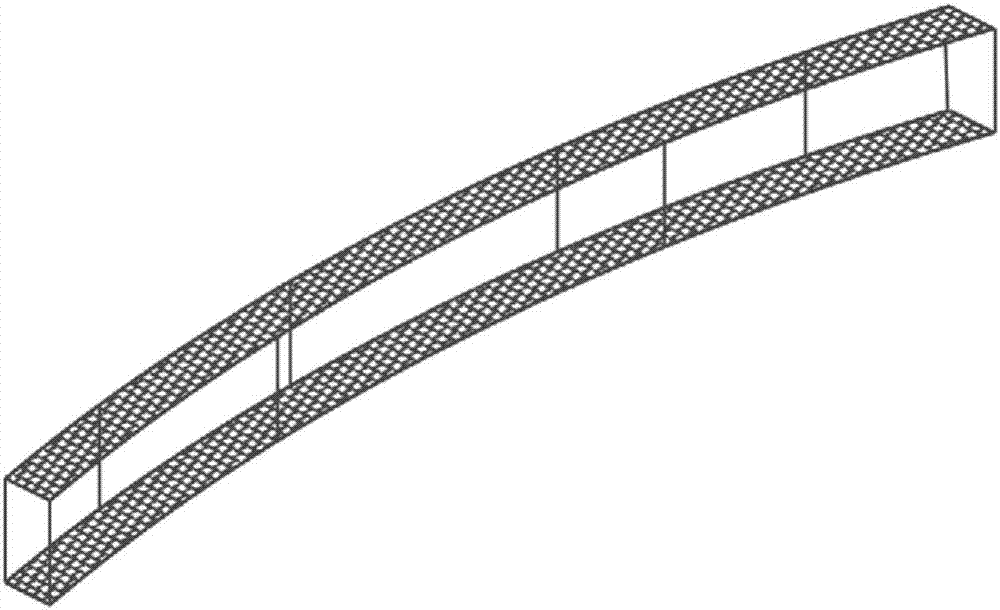

Three-dimensional model lightweight method based on unit reuse in three-dimensional scene

InactiveCN103646414AReduced time spent and labor costsTo achieve the effect of lightweight3D-image renderingThree dimensional modelCell based

The invention discloses a three-dimensional model lightweight method based on unit reuse in a three-dimensional scene. The method specifically comprises steps that: attitude alignment preprocessing on all the model units is carried out, and the preprocessing comprises translation-independent processing, rotation-independent processing and zoom-independent processing; after the preprocessing, each characteristic descriptor of each unit under the alignment attitude is extracted, matching and classification for all the model units are carried out through a matching method, and the model units which can be reused are found out; after the model units which can be reused are found out, the redundant repeated units are removed to realize an effect of lightweight model data. The method is employed, whether two model units are same is determined by comparing how many same numbers do voxel states of same indexes have, and lightweight time and manpower cost are obviously reduced compared with other methods.

Owner:贾金原

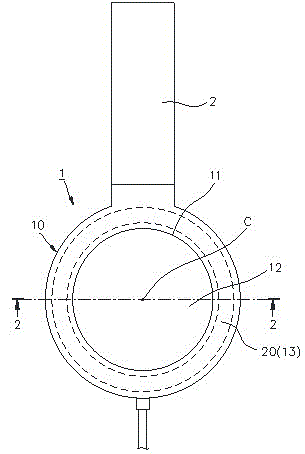

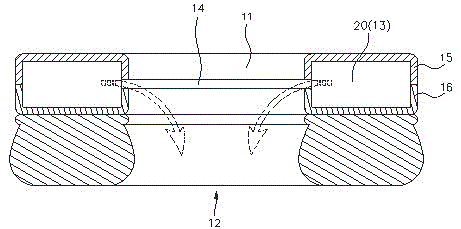

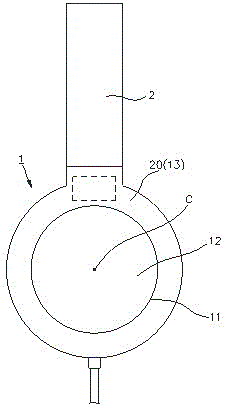

Broadcasting device of headphone

ActiveCN104581475ATo achieve the effect of lightweightComfortable to wearEarpiece/earphone attachmentsHeadphonesBroadcasting

The invention discloses a broadcasting device of a headphone. The broadcasting device comprises a main body and a broadcasting unit, wherein the main body is annular and defines an audio cavity by surrounding the side surface, facing the center, of the main body; an accommodating space is formed inside the main body; at least one audio outlet is formed in the side surface, and is communicated with the accommodating space and the audio cavity; the broadcasting unit is arranged in the accommodating space. The main body of the broadcasting device has relatively hollow lightweight sense in terms of vision, and when a user wears the headphone, the audio cavity faces the ears of the user and meanwhile is in contact with the air of the external environment, so that the broadcasting device has good air permeability and enables the user to more comfortably wear the headphone.

Owner:MERRY ELECTRONICS (SHENZHEN) CO LTD

Polyurethane-coated hollow glass micro-bead toughened cast nylon 6 composite material and preparation method thereof

InactiveCN110818885AHighlight substantive featuresAvoid the problem of increased densityPolymer sciencePtru catalyst

The invention provides a polyurethane-coated hollow glass micro-bead toughened cast nylon 6 composite material preparation method, which specifically comprises: coating the surfaces of hollow glass micro-beads with a polyhydroxy raw material according to a certain ratio in a spraying manner, mixing with diisocyanate, carrying out in-situ polymerization on the surfaces of the hollow glass micro-beads at a proper polymerization temperature to prepare polyurethane-coated hollow glass micro-beads, intermittently adding lactam, the polyurethane coated hollow glass micro-beads, a catalyst and an activating agent into a reaction kettle according to a certain ratio, carrying out pre-polymerization activation, injecting the hot slurry with a certain viscosity into a hot mold, carrying out polymerization curing, and carrying out cooling demolding to prepare the composite material. According to the invention, hollow glass micro-beads are coated with polyurethane to toughen nylon, so that the toughness of the composite material can be improved on the premise of no reducing of the strength, the modulus, the rigidity, the hardness and the heat resistance of the composite material.

Owner:HENAN UNIV OF URBAN CONSTR

Integral wheel stamping and spinning manufacturing method

InactiveCN108655245AAchieve lightweight effectTo achieve the effect of lightweightRimsMetal-working apparatusEngineeringFlange

The invention discloses an integral wheel stamping and spinning manufacturing method. The method comprises the following steps that (1) stamping is carried out, specifically, stamping is carried out on a blank so as to form a spoke part; (2) pre-spinning is carried out on a rim, specifically, the blank is clamped by adopting an upper pre-spinning mandrel and a lower pre-spinning mandrel, the upperpre-spinning mandrel and the lower pre-spinning mandrel drive the blank to rotate synchronously, and meanwhile, lateral extrusion force is applied to the outer edge of the blank by adopting an autorotation and radial feed type spinning wheel so as to form the outer edge of the blank into the V-shaped rim with an outward opening; (3) spinning forming is carried out on the rim, specifically, the blank is clamped by adopting an upper rim forming mandrel and a lower rim forming mandrel, the upper rim forming mandrel and the lower rim forming mandrel drive the blank to synchronously rotate, and meanwhile, pressure is applied to the two sides of the V-shaped rim by adopting an autorotation and radial feed type forming spinning wheel so as to enable the two sides of the V-shaped rim to be attached to the upper rim forming mandrel and the lower rim forming mandrel respectively; and (4) spinning is carried out on a wheel flange.

Owner:BAOSHAN IRON & STEEL CO LTD

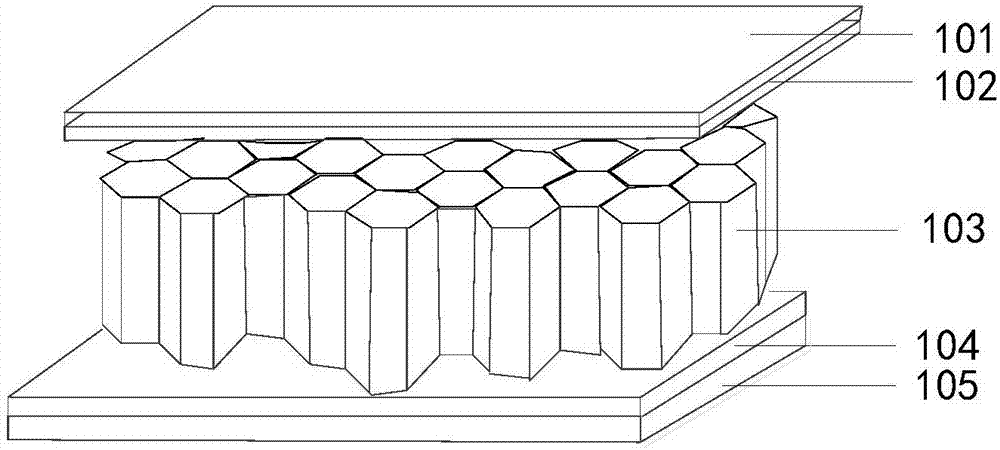

Aluminum alloy honeycomb plate

The invention discloses an aluminum alloy honeycomb plate. The aluminum alloy honeycomb plate comprises a first aluminum alloy layer, a first adhesive layer, a first honeycomb core layer, a second adhesive layer and a second aluminum alloy layer. The above layers are orderly stacked. The first aluminum alloy layer and / or the second aluminum alloy layer is one of an aluminum-copper alloy, an aluminum-silicon alloy and an aluminum-zinc alloy. The aluminum alloy honeycomb plate has high strength and low weight.

Owner:缪彬彬

Polyimide foam composite material

The invention discloses a polyimide foam composite material which is characterized in that raw materials of the polyimide foam composite material comprise glass beads and graphene sheets. The density of the material is 20-50g / cm<3>, the temperature range span with the damping coefficient of more than or equal to 0.3 is 250 DEG C, the polyimide foam composite material is a novel high-efficiency acoustic and heat insulation light material which is low in density, high in heat insulation property, safe and reliable to use and convenient in construction, and the application defects and potential safety hazard of existing materials are overcome. According to the polyimide high-efficiency acoustic and heat insulation light material, the operating safety of ships and naval vessels, aircrafts and high speed trains is improved, and the effect of lightening the weight is achieved, so that the navigational speed is improved, the fuel is saved, and the carrying capacity is improved.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

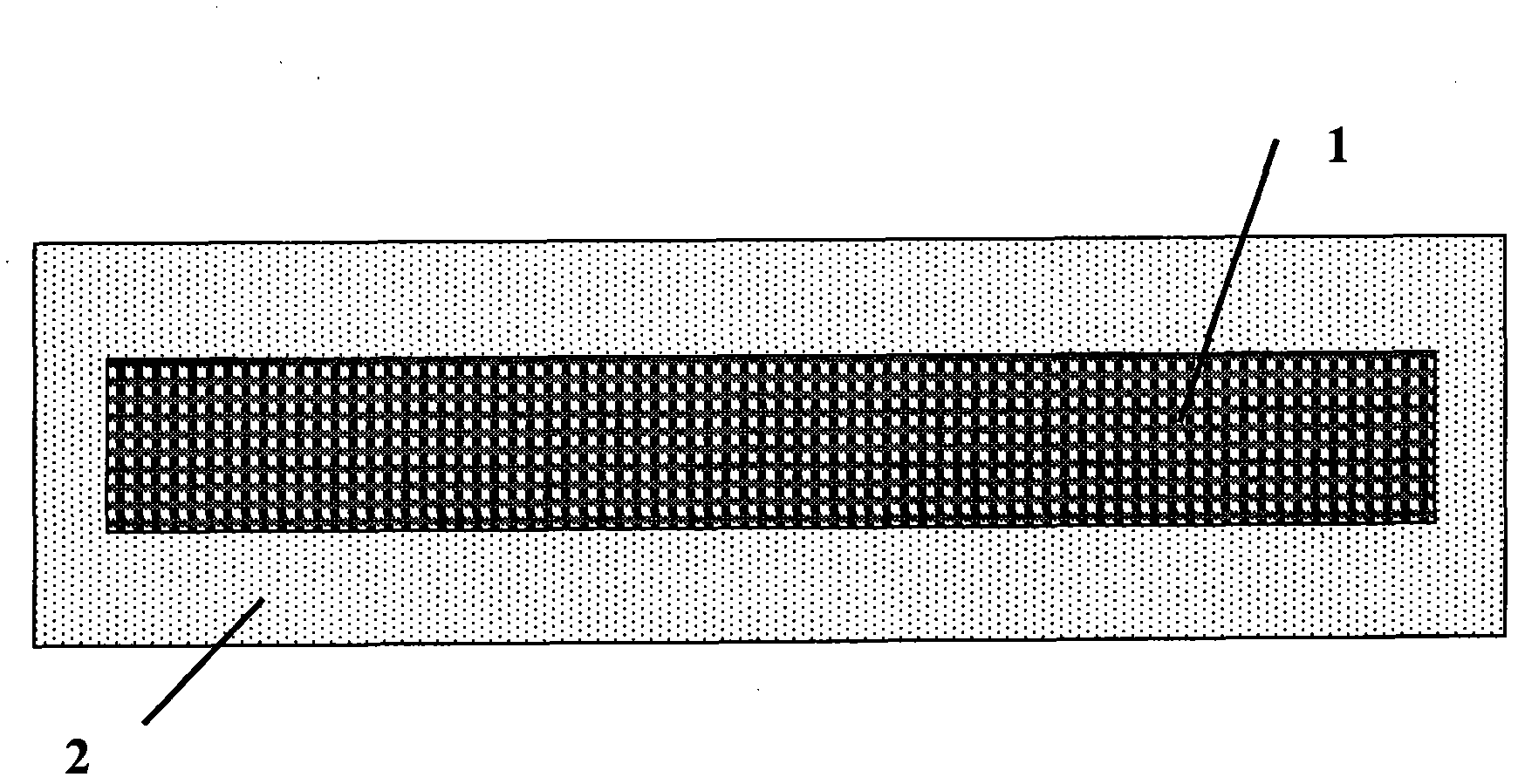

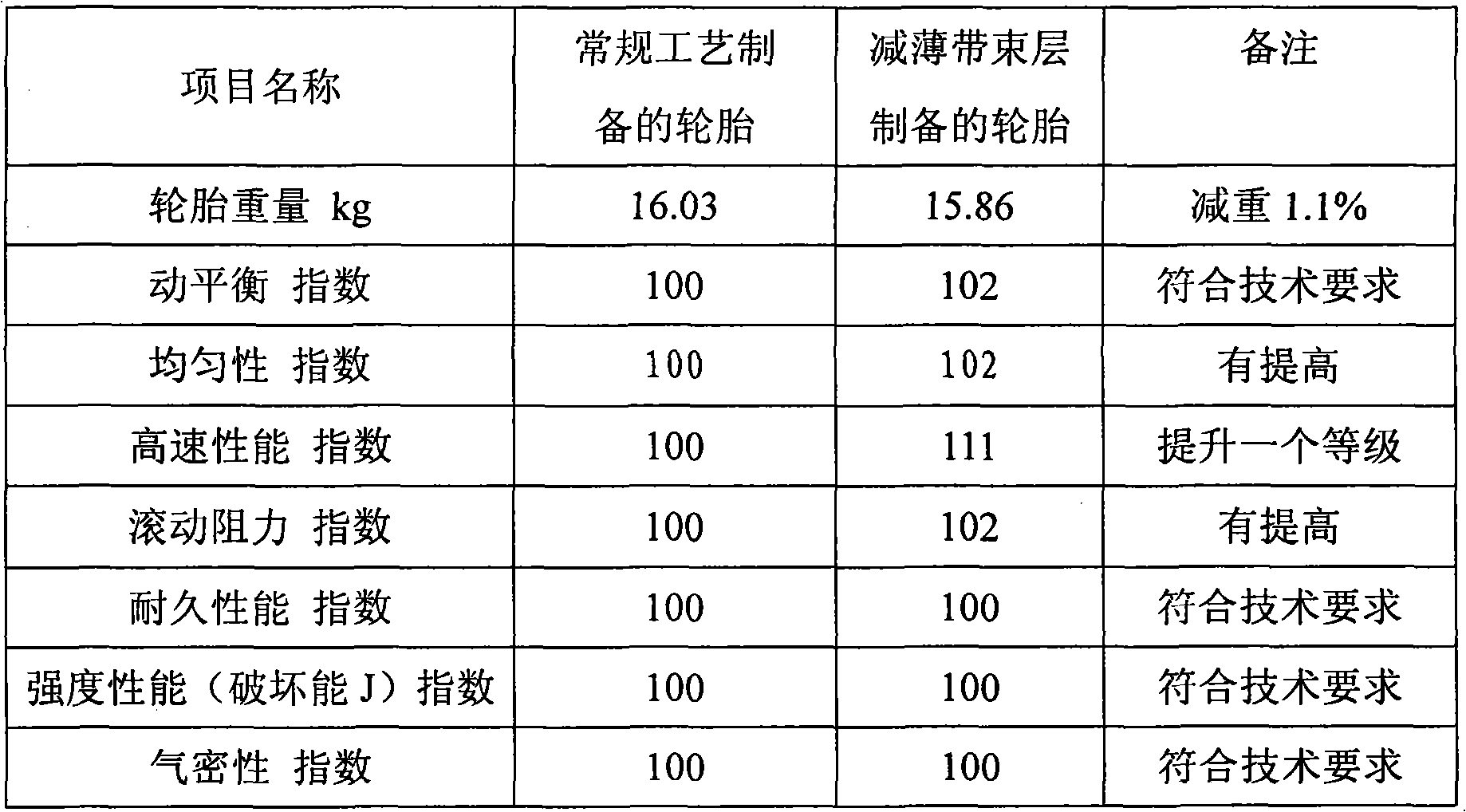

Thinned belted layer component for radial tire

The invention discloses a thinned belted layer component for a radial tire. The thinned belted layer component comprises a belted layer framework and a rubber coating layer, wherein the framework is made of a high-modulus cord thread material which comprises steel wire cord threads or fiber cord threads, and one or more cord thread layers are arranged; the rubber coating layer is made of natural rubber or a blend of the natural rubber and synthetic rubber; cord thread expansion, calendaring and rubber coating are carried out according to a radial tire belted layer production process to manufacture a thinned belted layer piece with a standard width, and the rubber layer thickness of the component is thinned by 3-10 percent compared with that of a component produced by a traditional process; and then, the thinned belted layer piece is radiated and prevulcanized by adopting an electronic accelerator radiation device to prepare a thinned belted layer component. The thinned belted layer component has a thinned belted layer structure and has the advantages of low rubber raw material dosage, high Green strength of the coated rubber, good rubber layer uniformity and strong structure stability, so that the performance and the quality of a manufactured tire is greatly improved, and the thinned belted layer component is suitable for preparing a high-performance radial tire.

Owner:BEIJING RADIATION APPL RES CENT

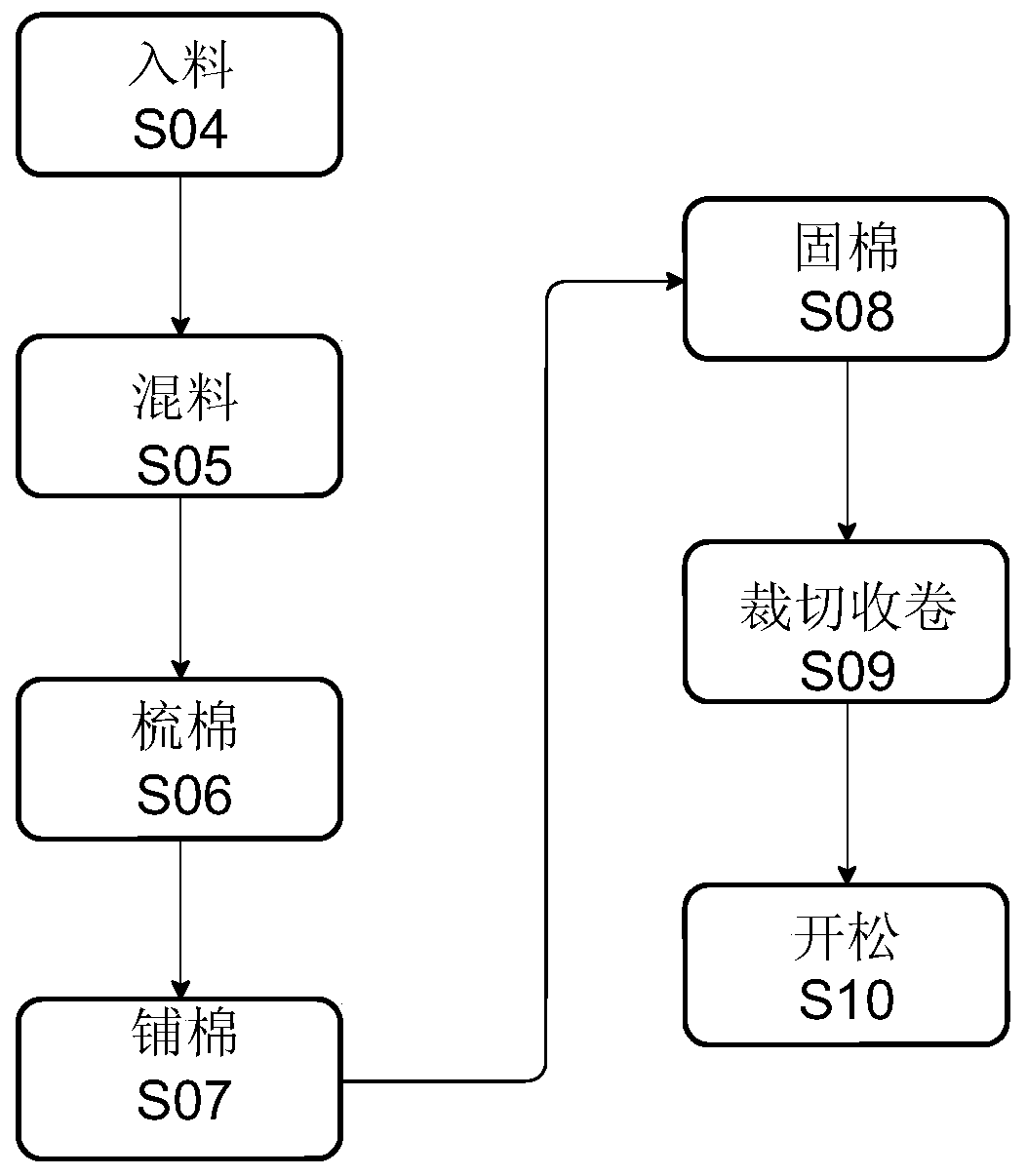

Chemical fiber cotton fiber filling material and manufacturing method thereof

InactiveCN110735227AAvoid washing tangled problemsLow costNon-woven fabricsPolymer scienceNatural fiber

The invention discloses a chemical fiber cotton fiber filling material and a manufacturing method thereof. The chemical fiber cotton fiber filling material replaces down feather to fill down feather products, and comprises at least 70 to 99 wt% of chemical fiber material and 1 to 30 wt% of natural fiber material. The chemical fiber material comprises at least one or more chemical fiber resin cotton of the above specification, the natural fiber material is a natural fiber made from a natural down material, and the fiber length of the natural fiber material is less than 3 cm.

Owner:KWONG LUNG ENTERPRISE

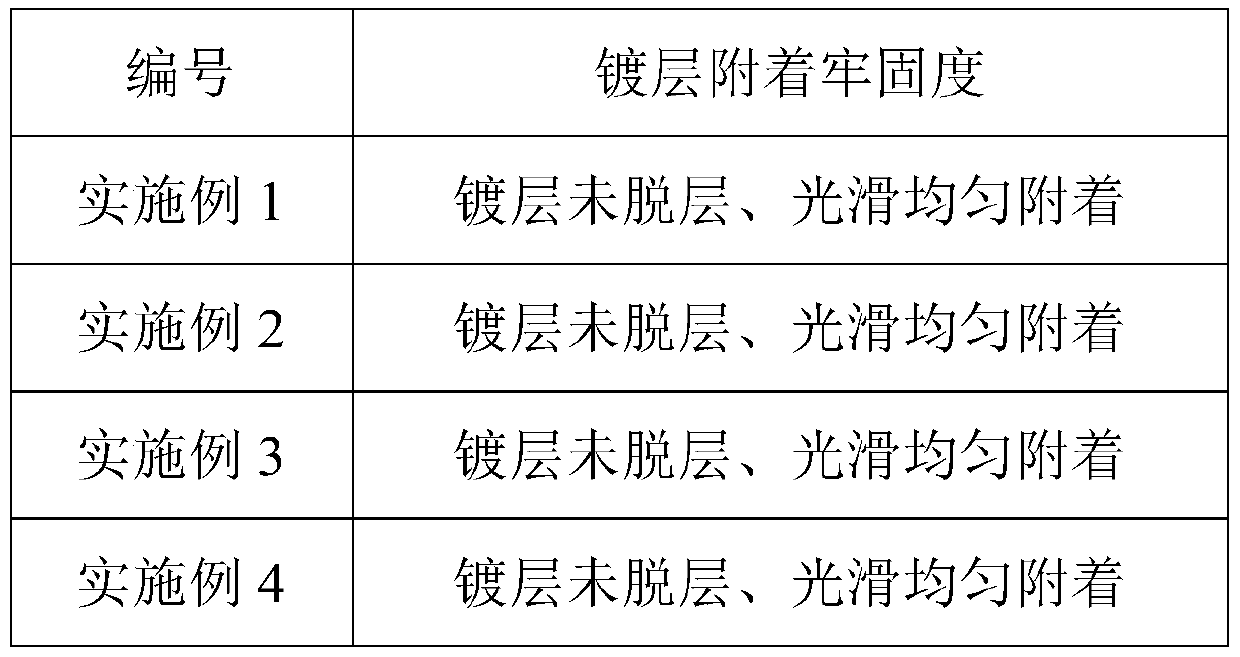

Nylon plastic material for automobile electroplating as well as preparation method thereof

The invention relates to a nylon plastic material for automobile electroplating as well as a preparation method thereof, and belongs to the technical field of automobile plastic. The invention aims toprovide the nylon plastic material for automobile electroplating as well as the preparation method thereof. By the method, the surface of a silicon dioxide microsphere is coated with a layer of alkalescent aluminum hydroxide with a porous structure through hydrothermal reaction, so that the lightweight effect is achieved, the specific surface area is enlarged and the adsorbing ability of the surface aluminum hydroxide on acid liquid is improved; and through compounding with nylon, the nylon material is easily etched in an acid solution and the etching effect is improved, so that the electroplating property of the nylon material is significantly improved. The method provided by the invention is simple and low in cost; the nylon material prepared by the method has small density, has excellent mechanical property and electroplating property, can significantly improve the electroplating property of an existing nylon material and can widely serve as an electroplating material for automobiles.

Owner:王良仁

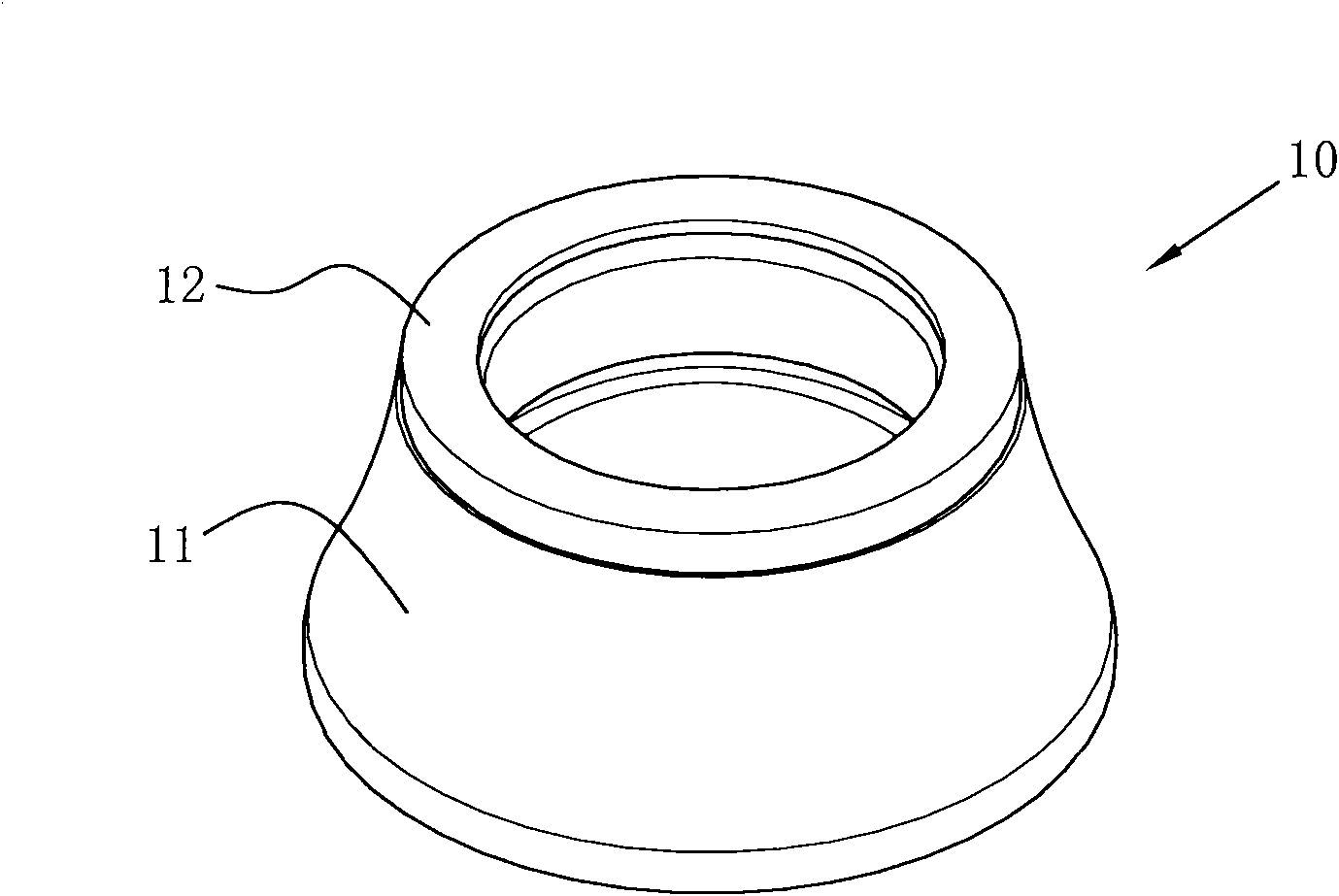

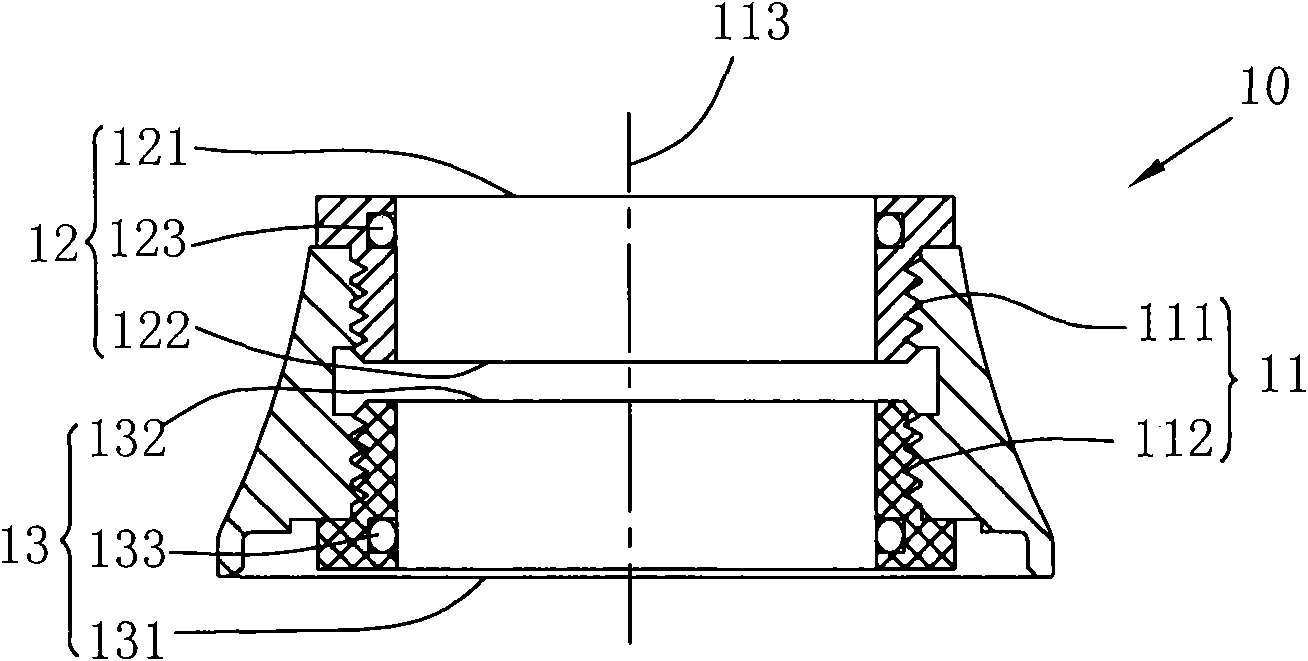

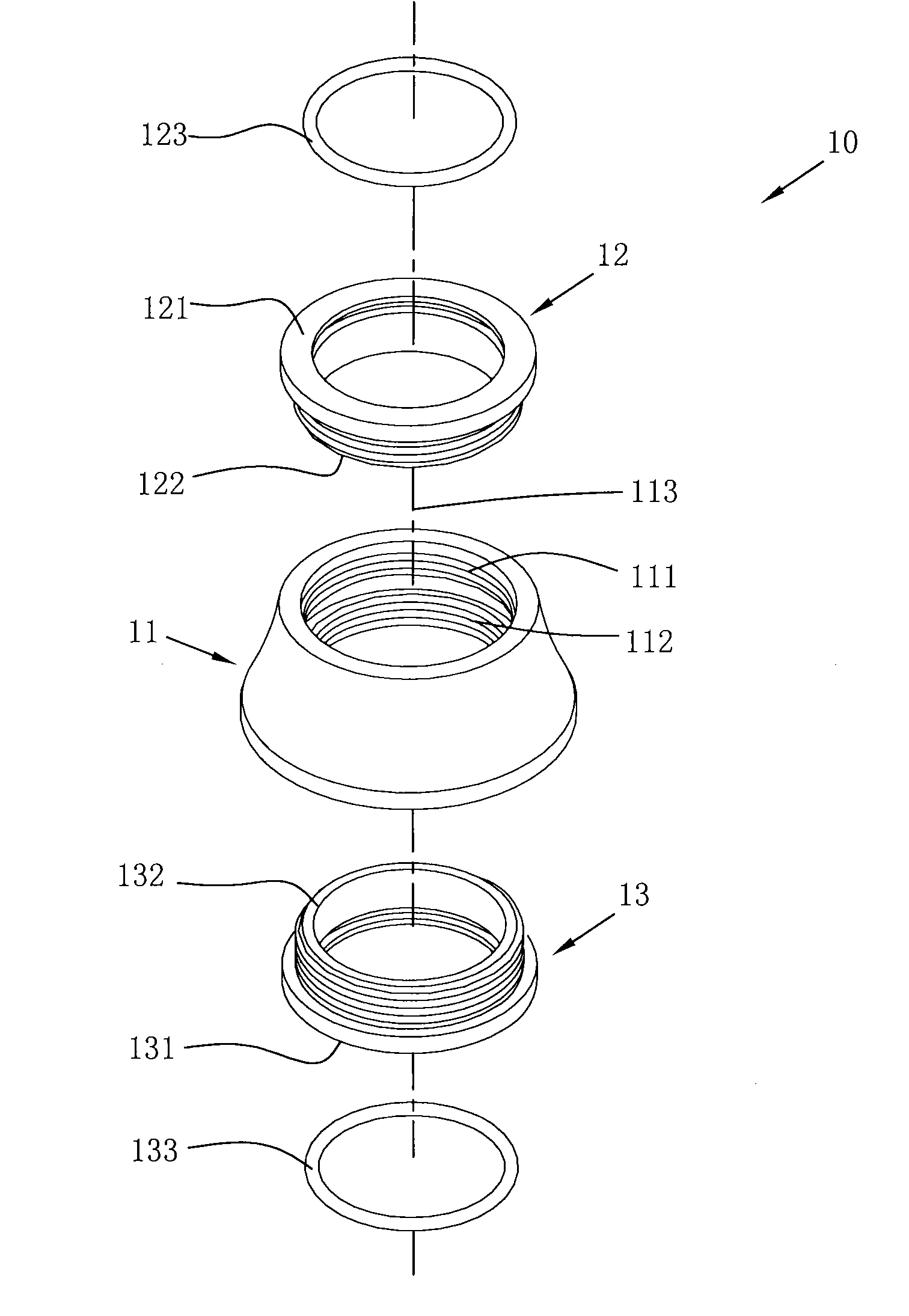

Headset upper cover structure having function of forcing regulation

InactiveCN101870326AIt has the function of adjusting tightness adjustmentHas a positioning effectSteering deviceCoaxial lineEngineering

The invention provides a headset upper cover structure having a function of forcing regulation, which is arranged between a headset set and a handle upright pipe. The structure comprises a base which is provided with reversely screwed first and second threaded parts along coaxial line along the internal edge, a first whirling element which is threaded on the first threaded part and is capable of generating radial displacement in the spiral way so as to resist one end face thereof on the handle upright pipe, and a second whirling element which is threaded on the second threaded part and is capable of generating radial displacement in the spiral way so as to resist one end face thereof on the headset. When the base is rotated, the first and second whirling elements will synchronously generate corresponding radial displacement so as to change the distance between the end faces for performing the function of forcing regulation.

Owner:李健豪

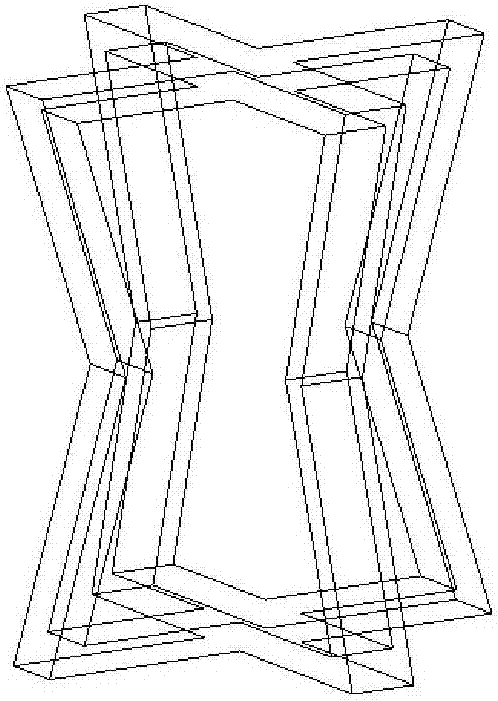

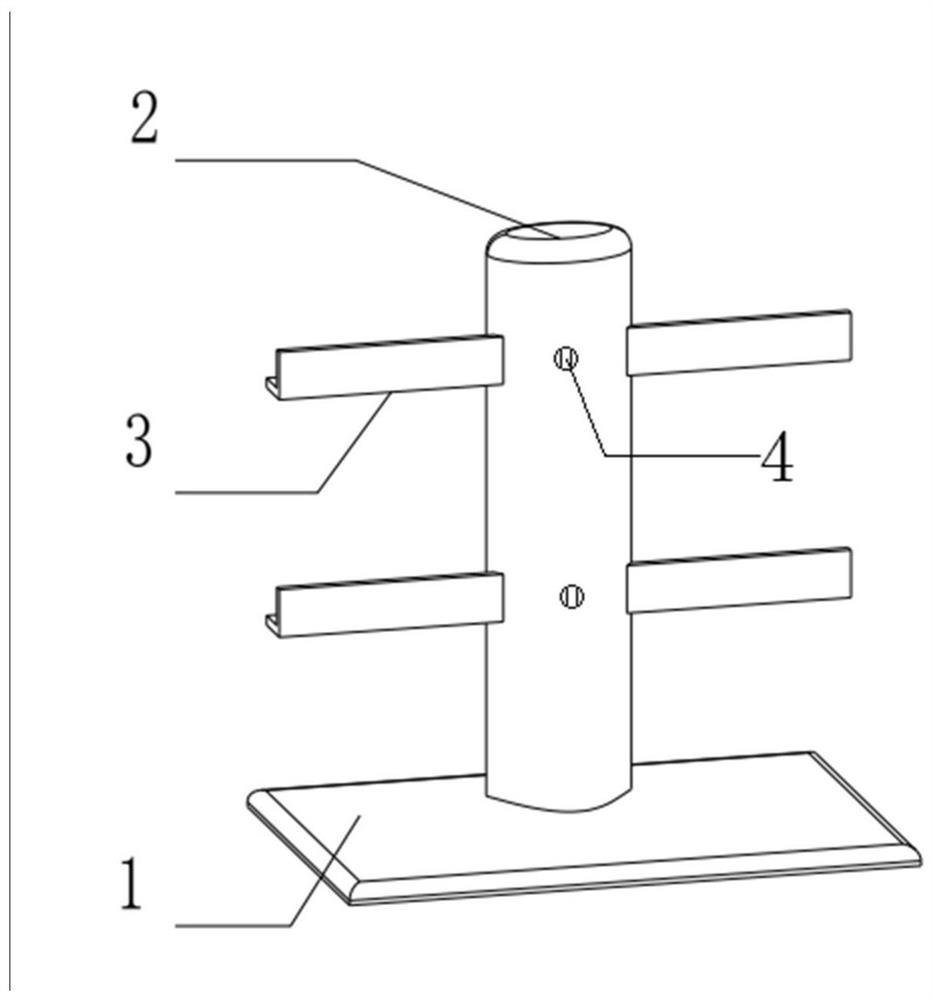

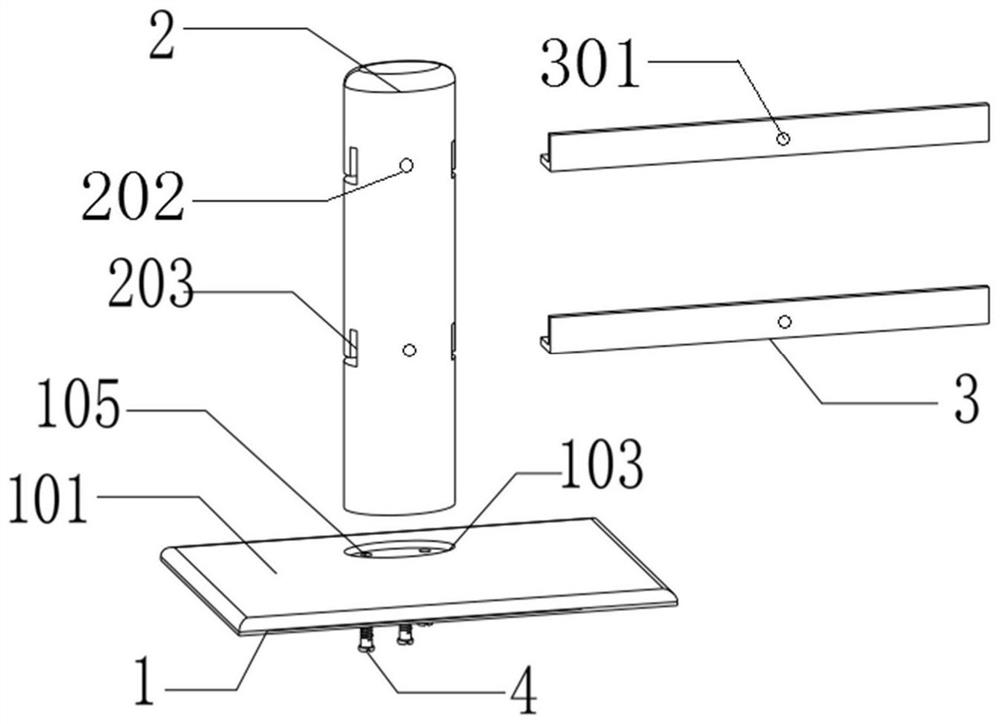

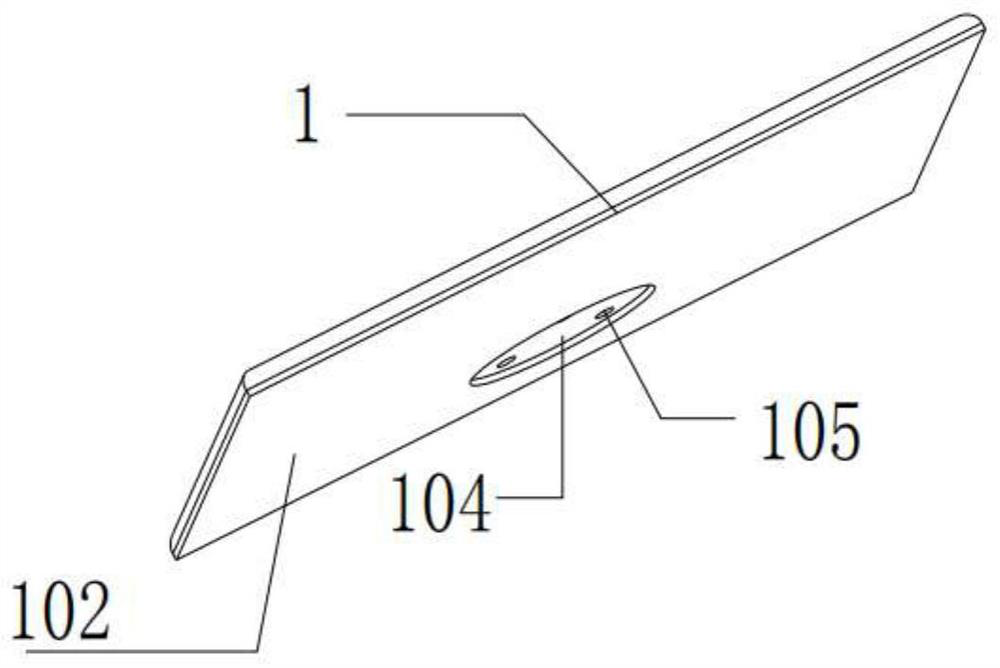

TV stand

ActiveCN111692465ASimple structureUniform strengthTelevision system detailsMachine framesMechanical engineeringTelevision set

Owner:LANGFANG RUILONG TRADING CO LTD

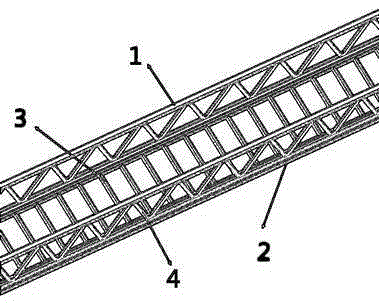

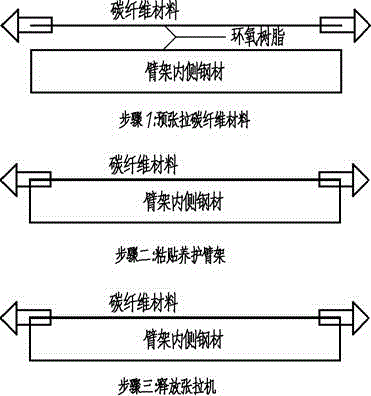

Prestress carbon fiber aerial ladder truck cantilever crane

PendingCN105332645AAvoid the disadvantage of not being able to exert the high-strength properties of the materialReduce usage ratioLaddersFiberCarbon fibers

A prestress carbon fiber aerial ladder truck cantilever crane mainly comprises vertical ladder columns, ladder steps, struts and lateral oblique beams, wherein the vertical ladder columns are connected with the lateral oblique beams; the lateral oblique beams are connected with the struts; the struts have the load-bearing effect; the left strut and the right strut are connected with each other by the ladder steps; and a worker can walk on the cantilever crane through the ladder steps. The structural style of cross sections of the struts is improved, carbon fiber materials are pretreated so that the carbon fiber materials have the prestress effect, and then the prestressed carbon fiber materials are connected with the struts of the cantilever crane. The invention provides an aerial ladder truck firefighting cantilever crane structure, the cross sections of the struts of the cantilever crane have novel C-shaped structures, and two sections of the cantilever crane are combined in an inserted mode. In addition, the carbon fiber materials are tensioned in advance, the cross sections of the struts of the cantilever crane have the novel C-shaped structures, and inner lower sides of the struts and the prestressed carbon fiber materials are anchored. The novel cantilever crane is subjected to a reverse prestress effect when not working; stress and deformation conditions of the cantilever crane can be improved effectively when the cantilever crane works, and therefore, the prestress carbon fiber aerial ladder truck cantilever crane is high in efficiency, good in performance and high in safety.

Owner:HUBEI INST OF SPECIALTY VEHICLE

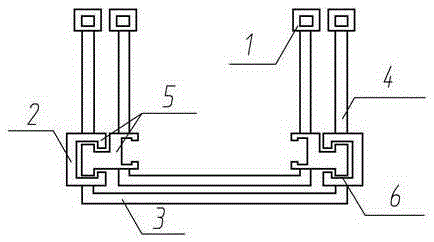

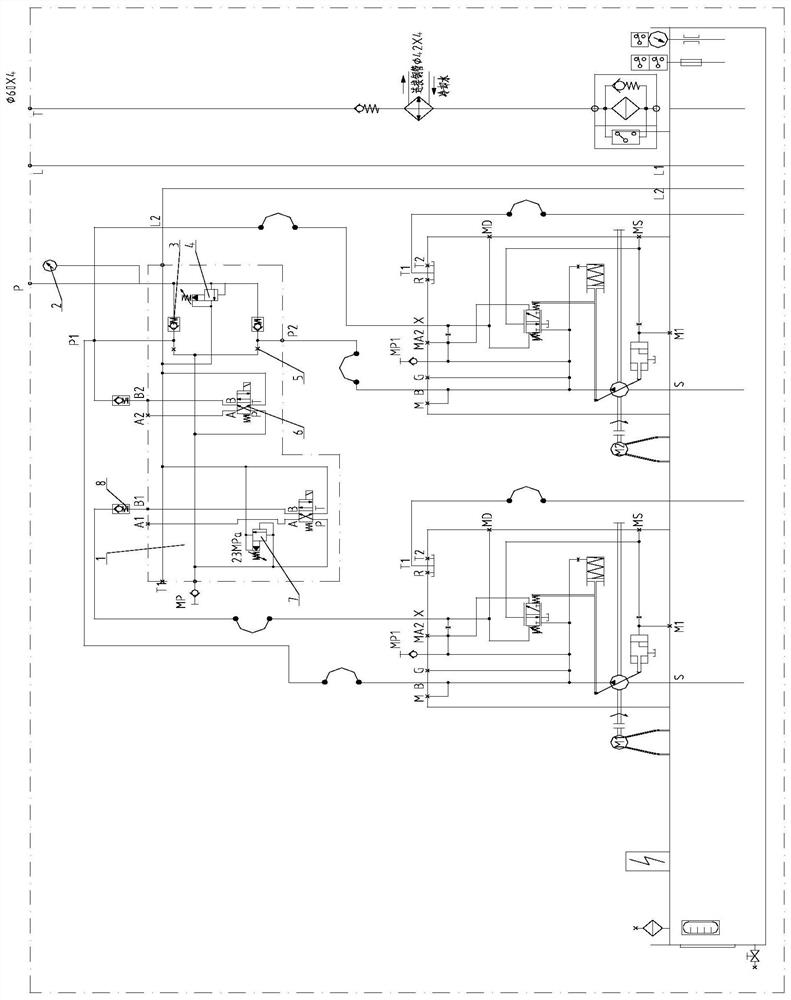

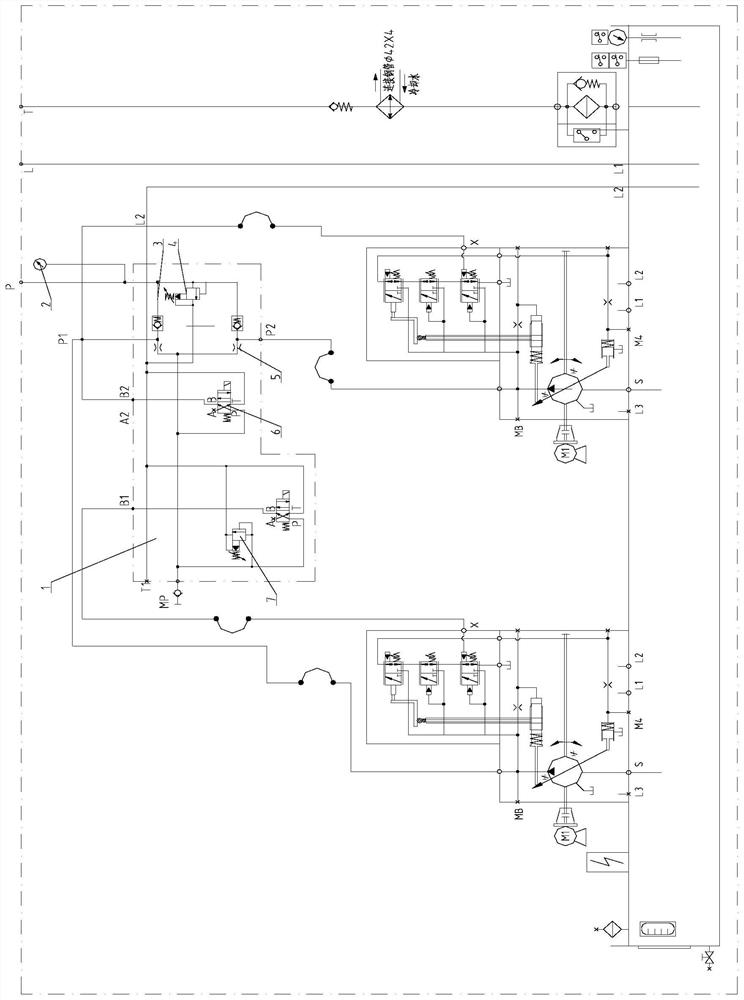

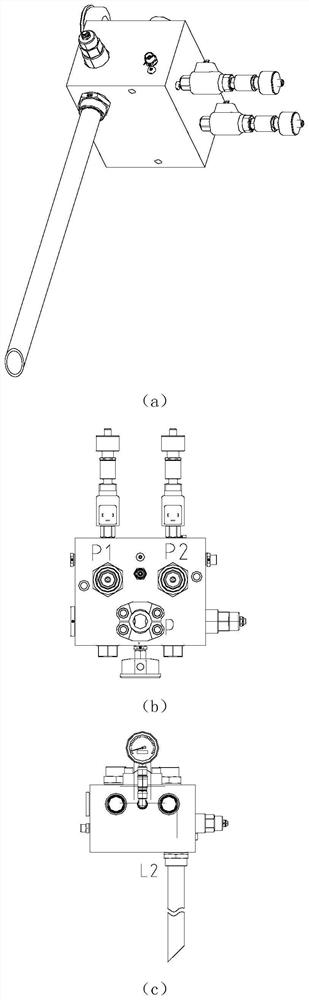

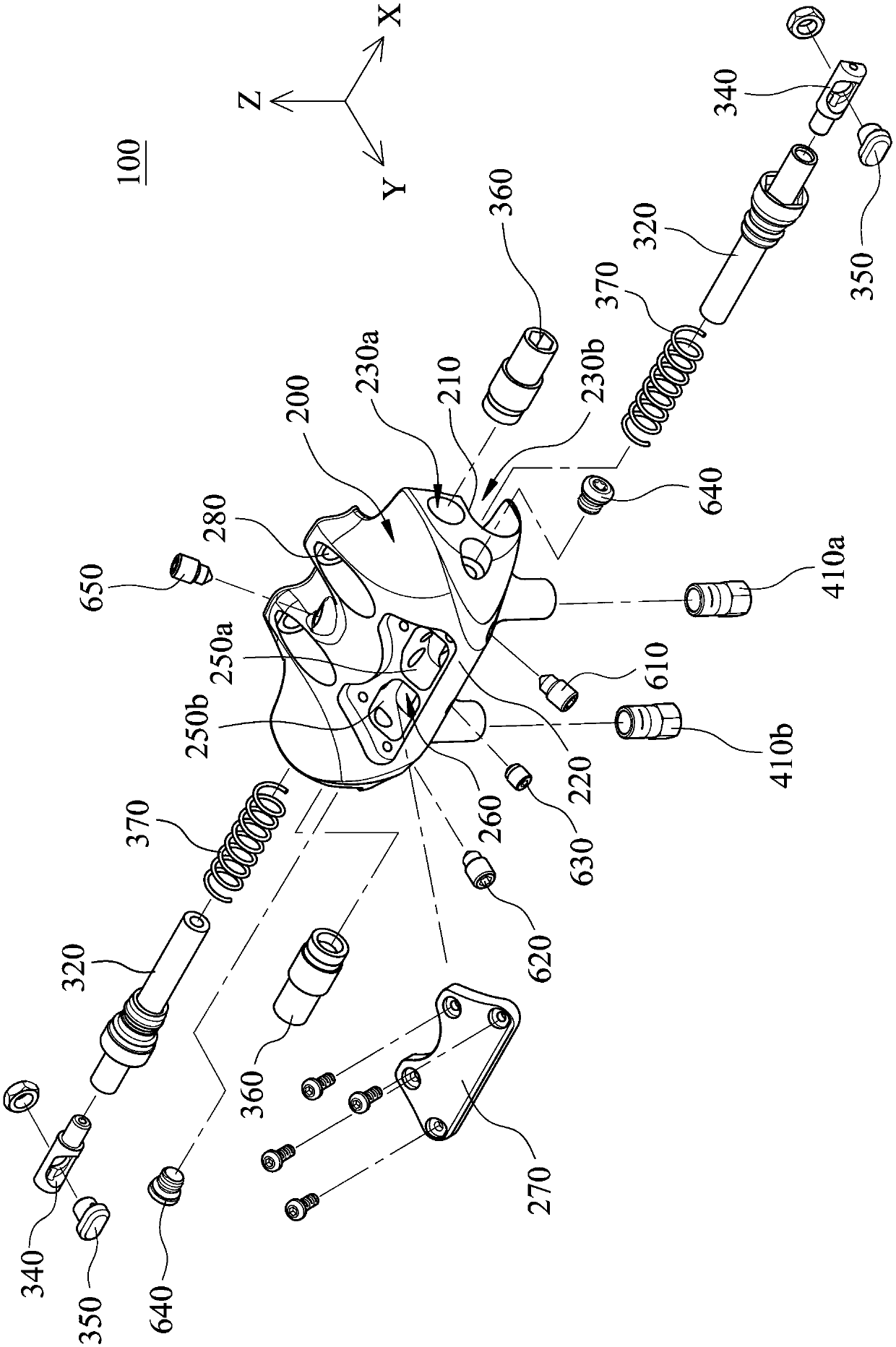

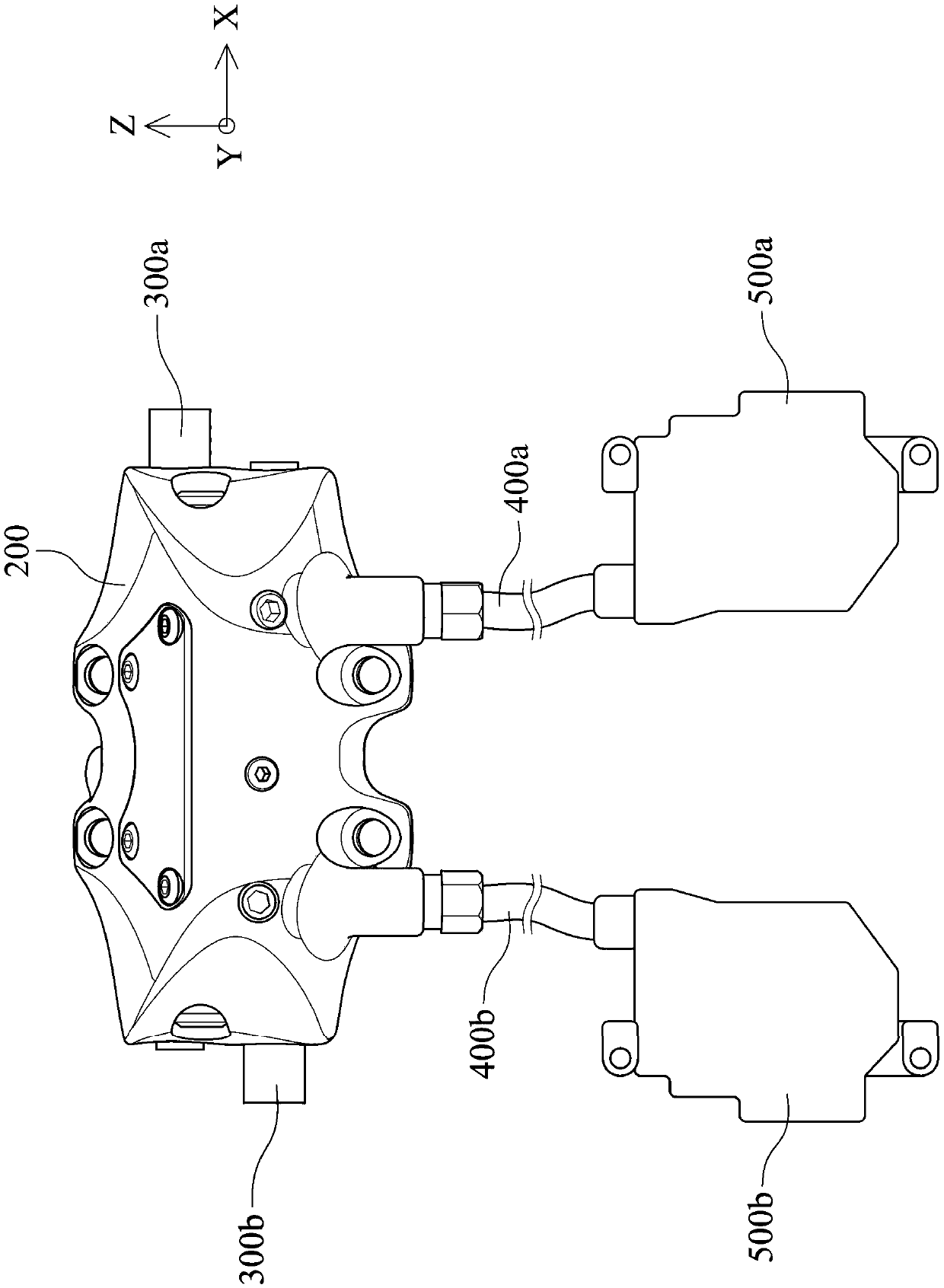

Large anchor and mooring machine pump station lightweight composite general valve group

PendingCN114060342AImprove versatilityImprove interchangeabilityFluid-pressure actuator testingServomotor componentsMarine engineeringEngineering

The invention discloses a large anchor and mooring machine pump station lightweight composite general valve group, which comprises two groups of control oil ways arranged in parallel, and each control oil way is composed of a general valve block, a first one-way valve, a first overflow valve, an electromagnetic directional valve, a second overflow valve and a second one-way valve which are connected in sequence; the electromagnetic directional valve is a two-position three-way electromagnetic valve and is inserted into the general valve block through threads, and the first one-way valve, the second one-way valve, the first overflow valve and the second overflow valve are connected with the general valve block through pipe joints and threads. The universality and interchangeability are greatly enhanced, meanwhile, the weight and the size of the product are reduced by about one third through the modularized and integrated optimization design, the light weight effect is achieved, and installation and use are more convenient. Due to the fact that the pipe hole of the valve block is optimized, noise and vibration are reduced.

Owner:CSSC NANJING LUZHOU MACHINE

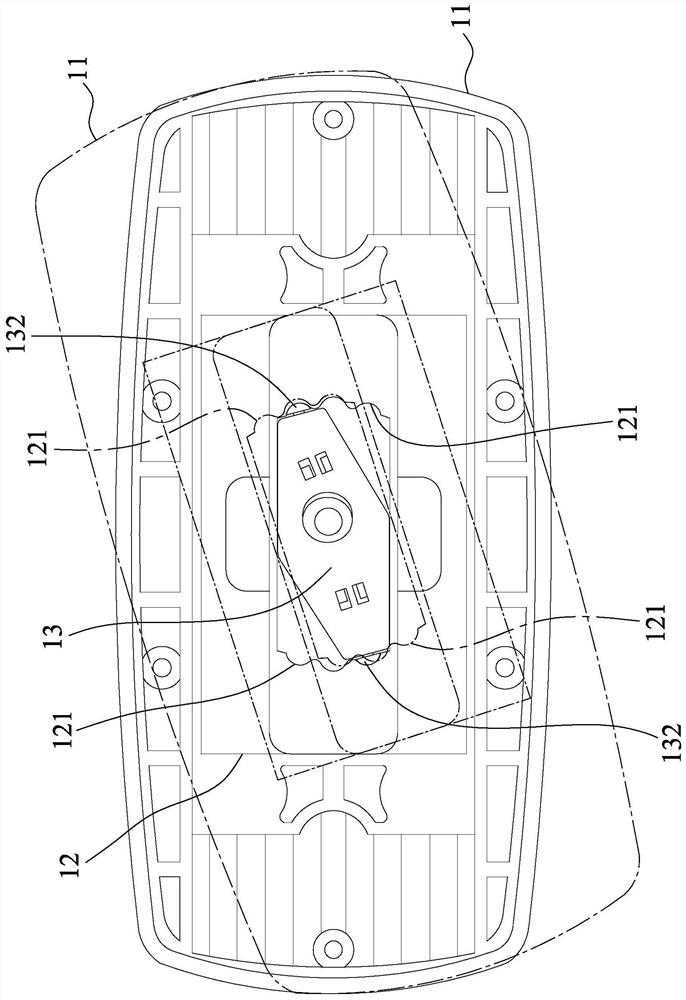

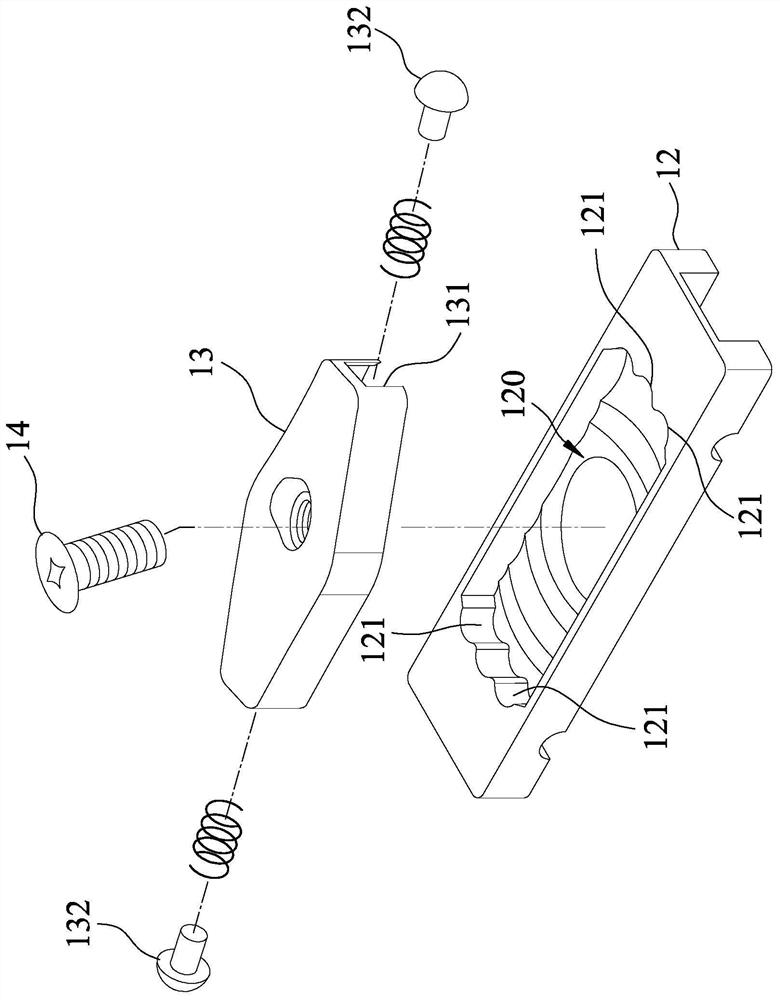

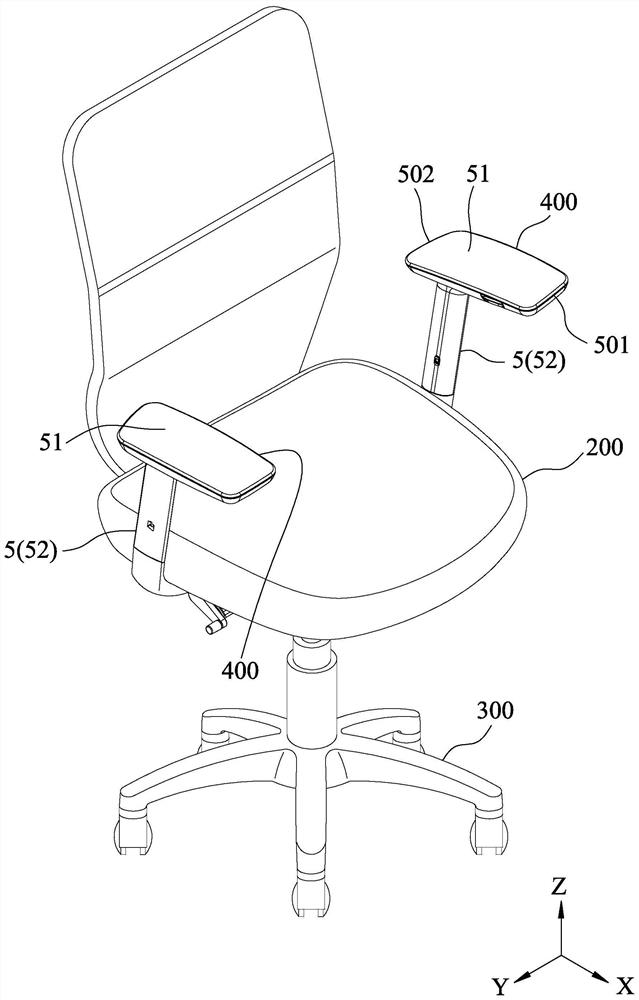

Rotary positioning mechanism, armrest frame with rotatable armrest seat, and chair

PendingCN112773122AAvoid misdirectionAvoid insufficient frictionStoolsChairsEngineeringStructural engineering

Owner:PAO SHEN ENTERPRISES

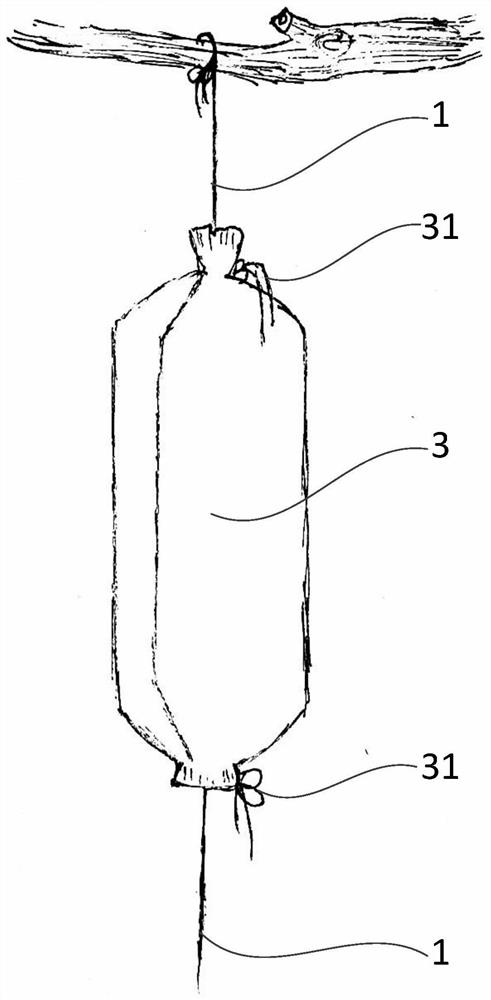

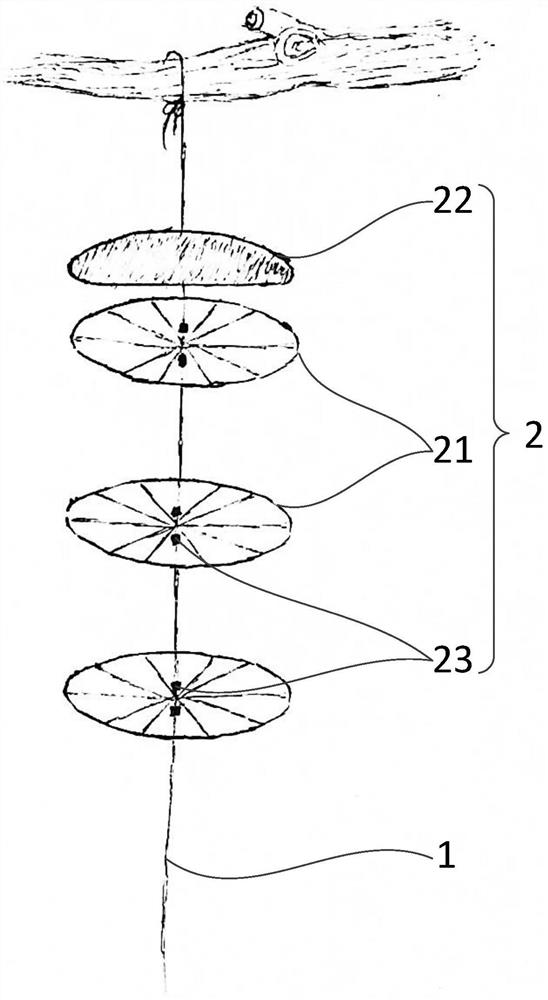

Bee keeping bag

The invention discloses a bee keeping bag. The upper part of a central bearing part is used for hoisting and hanging and can be hung at positions such as branches; the at least three fixed spleen bodies are positioned and mounted on the central bearing part, the fixed spleen bodies are made of hard materials, and each fixed spleen body radiates and extends towards the periphery in the radial direction with the central bearing part as the center to form a supporting framework to play a supporting role; the flexible deformable bag body is arranged on the periphery of the supporting framework formed by spleen fixing in a covering mode and surrounds the outside to achieve the protection effects of wind prevention, heat preservation and the like; the bag body surrounds to form a hollow bee breeding space, the top end of the bag body is closed, and the bottom end of the bag body is open for bees to enter and exit. A traditional hard wood beehive is replaced with the modular assembly type structure, the bag body can be made of various materials in a mixed mode, the requirement of bees for the nesting environment is better met, the overall mass can be effectively reduced, the light weight effect is achieved, the material cost is reduced, and the workload of outdoor beehive arrangement is reduced.

Owner:林清海

A kind of bubble cup and preparation method thereof

Owner:NINGBO LISI HOUSEWARE CO LTD

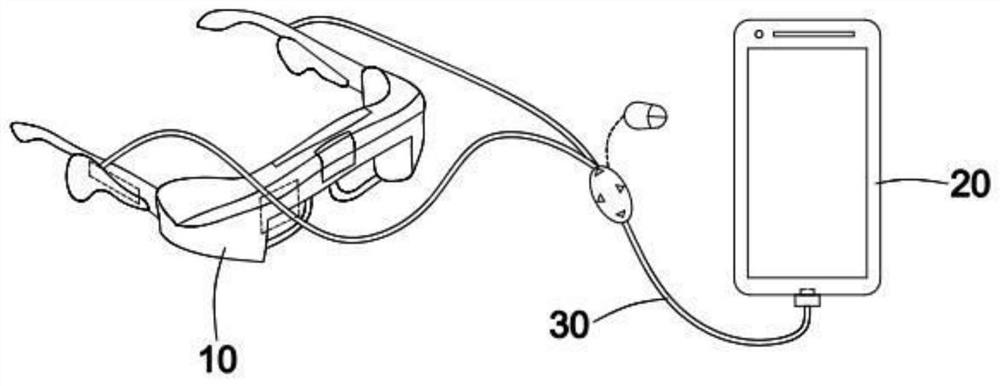

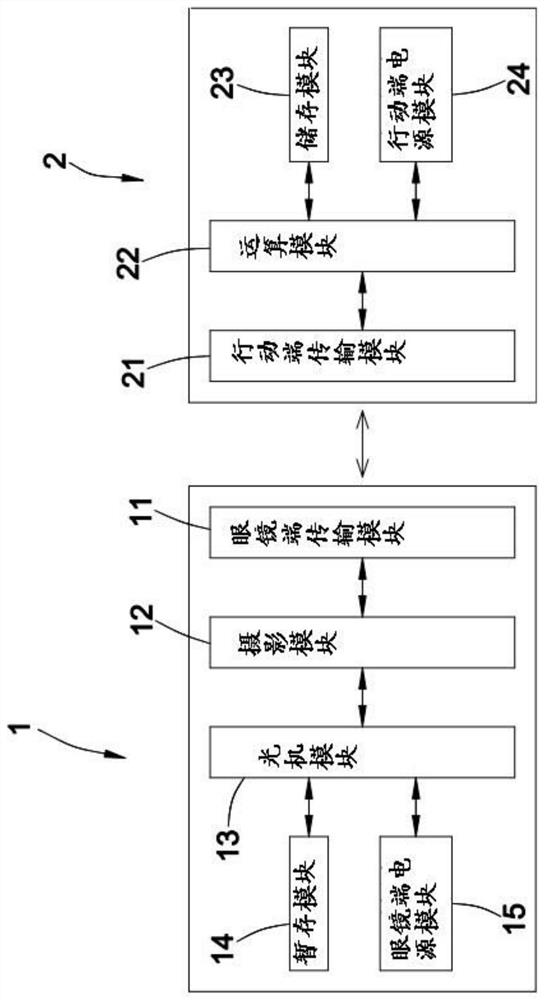

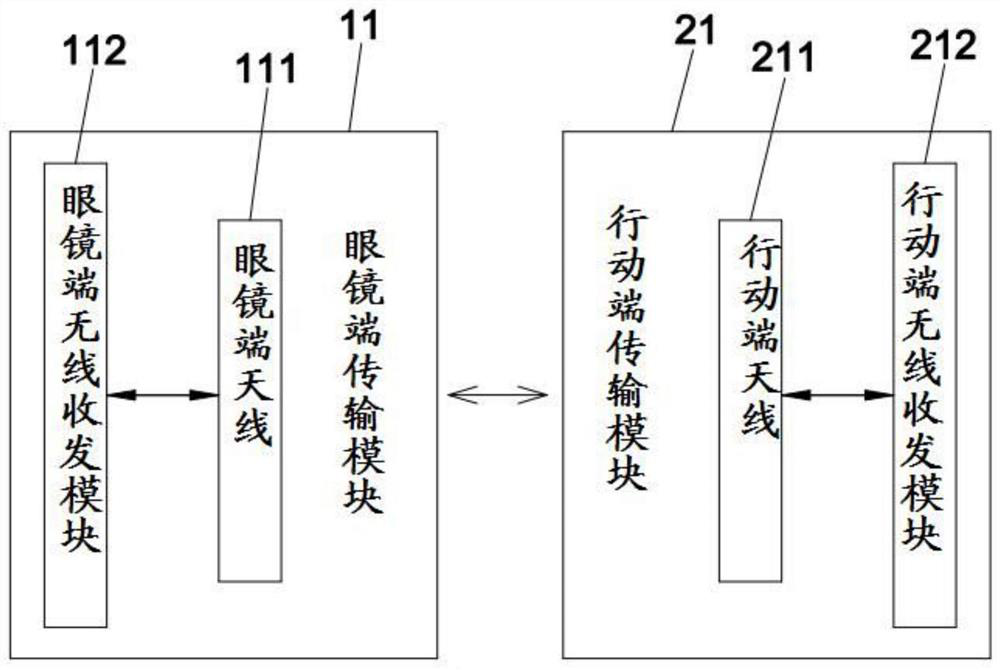

Lightweight intelligent glasses

InactiveCN112764215ATo achieve the effect of lightweightTake the hassle out of connectingClosed circuit television systemsTransmissionWireless transceiverSmartglasses

A pair of lightweight intelligent glasses comprises an intelligent glasses body and a mobile device, the intelligent glasses body is provided with a glasses end transmission module, the glasses end transmission module comprises a glasses end antenna and a glasses end wireless transceiver module, and the glasses end antenna is a millimeter wave antenna; the mobile device is provided with a mobile end transmission module, the mobile end transmission module comprises a mobile end antenna and a mobile end wireless transceiver module, the mobile end antenna is a millimeter wave antenna, the mobile device and the intelligent glasses body are in wireless electric connection through the mobile end transmission module and the glasses end transmission module, and the data transmission between the intelligent glasses body and the mobile device is carried out by the mobile end transmission module and the glasses end transmission module through radio waves above a millimeter wave level.

Owner:JORJIN TECH

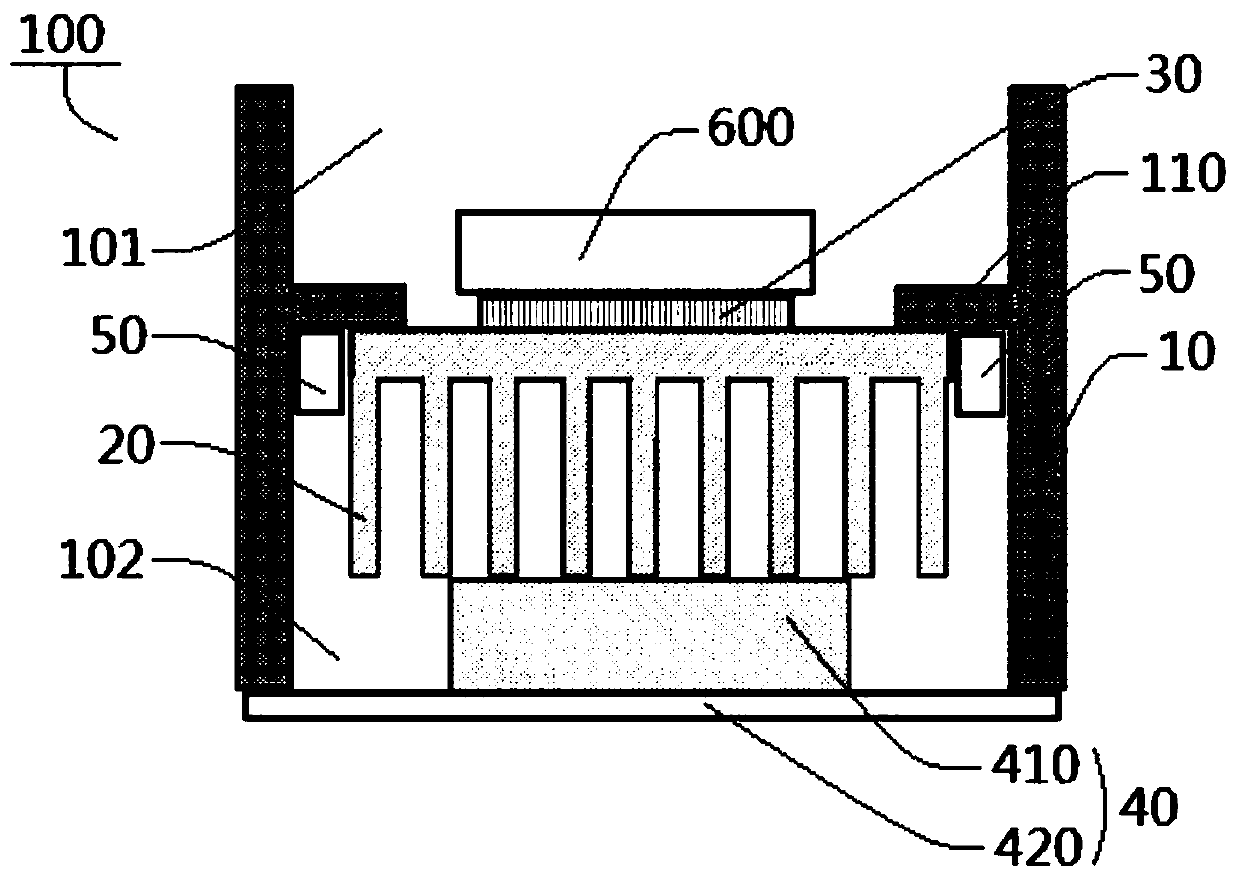

Fixing assembly of pumping module and laser

InactiveCN111106523ASimple structureEasy to assembleLaser detailsSemiconductor lasersResonant cavityEngineering

The invention provides a fixing assembly of a pumping module and a laser. The fixing assembly comprises a shell, a radiator, a refrigerator and a fan assembly. A resonant cavity and a mounting cavityare defined by the shell, and a flange for separating the resonant cavity from the mounting cavity is arranged on the inner wall of the shell. The radiator is located in the mounting cavity. Part of the radiator abuts against the flange, and the end, facing the resonant cavity, of the radiator is connected with the pumping module. The refrigerator is located between the radiator and the pumping module. The fan assembly is connected with the shell, and the end, facing the resonant cavity, of the fan assembly abuts against the end, away from the resonant cavity, of the radiator. According to thefixing assembly of the pumping module, the radiator is fixed and limited through the fan assembly and the flange of the shell; the problems that due to the fact that the radiator is fixed to the shell through screws, mechanical deformation happens to the shell, a resonant cavity is detuned, and laser output energy is reduced can be avoided; and moreover, the fixing assembly is simple in structureand convenient to assemble.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

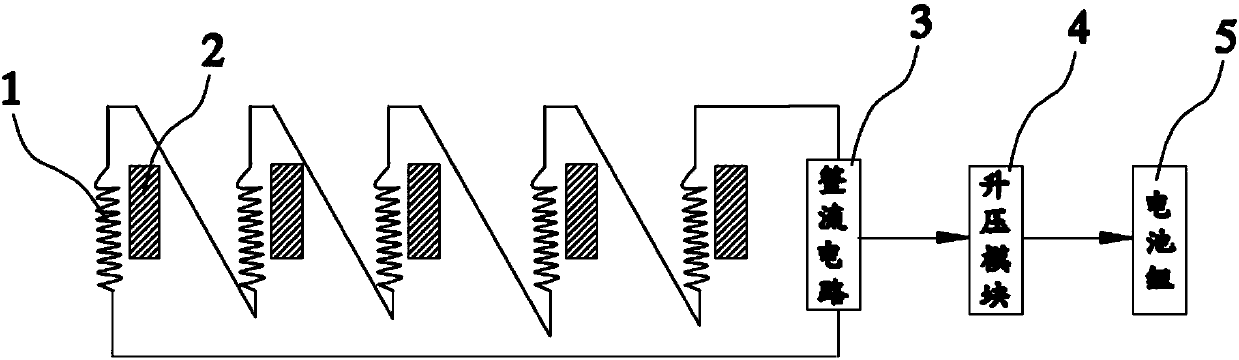

Automobile built-in tire pressure flow power generation system

InactiveCN107769356AImprove battery lifeTo achieve the continuity of power generationBatteries circuit arrangementsElectric powerPower flowAutomotive battery

The invention discloses an automobile built-in tire pressure flow power generation system which comprises a plurality of individual iron core coils connected in series and rare earth magnets arrangedon the individual iron core coils. The individual iron core coils and the rare earth magnets are installed in the U-shaped groove of an automobile tire rim. The individual iron core coils are electrically connected with a boost module and a battery pack included in the automobile to boost the current generated by the air pressure cutting magnetic induction lines during driving of the automobile and to charge the battery pack. The series structure formed by the iron core coils and the rare earth magnets is installed in the U-shaped groove of the automobile tire rim, and the current generated bythe air pressure cutting magnetic induction lines during driving of the automobile charges the battery pack. Thus, the cruising power of the automobile is improved. The rotation of the wheels can realize 360-degree rotary power generation and achieves the continuity of power generation. The air pressure cuts the magnetic induction lines to produce pulse current. The automobile built-in tire pressure flow power generation system has a good charging effect, is easy to install, does not occupy space, and achieves light weight.

Owner:重庆其凯车辆制造有限公司

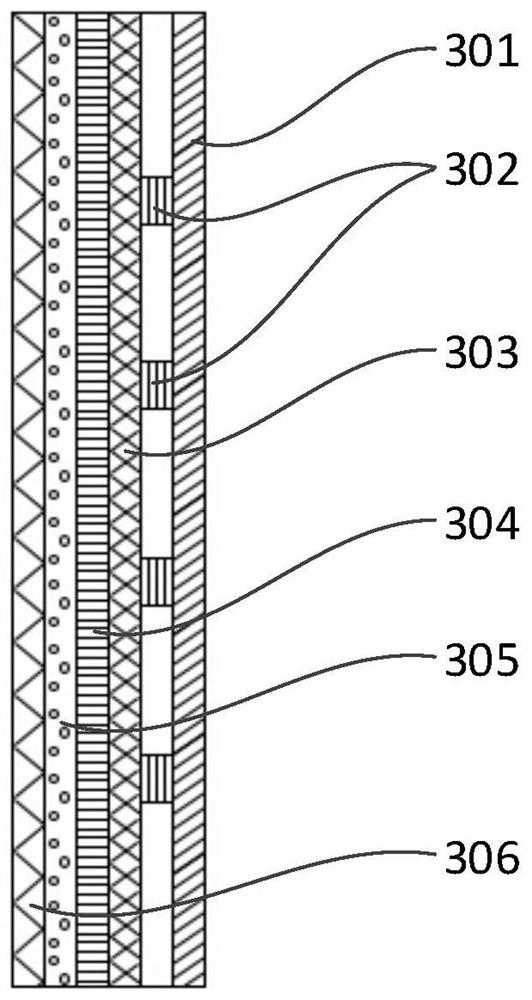

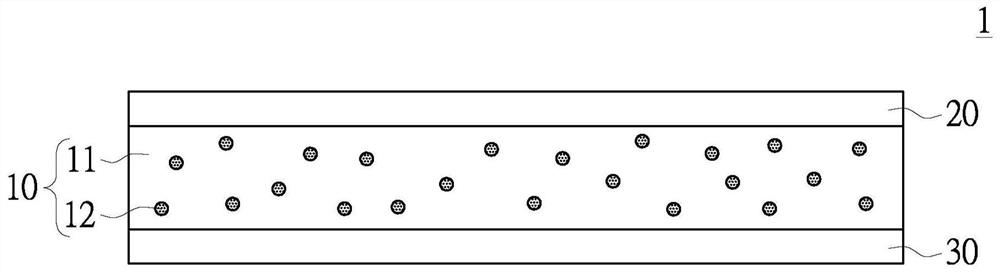

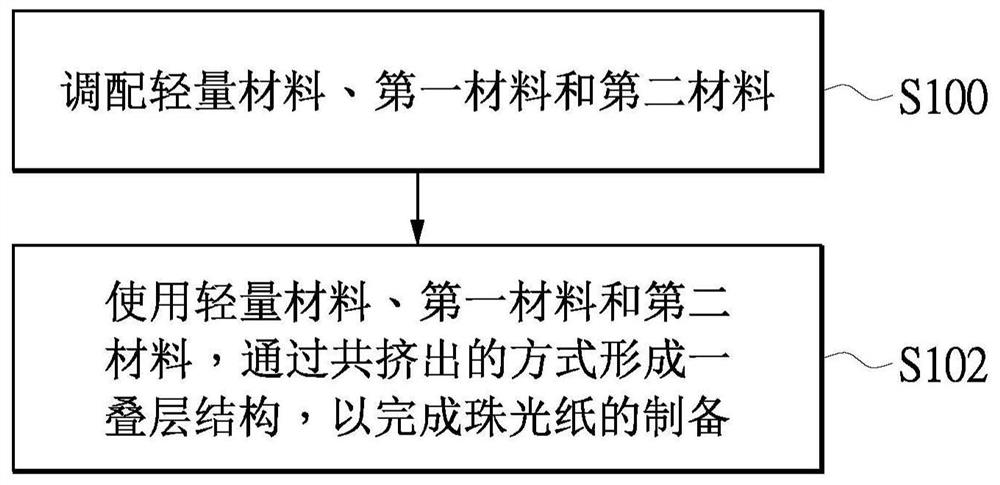

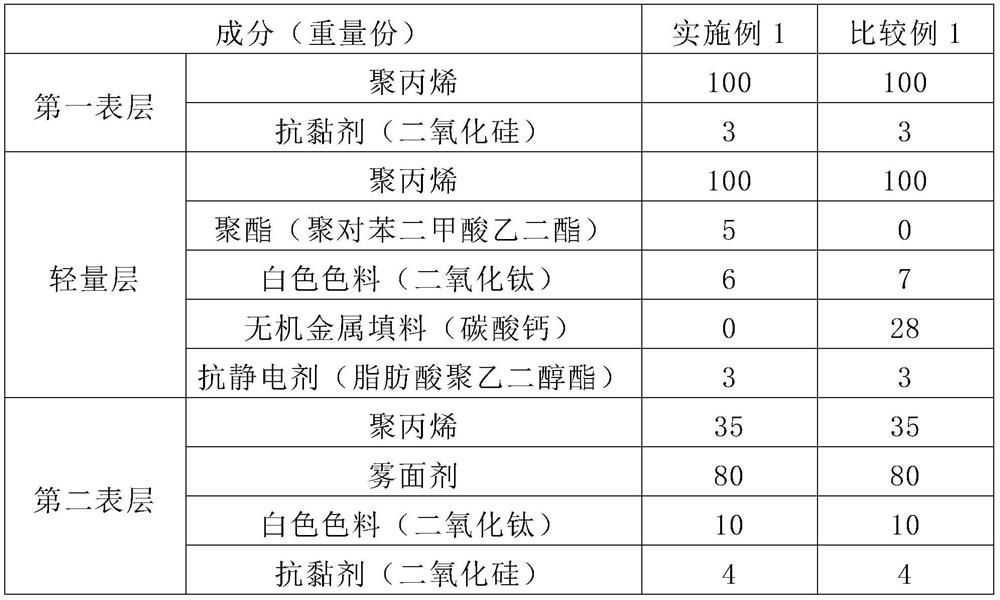

Pearl paper and method for manufacturing the same

InactiveCN112477345ALow densityTo achieve the effect of lightweightSpecial paperSynthetic resin layered productsCalcium silicatePolyester

A pearl paper and a method for manufacturing the same are provided. The pearl paper includes a first surface layer, a second surface layer, and a lightweight layer. The lightweight layer is disposed between the first surface layer and the second surface layer. The first surface layer is a polypropylene layer. The second surface layer is a polypropylene layer. The lightweight layer has a continuousphase part and a dispersed phase part. A material of the continuous phase part contains polypropylene and a material of the polymer dispersed phase part contains polyester. According to the invention, a film can be formed under the condition that calcium carbonate or calcium silicate (inorganic metal filler) is not added, and the light-weight pearl paper is manufactured.

Owner:NANYA PLASTICS CORP

Bubble cup and preparation method thereof

The invention belongs to the field of production and manufacturing of plastic cups made of SNA materials, and relates to a bubble cup and a preparation method thereof. A small amount of polyhydroxy acid sodium salt and sodium bicarbonate powdery mixed foaming agent are added into SNA resin, the bubble cup with the bubble density being 17-21 / cm<3>, the bubble diameter being 0.9-1.5 mm and the bubble cup wall thickness being 2.6-2.8 mm is obtained through screw extrusion, injection molding, forming, cooling and mold opening, bubbles are distributed evenly and beautifully, the effect of light weight of the cup body is achieved, the consumption of raw materials is reduced; the production cost is greatly reduced; the bubble cup prepared by taking the SNA resin as the main raw material has good strength and temperature resistance, the preparation method is simple, the raw material cost is low, and the bubble cup is very suitable for large-scale industrial production.

Owner:NINGBO LISI HOUSEWARE CO LTD

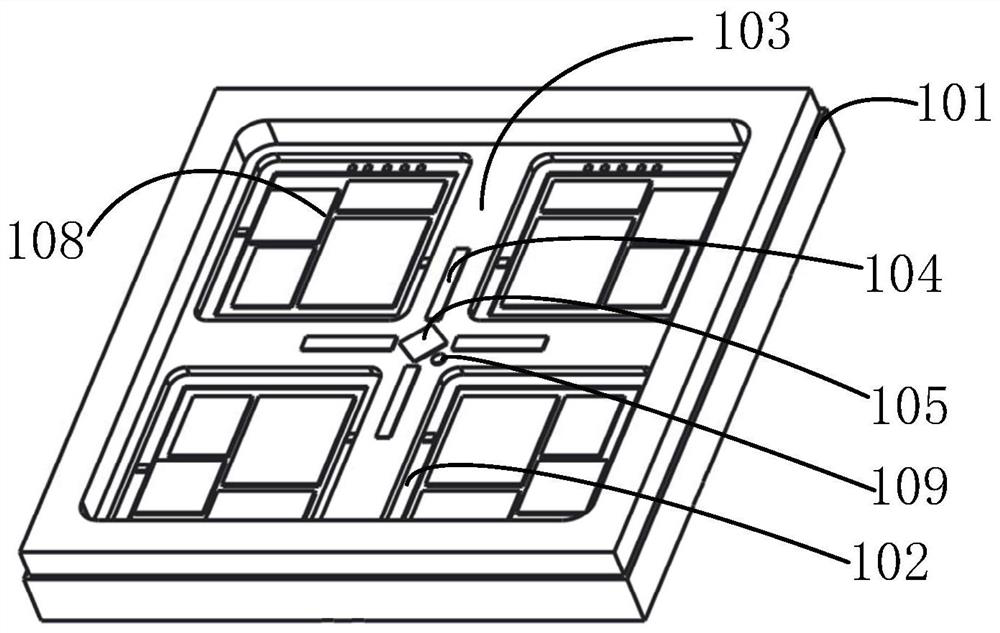

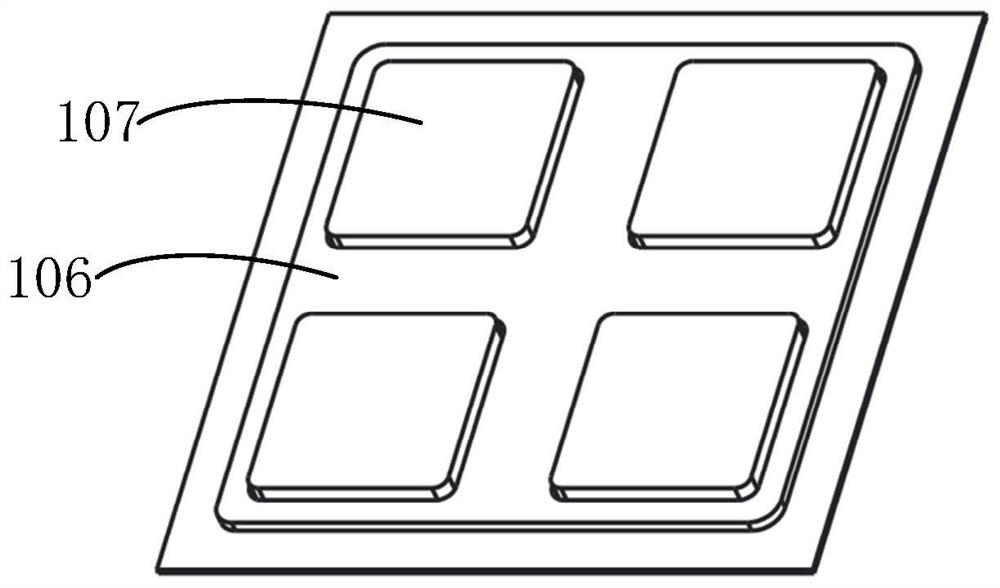

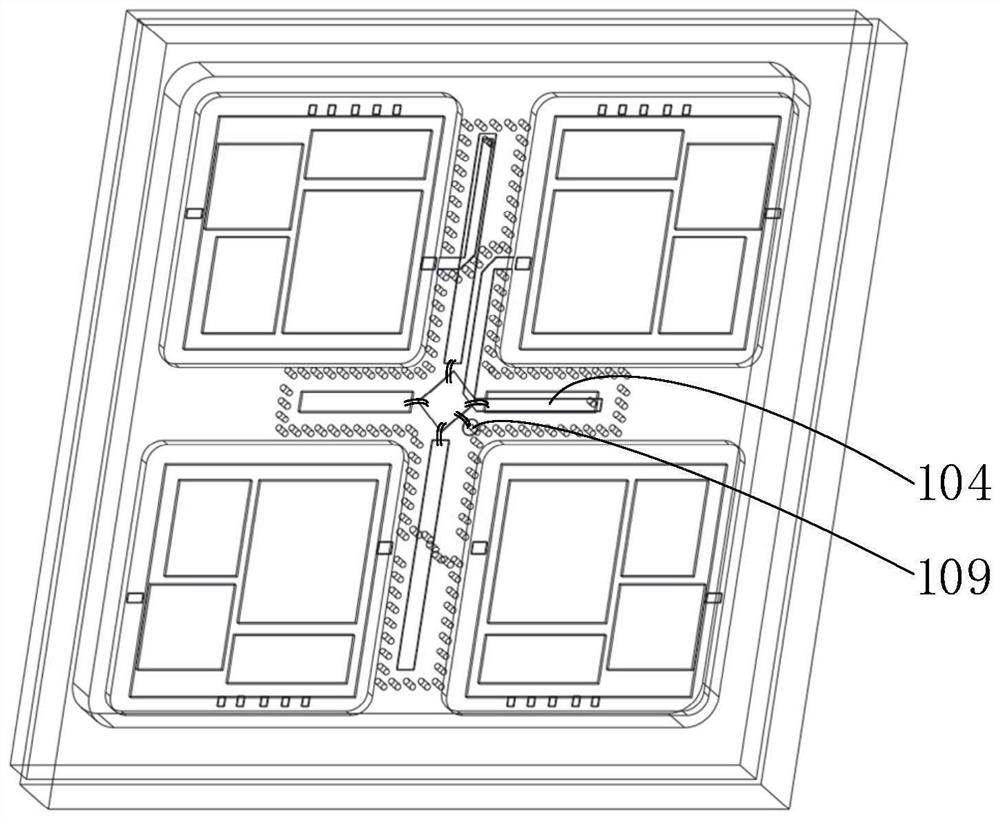

Multi-channel surface-mounted T/R assembly

PendingCN112838366AReduce usageMake the most of the interior spaceAntenna arraysAntennas earthing switches associationMetallic materialsMiniaturization

The invention discloses a multi-channel surface-mounted T / R assembly in the field of radio frequency microwave assemblies, which comprises a substrate, the upper surface of the substrate is fixedly connected with a metal ring frame, and the upper part of the metal ring frame is fixedly connected with a cover plate; the upper surface of the substrate is also provided with a plurality of grooves which are regularly distributed, radio frequency channels are arranged in the grooves, the radio frequency channels are electromagnetically isolated by partition walls among the grooves, and the partition walls and the substrate are made of the same material; an inner cavity is formed in the partition wall, and a microwave transmission line is arranged in the inner cavity; and a lumped circuit is further arranged on the substrate, one end of each radio frequency channel is connected to an antenna port of the T / R assembly, the other end of each radio frequency channel is connected to a branch port of the lumped circuit through a microwave transmission line, the electrical length of each radio frequency channel is equal to that of the microwave transmission line of the lumped circuit, and a total port of the lumped circuit is connected to a lumped port of the T / R assembly through a total port transmission line. According to the invention, a multi-channel comprehensive integrated structure is adopted, the usage amount of metal materials is reduced, the internal space of the T / R assembly is fully utilized, and the effects of miniaturization and light weight are achieved.

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

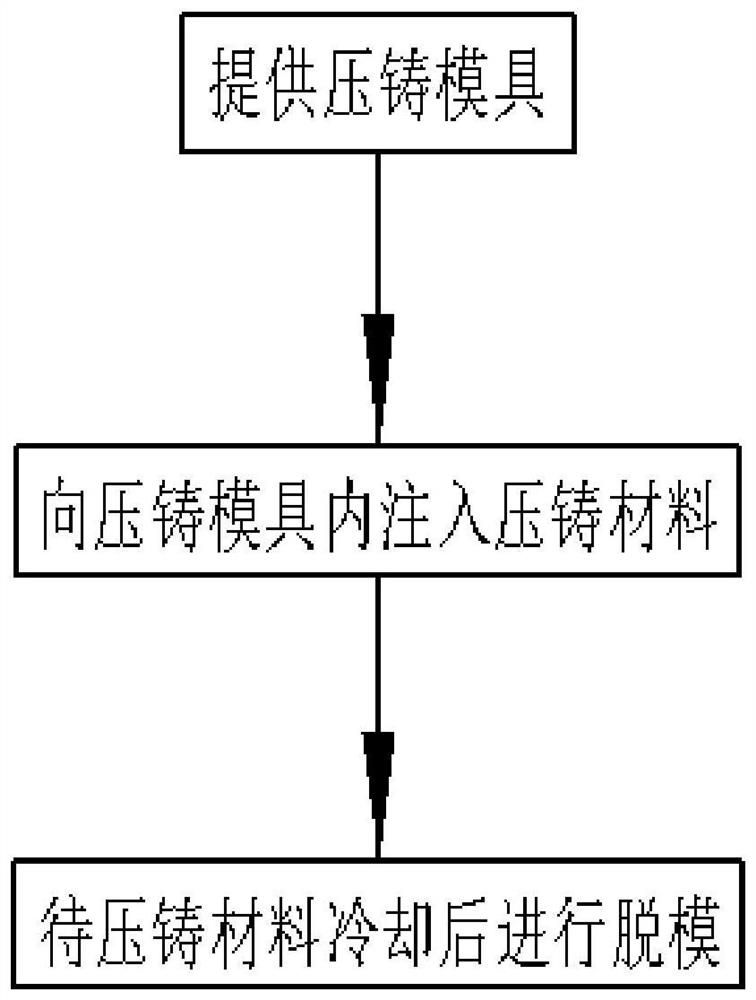

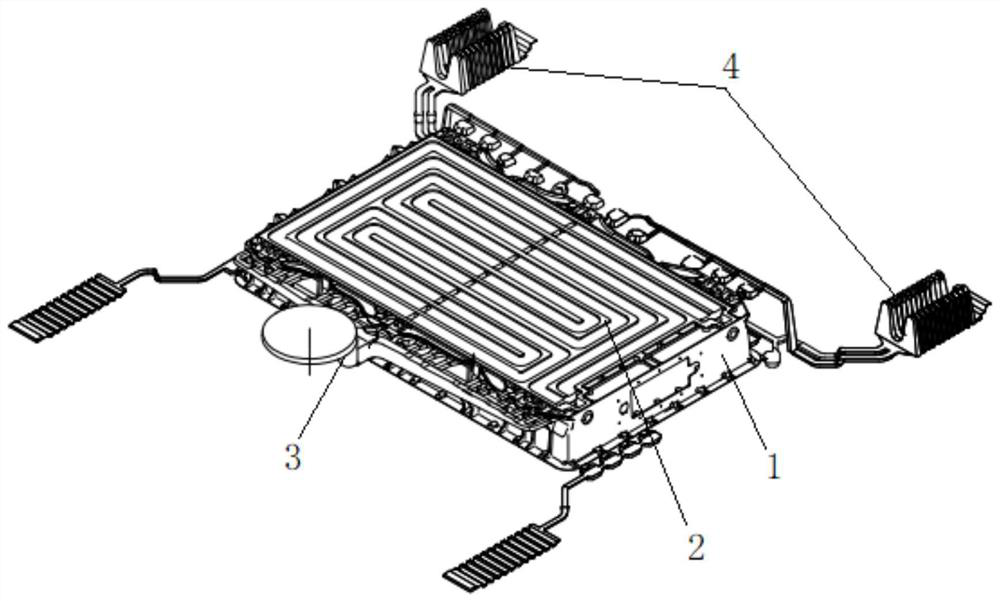

Manufacturing method of battery pack box body and battery pack box body

InactiveCN112338160ANo soldering requiredNo risk of weld seam defectsCell component detailsMechanical engineeringBattery cell

The invention discloses a manufacturing method of a battery pack box body and the battery pack box body, and relates to the technical field of battery pack box body manufacturing. The manufacturing method comprises the following steps of providing a die-casting die; injecting a die-casting material into the die-casting die; and demolding after the die-casting material is cooled. The battery pack box body is integrally formed by adopting a die-casting process, so that the strength of the battery pack box body is ensured, the wall thickness of the battery pack box body is reduced, and the lightweight effect is achieved.

Owner:安徽镁美科技有限公司

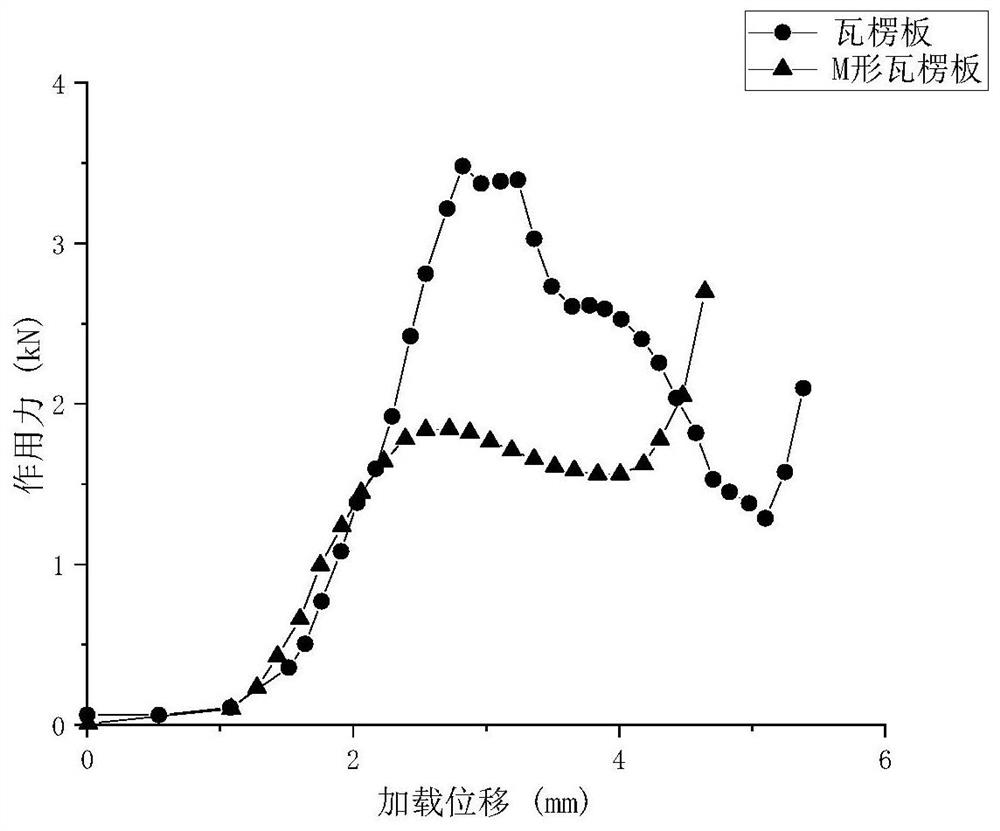

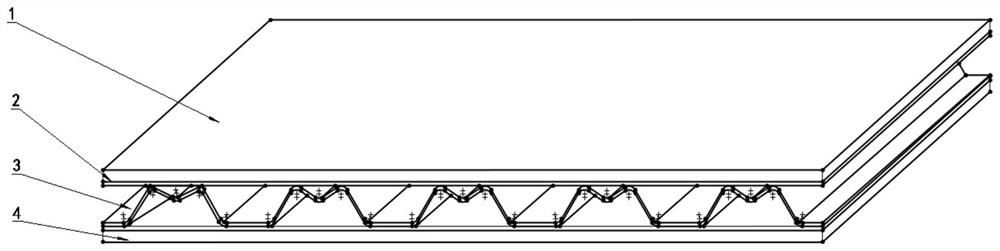

Lightweight composite automobile body plate for automobile impact buffering and energy absorption

The invention discloses a lightweight composite automobile body plate for automobile impact buffering and energy absorption, and belongs to the technical field of automobile body plates. The lightweight composite automobile body plate comprises layered fiber reinforced composite materials on the two sides and a corrugated metal component arranged in the center, and the layered fiber reinforced composite materials on the two sides are connected with the corrugated metal component in the center through an adhesive or a fastener. According to the lightweight composite vehicle body plate disclosed by the invention, the defects of brittle fracture of a traditional fiber reinforced composite material and overlarge plastic deformation of a traditional metal plate are overcome; when being impacted, the lightweight composite vehicle body plate is not easy to deform; the synergistic plastic deformation energy absorption capacity of the layered fiber reinforced composite materials on the two sides and the corrugated metal component in the center can be utilized to a greater extent, and the lightweight composite automobile body plate has more advantages than an aluminum honeycomb structure in vehicle body board application, so that the lightweight composite automobile body plate has better physical properties such as buffering, shock absorption and energy absorption than a traditional groove-shaped corrugated board.

Owner:UNIV OF SCI & TECH BEIJING

A method to make bim model lightweight

ActiveCN107247822BReduce the amount of large dataTo achieve the effect of lightweightGeometric CADDesign optimisation/simulationModelSimSoftware engineering

Owner:南京戎光软件科技有限公司

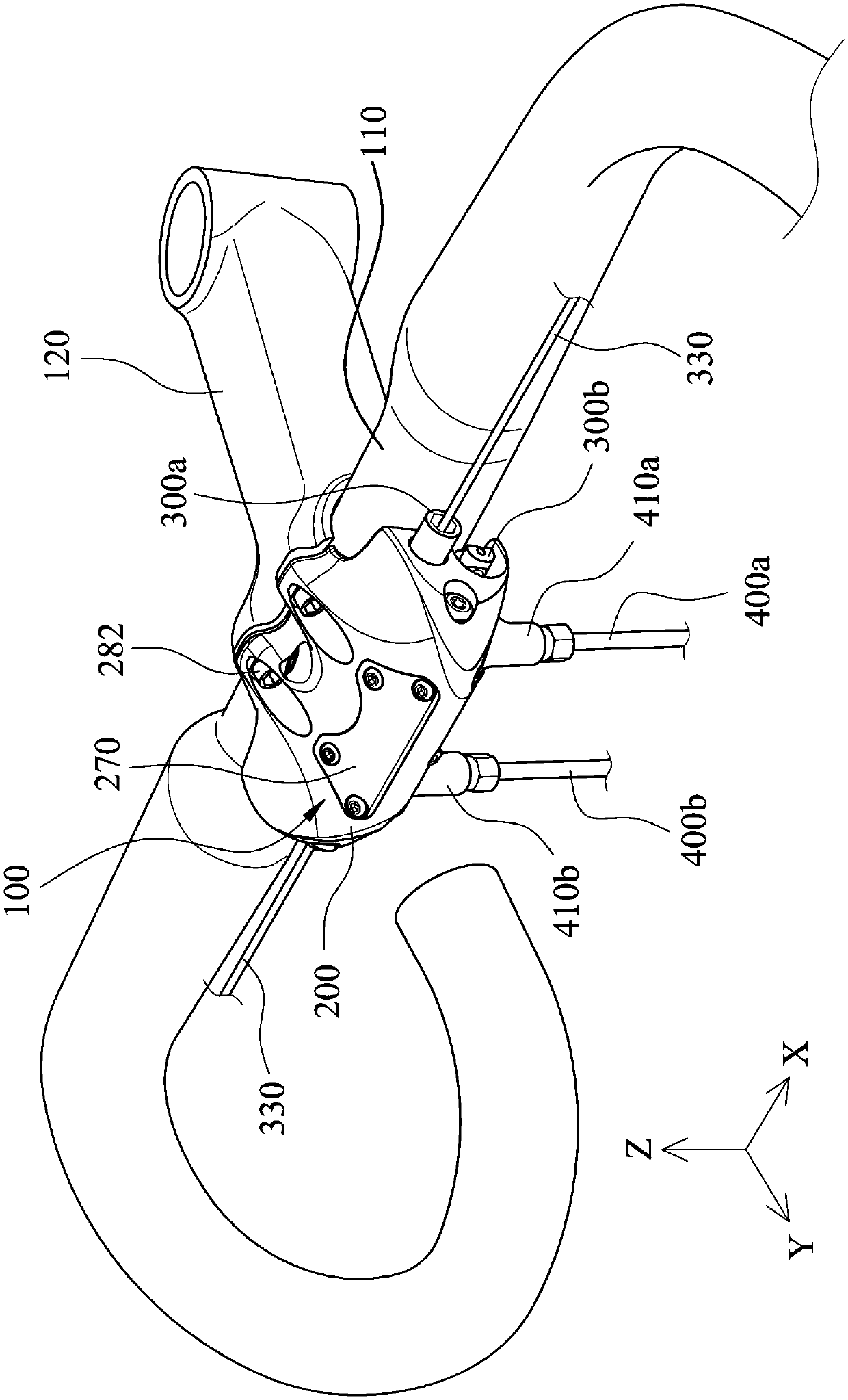

Bicycle hydraulic disc brake device

ActiveCN107010157BReduce wind resistanceNo increase in areaBrake actuating mechanismsCycle brakesHydraulic cylinderEngineering

A hydraulic disc brake device includes a cover, a hydraulic unit, an oil tube and a disc brake unit. The cover includes at least one accommodating space, at least one oil route, a proximal end and a distal end. The distal end towards a moving direction of the bicycle. The hydraulic unit includes a hydraulic cylinder and a piston. The hydraulic cylinder is assembled in the accommodating space. The piston is assembled in the hydraulic cylinder for controlling a pressure of the oil route. The disc brake unit is connected with the oil tube and controlled by a pressure of the oil tube.

Owner:GIANT BICYCLES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com