Multi-channel surface-mounted T/R assembly

A surface-mounted, multi-channel technology, applied in the direction of electrical components, antenna components, antenna coupling, etc., can solve problems such as difficult to meet the development needs of phased array technology, and achieve the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

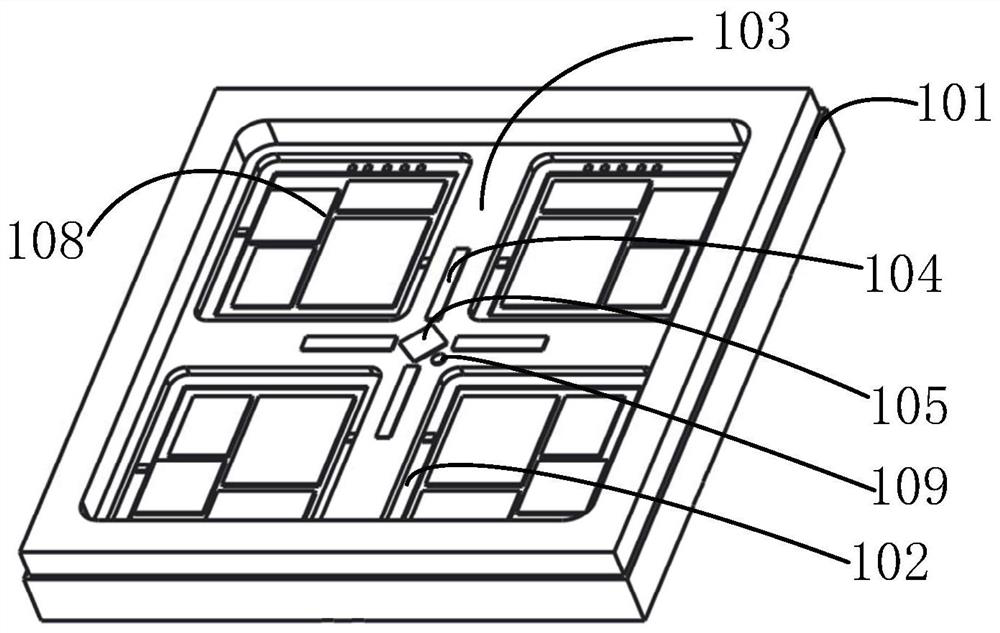

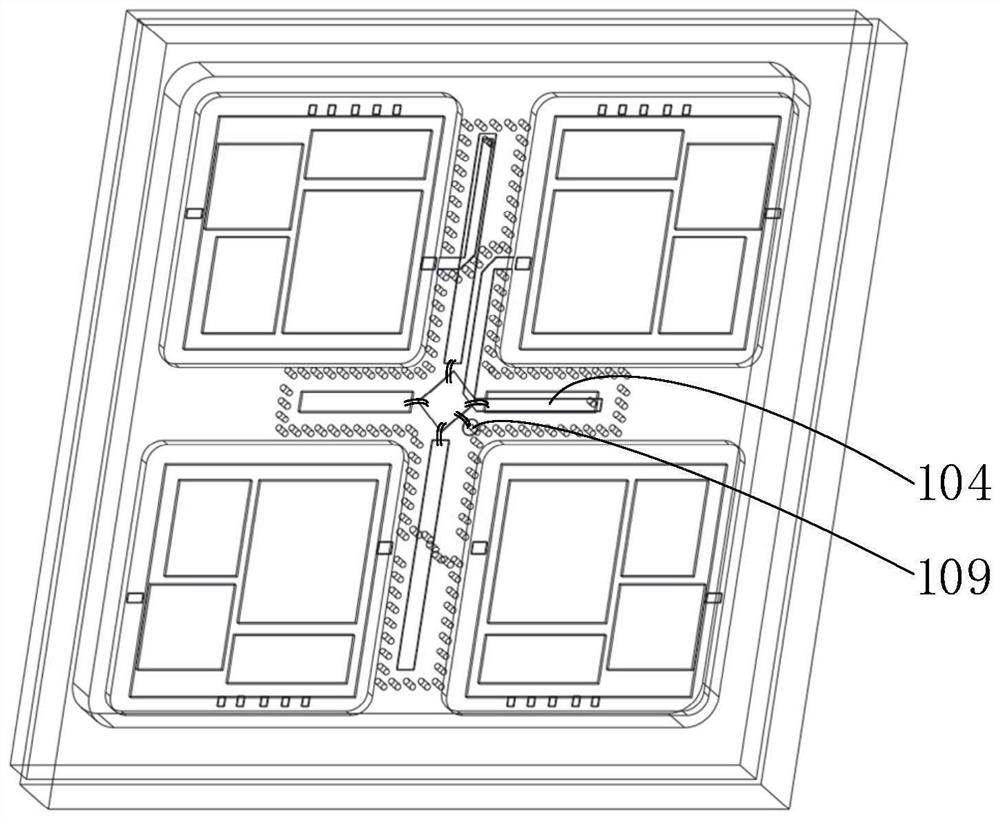

[0033] Embodiment 1, the number of grooves 102 is four symmetrically distributed in parallel, the number of radio frequency channels 108 is also four, the partition wall 103 is distributed between each groove 102 in a cross shape, and the lumped circuit 105 is located in the partition wall At the center of 103 , the electrical lengths of each radio frequency channel 108 and the microwave transmission line 104 of the lumped circuit 105 are equal, so that the insertion loss is consistent. The cavity of the partition wall 103 constitutes a multi-channel structure, and the microwave transmission lines 104 are distributed along the structure direction of the cavity of the partition wall 103 , making full use of the three-dimensional space formed by the partition wall 103 . With this structure, a relatively closed cavity is formed inside the partition wall 103, and the radio frequency coaxial hole and the strip line of the microwave transmission line 104 are arranged in the cavity of...

Embodiment 2

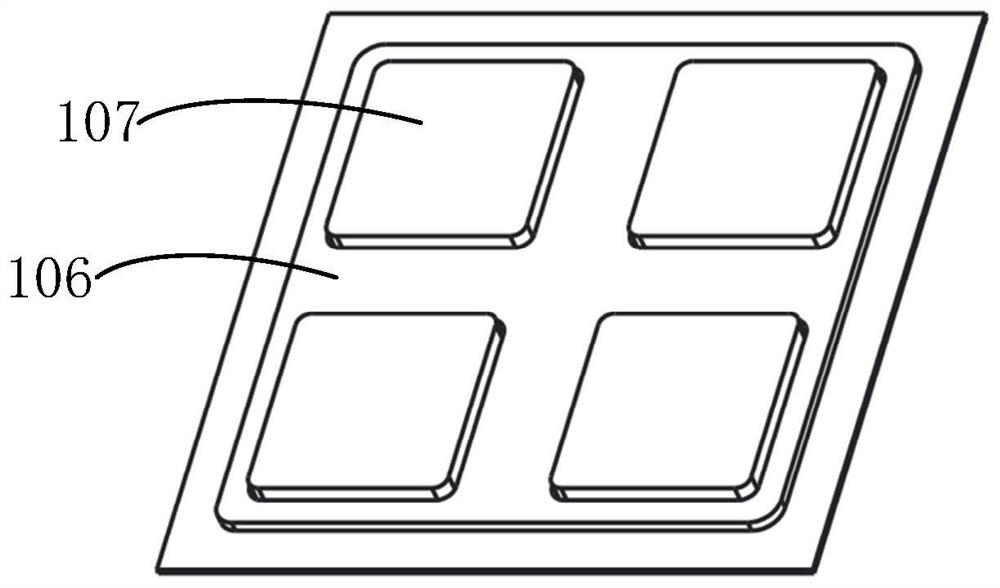

[0034] In Embodiment 2, several grooves 102 are provided and distributed evenly in a circular shape, and the number of radio frequency channels 108 is the same as the number of grooves 102 . The partition wall 103 extends outward until it touches the inner wall of the substrate 101, thereby separating each groove 102, and the lumped circuit 105 is located at the center of the partition wall 103, so that each radio frequency channel 108 and the lumped circuit 105 are connected The electrical lengths of the microstrip lines 104 are equal. Similar to Embodiment 1, the microwave transmission line 104 and the mains transmission line 109 in this embodiment are also arranged along the structural direction of the partition wall 103, making full use of the internal space of the T / R assembly.

[0035]The upper surface and the lower surface of the partition wall 103 are provided with a metal film layer, and the upper surface and the lower surface are used for laying the microwave transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com