Wave type carbon felt electromagnetic shielding structural body and preparation method thereof

An electromagnetic shielding and wave-type technology, which is applied in the fields of magnetic field/electric field shielding, chemical instruments and methods, electrical components, etc., can solve the problems of limited electromagnetic wave scattering effect, limited absorption performance, small carbon felt, etc., achieving good application prospects and satisfying Shielding requirements, low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

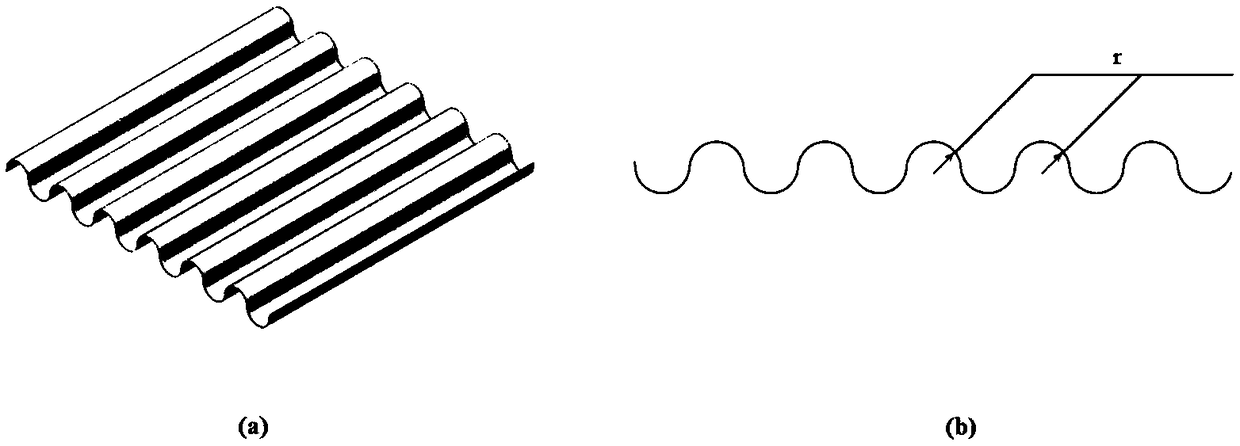

[0045] The invention provides a method for designing and preparing a corrugated carbon felt electromagnetic shielding structure. The structure is formed by combining multiple layers of corrugated carbon felt according to a certain angle and bonding with an adhesive.

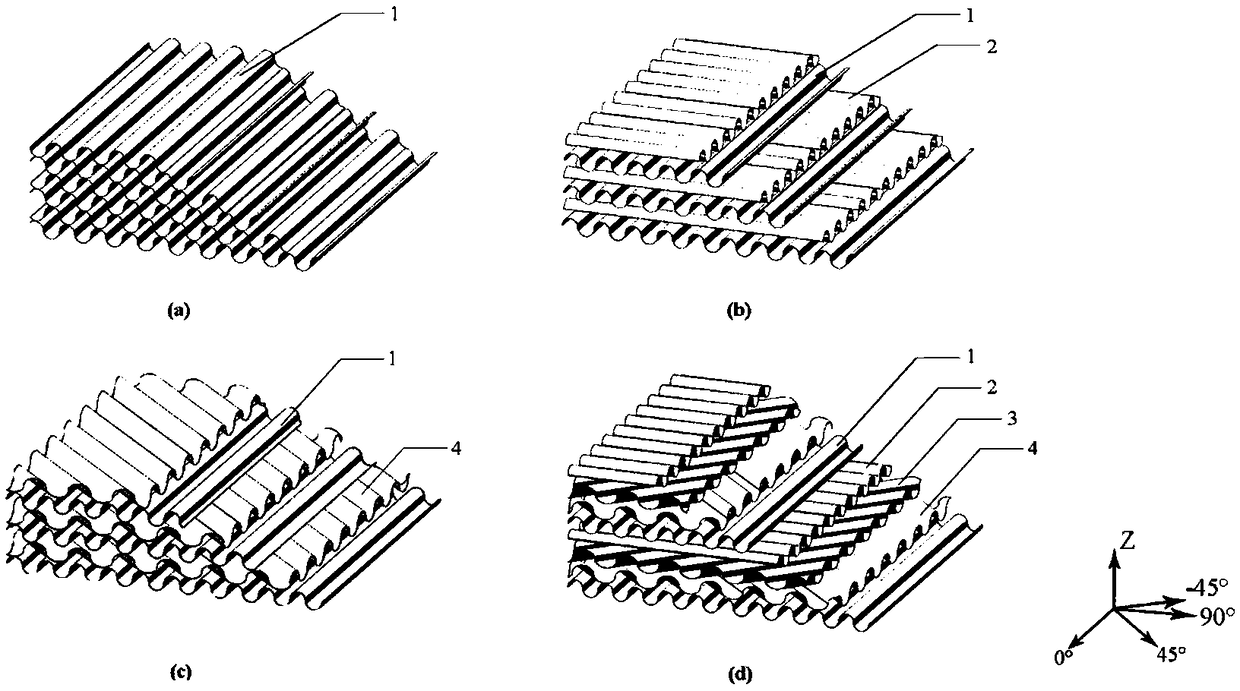

[0046] In the present invention, the corrugated carbon felt electromagnetic shielding structure can be designed as attached figure 2 Multiple combination angles shown. in the attached figure 2 In, (a) 6 layers[0] 6 Schematic diagram of the structure of the wavy carbon felt assembly; (b) 6 layers [0 / 90] 3 Schematic diagram of the structure of the wavy carbon felt assembly; (c) 6 layers [0 / 45] 3 Schematic diagram of the structure of the wavy carbon felt assembly; (d) 8 layers [0 / ±45 / 90] 2 Structural diagram of the wavy carbon felt assembly: 1 is a single-layer wavy carbon felt with a stacking angle of 0°, 2 is a single-layer wavy carbon felt with a stacking angle of 90°, and 3 is a single-layer wavy carbon felt...

Embodiment 1

[0053] This embodiment adopts fiber length 6mm, weight per unit area 10g / m 2 The carbon felt is used as the functional body, epoxy resin is used as the matrix, and an electromagnetic shielding structure with a curvature radius of 4 mm of 5-layer unit wave carbon felt is prepared by molding method, and the laying angle is figure 2 [0] in (a) 6 . The adhesive is epoxy resin, and the release agent is simethicone.

[0054] Step 1: Preparation of resin curing agent

[0055] According to the mass ratio of epoxy resin: imidazole = 100:3, weigh the corresponding mass of epoxy resin and imidazole, mix the above two solutions of a certain mass at room temperature and keep stirring until the solution is homogeneous.

[0056] Step 2: Pretreatment of carbon felt and mold

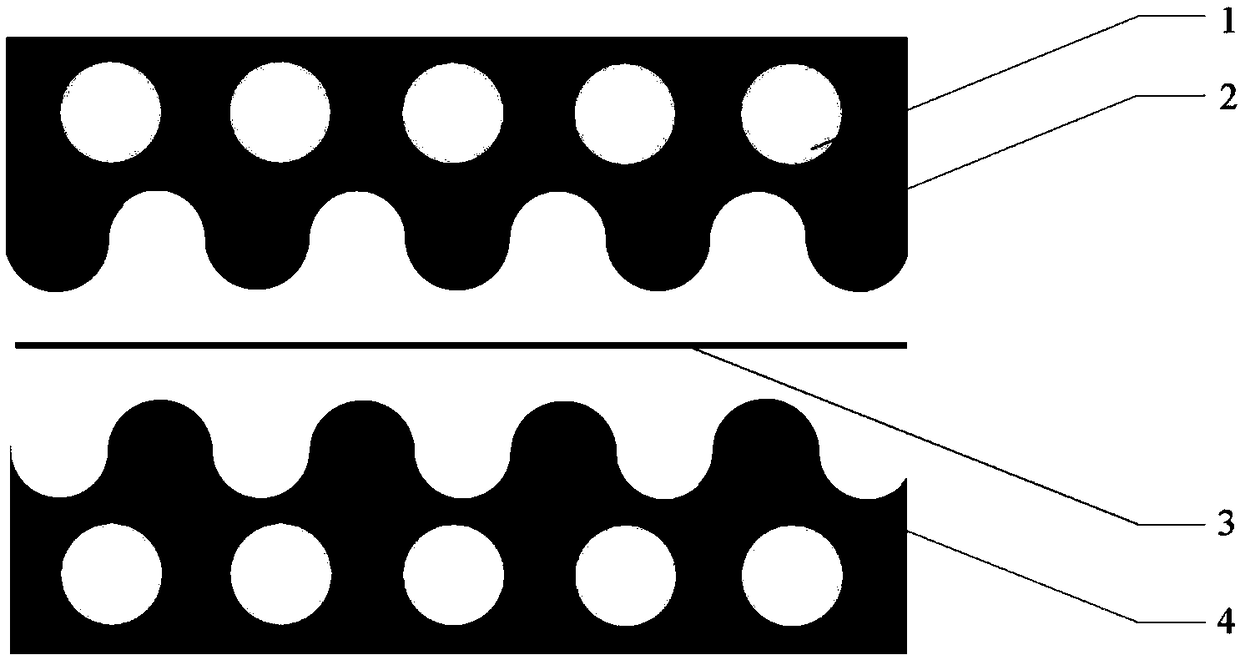

[0057] According to attached image 3 Cut the carbon felt to the appropriate size for the flat-panel mold shown. Immerse the cut carbon felt in the prepared resin solution to ensure that the resin solution is evenl...

Embodiment 2

[0064] This embodiment adopts fiber length 8mm, weight per unit area 5g / m 2 The carbon felt is used as the functional body, polyethylene is used as the matrix, and an electromagnetic shielding structure with a radius of curvature of 6-layer unit wave carbon felt of 4 mm is prepared by using the pultrusion process, and the laying angle is figure 2 [0 / 90] in (c) 3 . The adhesive is polybutadiene.

[0065] Step 1: Pretreatment of carbon felt

[0066] The matrix resin uses polyvinyl chloride, and the carbon felt is covered with two layers of polyvinyl chloride film to form a sandwich structure as shown in the attached Figure 6 shown. Then put the wrapped carbon felt and resin film into the attached Figure 6 Carry out pre-curing roll pressing in the heating furnace shown in 3, and the pre-curing temperature is 140°C.

[0067] Step 2: Pultrusion molding of single-layer corrugated carbon felt

[0068]Put the pretreated carbon felt and resin film in the middle of the flat mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com