Thinned belted layer component for radial tire

A radial tire and belt layer technology, applied in the field of thinning belt layer components, can solve the problems of thinning and reducing the thickness of the belt layer adhesive layer, achieve thinning of the adhesive layer thickness, ensure structural stability, and improve Green The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

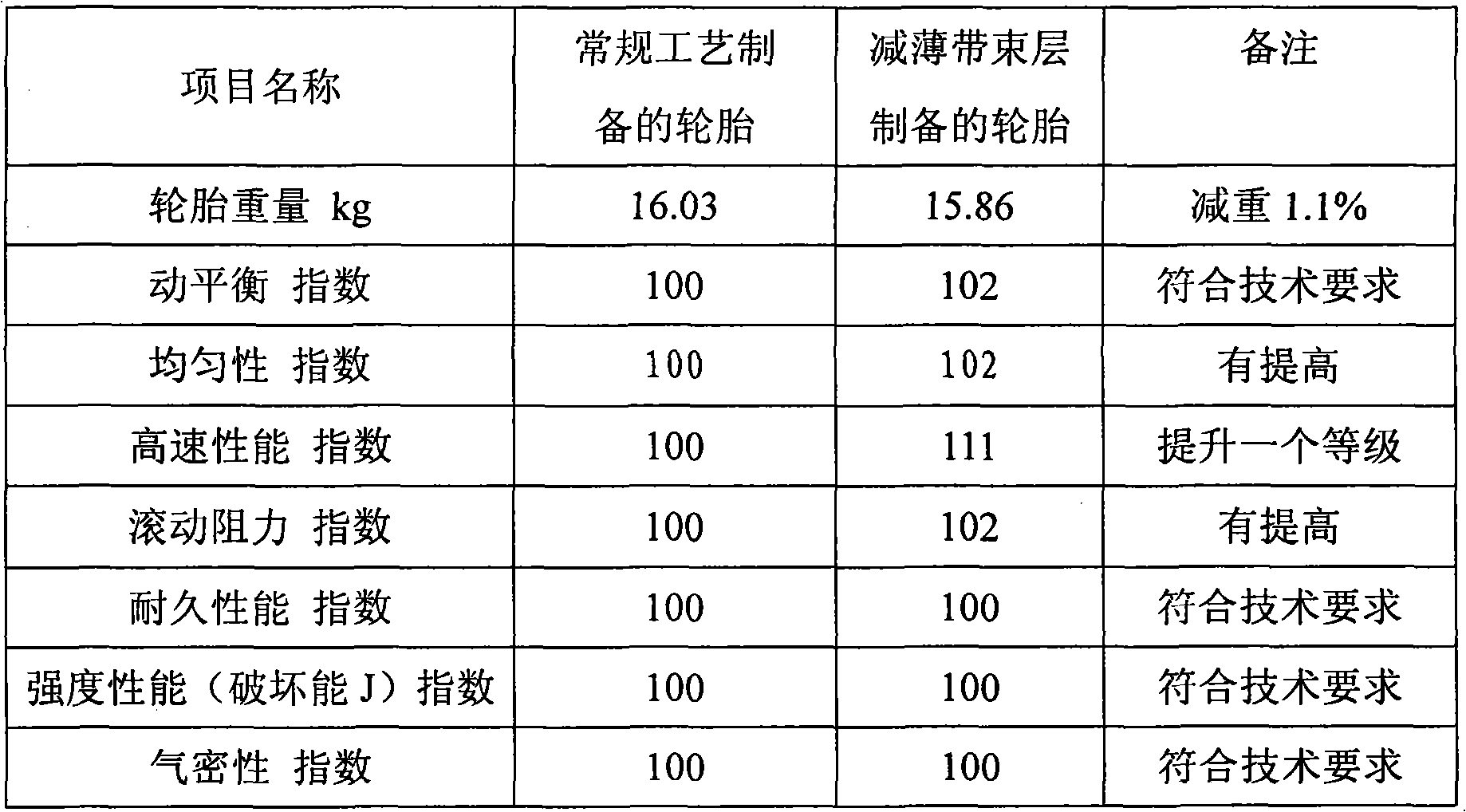

[0012] Example: P235 / 75R15 radial tire

[0013] Below in conjunction with specific embodiment further describe the present invention in detail,

[0014] A thinning belt part for radial tires, comprising a belt skeleton 1 and a rubber covering layer 2, the skeleton 1 is made of a high-modulus cord material, including steel cords or fiber cords, and the cord layer The number is single-layer or multi-layer, and the rubber layer 2 is raw rubber of natural rubber or a blend of natural rubber and synthetic rubber. According to the formula of 100 parts by mass, 5 parts of sensitizer triallyl isocyanurate are added Acetate (TAIC), mixed in a 50L internal mixer according to the conventional process, and made into a thinning belt layer sheet. Adjust the roller pitch of the calender, and perform steel cord expansion, calendering, gluing and winding according to the conventional process to obtain a double-layer belt part with a standard length and width and a thickness of 2.4 mm. Fix th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com