Large anchor and mooring machine pump station lightweight composite general valve group

A general-purpose valve, anchor winch technology, applied in mechanical equipment, servo motor components, fluid pressure actuating system components, etc., can solve the problems of single function of safety valve group, high pump pressure, energy waste, etc., to achieve universal Enhanced compatibility and interchangeability, optimized tube holes, and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

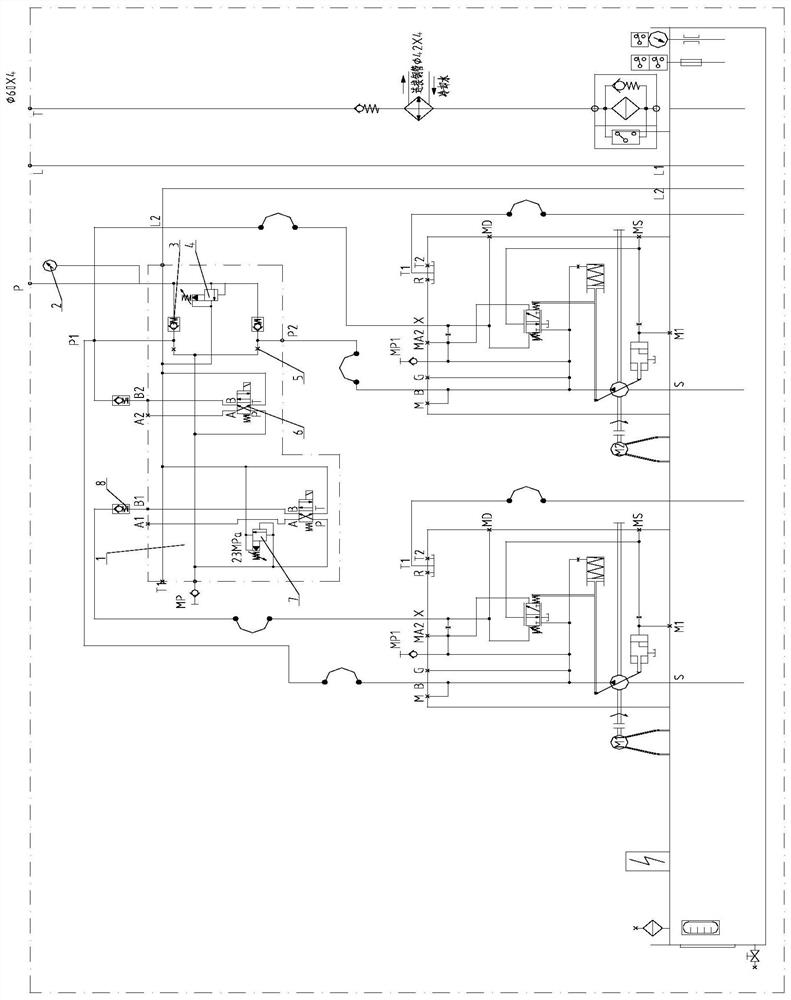

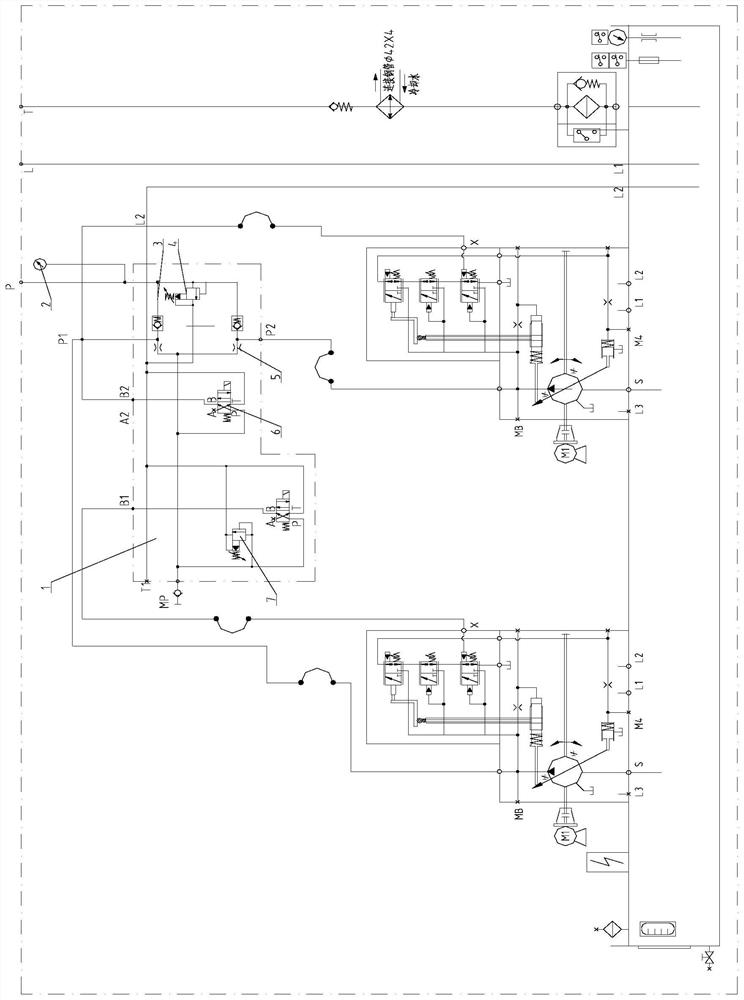

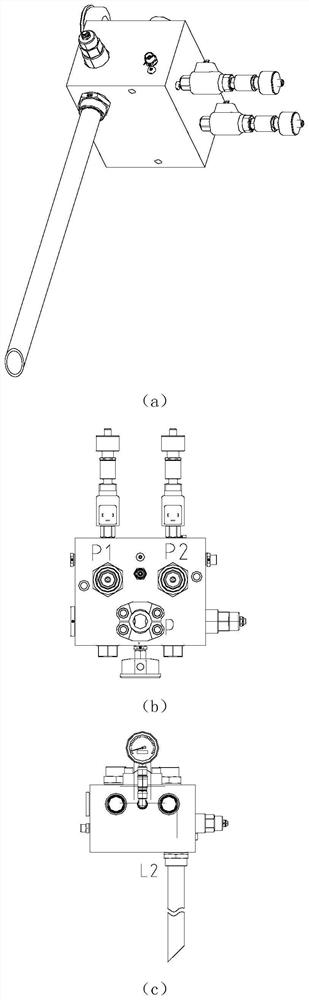

[0018] This embodiment proposes a light-weight composite general-purpose valve group of a large-scale anchor winch pump station, and its structure is shown in the figure.

[0019] Combining and optimizing the previous multiple valves into a valve group, so that the product is lighter than before, smaller in size, easier to install, and reduces vibration and noise problems during startup. By adopting a special valve block hole design, Different combinations of plug-in overflow valve, plug-in two-position three-way electromagnetic reversing valve, plug-in check valve, damping plug and plug are used to meet the requirements of double-pump isolation, safety protection, Unloading start and double pump synchronous control and other functions. The versatility of this valve group is reflected in the fact that it can control pump groups with different control functions. 2. The main overflow valve 4 is installed behind the one-way valve 3, so that double pumps or multi-pumps can share ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com