Aluminum alloy honeycomb plate

A technology of aluminum alloy and honeycomb panel, which is applied in the field of aluminum alloy to achieve the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and effect of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

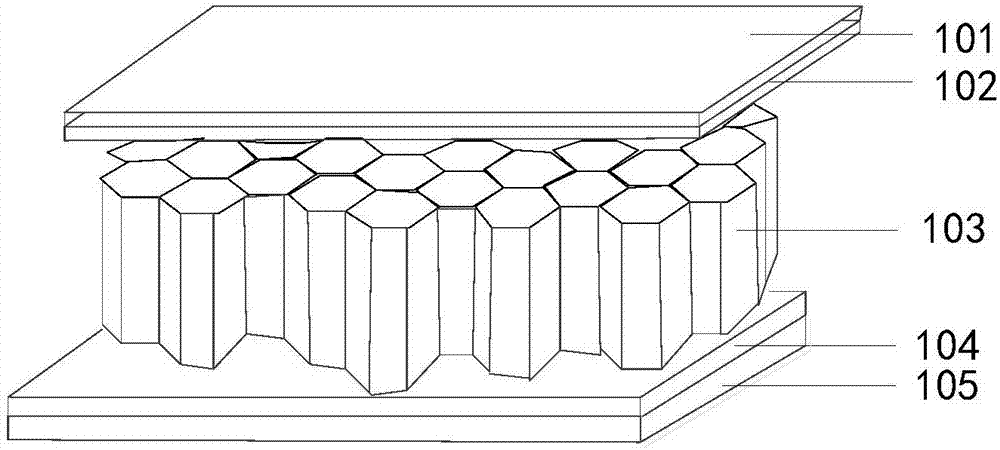

[0017] see figure 1 , figure 1 It is a structural schematic diagram of an embodiment of the aluminum alloy honeycomb panel of the present invention. This embodiment provides an aluminum alloy honeycomb panel, which includes: a first aluminum alloy layer 101, a first adhesive layer 102, a first honeycomb core layer 103, and a second adhesive layer 104 that are stacked in sequence , the second aluminum alloy layer 105, wherein the first aluminum alloy layer 101 and / or the second aluminum alloy layer 105 is one of aluminum-copper alloy, aluminum-silicon alloy, and aluminum-zinc alloy.

[0018] Aluminum alloy is the most widely used non-ferrous metal structural material in industry, and has been widely used in aviation, aerospace, automobile, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com