Prestress carbon fiber aerial ladder truck cantilever crane

A prestressed and carbon fiber technology, applied in the field of special vehicles, can solve problems such as the inability to guarantee the stability and safety of the vehicle, the low level of parts matching and manufacturing, and the lack of in-depth research on intelligent control settings, etc., to achieve improved deformation and high strength. Effect of improving performance and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the description of the accompanying drawings and specific embodiments. Various modifications, substitutions and alterations made according to the general techniques and common methods in this field shall be included within the scope of the present invention.

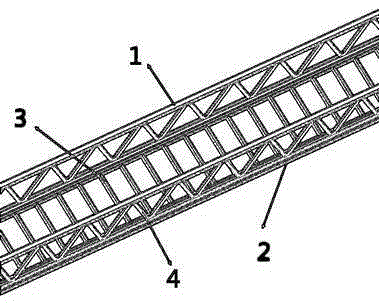

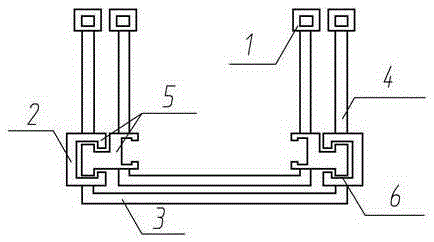

[0023] Such as figure 1 , figure 2 , image 3 shown.

[0024] The boom structure of the prestressed aerial ladder truck in the present invention is mainly composed of ladder strings 1, pillars 2, ladder pedals 3, side inclined beams 4, C-shaped inner pillars 5, and carbon fiber materials 6. The pillars 2 and C-shaped inner pillars 5 are mainly The cross-section of the beam is C-shaped, and the inner side of the pillar is pasted with prestressed carbon fiber material 6 .

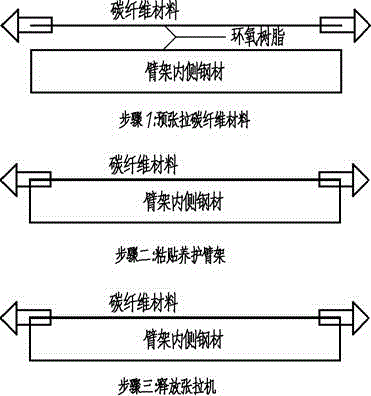

[0025] The method for applying the prestress in the present invention is as follows: using a stretching machine to stretch the carbon fiber material at a slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com