Integral wheel stamping and spinning manufacturing method

A manufacturing method and an integrated technology, applied in the manufacturing field, can solve the problems of difficulty, need more equipment, and the inability to optimize the thickness of the rim part, and achieve the effect of high surface accuracy, shape accuracy, and wall thickness optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

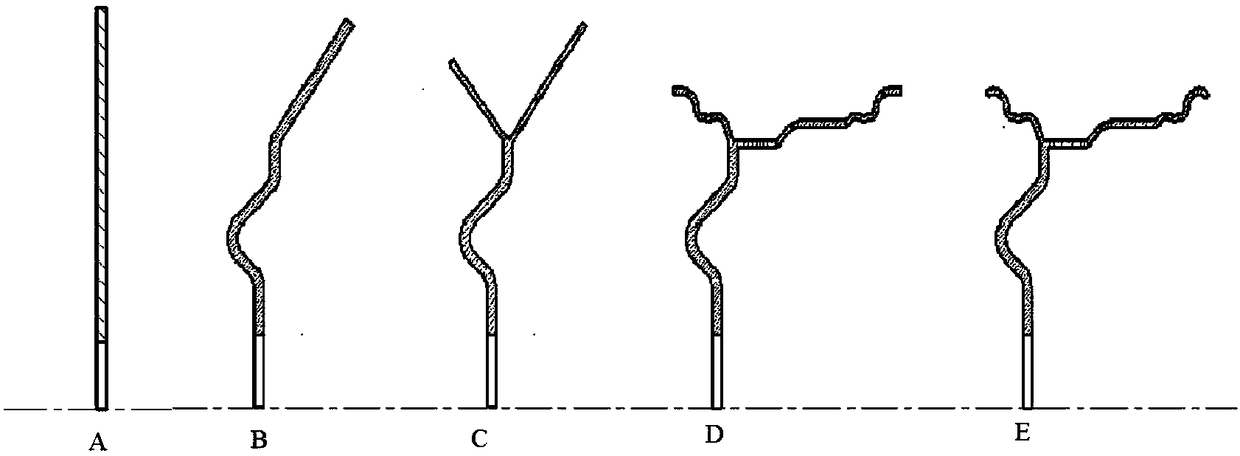

[0039] In Examples 1-7, figure 1 The specific steps of the forming process path of the integral wheel punching and spinning manufacturing method shown are as follows:

[0040] Step A: blanking and punching the center hole, see the three-dimensional structure of the blank formed in step A figure 2 ;

[0041] Step B: Stamping, please refer to Figure 7 ,Such as Figure 7 As shown, the blank 1 prepared by blanking and center punching is placed between the punching dies 2, 4 and pressed tightly. The middle part of the blank 1 is formed into a spoke shape, and the outer edge of the blank 1 is used to subsequently form the rim shape, step B The three-dimensional structure of the formed blank see image 3 ;

[0042] Step C: Wheel rim pre-spinning, its specific application is as Picture 8 As shown, the pre-spinning upper core mold 10 and the pre-spinning lower core mold 12 are used to clamp the blank 1, and the spinning upper core mold 10 and the spinning lower core mold 12 drive the blank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com