Polyurethane-coated hollow glass micro-bead toughened cast nylon 6 composite material and preparation method thereof

A technology of hollow glass microspheres and cast nylon, which is applied in the field of polyurethane-coated hollow glass microspheres to toughen cast nylon 6 composite materials and its preparation, and can solve problems such as poor compatibility, poor toughening effect, and reduced tensile strength. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

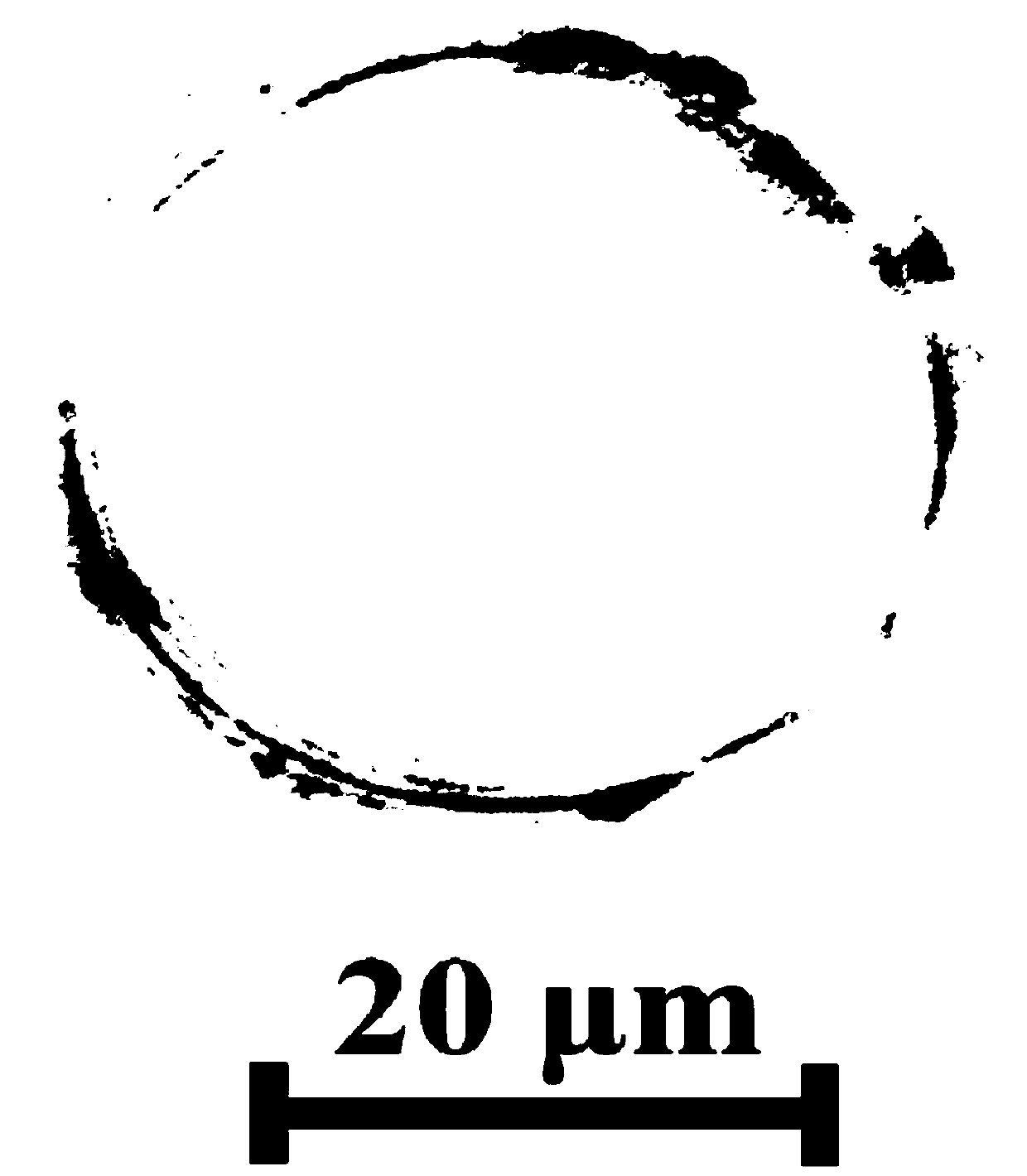

Image

Examples

Embodiment 1

[0026] This embodiment provides a method for preparing a polyurethane-coated hollow glass microsphere toughened cast nylon 6 composite material, which specifically includes the following steps:

[0027] (1) Weigh 10g of ethylene glycol and dissolve it in 140g of acetone solvent to make solution A with a concentration of 6.67%; weigh 73.5g of diphenylmethane diisocyanate (MDI) and dissolve it in 700g of acetone solvent to make a concentration of 9.50% solution B;

[0028] Mix solution A and solution B, and form a uniform mixed solution after stirring, shaking, and ultrasonication; wherein, the mixed system contains 10g (0.147mol) of ethylene glycol, 73.5g (0.294mol) of diphenylmethane Isocyanate (MDI), the ratio of the amount of hydroxyl substances in the mixed solution to the amount of isocyanate group substances is 1:2;

[0029] Add the mixed solution into a high-pressure sprayer, spray the mixed solution on the surface of the glass beads by spraying, and stir rapidly to mak...

Embodiment 2

[0037]This embodiment provides a method for preparing a polyurethane-coated hollow glass microsphere toughened cast nylon 6 composite material, which specifically includes the following steps:

[0038] (1) Weigh 9.2g of glycerol, dissolve it in 40g of benzene solvent, and make a solution A with a concentration of 18.70%; weigh 31.32g of 2,4-toluene diisocyanate (TDI) and dissolve it in 150g of benzene solvent In, be made into the solution B that concentration is 17.21%;

[0039] Mix solution A and solution B, and form a uniform mixed solution after stirring, shaking and ultrasonication. The mixed system contains 9.2g (0.1mol) glycerol, 31.32g (0.18mol) 2,4-toluene di isocyanate), the ratio of the amount of hydroxyl substances in the mixed solution to the amount of isocyanate group substances is 1:1.2;

[0040] Add the mixed solution into a high-pressure sprayer, spray the mixed solution on the surface of the glass beads by spraying, and stir rapidly to make the surface of the...

Embodiment 3

[0047] This embodiment provides a method for preparing a polyurethane-coated hollow glass microsphere toughened cast nylon 6 composite material, which specifically includes the following steps:

[0048] (1) Weigh 12g of polyethylene glutarate with a molecular weight of 800, dissolve it in 200g of ethyl acetate solvent, and make solution A with a concentration of 10.71%; weigh 3.78g of hexamethylene diisocyanate (HDI) was dissolved in 100g of ethyl acetate solvent to prepare a solution B with a concentration of 3.64%;

[0049] Mix solution A and solution B, and make the two solutions form a uniform mixed solution through stirring, shaking and ultrasonication. The mixed system contains 12g (0.015mol) of polyethylene glycol glutarate, 3.78g of hexamethylene diisocyanate (HDI) (0.0225mol), the amount of hydroxyl substances in the mixed solution is equal to the amount of isocyanate group substances The ratio is 1:1.5;

[0050] Add the mixed solution into a high-pressure sprayer, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com