An interlocking aluminum alloy air storage cylinder assembly and manufacturing method thereof

A production method and the technology of the air storage tank, which are applied in the direction of the hydraulic brake transmission device, etc., can solve the problems of poor installation effect, achieve the effects of convenient operation, light weight effect, and low installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

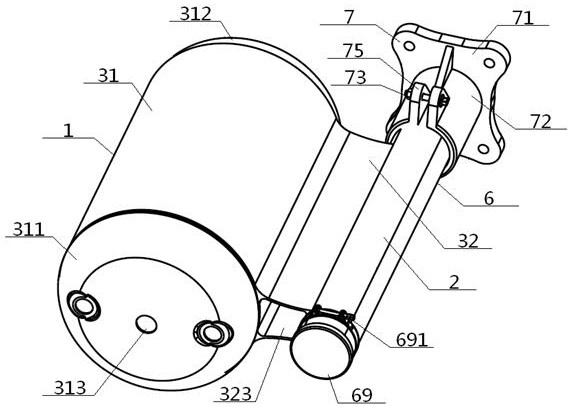

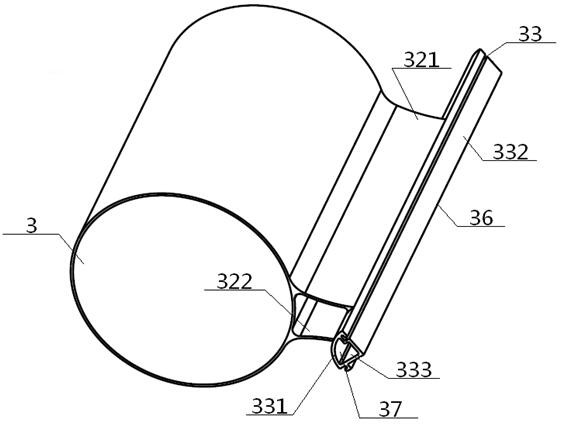

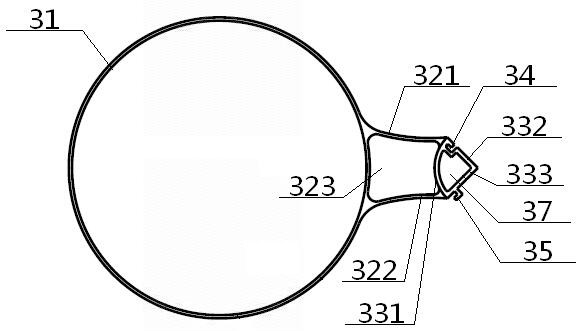

[0066] see Figure 1 to Figure 13, an interlocking aluminum alloy gas storage cylinder assembly, including a cylinder unit 1 and a fixing device 2 connected to each other, the cylinder unit 1 includes a No. 1 gas storage cylinder 3; the fixing device 2 includes a support rod 6, and the support rod The inside of 6 is provided with intersecting pole A inner cutting surface 61 and pole second inner cutting surface 62, and the pole first inner cutting surface 61 is connected with a pole first lock convex strip 611, and the pole second inner cutting surface 62 is provided with a pole second lock groove 621; The No. 1 gas tank 3 includes a No. 1 cylinder body 31, a No. 1 connecting portion 32 and a No. 1 interlocking portion 33, and the No. 1 interlocking portion 33 includes a No. 1 inner connecting plate 331, a No. 1 upper sloping plate 332 and a No. There is a No. 1 lock groove 34 on the No. 1 upper slant plate 333 and the No. 1 upper slant plate 332. A No. 1 lock protrusion 35 is...

Embodiment 2

[0069] Basic content is the same as embodiment 1, the difference is:

[0070] The cylinder unit 1 also includes a No. 2 air storage tank 4 having the same structure as the No. 1 gas storage tank 3. The No. 2 gas storage tank 4 includes a No. 2 cylinder body 41, a No. 2 inner connecting plate 431, a No. Lower inclined plate 433, No. 2 lock groove 44 and No. 2 lock convex strip 45; the inner cut surface 61 of the rod first and the inner cut surface 62 of the rod second are located on the first inclined plane 66, and the outer end of the first cut surface 61 of the rod is connected with Rod A lock convex strip 611, the inner end of the rod A inner cut surface 61 is connected with the inner end of the rod B inner cut surface 62, and the outer end of the rod B inner cut surface 62 is provided with a rod B lock groove 621, and the rod A lock convex The bar 611 is interlocked with the No. 1 lock groove 34, the No. 1 lock convex strip 35 is interlocked with the No. 2 lock groove 44, a...

Embodiment 3

[0072] Basic content is the same as embodiment 1, the difference is:

[0073] The cylinder unit 1 also includes a No. 2 air storage tank 4 having the same structure as the No. 1 gas storage tank 3. The No. 2 gas storage tank 4 includes a No. 2 cylinder body 41, a No. 2 inner connecting plate 431, a No. The lower inclined plate 433, No. 2 lock groove 44 and No. 2 lock protrusion 45; the inside of the support rod 6 is also provided with a rod C inner cut surface 63 and a rod D inner cut surface 64, and the outside of the rod C inner cut surface 63 The end is connected with a rod C lock convex strip 631, the inner end of the rod C inner cut surface 63 is connected with the inner end of the rod A inner cut surface 61, and the outer end of the rod A inner cut surface 61 is connected with a rod A lock convex strip 611, the rod The outer end of the inner cutting surface 64 of the third rod is provided with a lock groove 641 of the third rod. Groove 621, the No. 2 inclined plane 67 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com