Patents

Literature

30results about How to "Improve poor quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

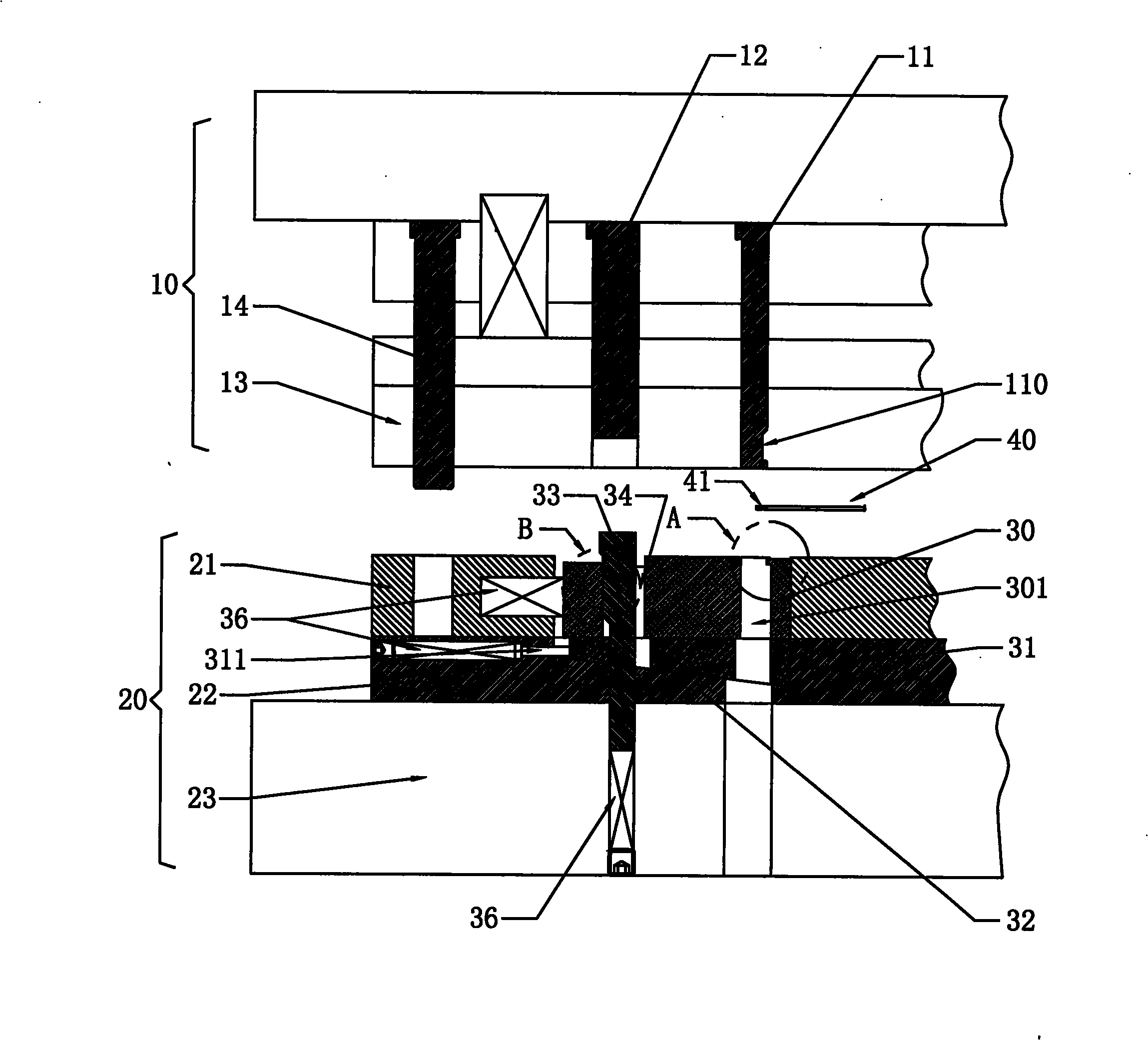

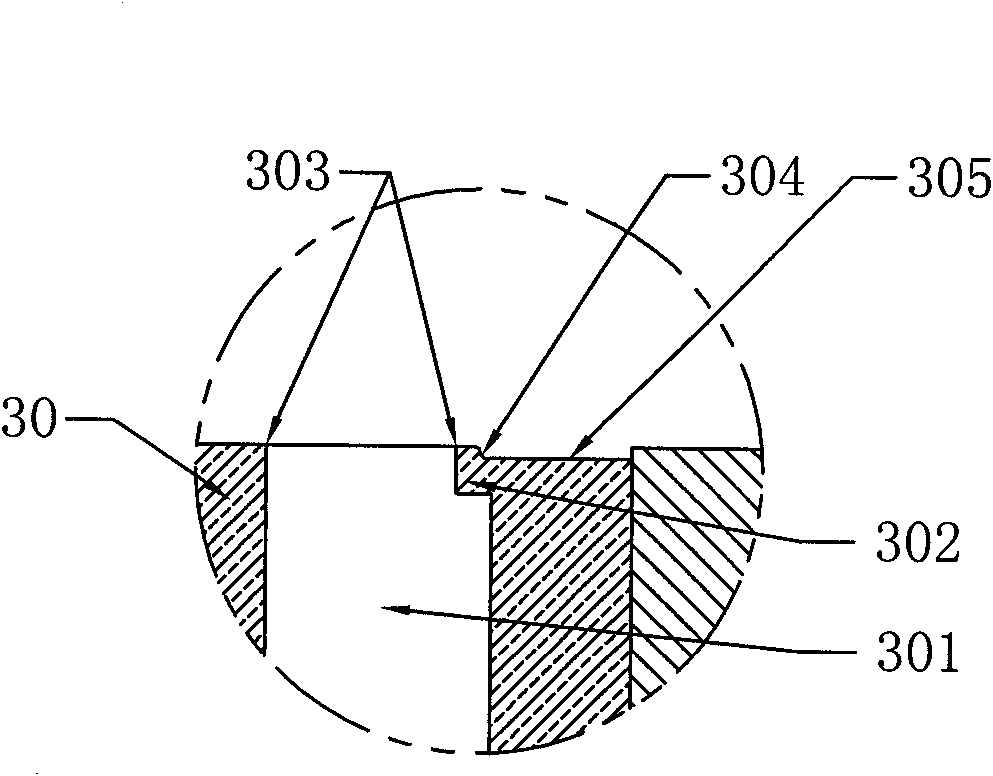

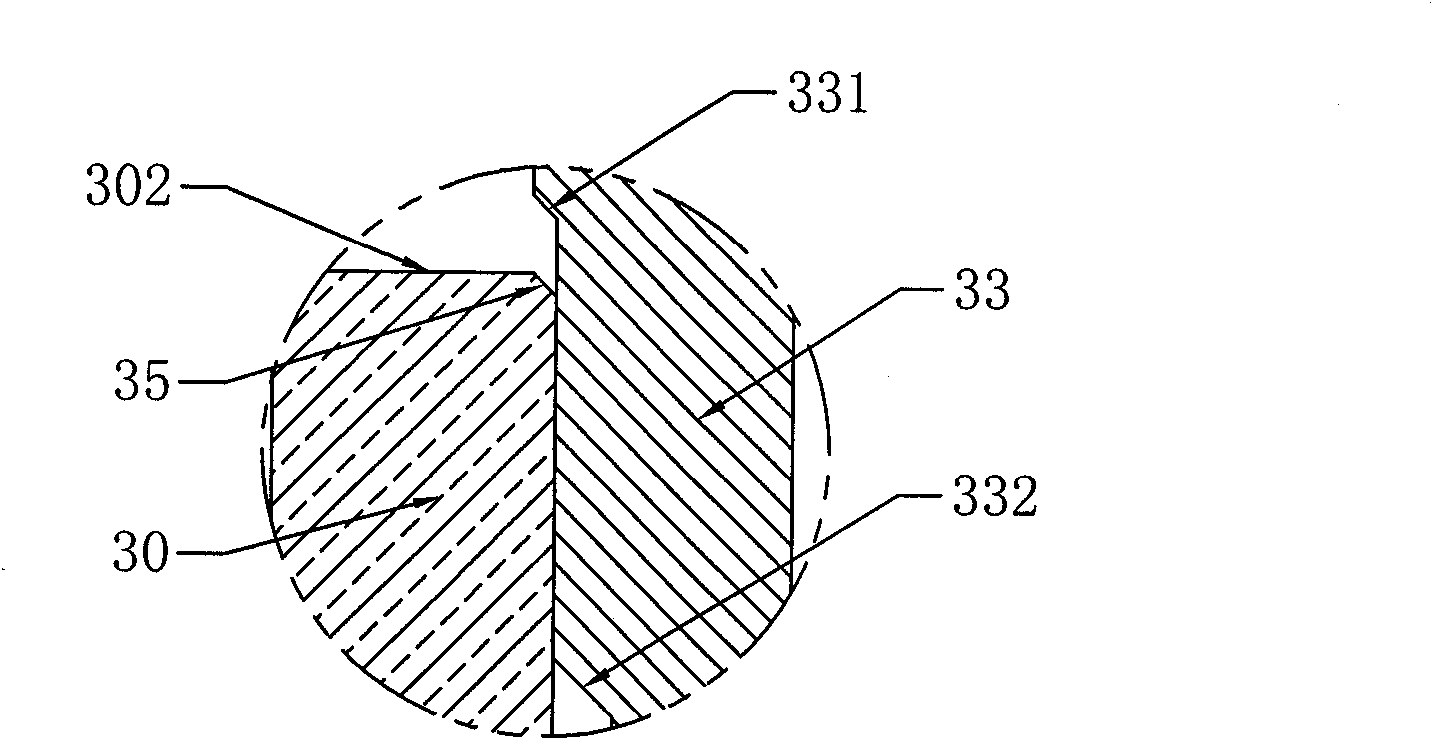

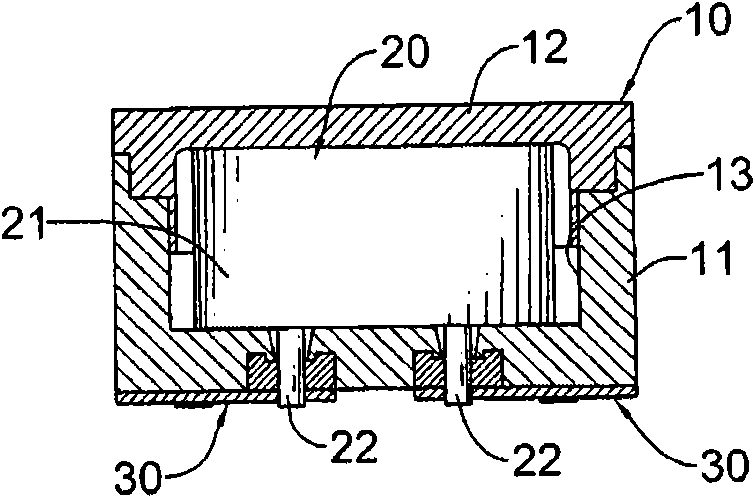

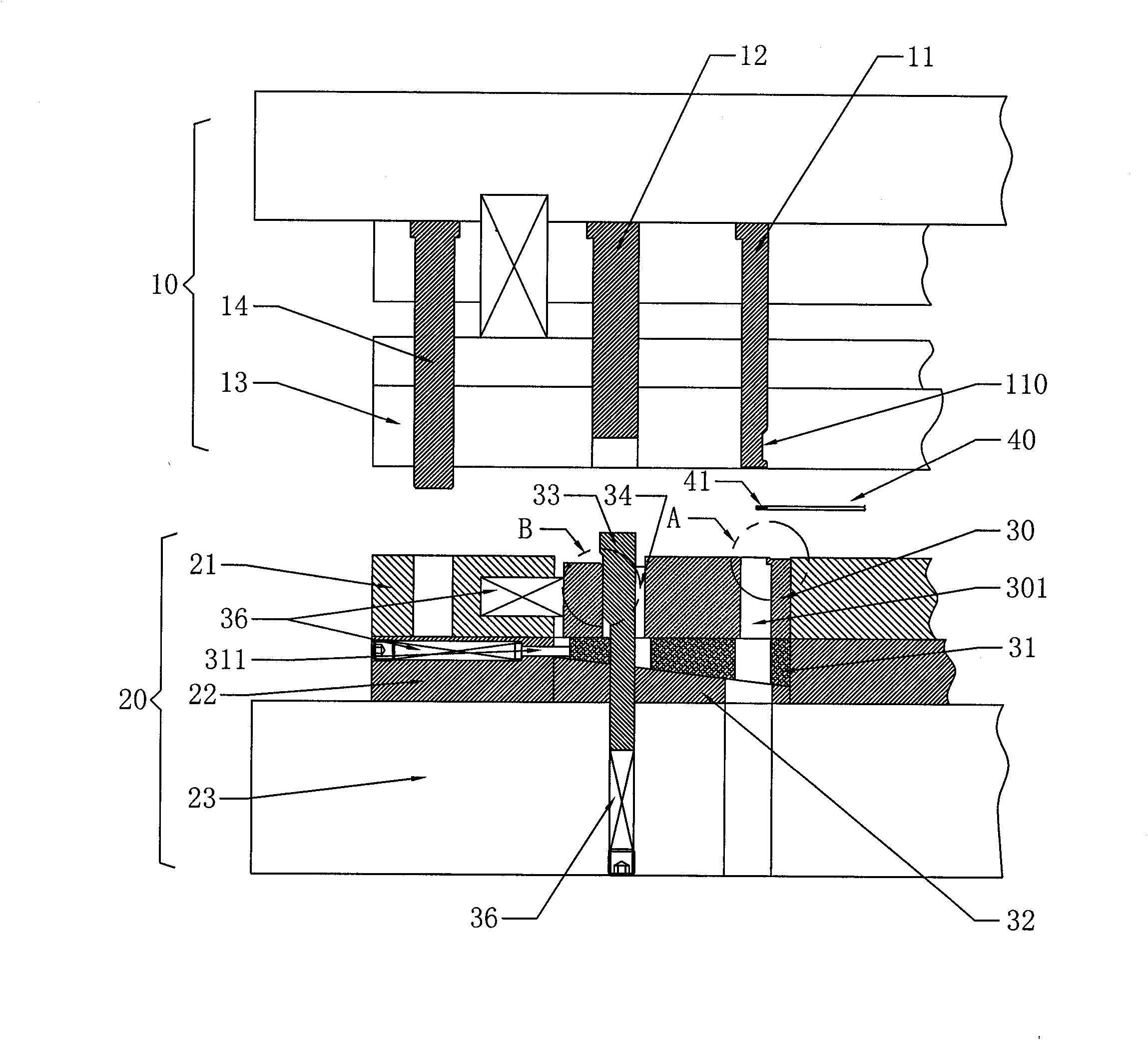

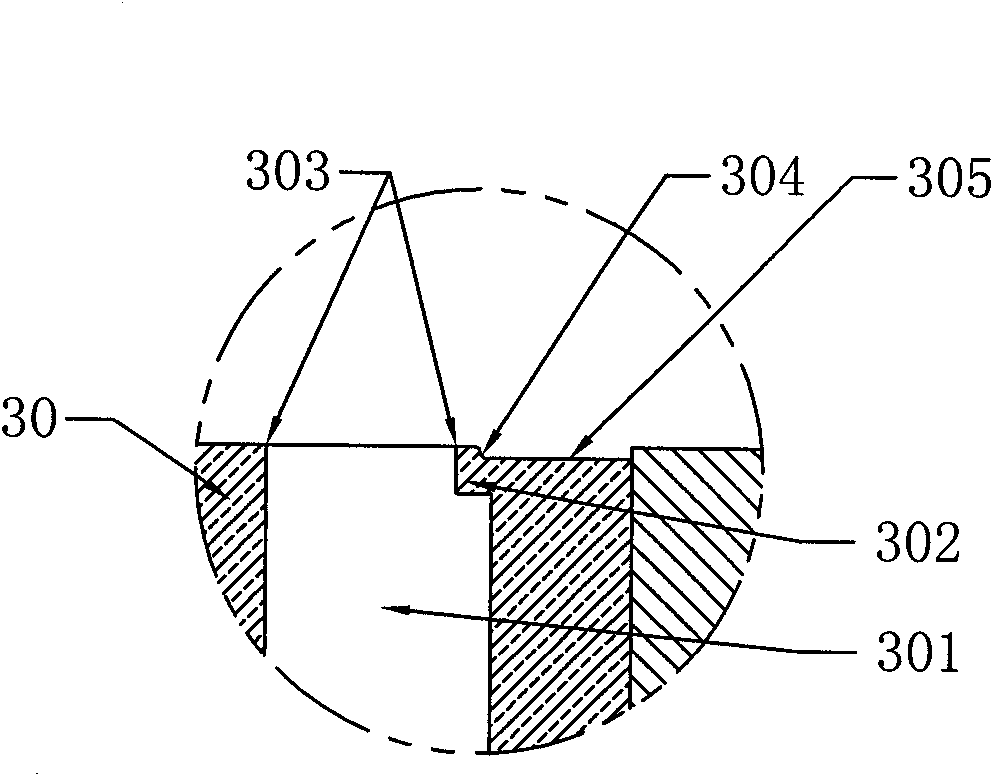

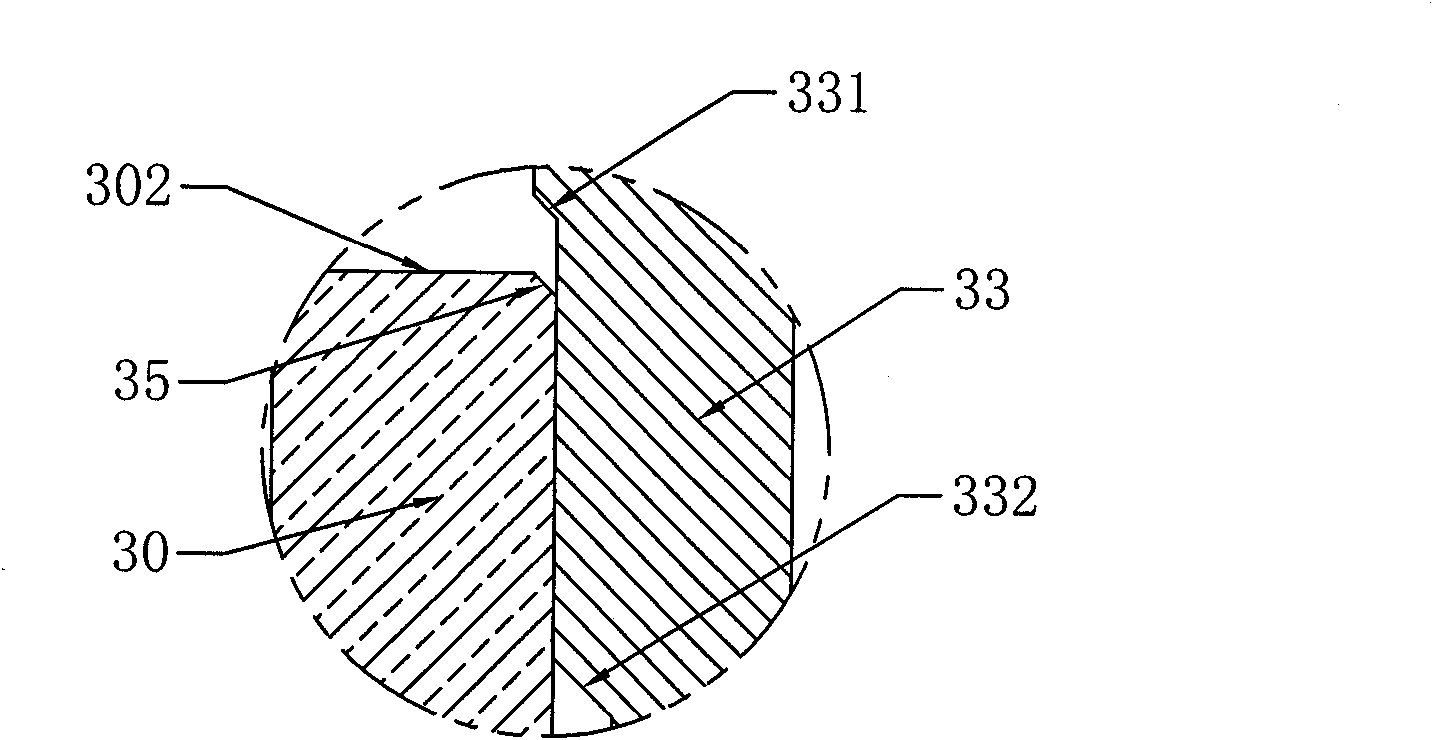

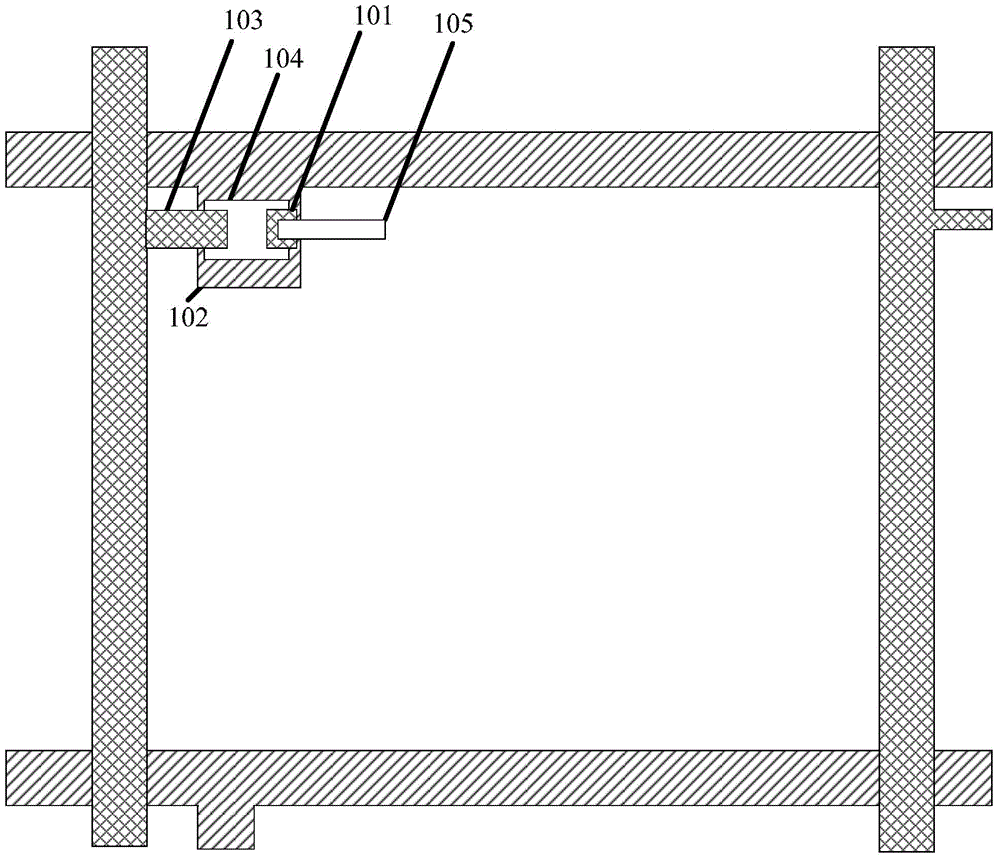

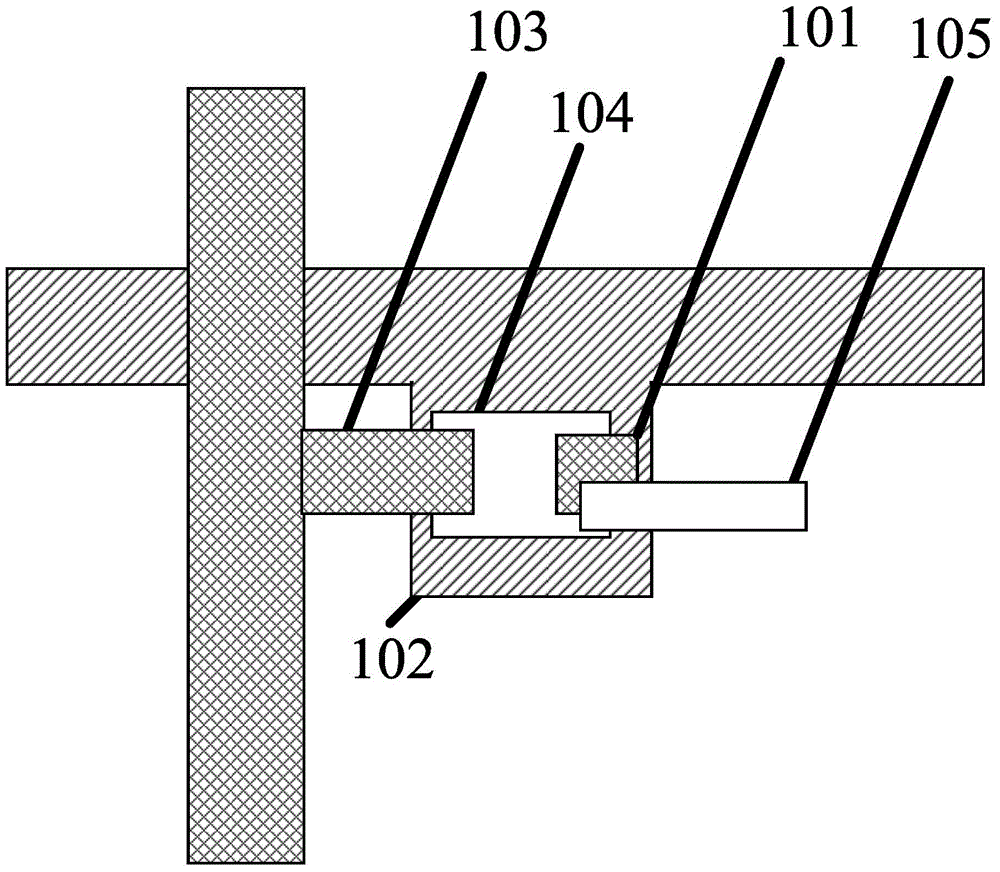

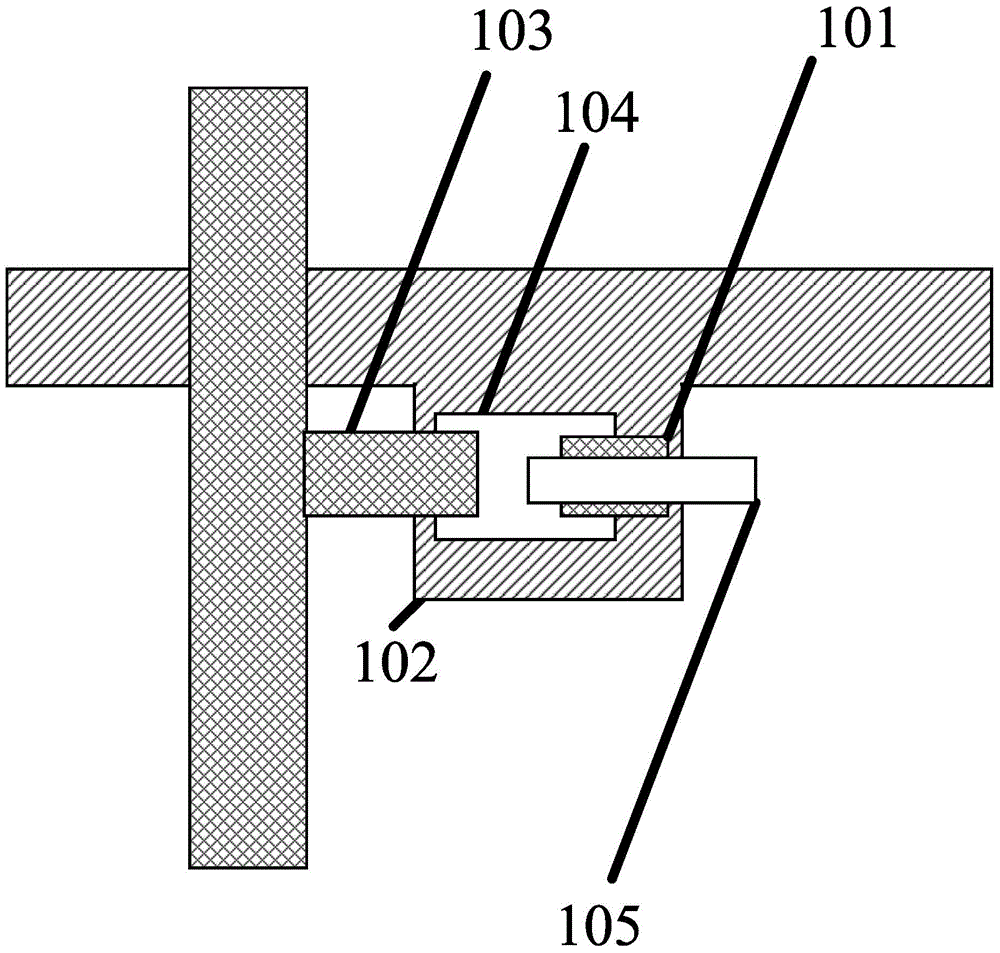

Device for synchronously blanking scraps and removing burrs for progressive die

InactiveCN102310144ASolve the problem of not being able to remove the last burr left by the edge joint materialSave resourcesShaping toolsEngineeringScrap

The invention discloses a device for synchronously blanking scraps and removing burrs for a progressive die. An insert assembly capable of sliding leftwards and rightwards is arranged at a notch at the final blanking position of the progressive die. The insert assembly comprises a female die sliding block, a sliding block cushion, an up-and-down floating sliding block and an inclined wedge, wherein the female die sliding block can move transversely and longitudinally in a female die plate; the sliding block cushion is embedded in a lower base plate; the up-and-down floating sliding block can slide along the sliding block cushion; the inclined wedge can vertically move; the upper end face of the sliding block cushion and the lower end face of the up-and-down floating sliding block are inclined planes which are in sliding fit; the female die sliding block is provided with a blanking working hole; the upper end of the blanking working hole is provided with a burr step protruding towards the inside of the hole; and the edge of the burr step is provided with a chamfer angle. Due to the adoption of the device, the problem that the scraps and connected materials of the progressive die cannot be removed so that the burrs are finally left is completely solved, the scrap blanking and the burr removal on a blanked workpiece can be completed only by once positioning, the cost of manually removing the burrs or removing the burrs by a single engineering die is saved, and the production efficiency and the product quality are greatly improved.

Owner:SHENZHEN EVA PRECISION TECH GRP CO LTD

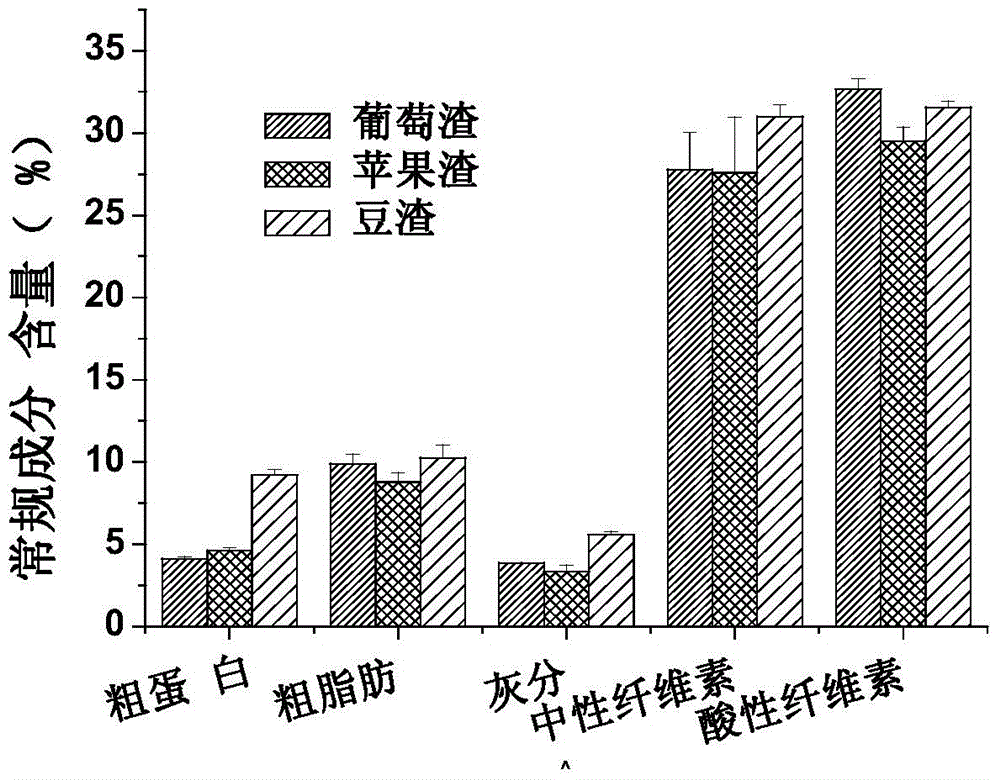

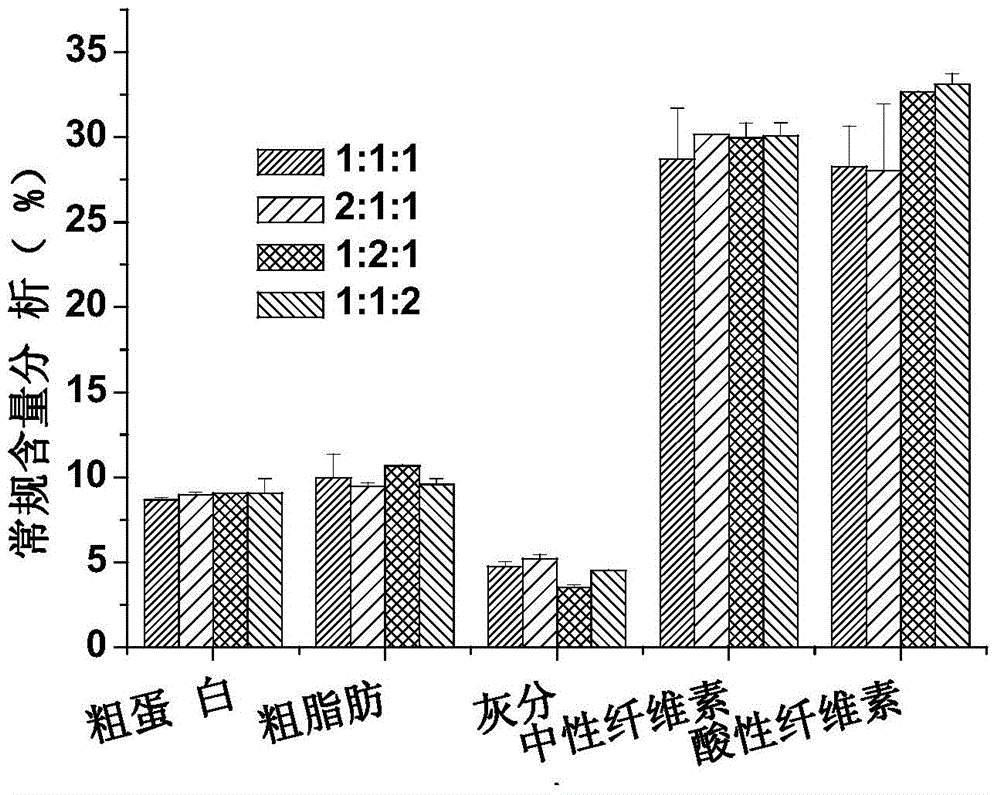

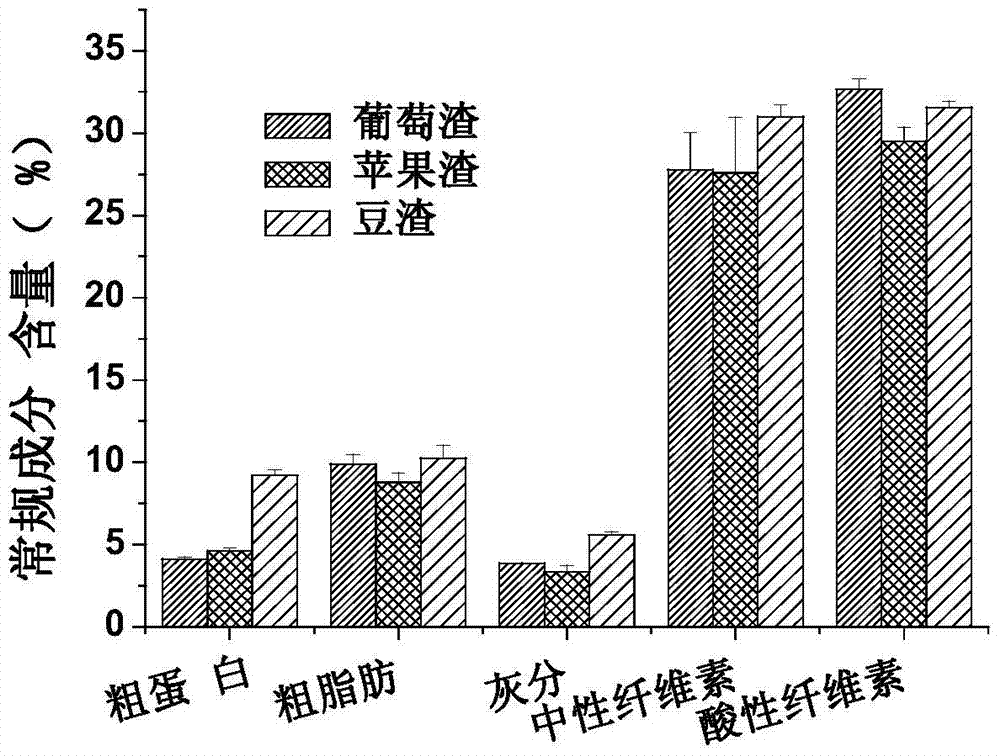

Compound protein feed and preparation method thereof

ActiveCN104522306AEnhance nutritional propertiesHigh nutritional valueAnimal feeding stuffConjugated proteinDigestion

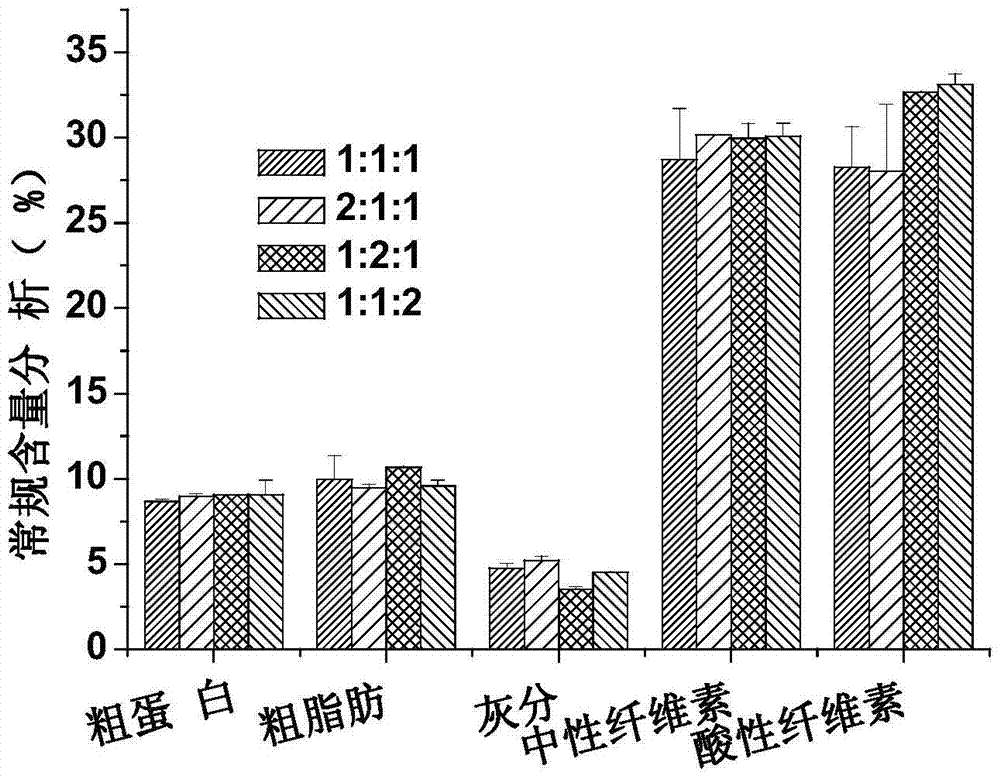

The invention relates to a compound protein feed and a preparation method thereof. The compound protein feed is prepared by the following steps: as bean dregs, grape residues and apple pomace are used as fermentation raw materials, inoculating saccharomyces cerevisiae, lactic acid bacillus and cellulase, and fermenting, thereby obtaining the compound protein feed. According to the fermented compound protein feed, the content of crude proteins and crude fat is obviously increased, the content of ash cellulose is obviously reduced, the digestion rate of the crude proteins eaten by animals is obviously increased, and the highest digestion rate is 73.11 percent. According to the solid state fermentation method, the low quality of the compound protein feed is improved, the quality of the proteins is improved and the feed utilization rate is increased, and the compound protein feed is low in cost, can meet the requirements of animal husbandry on the protein feed and has good market application prospects.

Owner:LANZHOU INST OF ANIMAL SCI & VETERINARY PHARMA OF CAAS

Orchid cultivation method

InactiveCN104920045AImprove poor qualityImprove survival ratePlant cultivationCultivating equipmentsOrchisPotting soil

The invention provides an orchid cultivation method. The method comprises the following steps that a stock plant is planted into a pot with a drain hole, and pot soil comprises a main material providing nutrients and auxiliary materials for ventilation and drainage; when pot soil is placed, the auxiliary materials and the main material are placed in a crossed and mixed mode, the degree of wetness of the pot soil materials is kept 40%, one quarter in height of a flower pot is filled with the pot soil, and the stock plant is placed into the flower pot. The orchid cultivation method has the advantages that by the adoption of the orchid cultivation method, the poor orchid quality can be improved, and the orchid survival rate is greatly improved.

Owner:柳州市长林苗木种植专业合作社

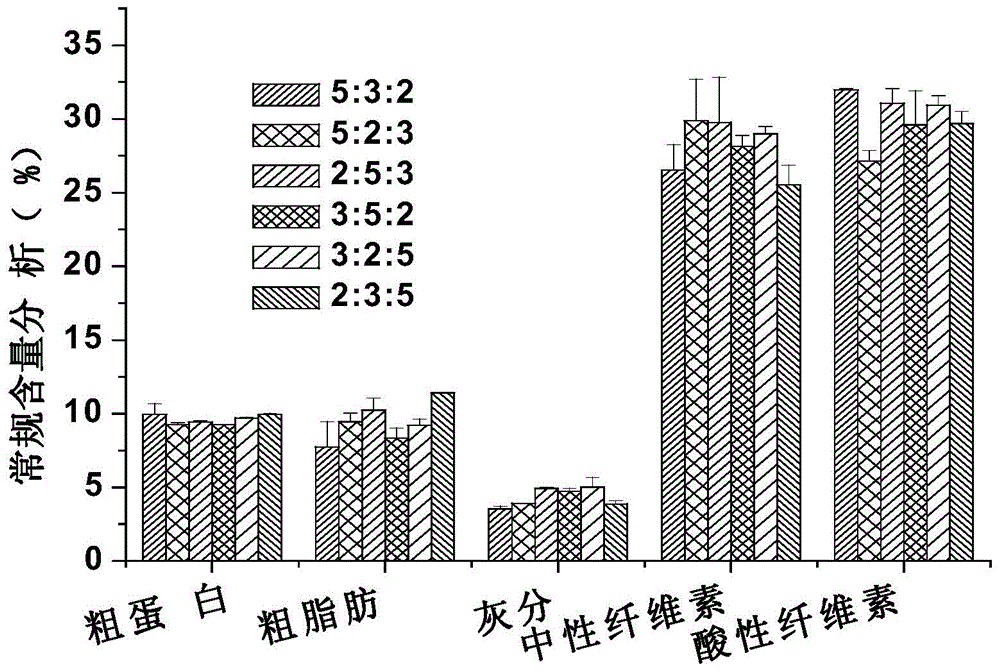

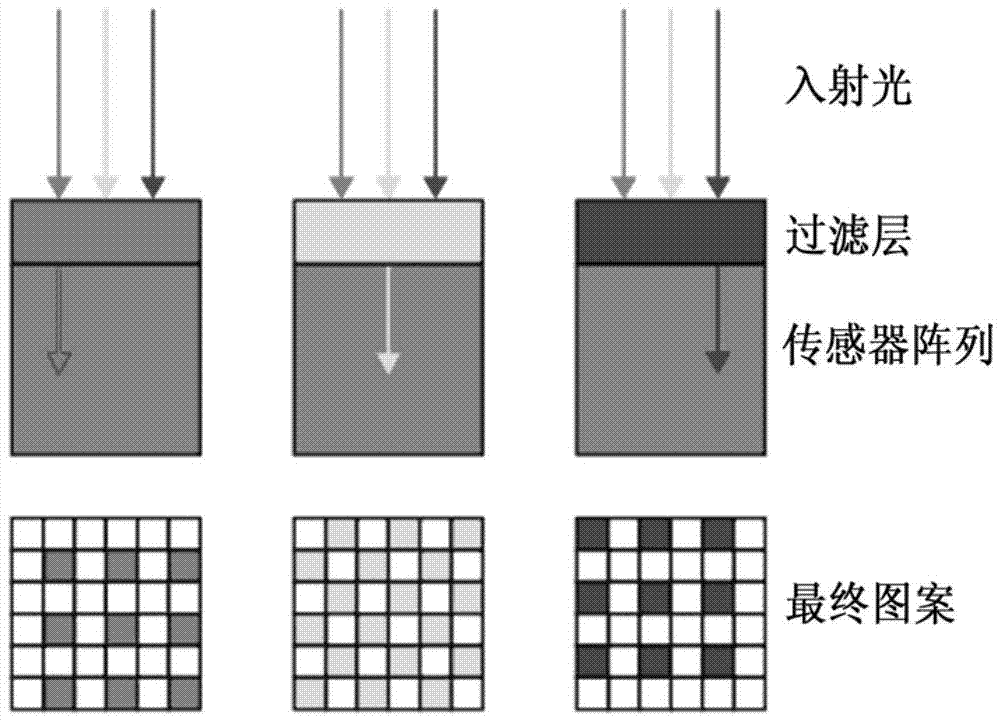

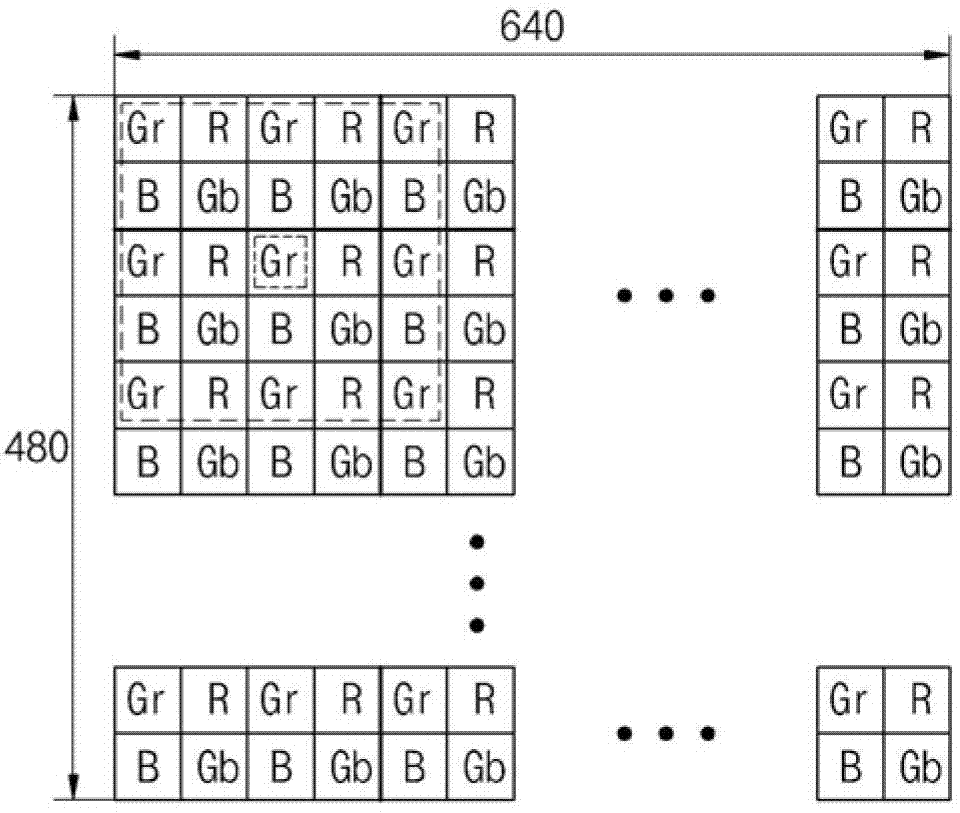

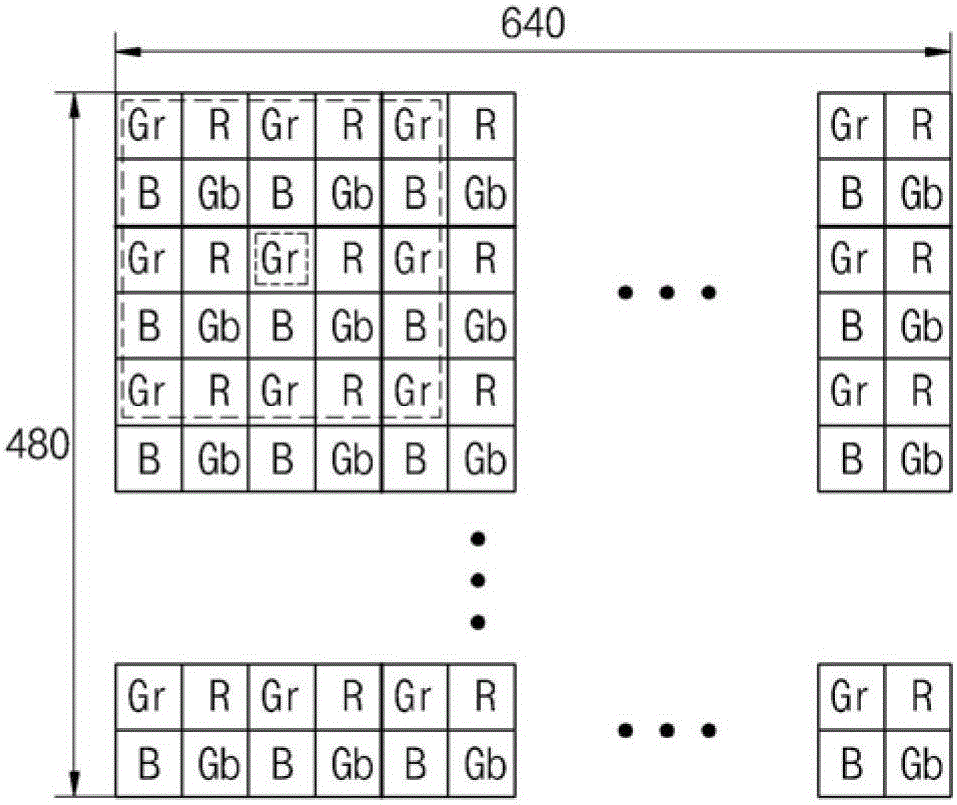

Device for correcting offset correction between pixels of image sensor and correction method thereof

InactiveCN102957879AImprove poor qualityEasy wiringTelevision system detailsImage analysisCorrection methodImage sensor

Owner:HYUNDAI MOBIS CO LTD

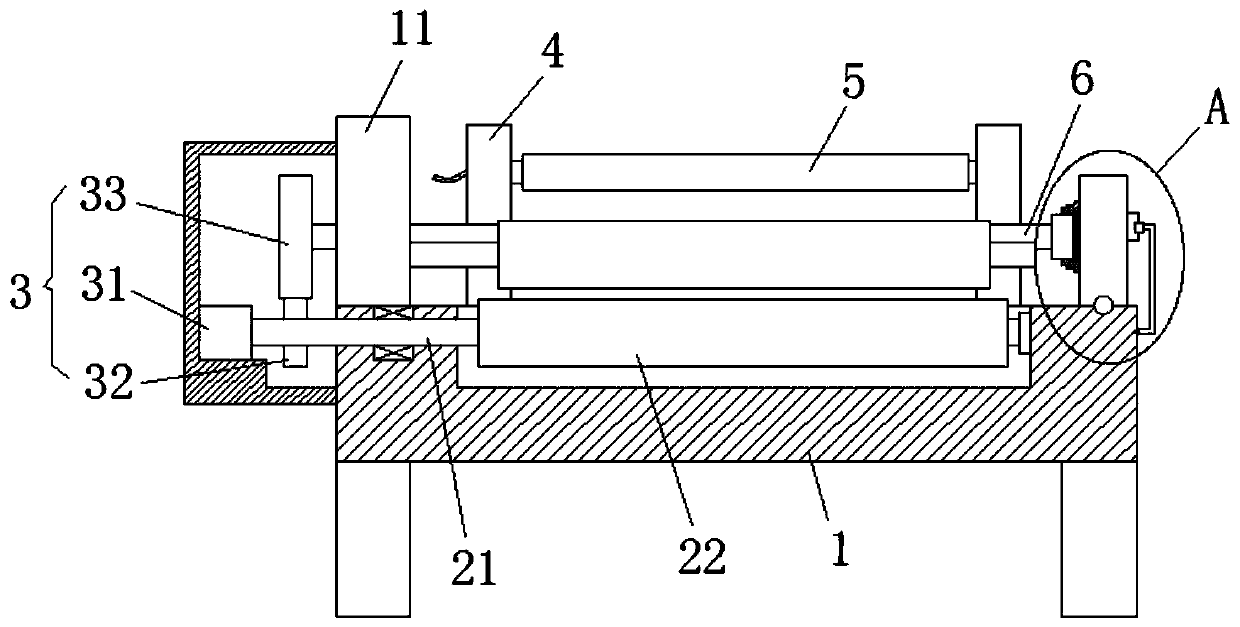

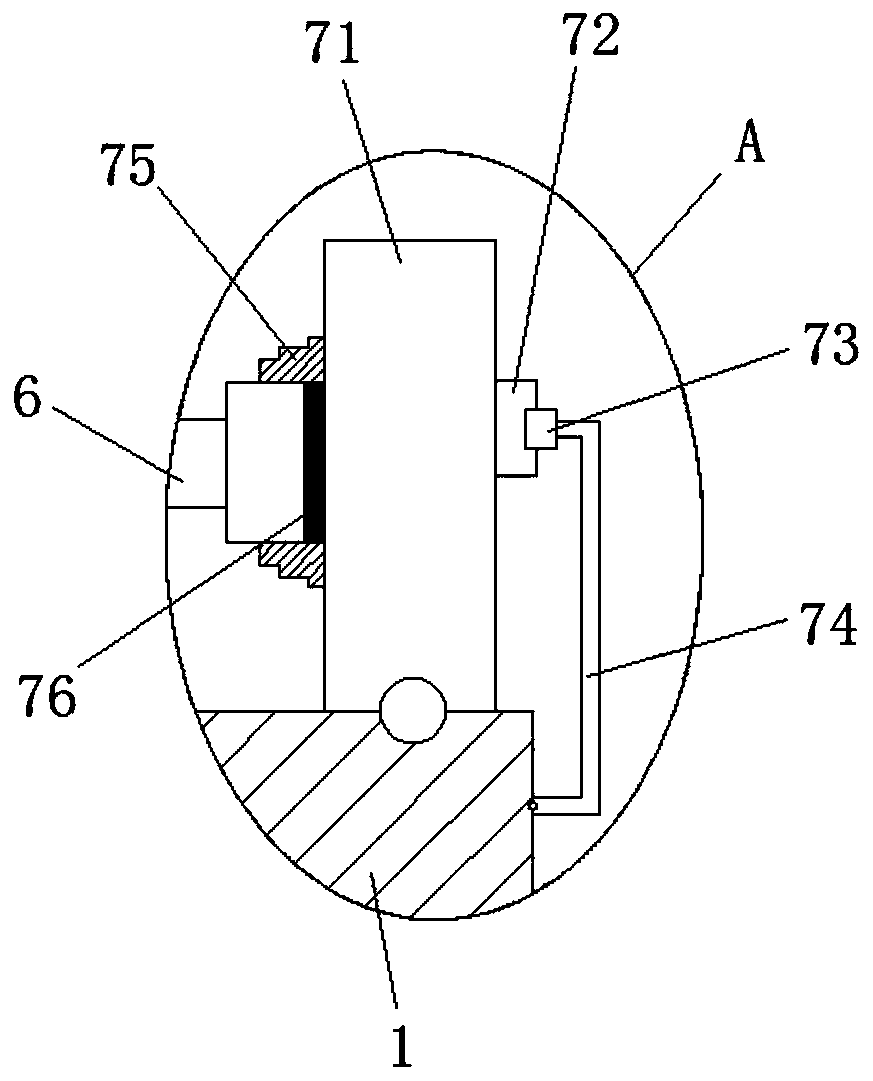

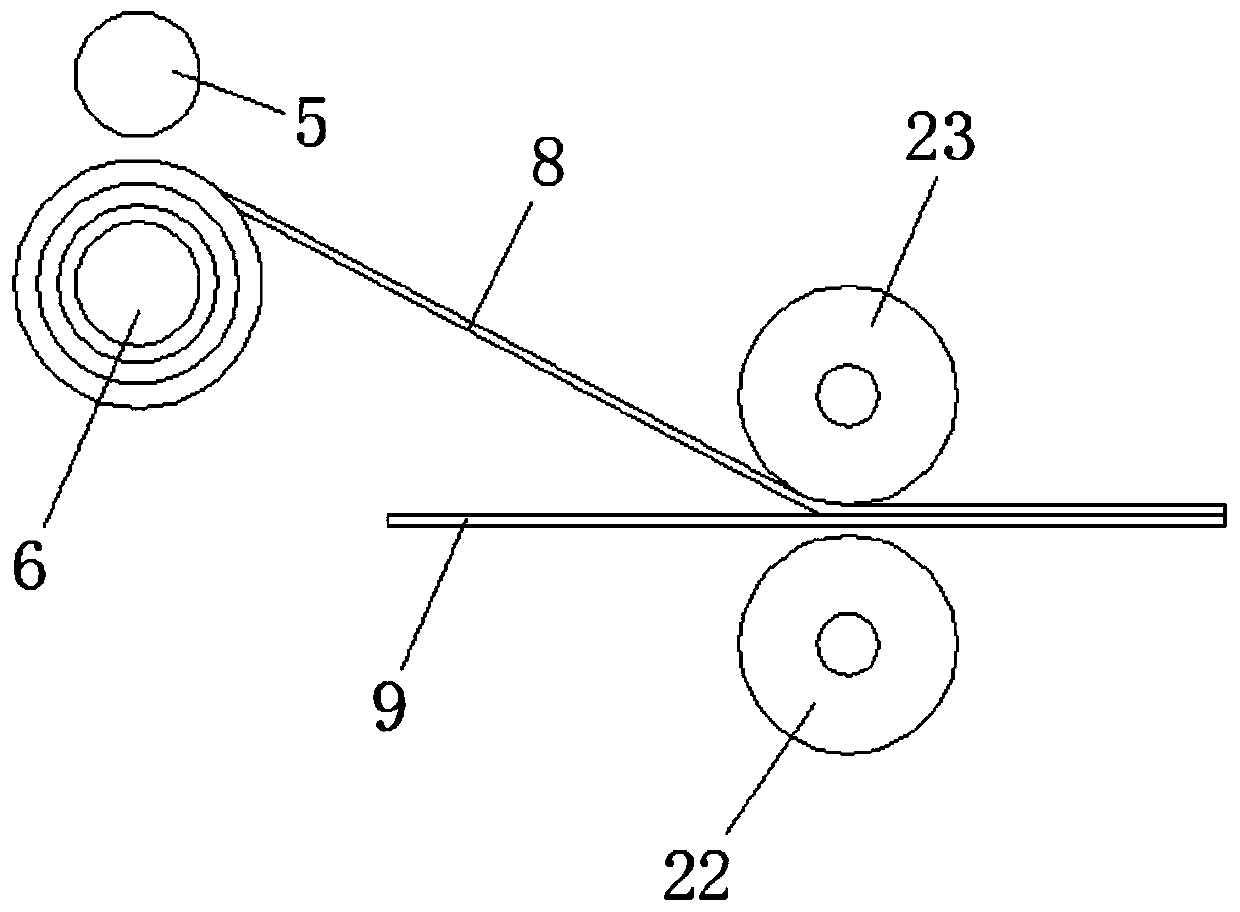

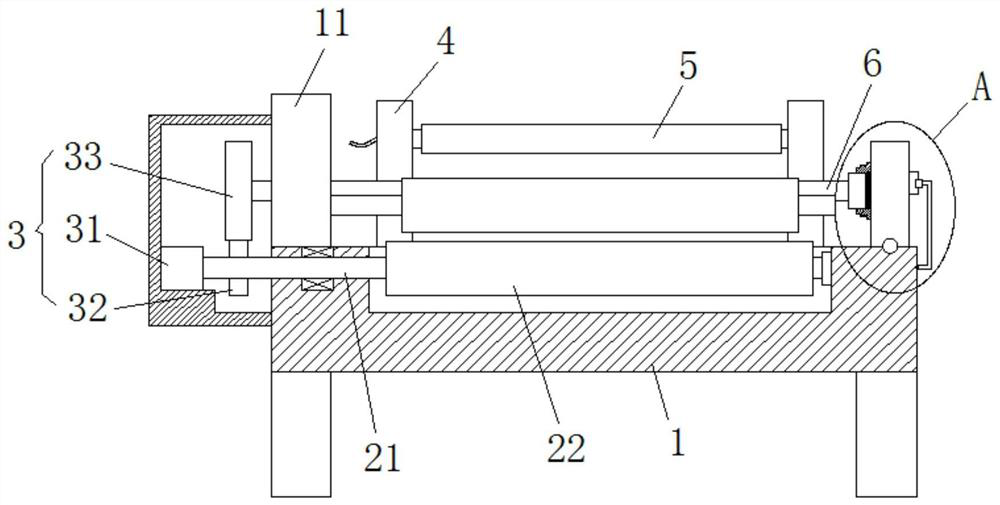

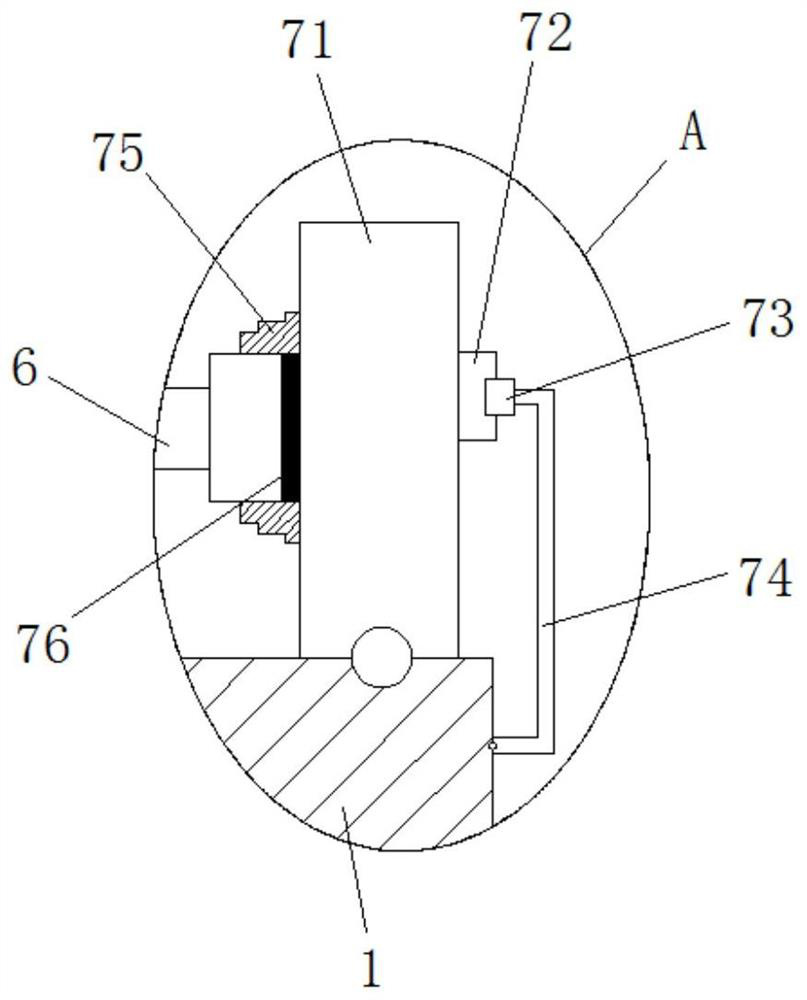

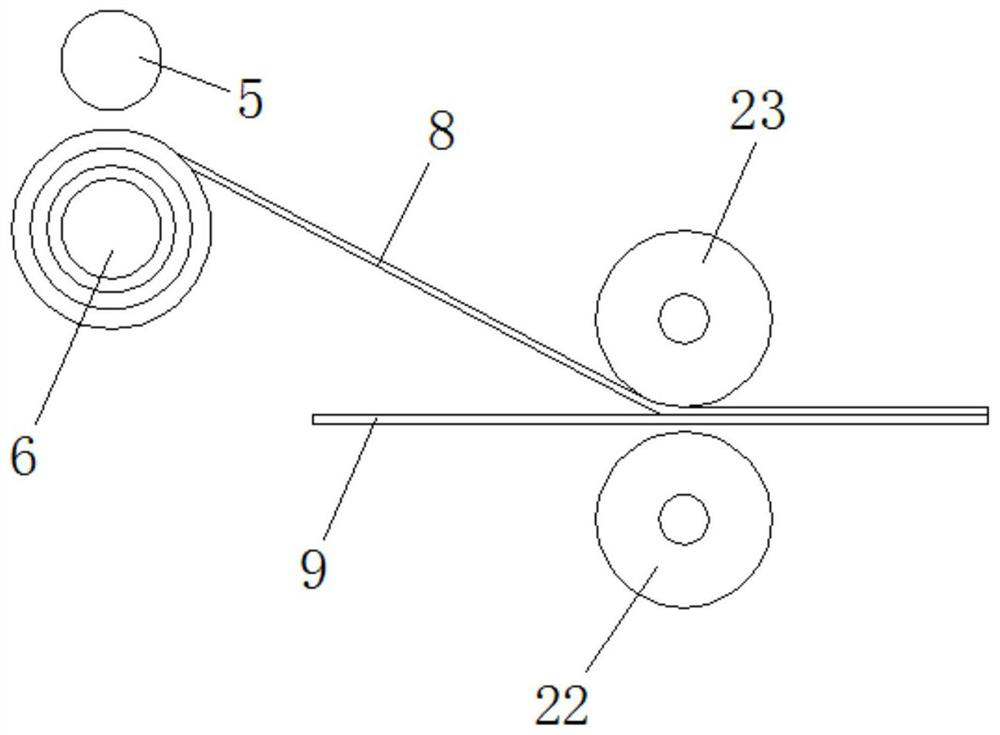

Anti-counterfeiting label outer surface laminating machine

ActiveCN110126431AWarm up evenlyProtect the internal structureLamination ancillary operationsLaminationTectorial membraneCoupling

The invention relates to an anti-counterfeiting label outer surface laminating machine. The laminating machine comprises a base, wherein the left end of the base is provided with a power mechanism, the top surface of the base is provided with an upper pressing roller and a lower pressing roller through a driving shaft, a gap is left between the upper pressing roller and the lower pressing roller to ensure the passage of an anti-counterfeiting label and a membrane, the driving shaft is connected with the power mechanism by a coupling, a driven shaft is arranged above the base by a left side plate and a right side plate, the driven shaft is connected with the power mechanism, a membrane roll is arranged on the periphery of the driven shaft, and the top surface of the base is provided with apre-heating mechanism through two mounting mechanisms. According to the provided anti-counterfeiting label outer surface laminating machine, a gap is left between pre-heating rollers and the membraneroll, the membrane roll temperature is reduced, the inner structure of the membrane is protected, the service life of the membrane is prolonged, the membrane roll is uniformly pre-heated, the pre-heating effect is good, the laminating quality is improved, the membrane is prevented from falling off, the pre-heating hot air flow impact force is small, and the risk of breaking the membrane is reduced.

Owner:湖北强大包装实业有限公司

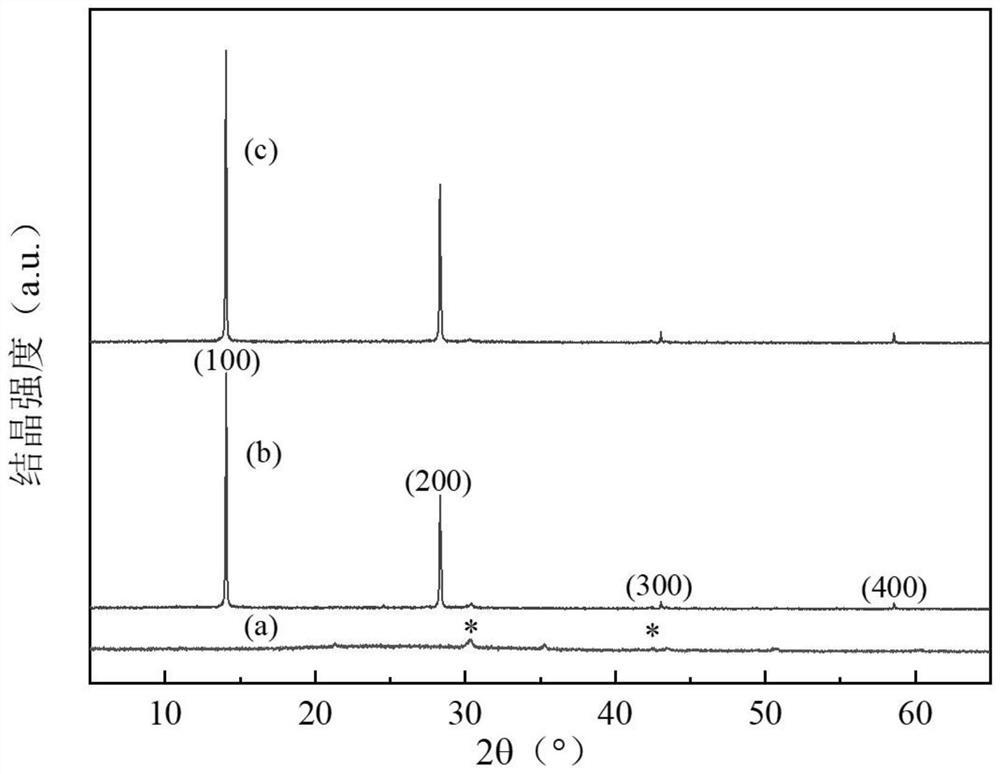

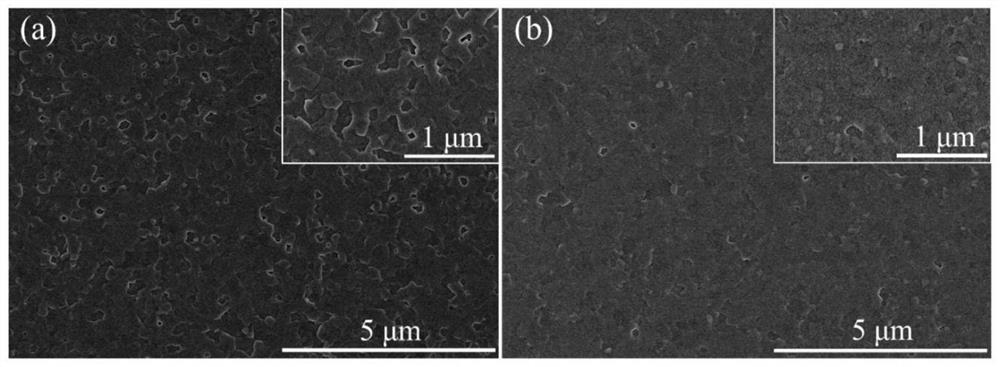

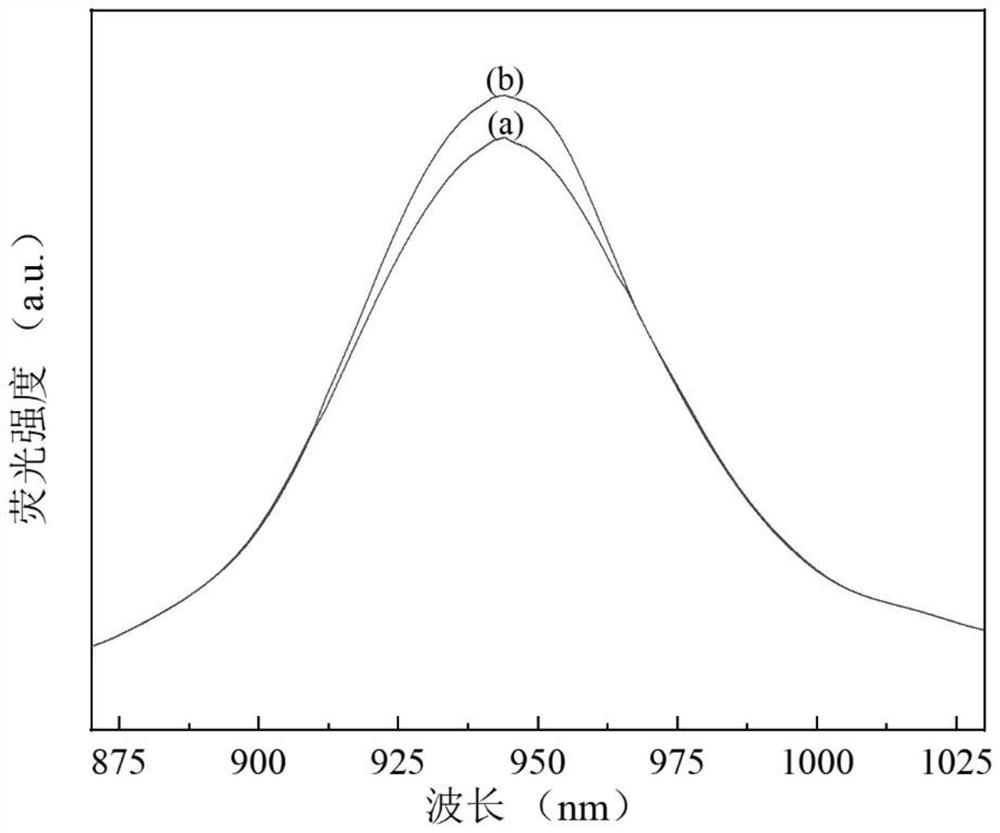

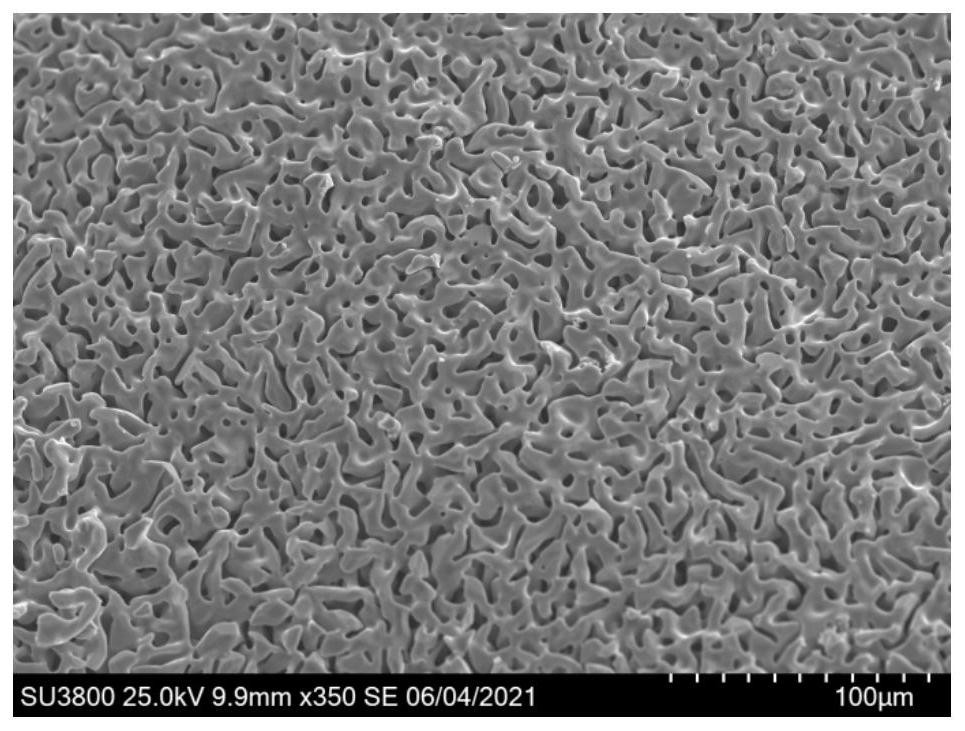

Tin-based perovskite thin film, quality improvement method thereof and tin-based perovskite solar cell

ActiveCN113410400AQuality improvementImprove the problem of poor film qualityFinal product manufactureSolid-state devicesPerovskite solar cellElectrical battery

The invention provides a tin-based perovskite thin film, a quality improvement method thereof and a tin-based perovskite solar cell. The method comprises the steps: dissolving a polyhydroxy material in a fixed-volume PEDOT:PSS aqueous solution to prepare a mixed solution of PEDOT:PSS and the polyhydroxy material, then carrying out the spin coating of the mixed solution on an electrode, and carrying out the annealing to form a flat and smooth hole transport layer; preparing the tin-based perovskite thin film on the hole transport layer through a one-step spin-coating method, and then forming a flat and compact perovskite thin film without pinholes after annealing treatment. The tin-based perovskite solar cell prepared on the basis of the method has excellent photoelectric conversion efficiency and good device stability.

Owner:NANJING UNIV OF POSTS & TELECOMM

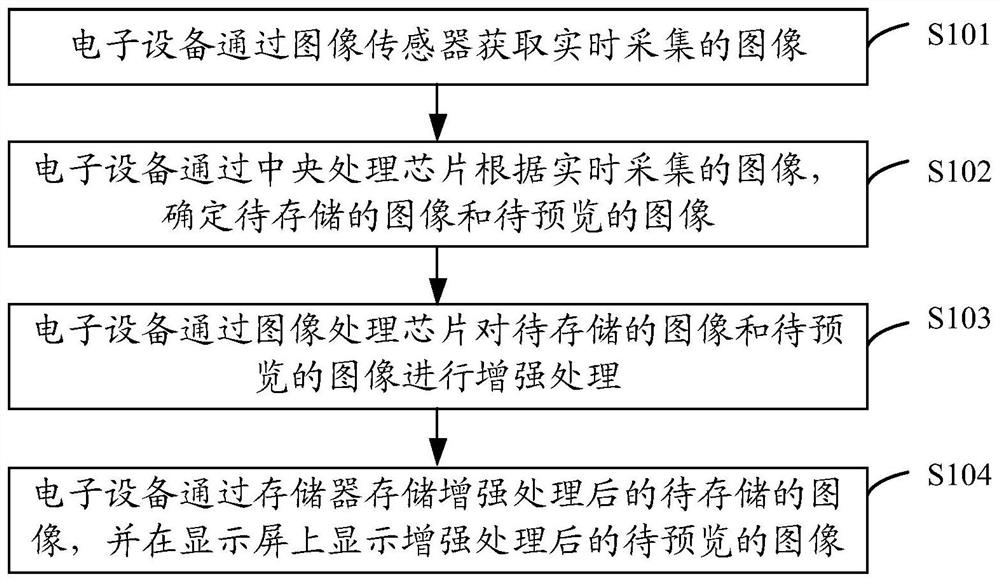

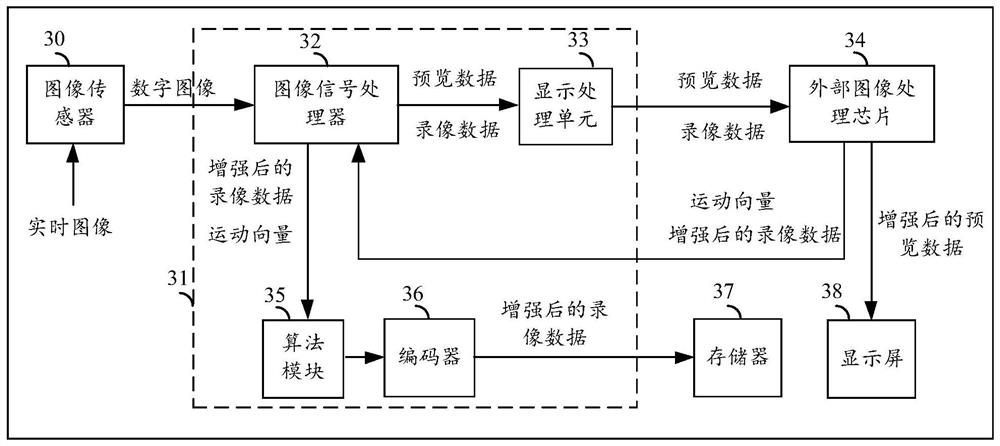

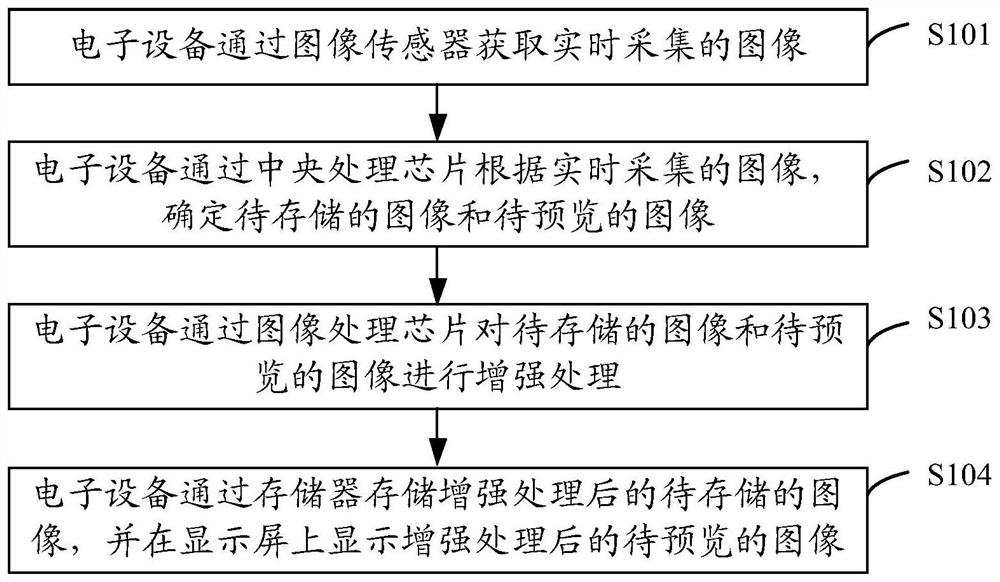

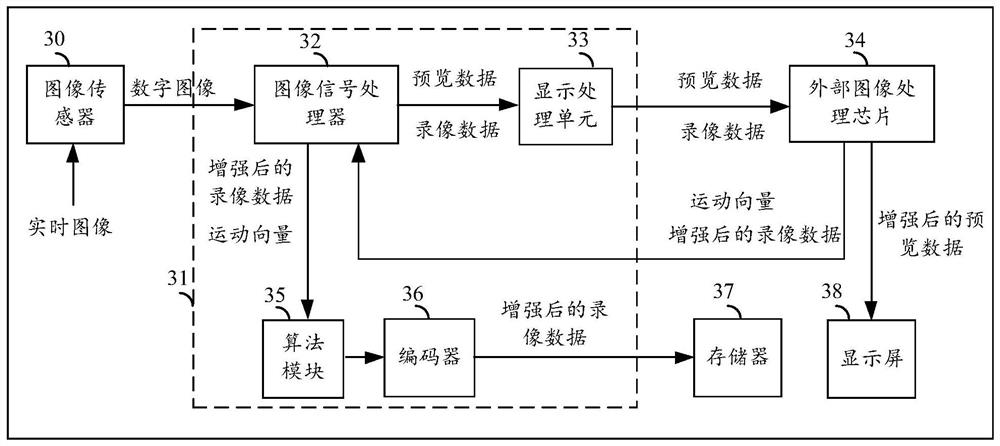

Image processing method and device and electronic equipment

ActiveCN112565603AReduce power consumptionImprove the display effectTelevision system detailsColor television detailsComputer hardwareImaging processing

The invention discloses an image processing method and device and electronic equipment, and belongs to the technical field of image processing. The problem that the quality of images shot by electronic equipment is poor can be solved. The method comprises the following steps: acquiring an image acquired in real time through an image sensor; determining a to-be-stored image and a to-be-previewed image through a central processing chip according to the image acquired in real time; performing enhancement processing on the to-be-stored image and the to-be-previewed image through an image processing chip; storing the enhanced image through a memory, and displaying the enhanced image to be previewed on a display screen.

Owner:VIVO MOBILE COMM CO LTD

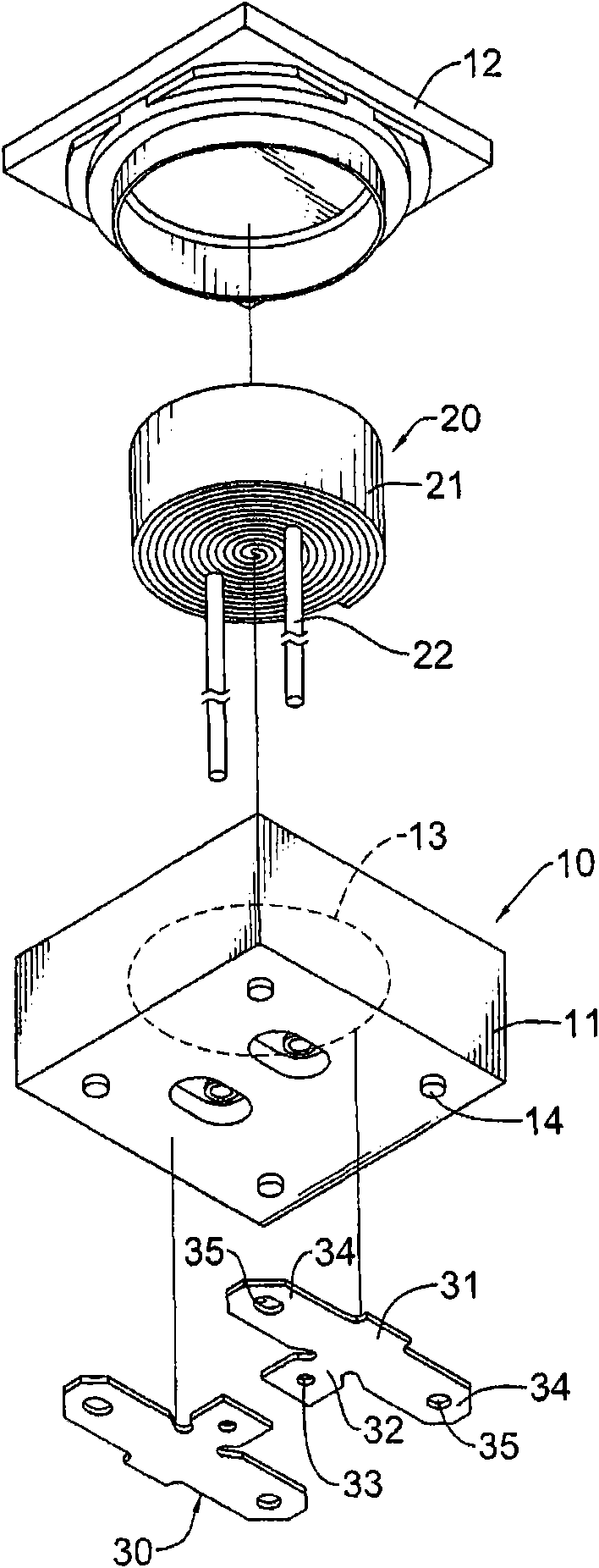

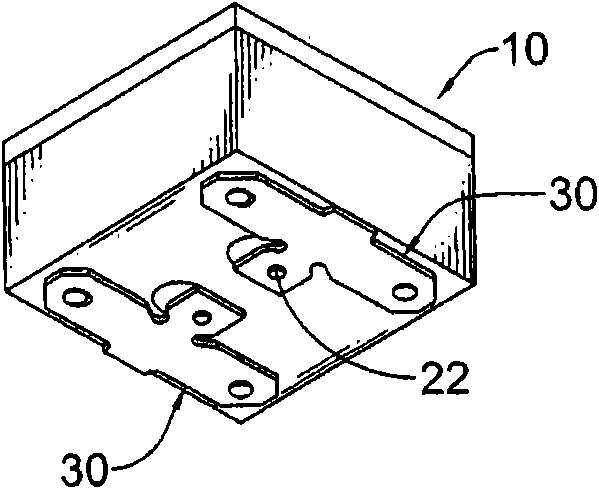

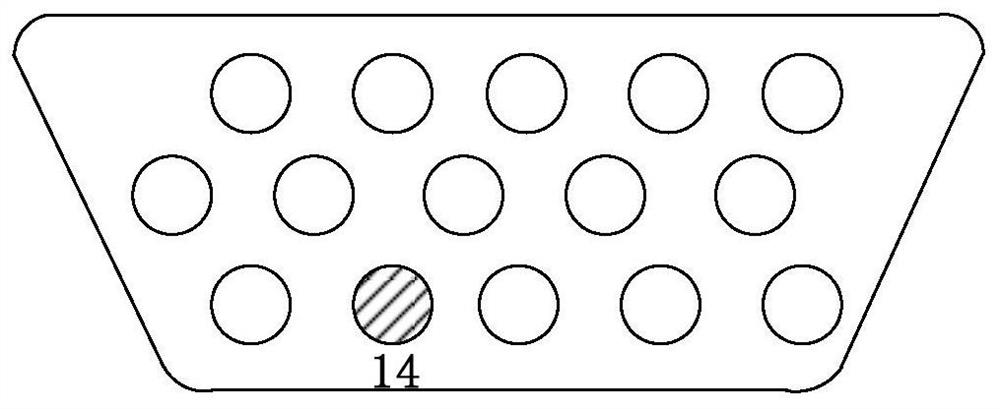

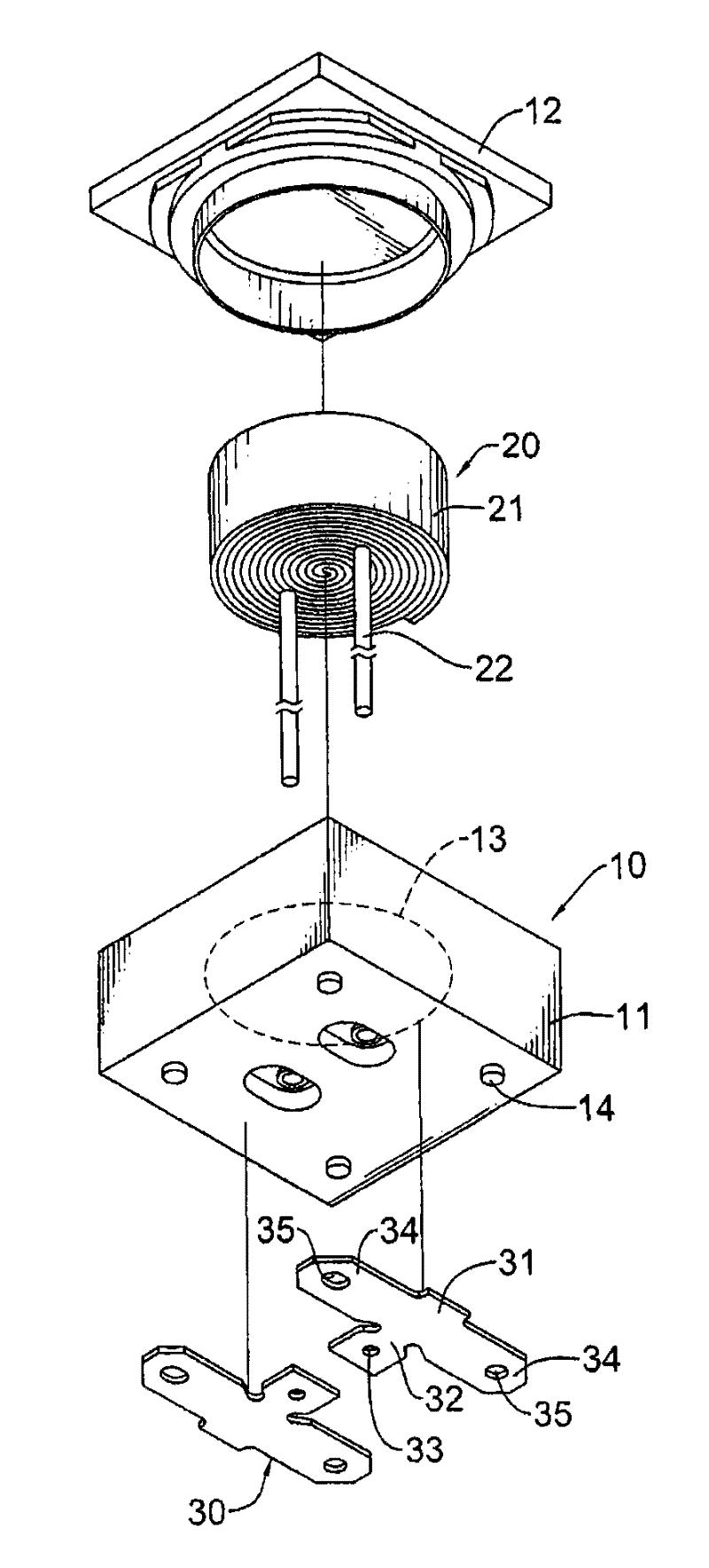

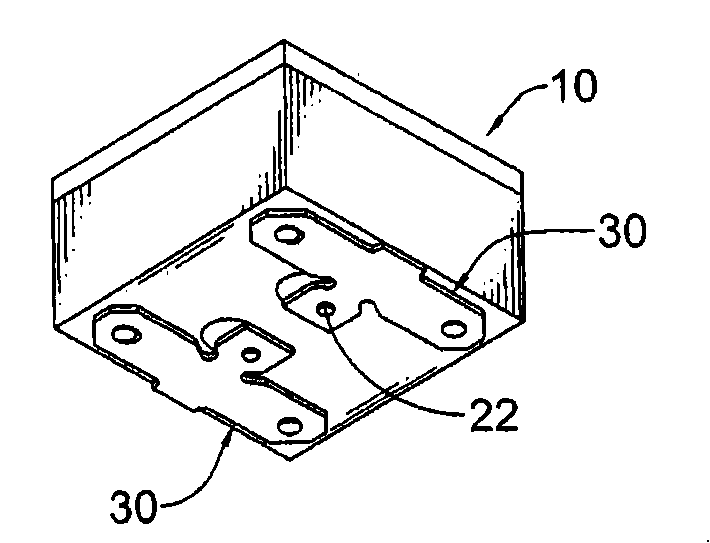

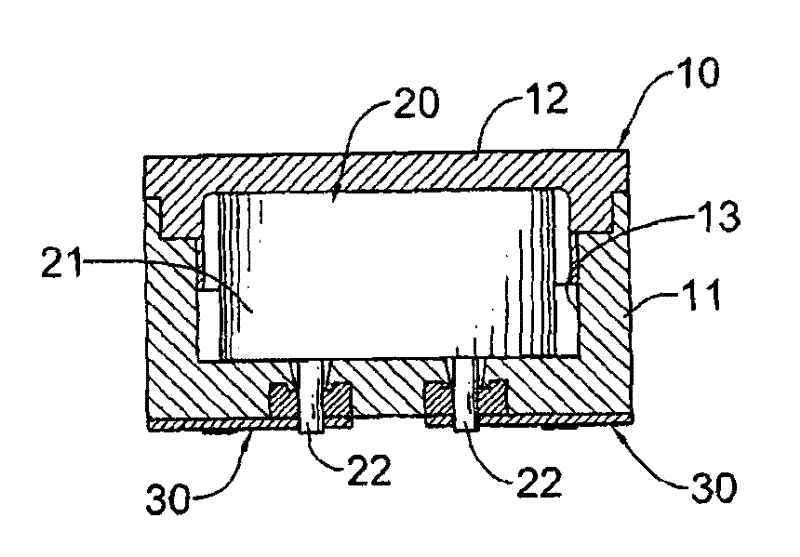

Electrolytic capacitor with external connected pin

InactiveCN101640130AGood SolderabilityGood product qualityCapacitor terminalsCapacitor housing/encapsulationCapacitanceElectrolytic capacitor

The invention relates to an electrolytic capacitor with an external connected pin, which comprises a shell, at least one capacitor element and a plurality of external pins. The shell comprises a hollow plastic shell seat and a seal cover which is sealed on the plastic shell seat and seals the capacitor element inside; the capacitor element is provided with a plurality of small sections of internalpins which pass through the bottom of the shell; the external pin comprises a plate pin body and a connecting part at one side of the pin body; and the connecting part is aligned and connected with the internal pins through conducting perforations on the connecting part, and embedded and fixedly combined with a fixedly-connected convex part corresponding to the plastic shell seat through fixedly-connected concave parts of fixed parts at two sides of the pin body. Therefore, the external pins of large area can provide good welding stability when the electrolytic capacitor is adhered to the surface.

Owner:GEMMY ELECTRONICS

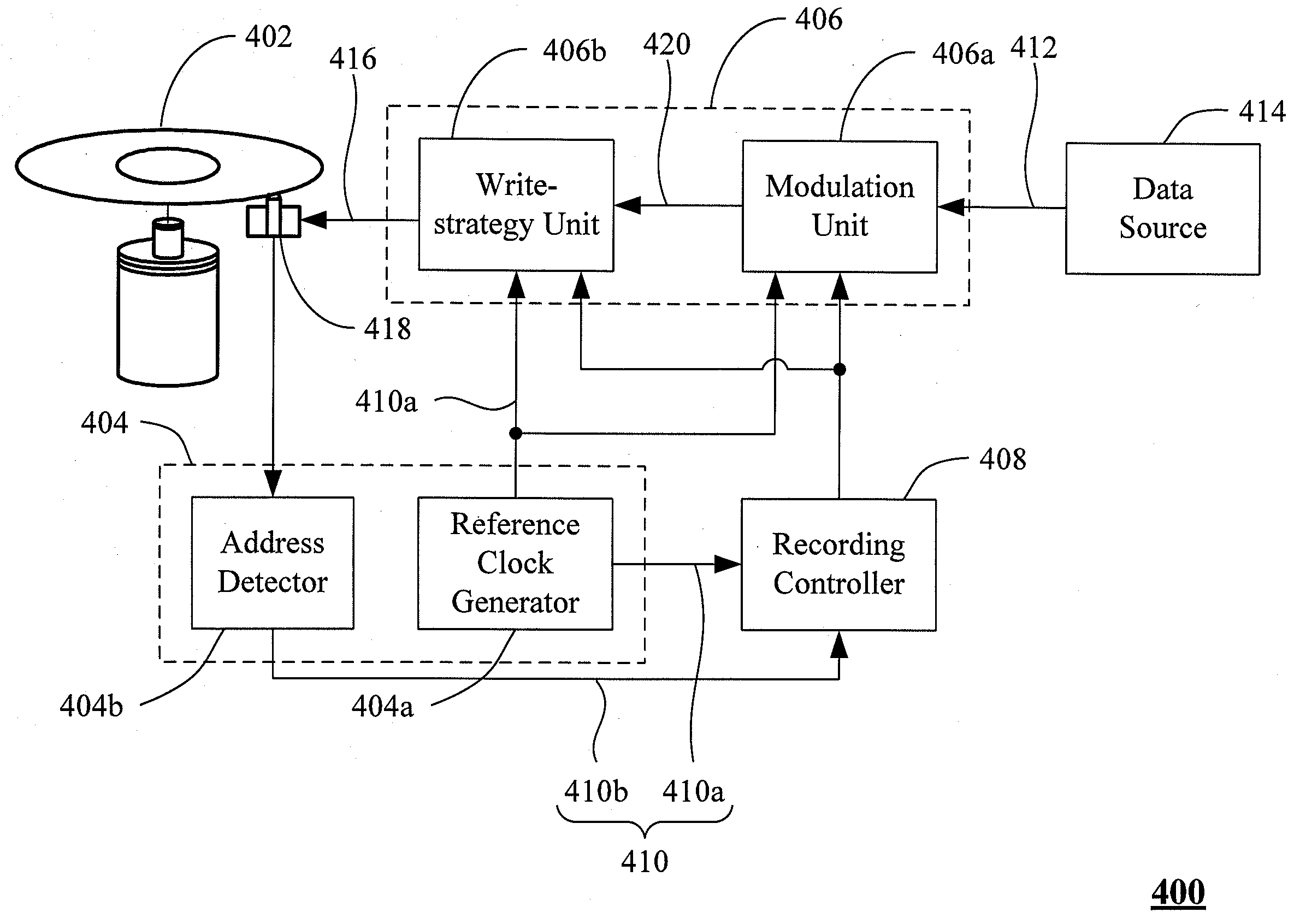

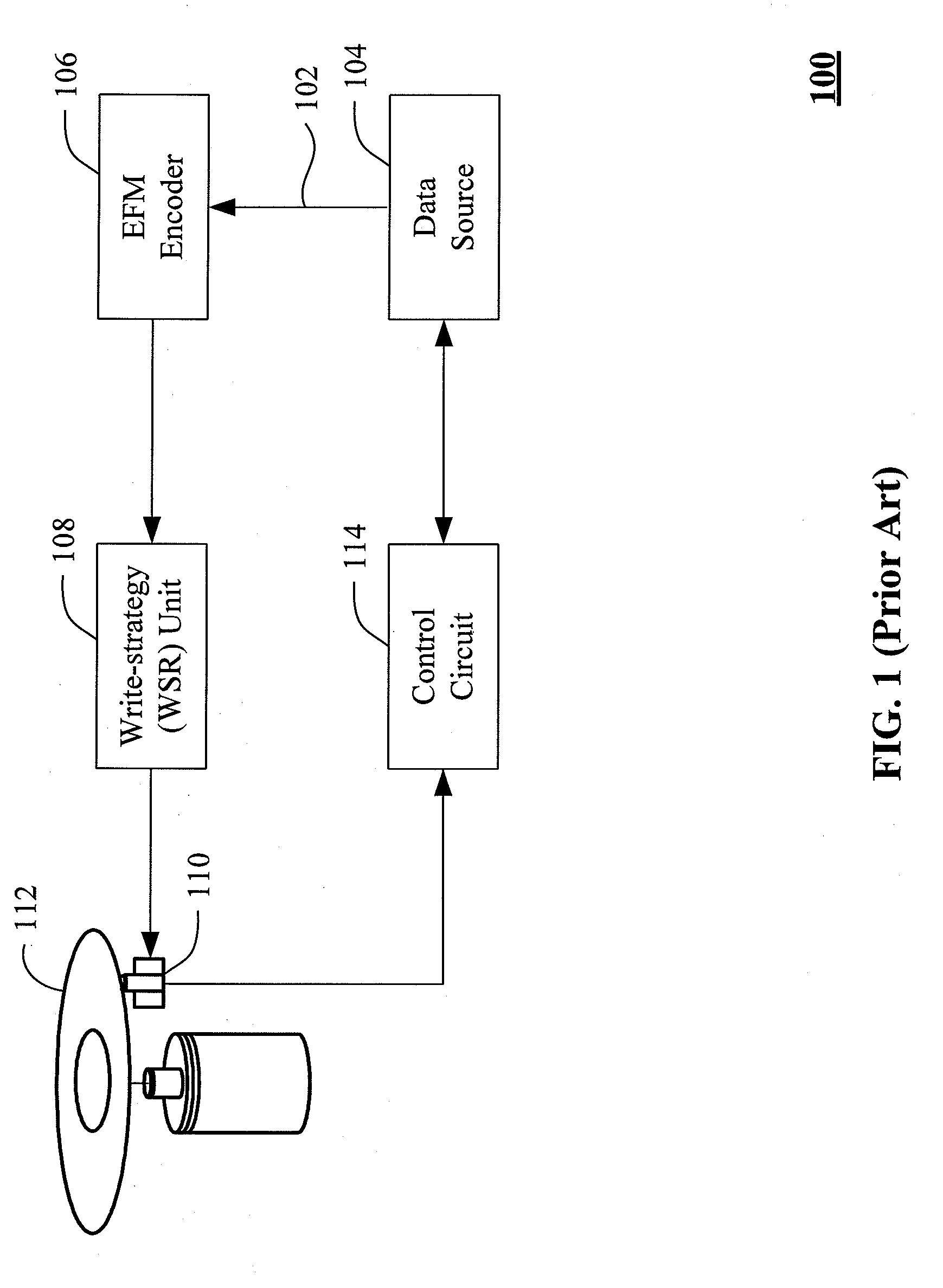

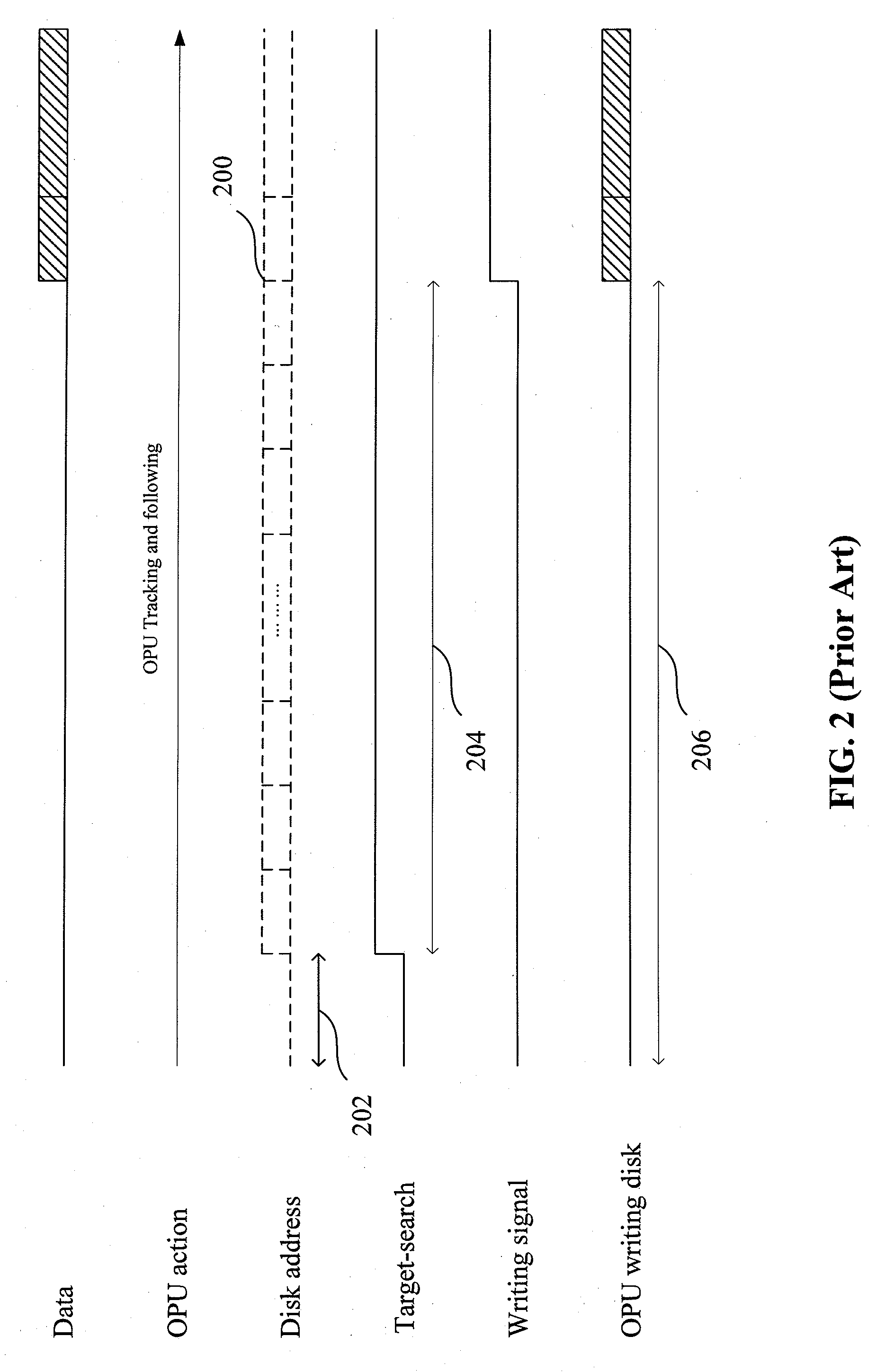

System and method for controlling data recording process of optical recording medium in sequential writing

InactiveUS20070274194A1Avoiding invalid trackingImprove poor qualityTelevision system detailsRecord information storageSignal onData translation

A system and method of controlling data recording process of optical recording medium by adjusting writing signal to record the adjusted writing signal on the optical recording medium in a sequential writing are described. The control system for controlling a recording process of an optical recording medium comprises an information unit, a data-preparing unit and a recording controller. The information unit generates an information signal. The data-preparing unit is coupled to the information unit receives data from a data source and prepares the data for recording. The data is then transformed into a writing signal according to the information signal. The recording controller coupled to the information unit and the data-preparing unit controls the data-preparing unit to adjust the writing signal while acquiring the information signal from the information unit during a sequential writing. Thus, the recording controller adjusts the writing signal according to the information signal. The data-preparing unit outputs the adjusted writing signal having desired recording area and undesired recording area and the adjusted writing signal is recorded on the optical recording medium during the sequential writing. The adjusted writing signal is outputted to OPU. The OPU then emits light corresponding to the adjusted writing signal to perform a recording process of the optical recording medium during the sequential writing.

Owner:MEDIATEK INC

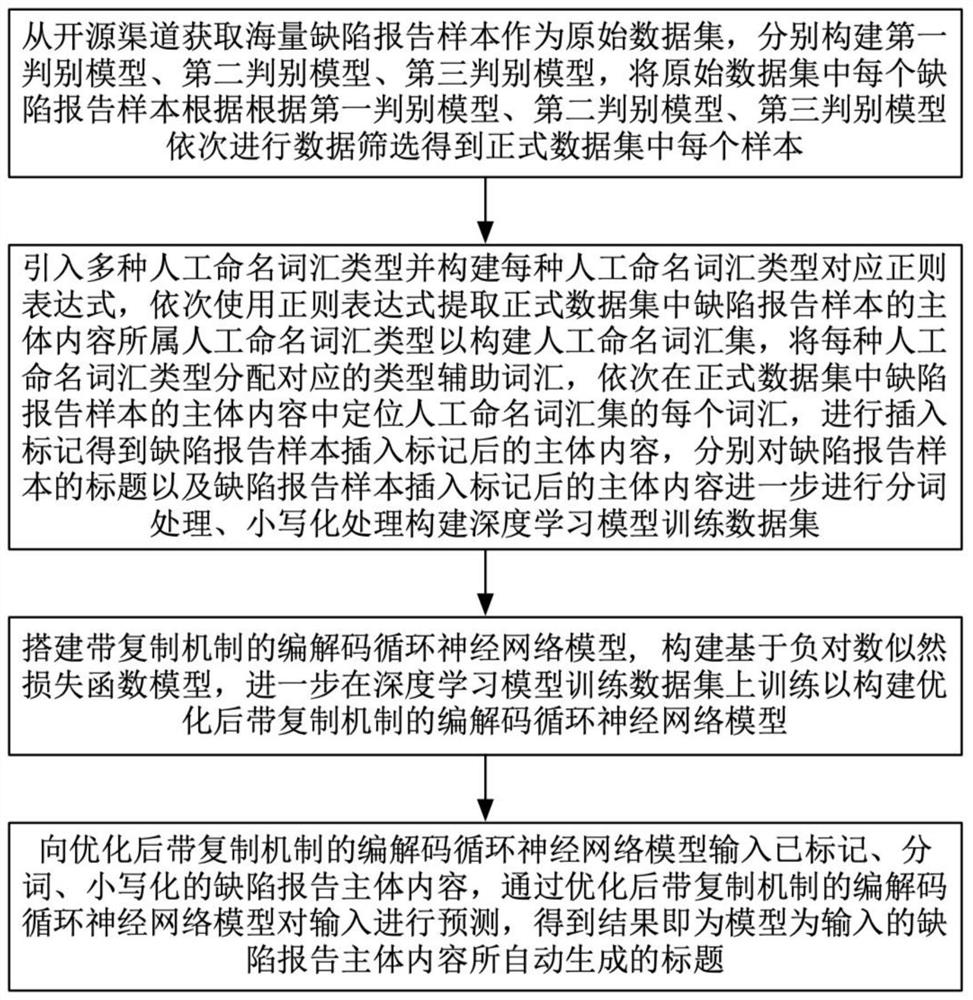

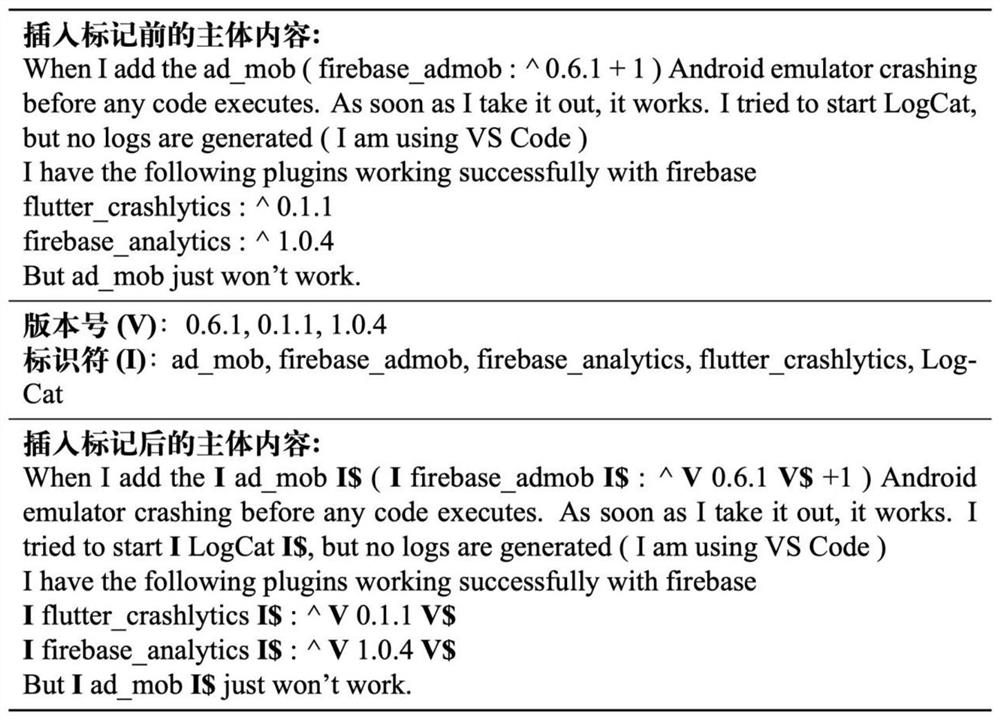

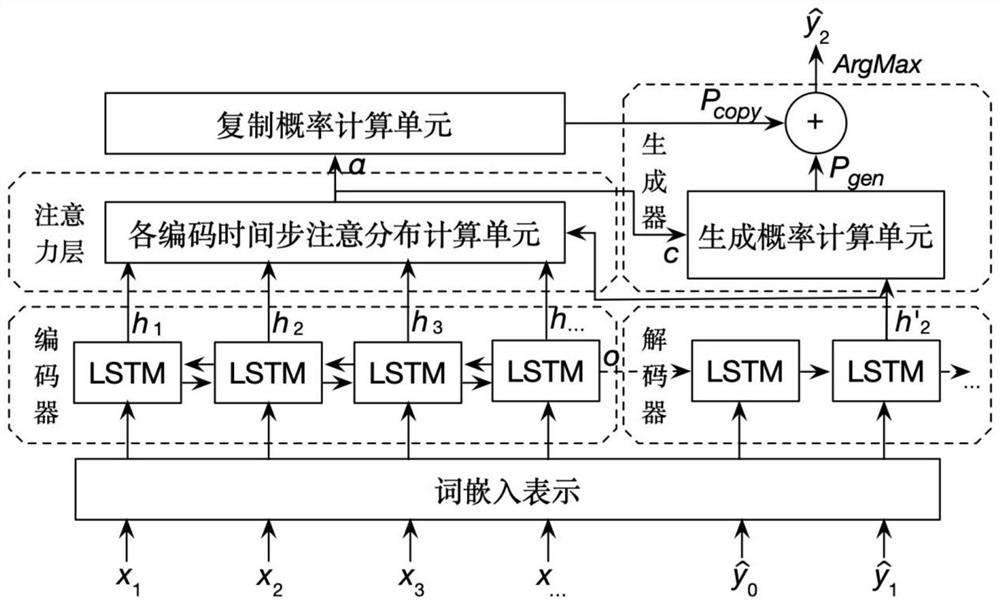

Deep learning-based automatic generation method for single sentence abstract defect report title

PendingCN111898337AEasy to handleImprove poor qualityNatural language data processingNeural architecturesData setSingle sentence

The invention provides a deep learning-based automatic generation method for a single sentence abstract defect report title. The method comprises the following steps: acquiring an open source defect report sample as an original data set, constructing three discrimination models to evaluate the sample in the original data set, and selecting a qualified sample to construct a formal data set; introducing a plurality of artificially named vocabulary types and constructing a corresponding regular expression for extracting and positioning artificially named vocabularies in the main body content of the formal data set sample; inserting type marks in front of and behind each artificial named vocabulary, and performing word segmentation and minimization processing on titles of the samples and the marked main content to construct a training data set; building a coding and decoding recurrent neural network model with a copying mechanism, and training on the training data set to obtain an optimized model; and inputting the defect report main body content of the title to be drafted into the optimized model, so that the model can automatically generate the corresponding title. According to the invention, the title writing quality and efficiency of the user are improved.

Owner:WUHAN UNIV

Automatic clamping device for automotive connector

InactiveCN107020719AHigh degree of automationImprove work efficiencyDomestic articlesEngineeringAutomaticity

The invention relates to an automatic clamping device for an automotive connector. The automatic clamping device comprises a fixed support, and a metal disk, an automatic lifting mechanism and a delivery mechanism which are installed on the fixed support respectively. The metal disk is connected to the automatic lifting mechanism and the delivery mechanism respectively; and a metal part to be clamped is placed in the metal disk, lifted to the set height through the automatic lifting mechanism, and then conveyed to the set position through the delivery mechanism. Compared with the prior art, the automatic clamping device provided by the invention has the advantages that the automaticity is high, and the product quality is improved; the production cost is reduced; the molding cycle is shortened, etc.

Owner:SHANGHAI CHIEF LAND ELECTRONICS CO LTD

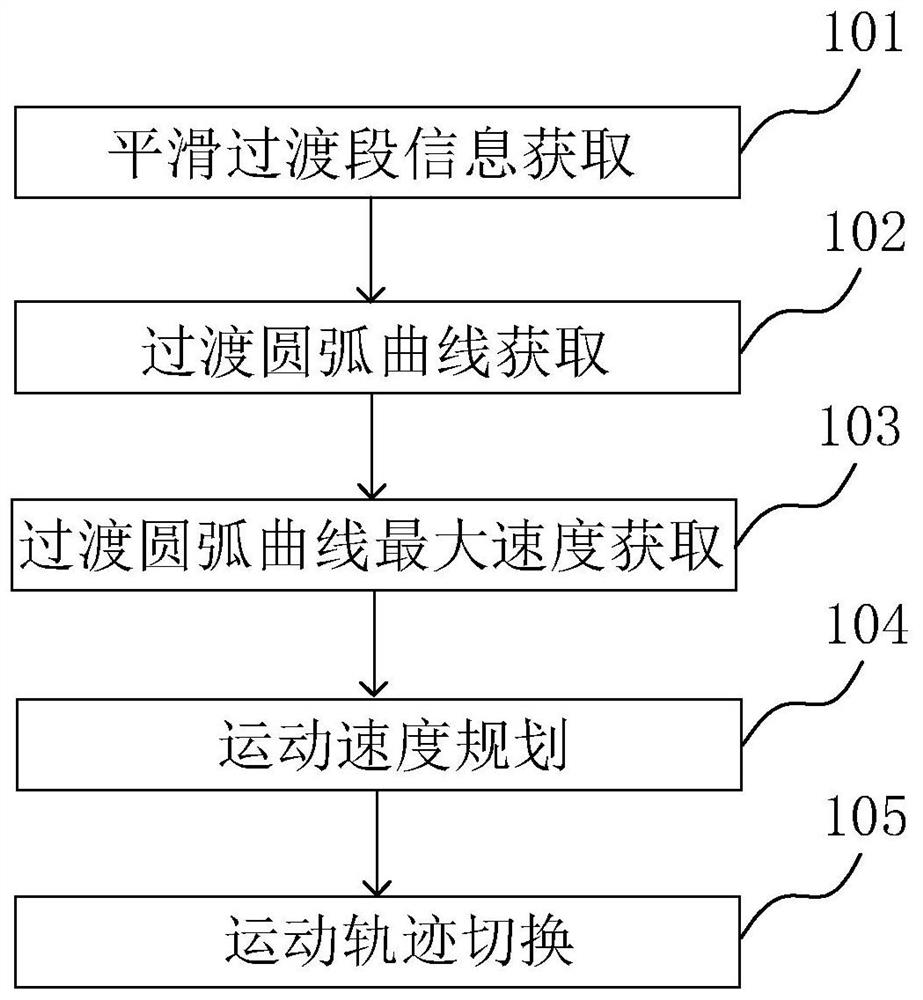

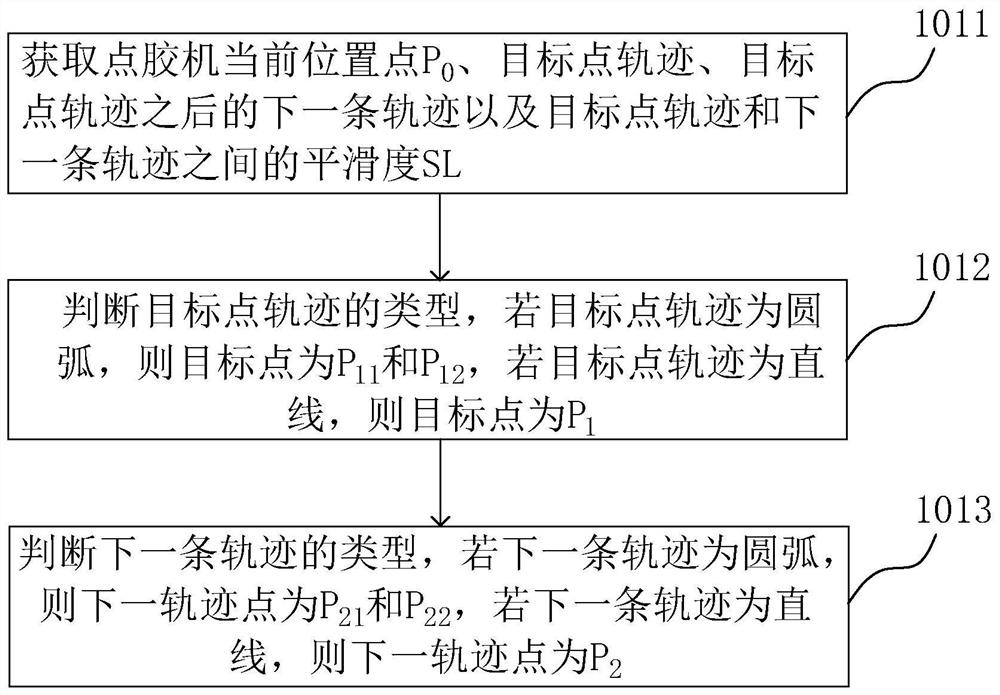

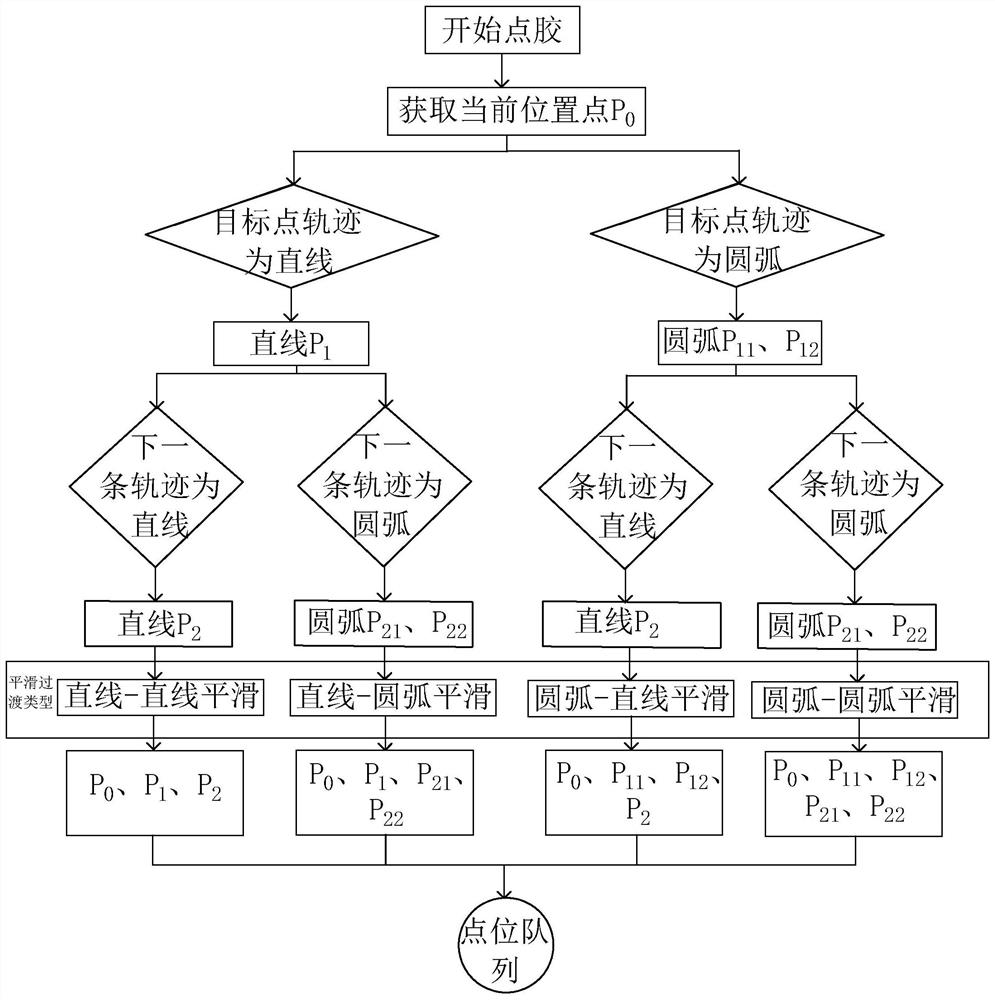

Glue dispenser motion planning method and system based on trajectory look-ahead

ActiveCN112547425AImprove poor qualitySmooth transitionLiquid surface applicatorsCoatingsAutomatic controlSimulation

The invention relates to a glue dispenser motion planning method and system based on trajectory look-ahead, and belongs to the technical field of automatic control. The motion planning method comprises smooth transition section information acquisition, transition arc curve acquisition, transition arc curve maximum speed acquisition, motion speed planning and motion trajectory switching; and the motion planning system comprises a smooth transition section information acquisition module, a transition arc curve acquisition module, a transition arc curve maximum speed acquisition module, a motionspeed planning module and a motion trajectory switching module. Compared with the prior art, the method and system have the effect of solving the problem of poor dispensing quality.

Owner:SHENZHEN HUACHENG IND CONTROL

A kind of compound protein feed and preparation method thereof

ActiveCN104522306BEnhance nutritional propertiesHigh nutritional valueAnimal feeding stuffAgricultural scienceConjugated protein

The invention relates to a compound protein feed and a preparation method thereof. The compound protein feed is obtained by fermenting bean dregs, grape pomace and apple pomace, inoculated with Saccharomyces cerevisiae, Lactobacillus and cellulase. The crude protein and crude fat content of the fermented compound protein feed is obviously increased, the ash cellulose content is obviously reduced, and the digestibility of crude protein after the animal eats is significantly improved, and the highest digestibility reaches 73.11%. The invention improves the inferior quality of the composite protein raw material through the solid-state fermentation method, improves the protein quality and feed utilization rate, has low cost, can meet the demand of animal husbandry for protein feed, and has good market application prospect.

Owner:LANZHOU INST OF ANIMAL SCI & VETERINARY PHARMA OF CAAS

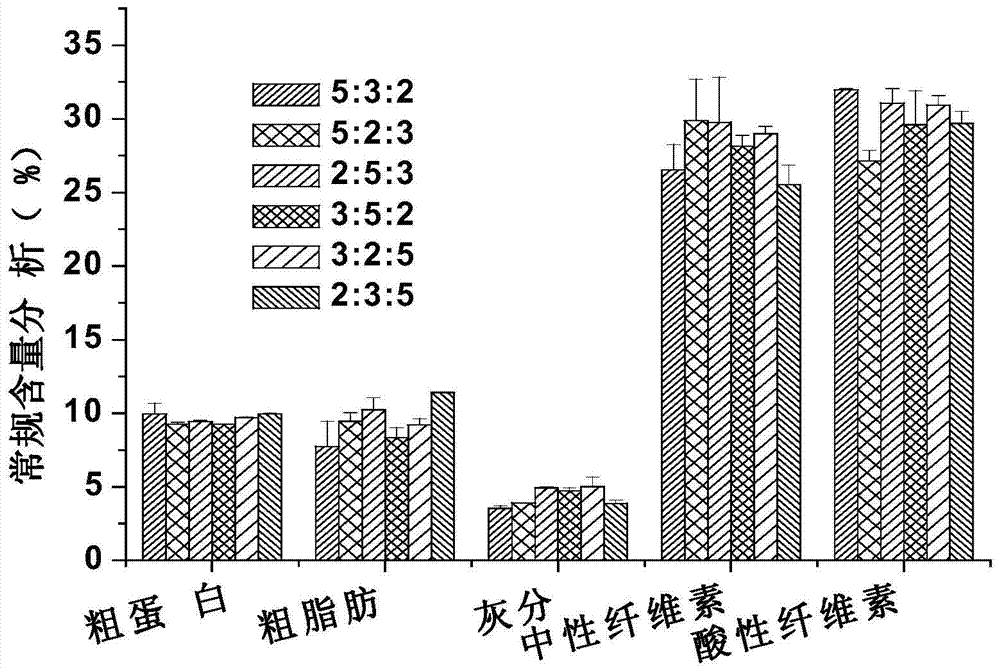

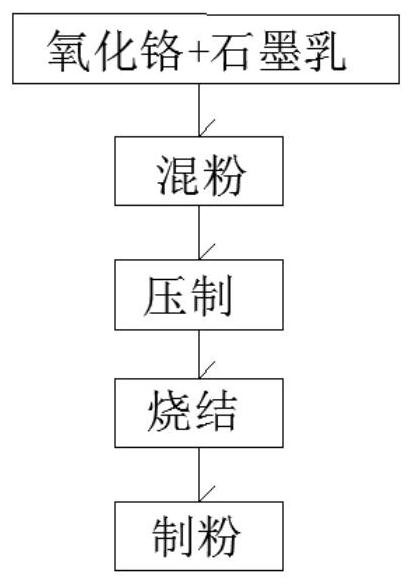

Method for preparing high-purity metal chromium through carbon reduction

The invention relates to the technical field of metal chromium preparation, and discloses a method for preparing high-purity metal chromium through carbon reduction. The method comprises the following steps of respectively measuring chromium oxide green powder and aquadag, wherein the mass ratio of the aquadag to the chromium oxide green powder is 1: (4 to 5); mixing the weighed chromium oxide green powder with the aquadag; then pressing the mixed material into a hollow blank by adopting a compression molding device, and uniformly forming circular ventilation ducts on the inner and outer side walls of the blank by a mold; loading the pressed hollow blank into a vacuum sintering furnace for sintering; and sequentially crushing, grinding and sieving a reduction product obtained through sintering, and obtaining metal chromium powder. According to the method for preparing the high-purity metal chromium through carbon reduction provided by the invention, the conversion rate of preparing the metal chromium powder from chromium oxide can be greatly increased; and the impurity content in the metal chromium powder is reduced.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

An anti-counterfeit label outer surface laminating machine

ActiveCN110126431BWarm up evenlyProtect the internal structureLamination ancillary operationsLaminationDrive shaftStructural engineering

The invention relates to an anti-counterfeiting label outer surface laminating machine. The laminating machine comprises a base, wherein the left end of the base is provided with a power mechanism, the top surface of the base is provided with an upper pressing roller and a lower pressing roller through a driving shaft, a gap is left between the upper pressing roller and the lower pressing roller to ensure the passage of an anti-counterfeiting label and a membrane, the driving shaft is connected with the power mechanism by a coupling, a driven shaft is arranged above the base by a left side plate and a right side plate, the driven shaft is connected with the power mechanism, a membrane roll is arranged on the periphery of the driven shaft, and the top surface of the base is provided with apre-heating mechanism through two mounting mechanisms. According to the provided anti-counterfeiting label outer surface laminating machine, a gap is left between pre-heating rollers and the membraneroll, the membrane roll temperature is reduced, the inner structure of the membrane is protected, the service life of the membrane is prolonged, the membrane roll is uniformly pre-heated, the pre-heating effect is good, the laminating quality is improved, the membrane is prevented from falling off, the pre-heating hot air flow impact force is small, and the risk of breaking the membrane is reduced.

Owner:湖北强大包装实业有限公司

Method for cultivating orchids

InactiveCN104920191AImprove poor qualityImprove survival rateGrowth substratesCulture mediaOrchisNutrient solution

The invention provides a method for cultivating orchids. The method comprises the steps of seedling hardening: to-be-transplanted tissue culture seedlings are moved from a constant temperature light culture room to an environment with weak light and temperature of 21-23 DEG C to be cultured for 10 to 12 days; pot culture: the tissue culture seedlings are planted into an orchid pot culture matrix, three strains are planted in each pot, the culture constant temperature ranges from 21 DGE C to 23 DEG C, the light intensity is 1,800 Lux, the light intensity period is 12 h of light or 8 h of darkness, water is sprayed to leaf surfaces of each seedling everyday, the indoor humidity is maintained above 80%, a nutrient solution is supplemented every twenty days after two weeks of plant setting, and the ratio for each strain is 15 ml every time. The method for the cultivating orchids has the advantages that not only can the quality of the orchids be improved, but also the survival rate can be improved.

Owner:柳州市长林苗木种植专业合作社

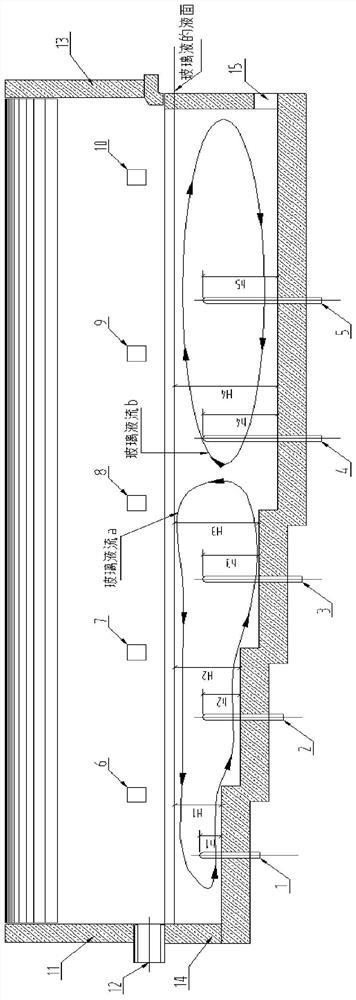

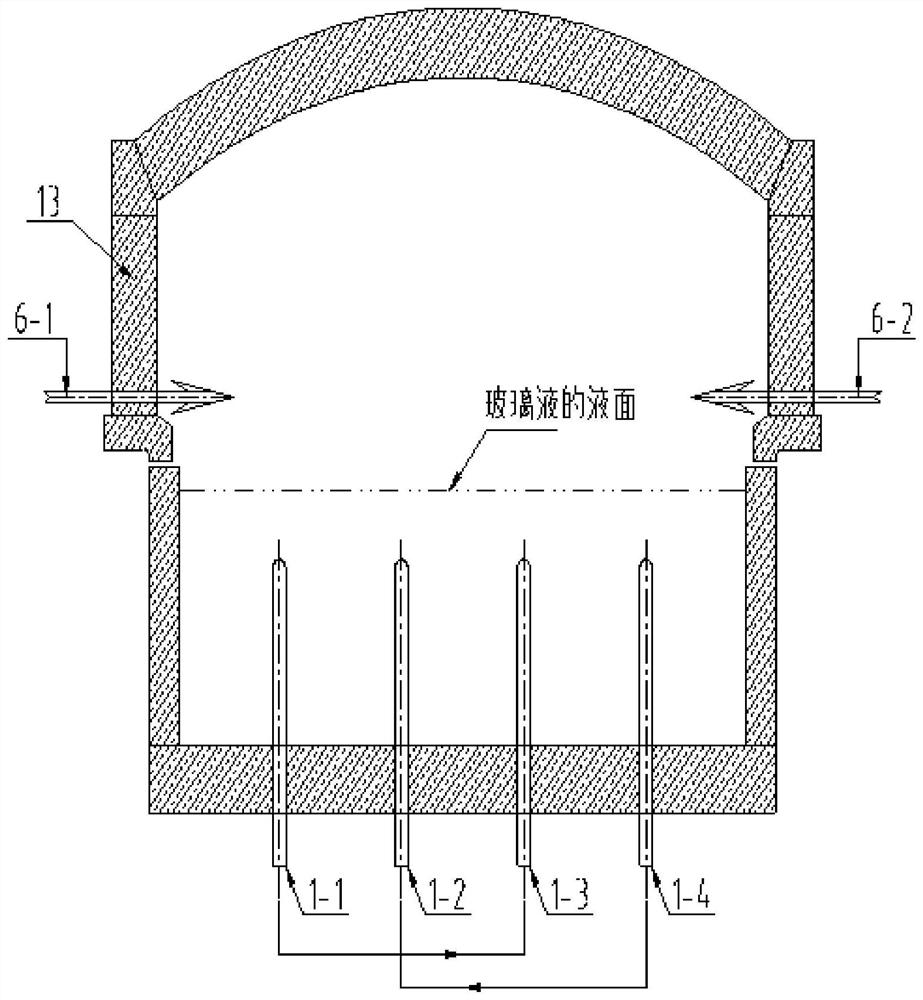

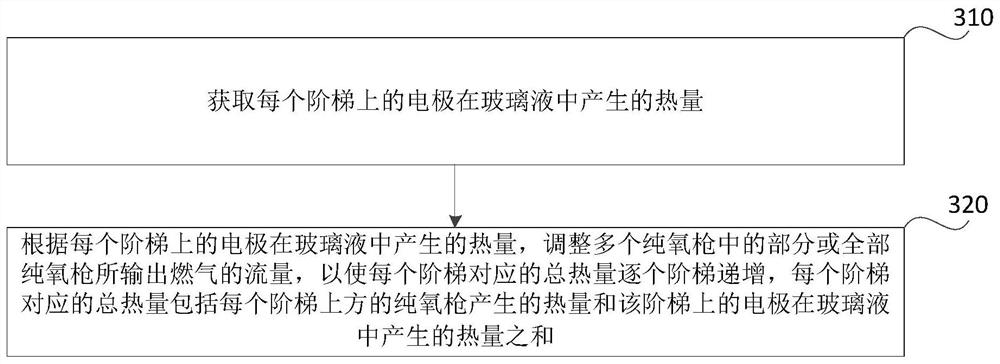

Glass furnace and glass melting control method

ActiveCN106746490BFlexible temperature controlImprove uniformityGlass furnace apparatusElectric furnaceCombustionGlass furnace

The disclosure relates to a glass furnace and a glass melting control method. The glass furnace is provided with a feeding port and a material outlet. The glass furnace includes: a furnace top and a furnace pool bottom; the furnace pool bottom is stepped The structure is used to place the molten glass. The bottom of the kiln pool includes multiple steps, and the depth of the multiple steps increases successively. The depth of each step is the distance between each step and the liquid level of the glass liquid. At least one electrode, the electrode set on each step is located below the liquid level of the glass liquid; the top of the kiln and the liquid level of the glass liquid form a combustion space, and a number of pure oxygen lances arranged in an even distribution are arranged in the combustion space; The inlet is located on the furnace wall at the end of the step with the shallowest depth at the bottom of the kiln, and the feeding port is higher than the liquid level of the glass liquid, and the outlet is located at the furnace wall at the end of the step with the deepest depth at the bottom of the kiln. The feed port is lower than the liquid level of the glass liquid. The disclosure has the effect of making the glass liquid have high uniformity and good quality.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

Image processing method, device and electronic equipment

ActiveCN112565603BReduce power consumptionImprove the display effectTelevision system detailsColor television detailsImaging processingComputer graphics (images)

The application discloses an image processing method, device and electronic equipment, belonging to the technical field of image processing. It can solve the problem of poor image quality captured by electronic equipment. The method includes: acquiring a real-time collected image through an image sensor; determining an image to be stored and an image to be previewed according to the real-time collected image through a central processing chip; determining the image to be stored and the image to be previewed through an image processing chip The image is enhanced; the enhanced image is stored in the memory, and the enhanced image to be previewed is displayed on the display screen.

Owner:VIVO MOBILE COMM CO LTD

Method for cultivating cut flower lily

InactiveCN104904582AImprove poor qualityIncrease productionGrowth substratesCulture mediaDevice typeCut flowers

The invention provides a method for cultivating cut flower lily. According to the method, equipment comprises a plastic-covered tunnel and a soil bed matrix; requirements on soil serving as a soil bed are the same with requirements on soil for planting of common cut flower lily; the required matrix comprises peat and perlite; the ratio of the peat to the perlite is 3:1; and after rectangular pieces of land in a field are prepared, furrows of which the widths are 8cm and the depths are 6-12cm are excavated on lines of the rectangular pieces according to cultivating spacing in rows and cultivating spacing between the rows. The method has the advantages that by the method, the quality of the cut flower lily is improved, and the yield of the cut flower lily can also be improved.

Owner:LIUZHOU HELIAN AGRI

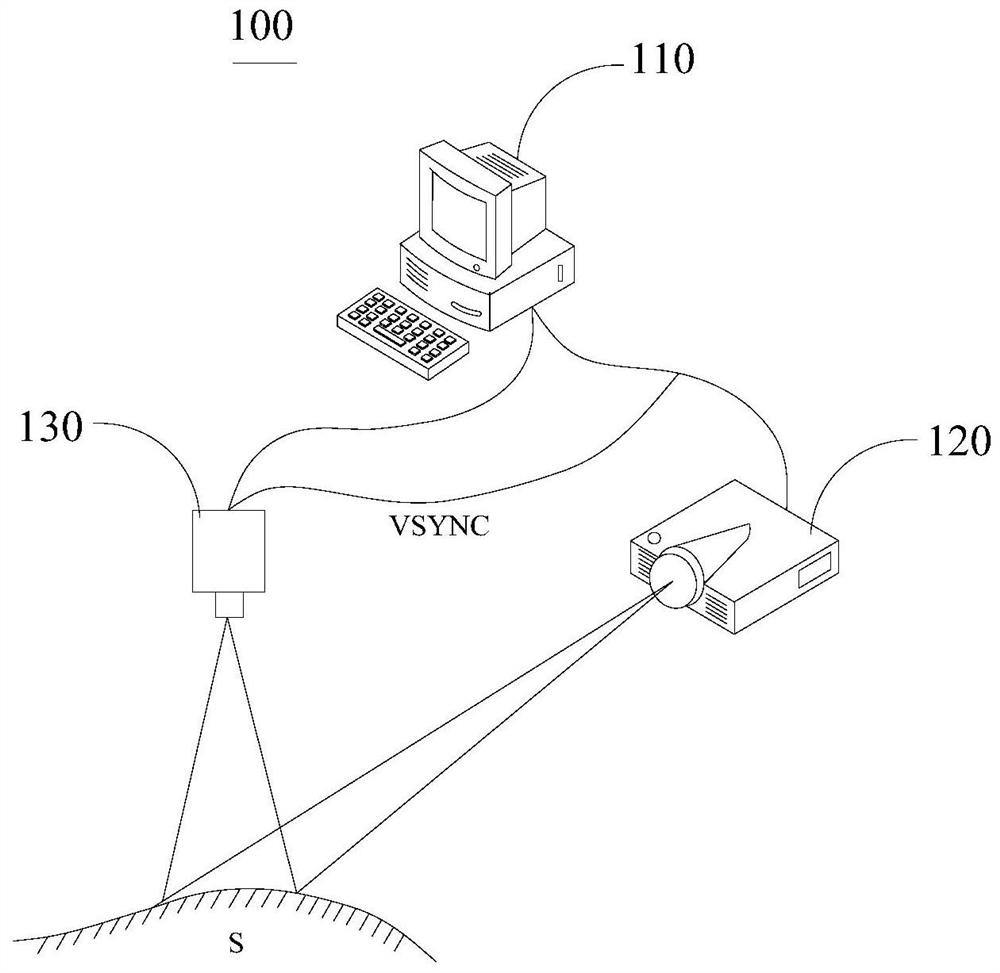

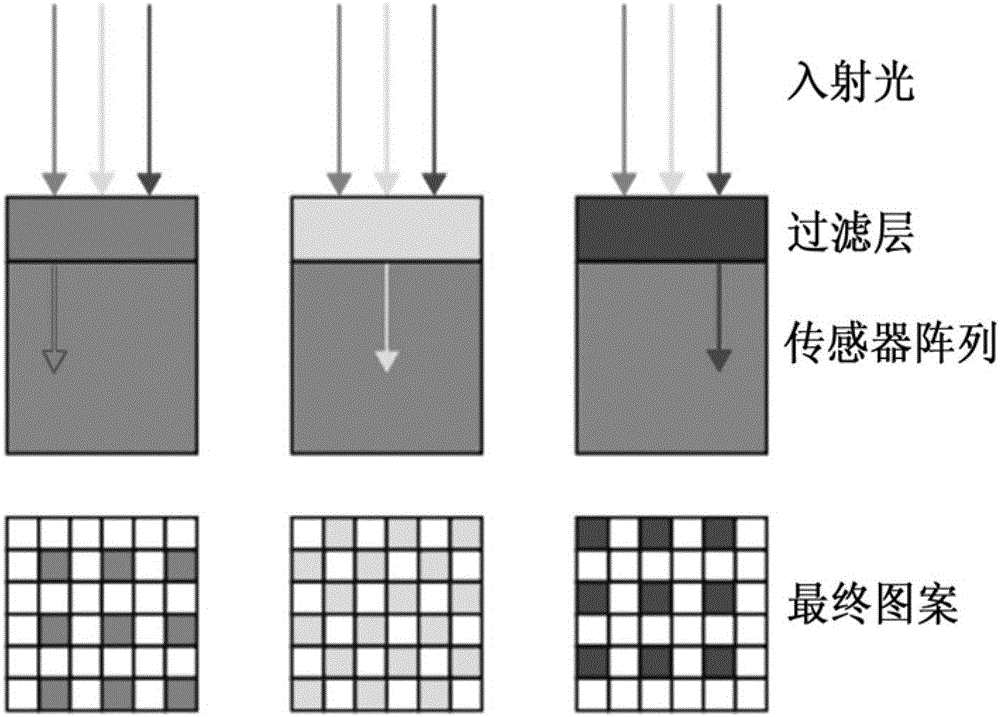

A synchronous control method, device and image acquisition system

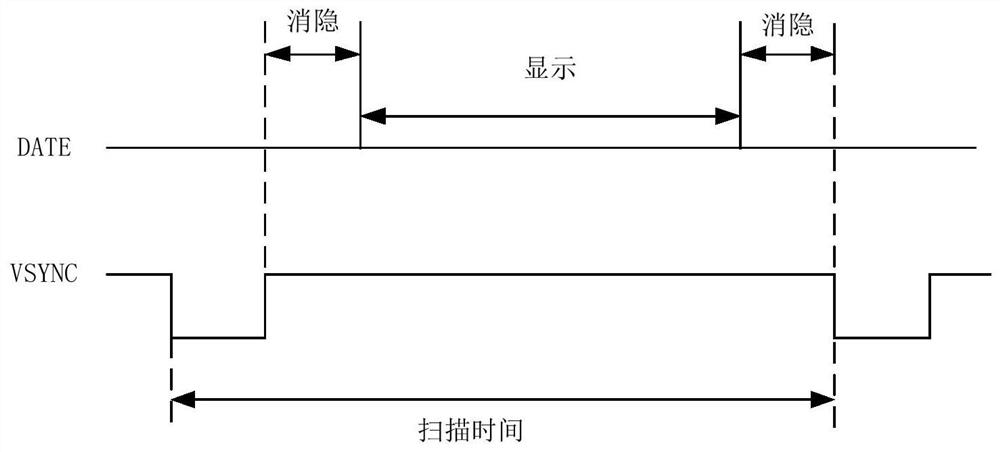

ActiveCN106303257BAchieve synchronizationGuaranteed synchronizationTelevision system detailsPicture reproducers using projection devicesComputer graphics (images)Synchronous control

The invention provides a synchronous control method, device and image acquisition system, belonging to the technical field of image acquisition. The synchronous control method is applied to an image acquisition system, and the method includes: the control device acquires the image; sends the image to the projector, and sends a capture command to the camera according to preset rules; During projection, the control device generates a vertical synchronous signal, and sends the vertical synchronous signal to the camera, so that the camera that receives the capture instruction captures the projected image of the current projector under the trigger of the vertical synchronous signal; obtains the current projection captured by the camera capture image of the image projected by the instrument. The synchronous control method effectively solves the problem that the flickering of the fluorescent lamp in the environment interferes with the image projected by the projector, resulting in poor quality of the image captured by the camera, and improves the speed of image acquisition.

Owner:SICHUAN UNIV

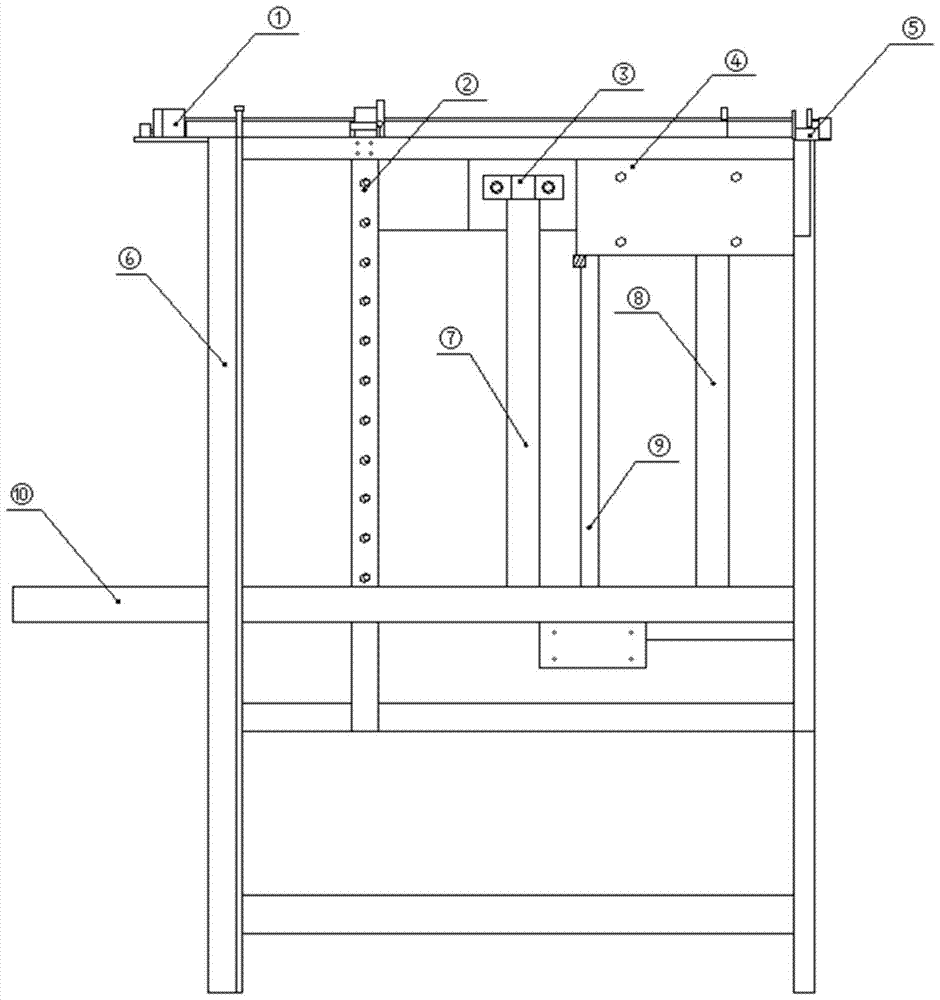

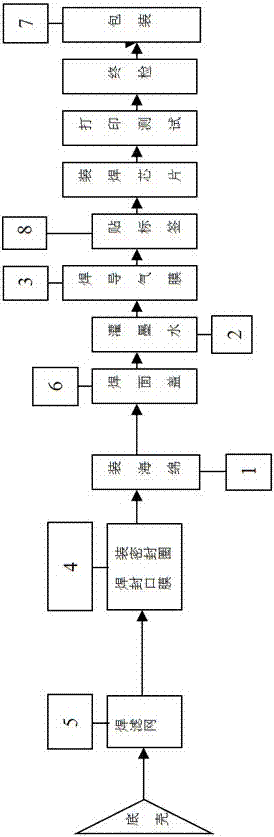

Split ink cartridge production system and its production process

InactiveCN105269976BReduce labor costsImprove poor qualityPrintingHigh productivityManufacturing engineering

The invention discloses a split ink cartridge production system and its production process, aiming to provide a split ink cartridge production system with low labor cost, high production efficiency and good quality, and also provides a split ink cartridge production system. A production process with fewer production steps and high production efficiency. The split-type ink cartridge production system includes a conveying line and an automatic sponge filling machine (1), an automatic ink filling machine (2), and an automatic sealing machine (3) arranged in sequence along the conveying direction of the conveying line. The production process of the split type ink cartridge production system includes 11 processes. The invention is applied to the technical field of producing split ink cartridges.

Owner:ZHUHAI GREE MEIDA TECH

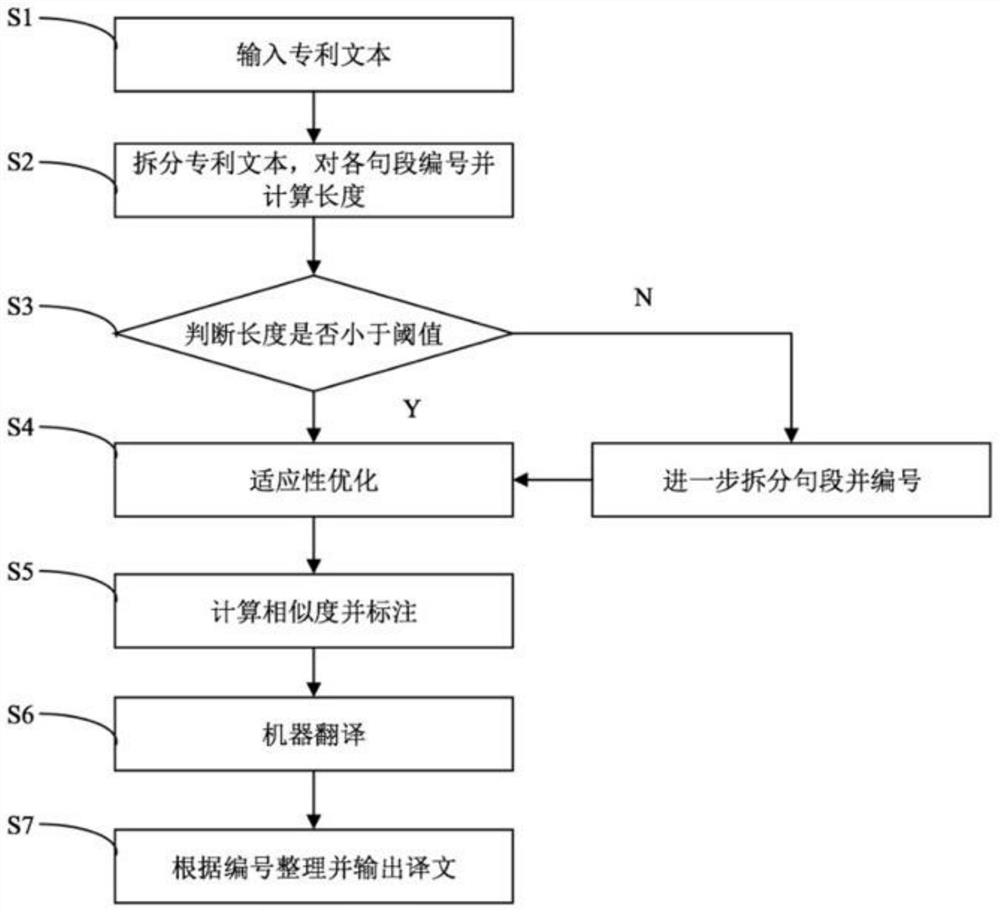

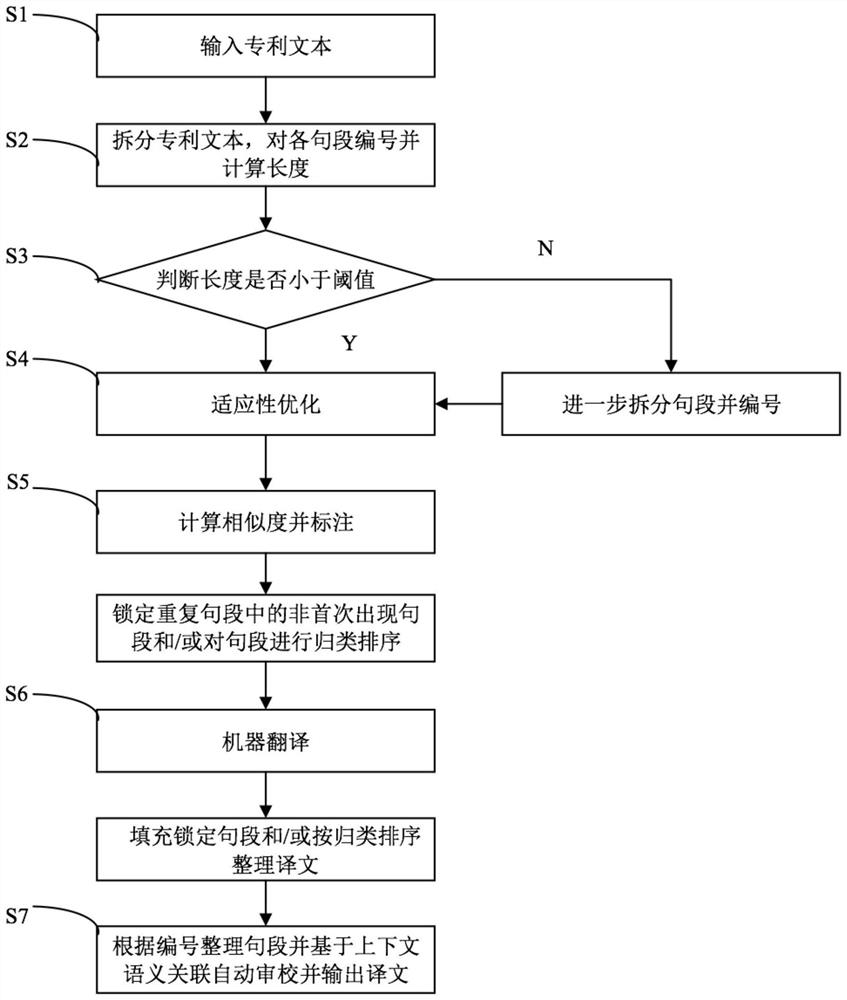

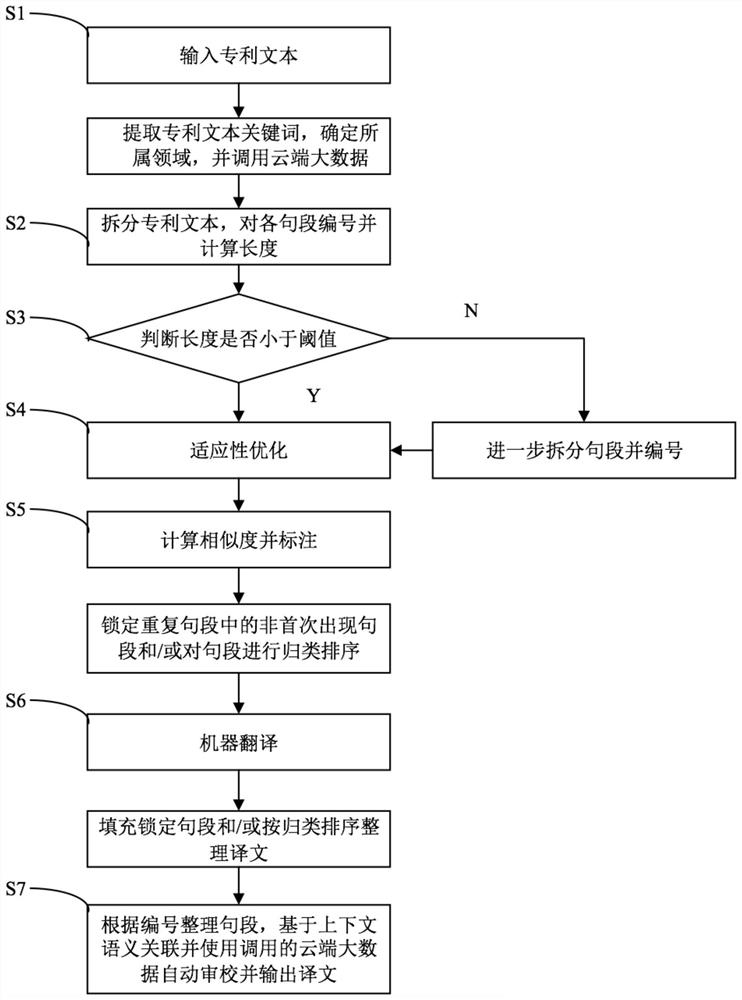

Pre-translation editing method and system for patent text machine translation

InactiveCN112487793AImprove match rateAvoid duplicationNatural language translationData processing applicationsAdaptive optimizationEngineering

The invention discloses a pre-translation editing method and a pre-translation editing system for patent text machine translation, which belong to the technical field of machine translation, and are used for further translating a patent text to obtain a translation after operations such as splitting, numbering, adaptive optimization, similarity calculation, locking and the like of the patent text.The translation obtained by the method solves that the quality of machine translation is poor when original text sentences are too long, sentence segments are numbered during splitting, reverse tracing can be conducted according to the numbers during arrangement and output of the translation, the output translation corresponds to source texts before splitting one to one in form and paragraph, andtherefore sentence-by-sentence contrast bilingual corpora are obtained.

Owner:JIANGSU SUNYU INFORMATION TECH CO LTD

Electrolytic capacitor with external connected pin

InactiveCN101640130BImprove solderabilityImprove qualityCapacitor terminalsCapacitor housing/encapsulationCapacitanceEngineering

The invention relates to an electrolytic capacitor with an external connected pin, which comprises a shell, at least one capacitor element and a plurality of external pins. The shell comprises a hollow plastic shell seat and a seal cover which is sealed on the plastic shell seat and seals the capacitor element inside; the capacitor element is provided with a plurality of small sections of internal pins which pass through the bottom of the shell; the external pin comprises a plate pin body and a connecting part at one side of the pin body; and the connecting part is aligned and connected with the internal pins through conducting perforations on the connecting part, and embedded and fixedly combined with a fixedly-connected convex part corresponding to the plastic shell seat through fixedly-connected concave parts of fixed parts at two sides of the pin body. Therefore, the external pins of large area can provide good welding stability when the electrolytic capacitor is adhered to the surface.

Owner:GEMMY ELECTRONICS

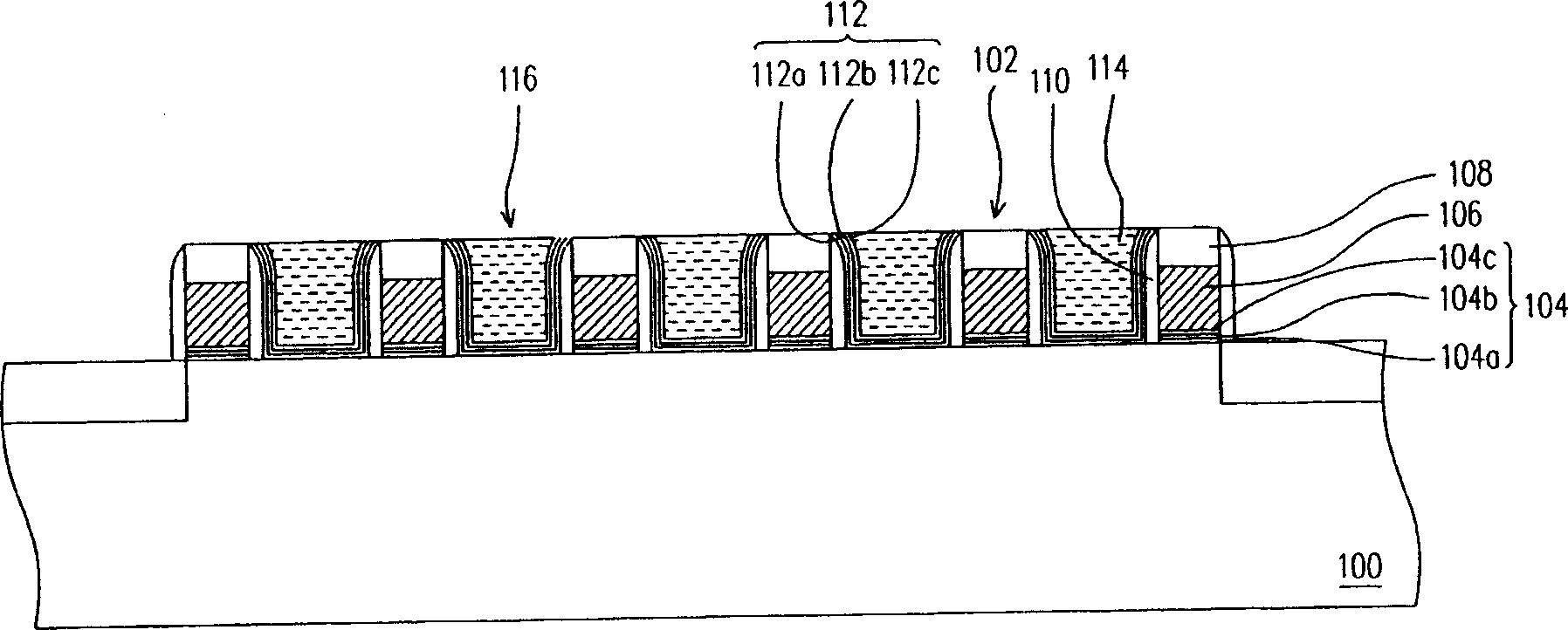

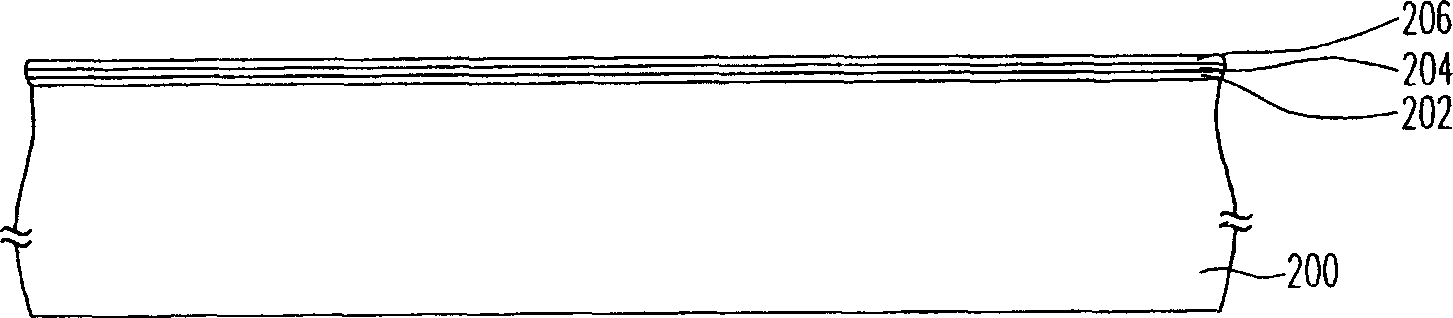

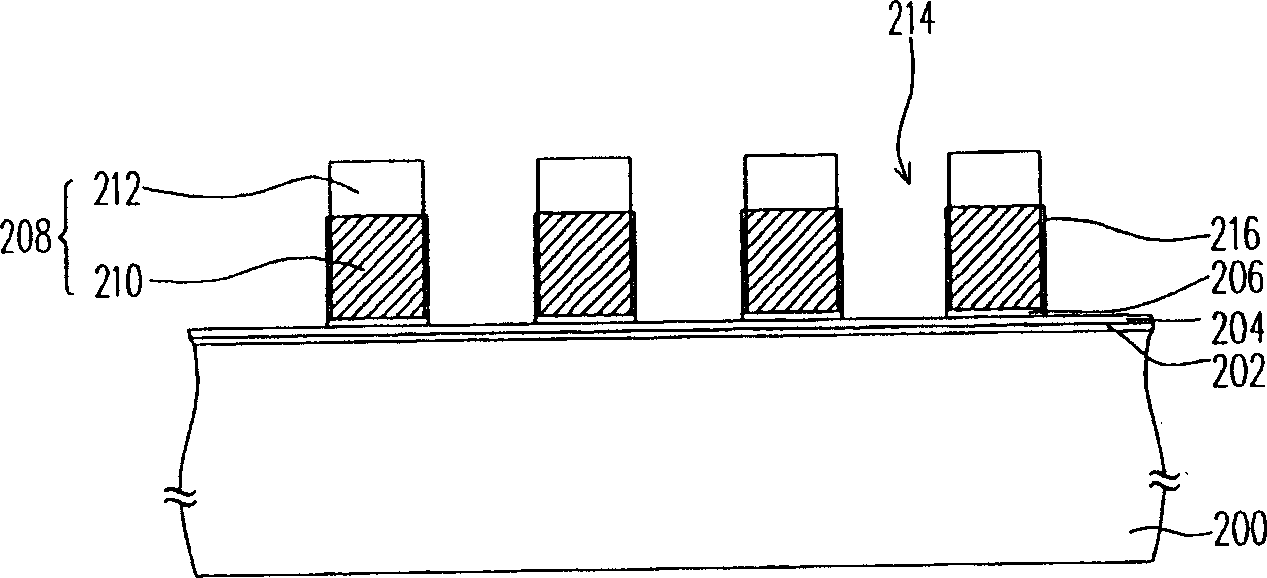

Production of non-volatile memory

InactiveCN1855441AImprove poor qualitySimple processSemiconductor/solid-state device manufacturingElectrical conductorGate stack

The method comprises: providing a substrate; sequentially forming a first dielectric layer, a charge-trapped layer and a second dielectric layer; forming multi gate stacking structures on said second dielectric layer; wherein each said gate stacking structure has a first gate electrode and roof cover; there is a gap between two adjacent gate stacking structures; forming an oxide layer on the sidewall of said first gate electrode; removing a portion of second dielectric layer not covered by the gate stacking structure; forming a third dielectric layer to overlap the gate stacking structure; forming a second conducting layer on said substrate; removing a portion of second conducting layer in order to form multi second gate electrodes in the gaps between said gate stacking structures; said second gate electrodes and the gate stacking structures composes a storage cell array; respectively forming a source region and a drain region at each side of said storage array.

Owner:POWERCHIP SEMICON CORP

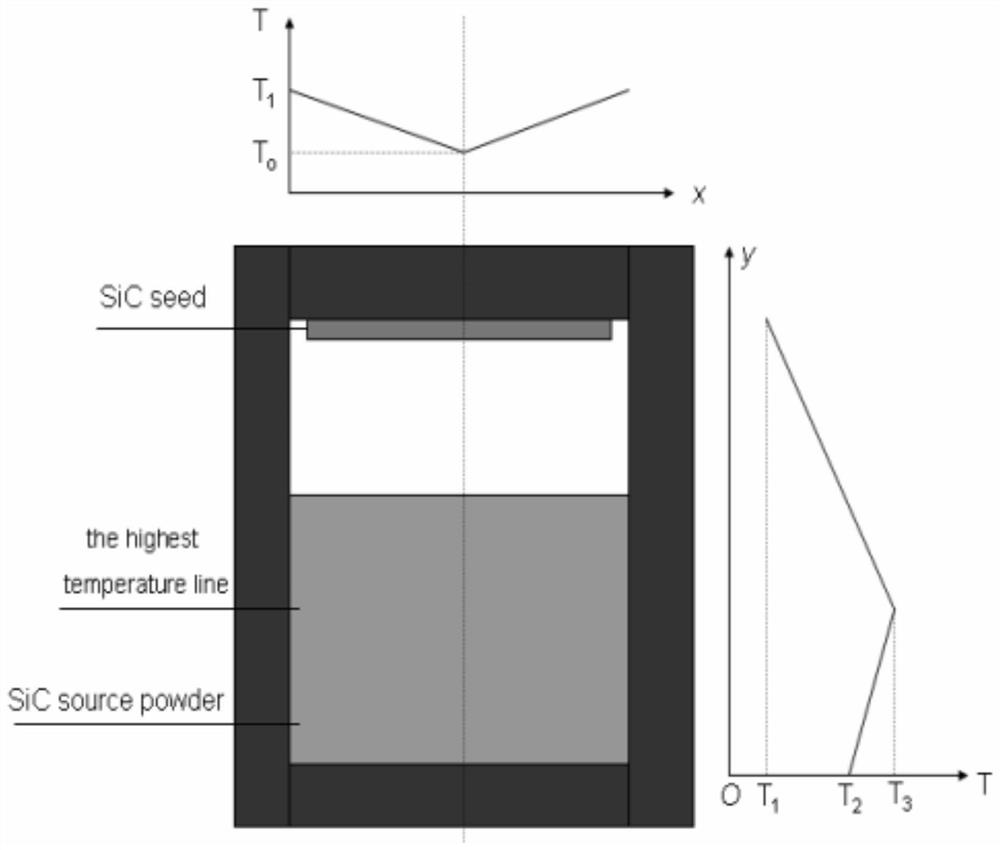

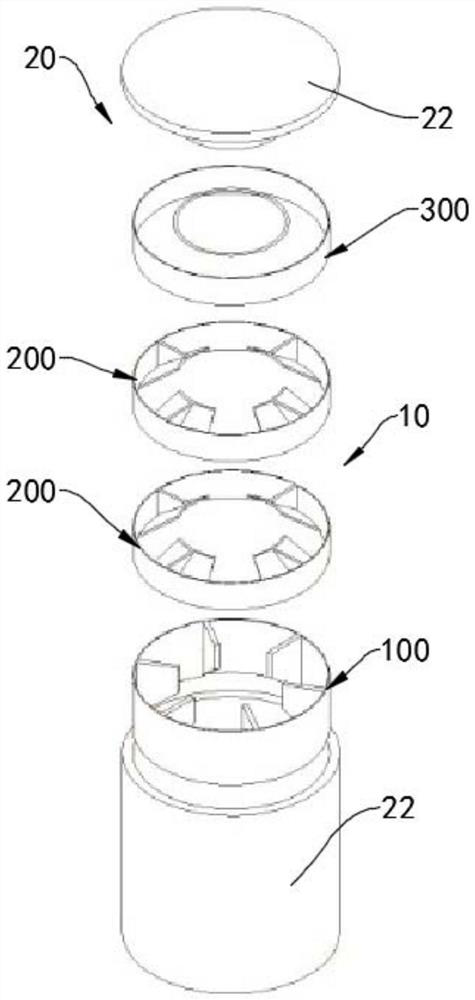

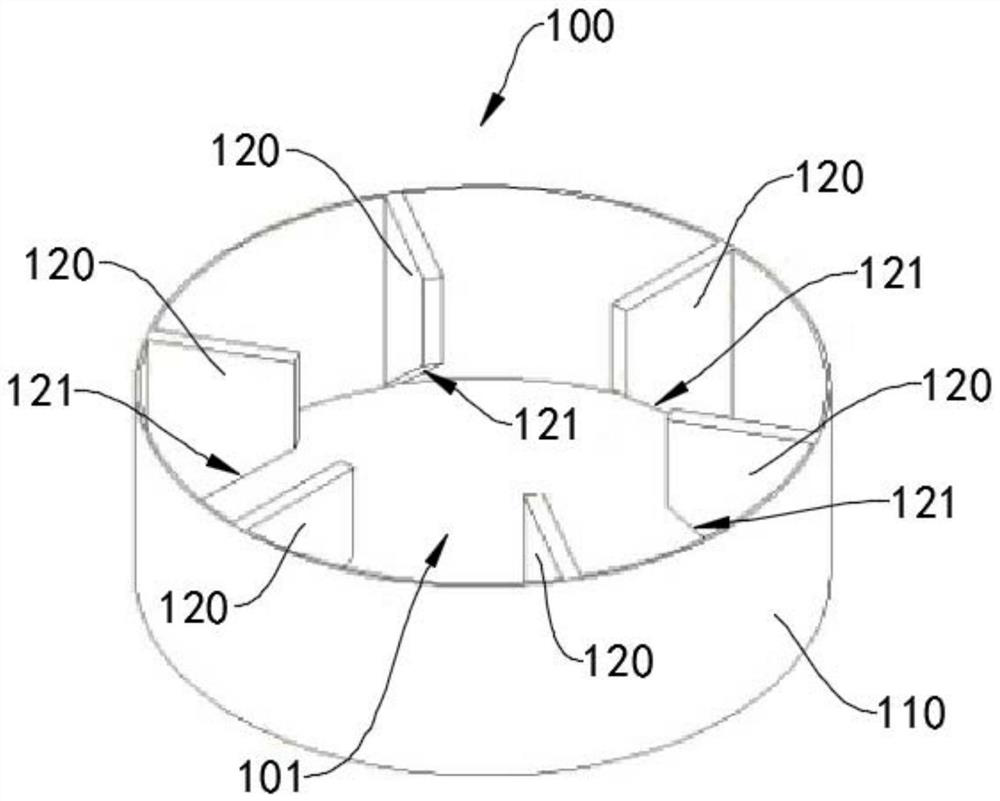

Crystal growth assembly, crystal growth apparatus and method

ActiveCN113122924BAvoid geometric asymmetryAvoid uneven thicknessPolycrystalline material growthFrom condensed vaporsCrystallographyEngineering

The invention relates to the technical field of semiconductors, in particular to a crystal growth component, a crystal growth device and a method. The crystal growth assembly includes a blade adjustment ring, and the blade adjustment ring includes an outer ring body and a plurality of blade parts; the outer ring body is used to arrange along the height direction of the crucible; the blade parts extend along the height direction of the crucible, and the plurality of blade parts are arranged at regular intervals On the inner wall of the outer ring body, and the ends of the plurality of blades away from the outer ring body are enclosed to form a central channel. It can guide and adjust the production atmosphere, so as to ensure the stable and efficient growth of crystals.

Owner:FUJIAN NORSTEL MATERIAL TECH CO LTD

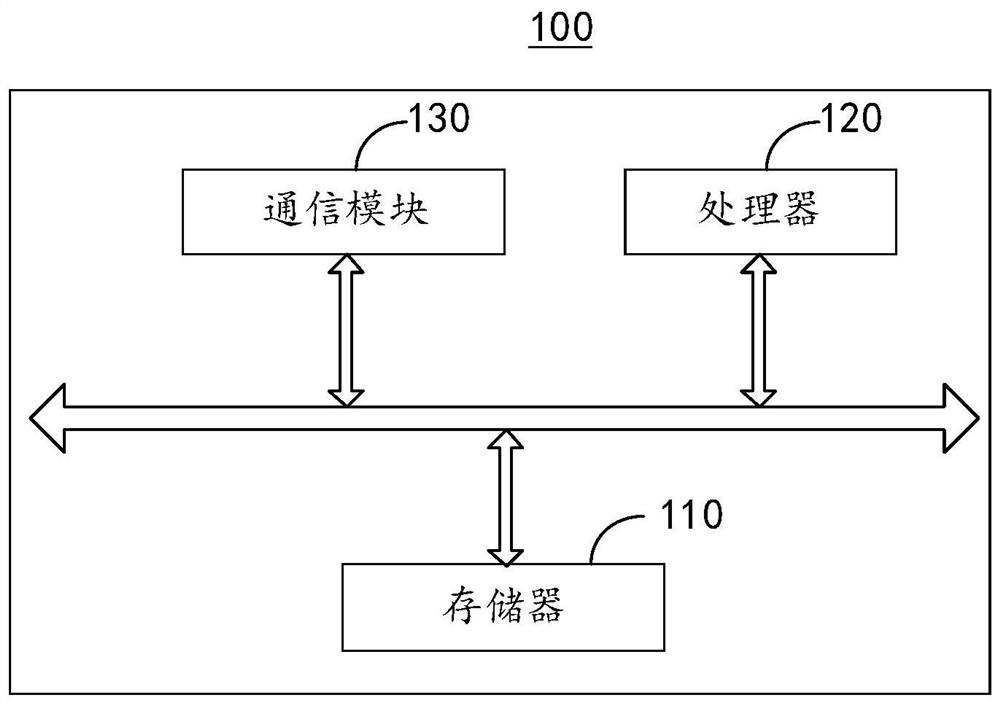

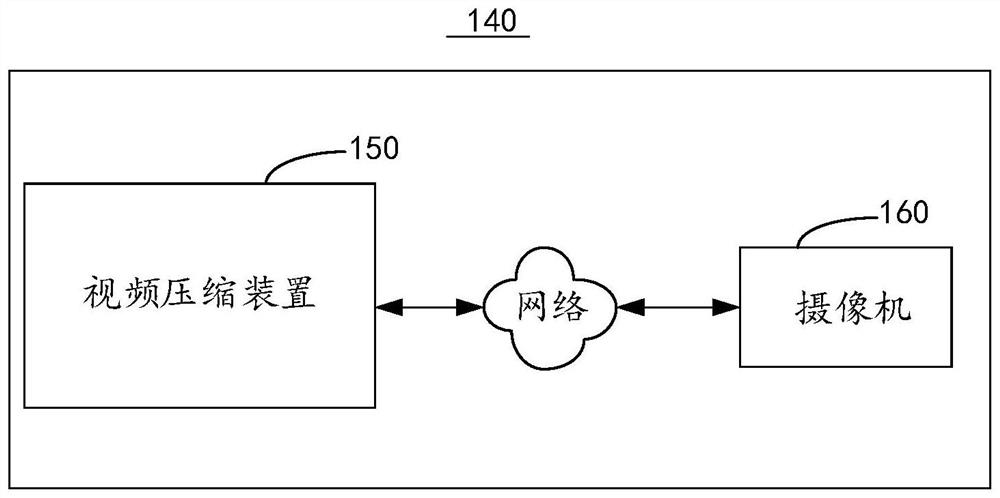

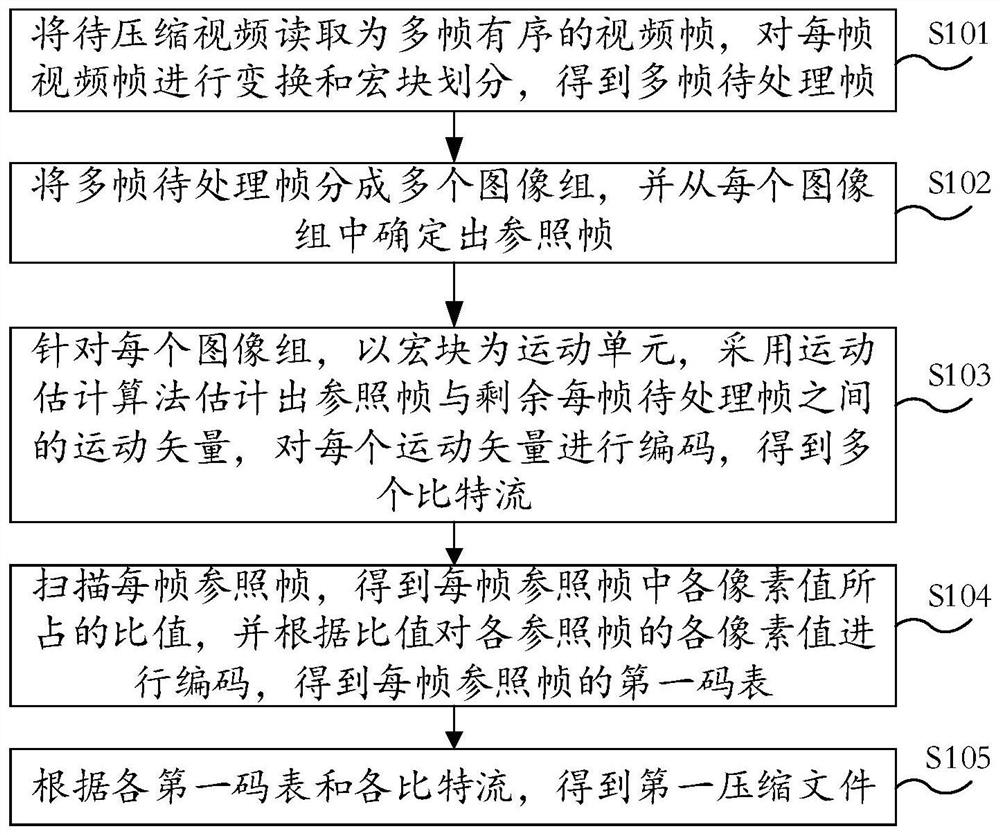

Video compression method, electronic equipment and computer readable storage medium

PendingCN114025166AImprove the problem of poor video qualityImprove poor qualityDigital video signal modificationMotion vectorEngineering

The embodiment of the invention provides a video compression method, electronic equipment and a computer readable storage medium, and belongs to the technical field of digital image processing, and the method comprises the steps: reading a to-be-compressed video into a plurality of ordered video frames, carrying out the conversion and macro block division of each video frame, obtaining a plurality of to-be-processed frames, dividing multiple frames to be processed into multiple image groups, determining a reference frame from each image group, estimating a motion vector between the reference frame and each remaining frame to be processed by adopting a motion estimation algorithm by taking a macro block as a motion unit for each image group, encoding each motion vector to obtain multiple bit streams, encoding the reference frames according to the ratio of the pixel values, and obtaining the first code table of the reference frames and the first compressed file, converting the change between the images in the video into the motion vector, and encoding the motion vector and the reference frames, so that the video quality of the compressed file can be improved, and the size of the compressed file is reduced.

Owner:CHENGDU UNIV OF INFORMATION TECH

Image sensor inter-pixel offset correction device and correction method thereof

InactiveCN102957879BImprove poor qualityEasy wiringTelevision system detailsImage analysisComputer scienceCorrection method

Owner:HYUNDAI MOBIS CO LTD

Quick-fermentation coarse cereal health-care bread

InactiveCN107347956APrevent arteriosclerosisBroad market prospectDough treatmentModified nutritive productsChemistryCorn starch

The invention relates to quick-fermentation coarse cereal health-care bread. The quick-fermentation coarse cereal health-care bread is characterized by being made through the following steps of performing hydroxypropyl replacement and acetylation replacement on part of hydroxyl on corn starch molecules, so as to obtain acetylated hydroxypropyl starch; then, using wheat flour as a main material, adding corn flour, the acetylated hydroxypropyl starch and other auxiliary materials, performing mixing with a flour mixing agent, performing dough mixing, performing standing, performing rounding, performing shaping, performing leavening, performing shaping once again, performing fermentation once again, finally, performing baking, performing quick cooling, performing packing, and performing mixing so as to obtain the quick-fermentation coarse cereal health-care bread. According to the quick-fermentation coarse cereal health-care bread, the corn being rich in nutrient components is added to flour to be made into the bread, so that the made quick-fermentation coarse cereal health-care bread not only has various health-care functions of resisting ageing, preventing cancer, reducing blood pressure, preventing arteriosclerosis and the like based on common bread, opens up a new way for deep processing of the corn, and has a broad market prospect.

Owner:合肥台香食品有限公司

Device for synchronously blanking scraps and removing burrs for progressive die

The invention discloses a device for synchronously blanking scraps and removing burrs for a progressive die. An insert assembly capable of sliding leftwards and rightwards is arranged at a notch at the final blanking position of the progressive die. The insert assembly comprises a female die sliding block, a sliding block cushion, an up-and-down floating sliding block and an inclined wedge, wherein the female die sliding block can move transversely and longitudinally in a female die plate; the sliding block cushion is embedded in a lower base plate; the up-and-down floating sliding block can slide along the sliding block cushion; the inclined wedge can vertically move; the upper end face of the sliding block cushion and the lower end face of the up-and-down floating sliding block are inclined planes which are in sliding fit; the female die sliding block is provided with a blanking working hole; the upper end of the blanking working hole is provided with a burr step protruding towards the inside of the hole; and the edge of the burr step is provided with a chamfer angle. Due to the adoption of the device, the problem that the scraps and connected materials of the progressive die cannot be removed so that the burrs are finally left is completely solved, the scrap blanking and the burr removal on a blanked workpiece can be completed only by once positioning, the cost of manually removing the burrs or removing the burrs by a single engineering die is saved, and the production efficiency and the product quality are greatly improved.

Owner:SHENZHEN EVA PRECISION TECH GRP CO LTD

Method for manufacturing array substrate

ActiveCN103560111BImprove poor qualityAvoid Parasitic CapacitanceTransistorSolid-state devicesImaging qualityDisplay device

The invention provides a method for manufacturing an array substrate, the array substrate and a display device. The method for manufacturing the array substrate comprises the steps that through the picture composition technology, a pattern of a semiconductor layer located in a first zone and a pattern of a source and drain electrode layer located in the first zone are formed, wherein the first zone is a preset zone used for enabling a source electrode and a drain electrode of a thin film transistor to be formed; a transparent conductive layer is formed on the portion, with the source and drain electrode layer of the first zone reserved, of a substrate; through the picture composition technology, a pattern of a first transparent electrode and a pattern of an extending portion are formed; the extending portion extends to the portion above a first position where the source electrode is formed in a preset mode, wherein the first position is in the first zone; through the picture composition technology, the portions, outside the first position and a second position, of the source and drain electrode layer are removed, so that a pattern of the source electrode and a pattern of the drain electrode are formed, wherein the second position is a position where the drain electrode is formed in a preset mode. According to the method for manufacturing the array substrate, image quality is improved.

Owner:BOE TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com