Glue dispenser motion planning method and system based on trajectory look-ahead

A technology of motion planning and dispensing machine, which is applied to the device and coating of surface coating liquid, which can solve the problems of poor dispensing quality and achieve continuity, improve poor dispensing quality and smooth transition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

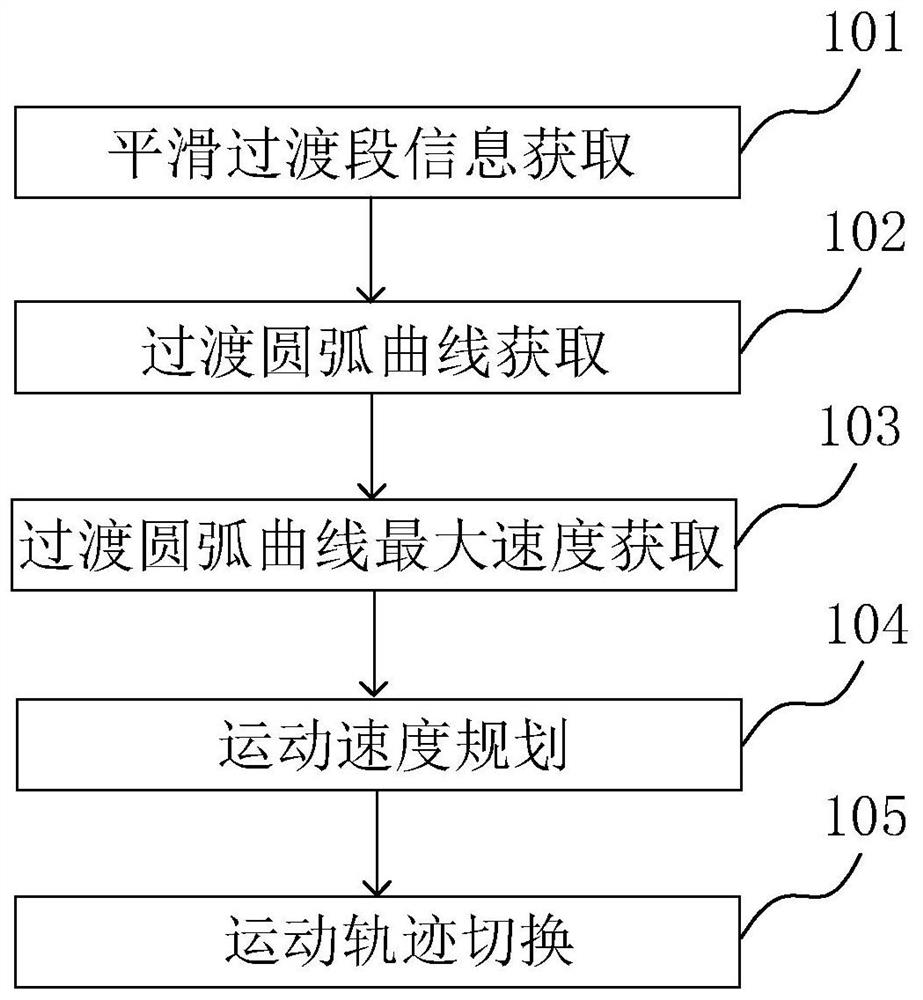

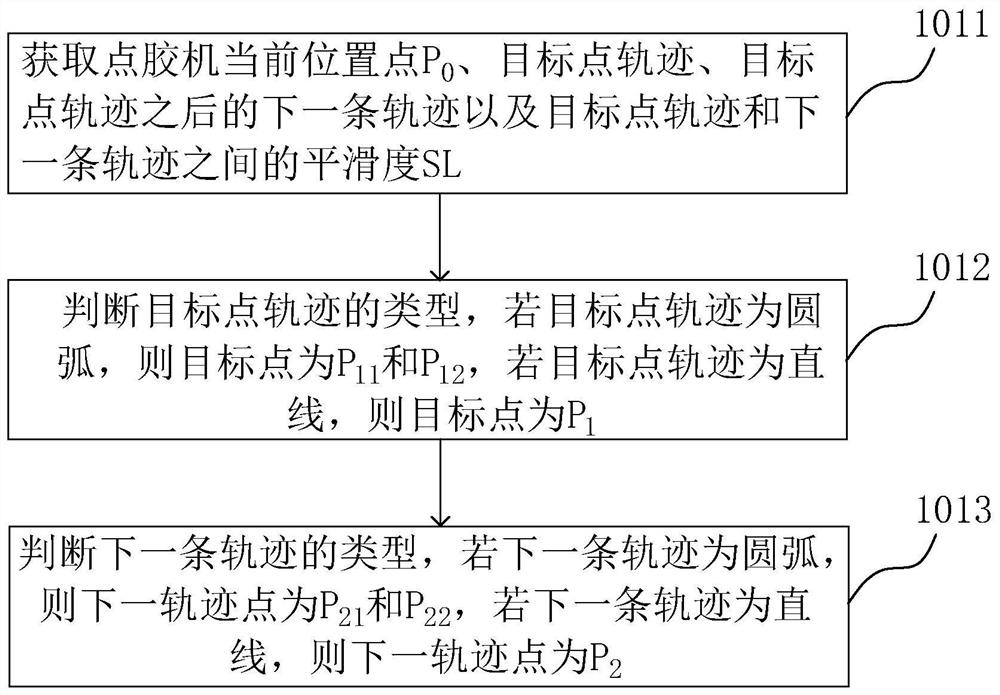

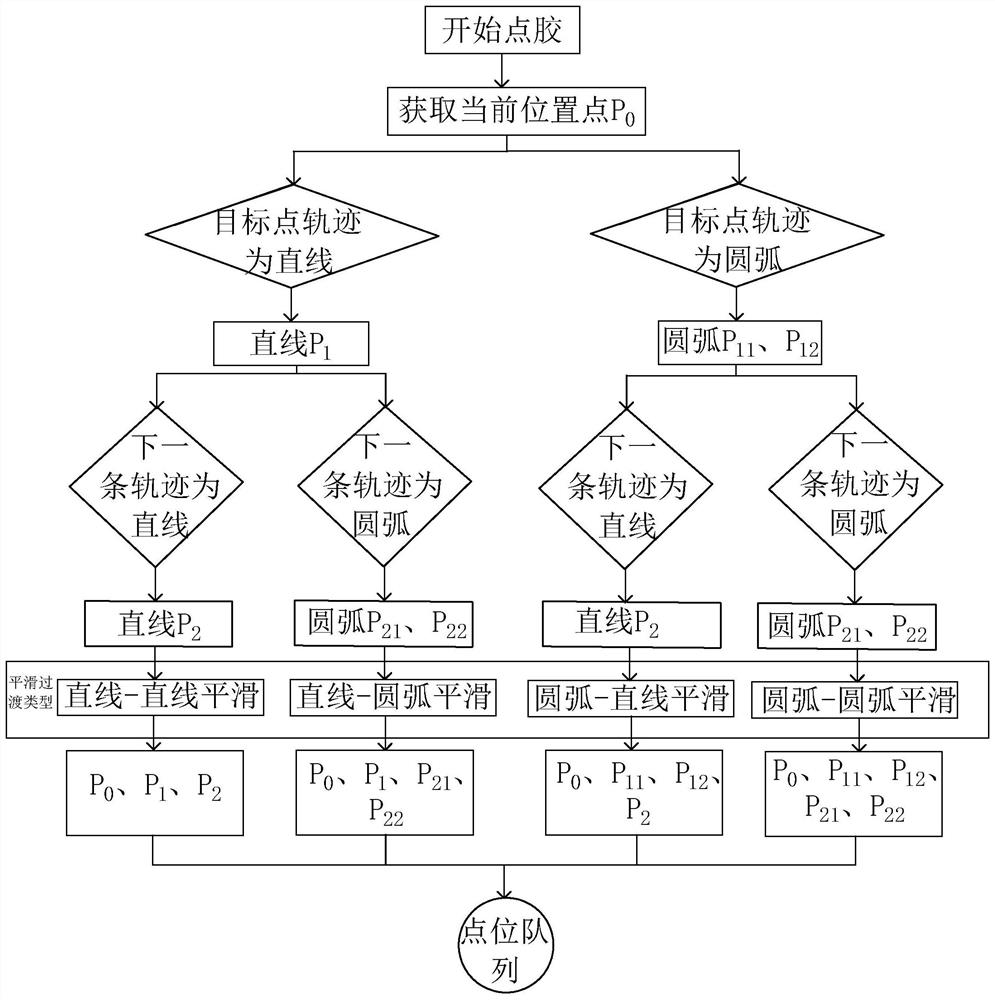

[0074] refer to figure 2 and image 3 , as an implementation of smooth transition segment information acquisition 101, including the following steps:

[0075] 1011. Obtain the current position point P of the dispenser 0 , the target point trajectory, the next trajectory after the target point trajectory, and the smoothness SL between the target point trajectory and the next trajectory.

[0076] Among them, when teaching the dispensing robot, the length of each dispensing track has been set, so the dispensing robot points P according to its current position. 0 , which can obtain the target point trajectory and the next trajectory.

[0077] 1012. Determine the type of target point trajectory, if the target point trajectory is an arc, then the target point is P 11 and P 12 , if the trajectory of the target point is a straight line, then the target point is P 1 .

[0078] Among them, P 11 is the target point trajectory, that is, the midpoint of the arc, P 12 is the targe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com