Method for manufacturing array substrate

A manufacturing method and array substrate technology, applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve problems such as not detailed one by one, and achieve the effect of avoiding parasitic capacitance and improving Flicker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

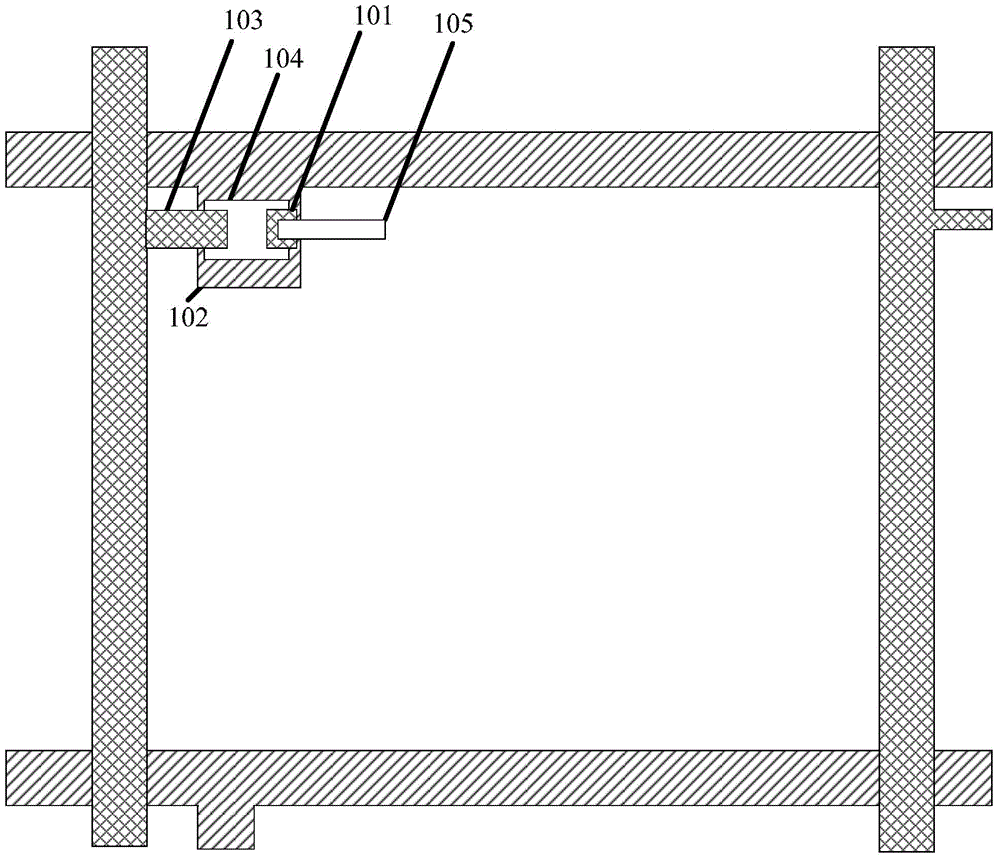

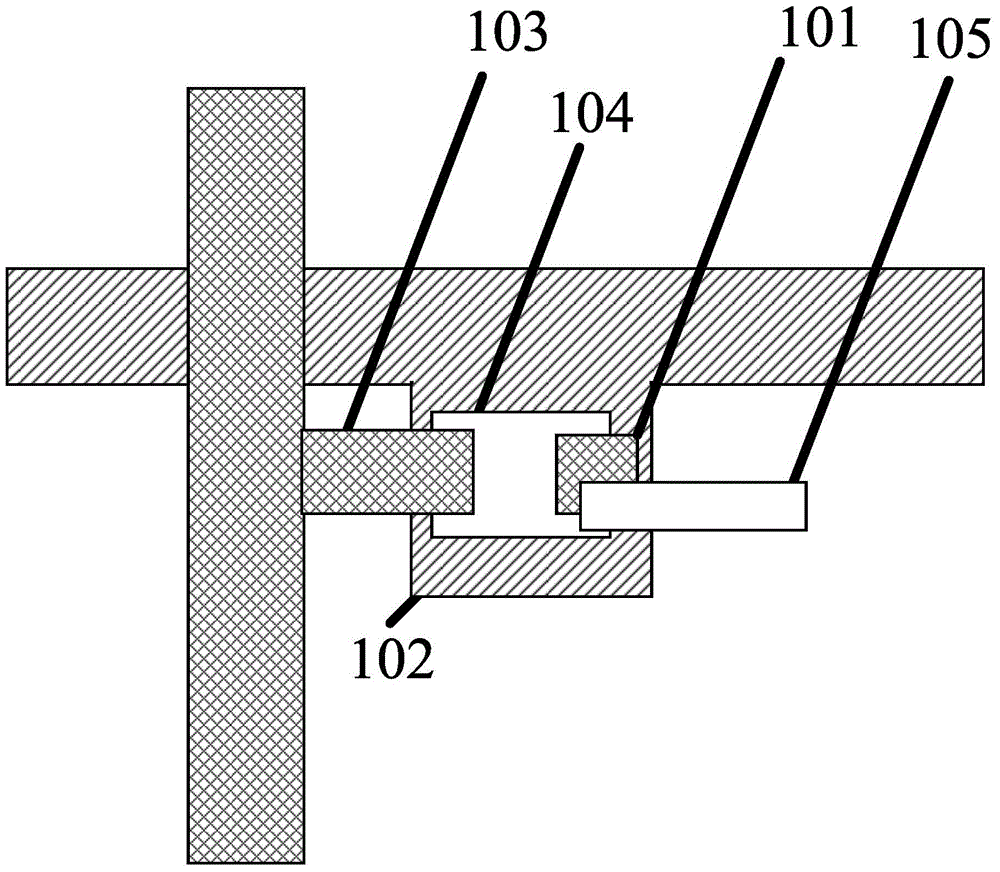

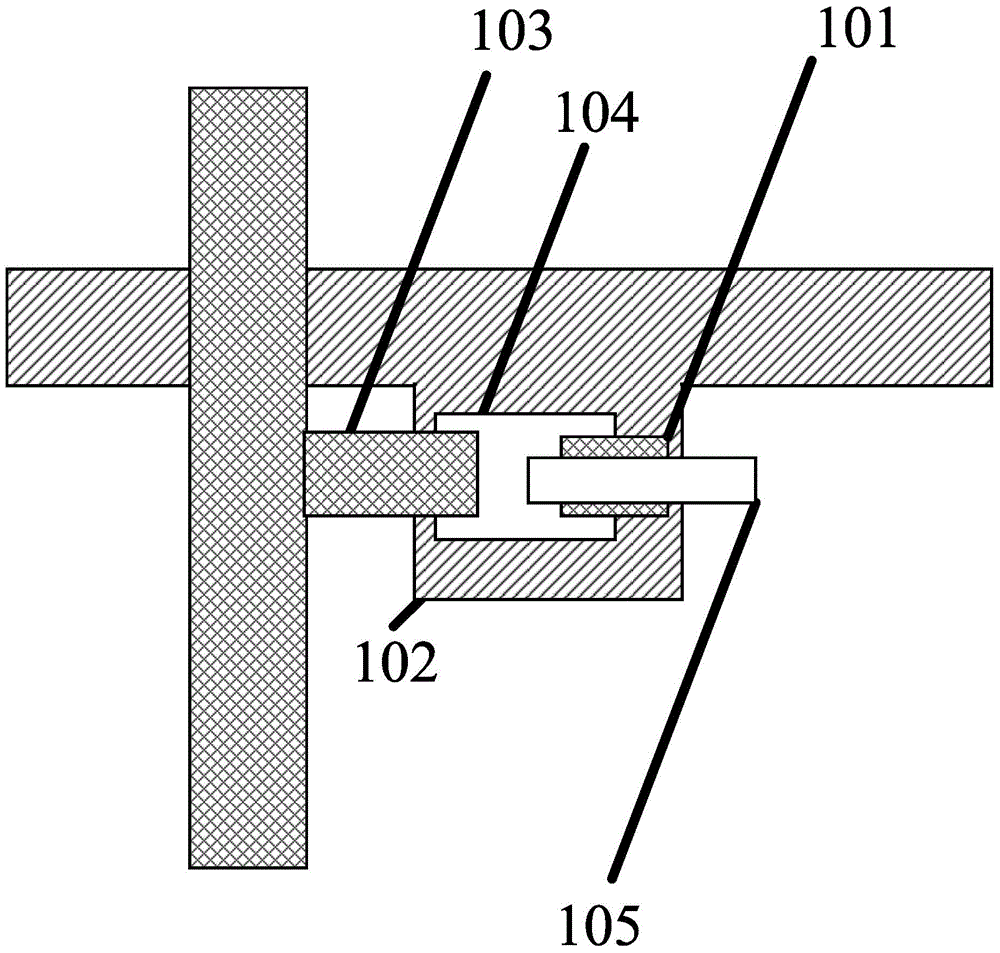

[0043]In the manufacturing method of the array substrate, the array substrate and the display device according to the embodiment of the present invention, after forming the semiconductor layer and the source-drain electrode layer for making the source-drain electrodes, the source-drain electrodes are not directly made, but reserved for Form the semiconductor layer and the source-drain electrode layer in the region of the source-drain electrode layer, and then after forming a transparent conductive layer (such as a commonly used ITO layer), process the transparent conductive layer to form an extension extending to the position where the source electrode is scheduled to be formed, Finally, the source-drain electrode layer located outside the predetermined position for forming the source-drain electrode in the reserved area is removed to finally form the source-drain electrode. In the above manner, the overlapping part of the extension part and the gate electrode is completely loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com