Crystal growth assembly, crystal growth apparatus and method

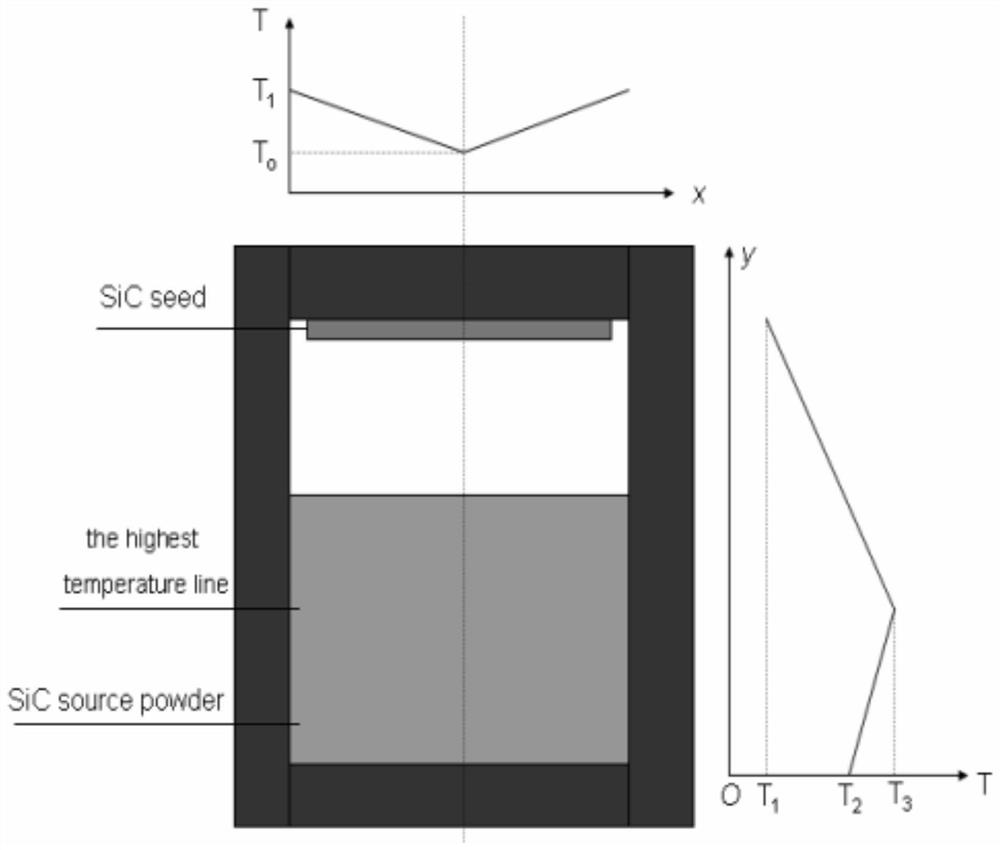

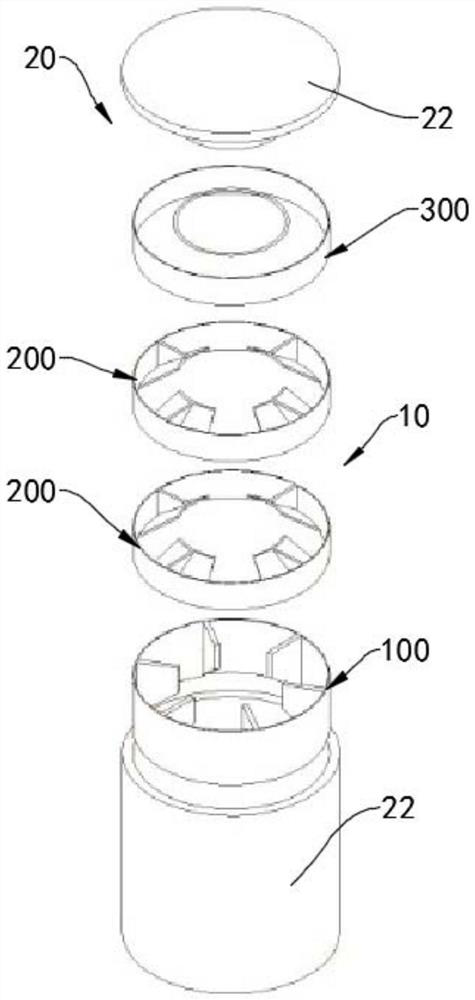

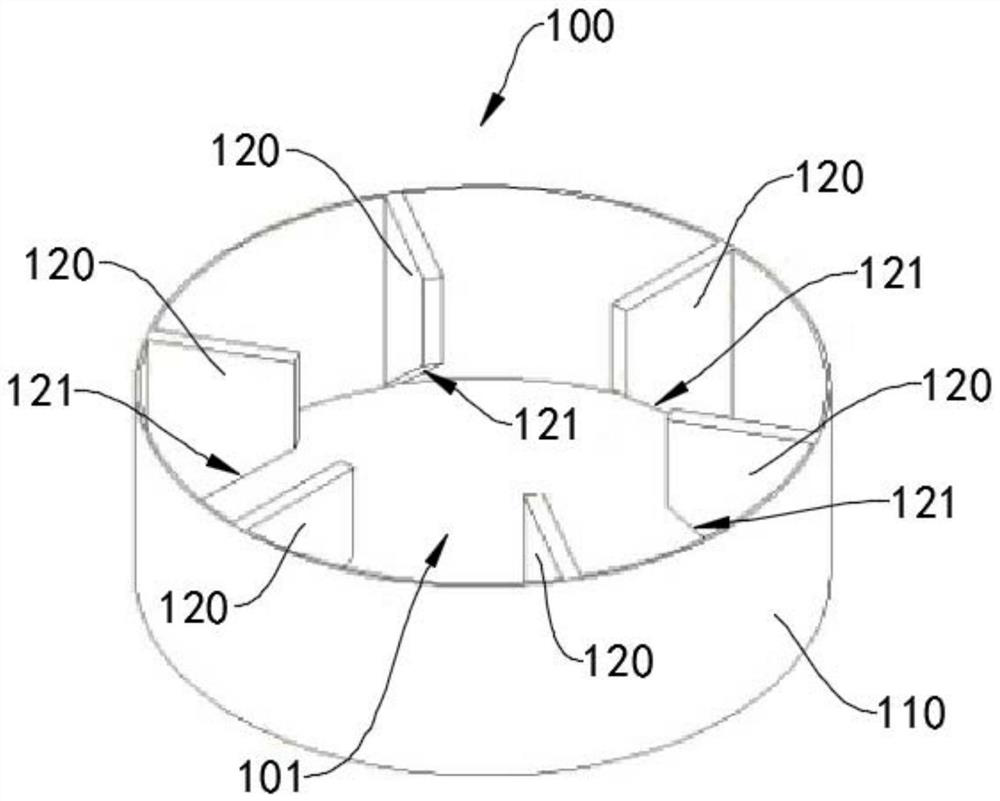

A technology of crystal growth and assembly, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of poor crystal quality and inconcentrated airflow, and achieve the effect of simple structure, uniform heating, and slow down carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] Embodiment 1. Using the thermal field structure of the raw material cylinder to grow a 4-inch N-doped 4H-SiC crystal, the crystal is a single crystal form 4H, and there are no macroscopic defects such as miscellaneous crystals and dense micropipes on the crystal surface, and the thickness of the crystal is measured in four directions , thickness difference -2 , BPD-2 , showing that using thermal field structure for crystal growth can effectively solve the problem of uneven crystal growth thickness without affecting the crystal defect density. The thickness difference is reduced from the original 3mm-10mm to <1mm, and the production capacity is increased by 50%-100%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com