Method for preparing high-purity metal chromium through carbon reduction

A high-purity metal chromium technology, applied in the field of carbon reduction to prepare high-purity metal chromium, can solve problems such as difficult to meet production requirements, low purity, waste of resources, etc., to improve low production efficiency, reduce impurity content, and increase conversion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

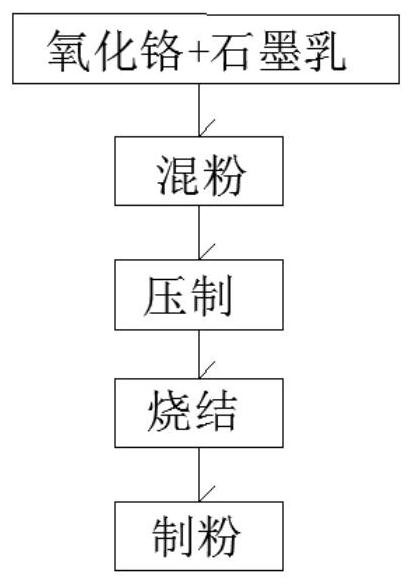

[0035] A method for preparing high-purity metal chromium by carbon reduction, comprising the following steps:

[0036] S1: weighing

[0037] Measure chromium oxide green powder and graphite milk respectively; the mass ratio of graphite milk to chromium oxide green powder is 1:4; the particle size of chromium oxide green powder is 20-30 μm;

[0038] Graphite milk includes 90% fixed carbon and organic solvent; its Baume degree is 60°; the organic solvent is alcohol;

[0039] S2: mixed powder

[0040] Pour the weighed chromium oxide green powder into the stirring mixer, then add graphite milk; mechanically stir for 1.5h;

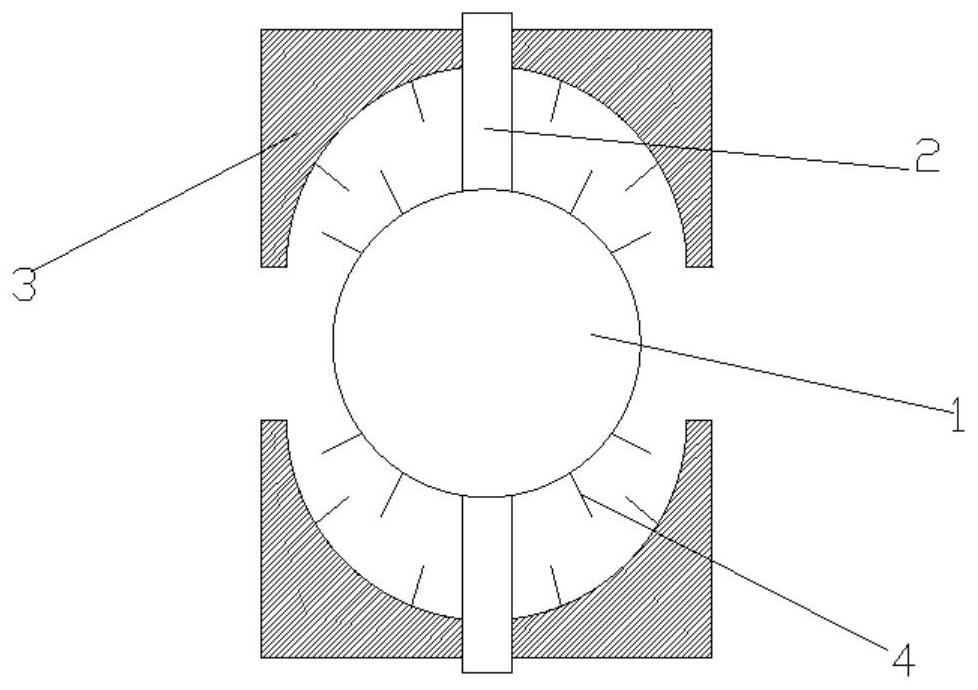

[0041] S3: suppression

[0042] Then use a compression molding device to compress the mixed material, and the pressure parameter is 10MPa;

[0043] The mold of the compression molding device presses the mixed material into a hollow blank; and the mold uniformly forms a circular vent hole on the inner and outer walls of the blank; the diameter of the vent ho...

Embodiment 2

[0050] A method for preparing high-purity metal chromium by carbon reduction, comprising the following steps:

[0051] S1: weighing

[0052]Measure chromium oxide green powder and graphite milk respectively; the mass ratio of graphite milk to chromium oxide green powder is 1:4; the particle size of chromium oxide green powder is 50-60 μm;

[0053] Graphite milk includes 98% fixed carbon and organic solvent; its Baume degree is 76°; the organic solvent is alcohol;

[0054] S2: mixed powder

[0055] Pour the weighed chromium oxide green powder into a stirring mixer, then add graphite milk; mechanically stir for 2 hours;

[0056] S3: suppression

[0057] Then use a compression molding device to compress the mixed material, and the pressure parameter is 40MPa;

[0058] The mold of the compression molding device presses the mixed material into a hollow blank; and the mold uniformly forms a circular vent hole on the inner and outer walls of the blank; the diameter of the vent ho...

Embodiment 3

[0065] A method for preparing high-purity metal chromium by carbon reduction, comprising the following steps:

[0066] S1: weighing

[0067] Measure chromium oxide green powder and graphite milk respectively; the mass ratio of graphite milk to chromium oxide green powder is 1:5; the particle size of chromium oxide green powder is 30-40 μm;

[0068] Graphite milk includes 94% fixed carbon and organic solvent; its Baume degree is 68°; the organic solvent is alcohol;

[0069] S2: mixed powder

[0070] Pour the weighed chromium oxide green powder into the stirring mixer, then add graphite milk; mechanically stir for 1.6h;

[0071] S3: suppression

[0072] Then use a compression molding device to compress the mixed material, and the pressure parameter is 25MPa;

[0073] The mold of the compression molding device presses the mixed material into a hollow blank; and the mold uniformly forms a circular vent hole on the inner and outer walls of the blank; the diameter of the vent ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com