Tin-based perovskite thin film, quality improvement method thereof and tin-based perovskite solar cell

A solar cell and quality improvement technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of increasing carrier recombination centers, high light absorption coefficient, low exciton binding energy, etc., to reduce trap state density, light The effect of strong absorption characteristics and simple and convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] PEA based on PEDOT:PSS (20 mg / mL) doped with D-sorbitol 0.1 (FA 0.75 MA 0.25 ) 0.9 SnI 3 Perovskite film and its quality improvement method, the method is as follows:

[0058] Step S1: First, weigh 20 mg of D-sorbitol and dissolve it in 1 mL of PEDOT:PSS aqueous solution, and stir for more than 30 minutes to obtain a mixed solution of PEDOT:PSS / D-sorbitol;

[0059] Step S2: After filtering the PEDOT:PSS / D-sorbitol mixed solution with a 0.45 μm water-based filter head, take 120 μL and spin-coat it on the surface of ITO at a speed of 3500 rpm, and transfer the ITO to a hot stage at 100 ° C after 60 seconds Annealed for 30 minutes to prepare an improved hole transport layer;

[0060] Step S3: Then, weigh 372.52mg of stannous iodide, 24.91mg of phenethylamine iodide, 116.08mg of formamidine hydroiodide, 35.77mg of methylamine hydroiodide, and 15.67mg of stannous fluoride, mix and dissolve in 800 μL DMF and 200μL DMSO in a mixed polar solvent, stirred for more than 12h...

Embodiment 2

[0076] Tin-based perovskite solar cell prepared based on the perovskite film described in Example 1

[0077] The operation steps of Example 2 are the same as those of Comparative Example 2, except that the hole transport layer used in Example 2 is the PEDOT:PSS film doped with D-sorbitol as the hole transport layer in Example 1.

[0078] Figure 5 Structural schematic diagram of the solar cell made for comparative example 2 and embodiment 2;

[0079] Figure 6 (a) and (b) are the comparison of the I-V characteristic curves of the perovskite solar cells prepared in Comparative Example 2 and Example 2 respectively under a standard sunlight intensity, wherein the current efficiency of the perovskite solar cells prepared in Example 2 is obvious Higher than Comparative Example 2;

[0080] Figure 7 (a) and (b) are respectively the efficiency tracking of the unpackaged perovskite solar cells prepared in Example 2 and Example 2 under a nitrogen environment, wherein the PEA prepar...

Embodiment 3

[0084] The operation procedure of embodiment 3 is the same as that of embodiment 1, the only difference is that in step S3, when the perovskite precursor solution is configured, the content of phenethylamine iodide salt, formamidine hydriodide and methylamine hydriodide Change to 49.82mg, 103.18mg, 31.80mg respectively in turn to get PEA 0.2 (FA 0.75 MA 0.25 ) 0.8 SnI 3 Perovskite precursor solution.

[0085] The difference between Comparative Example 3 and Example 3 is only whether PEDOT:PSS is doped with (20 mg / mL) D-sorbitol.

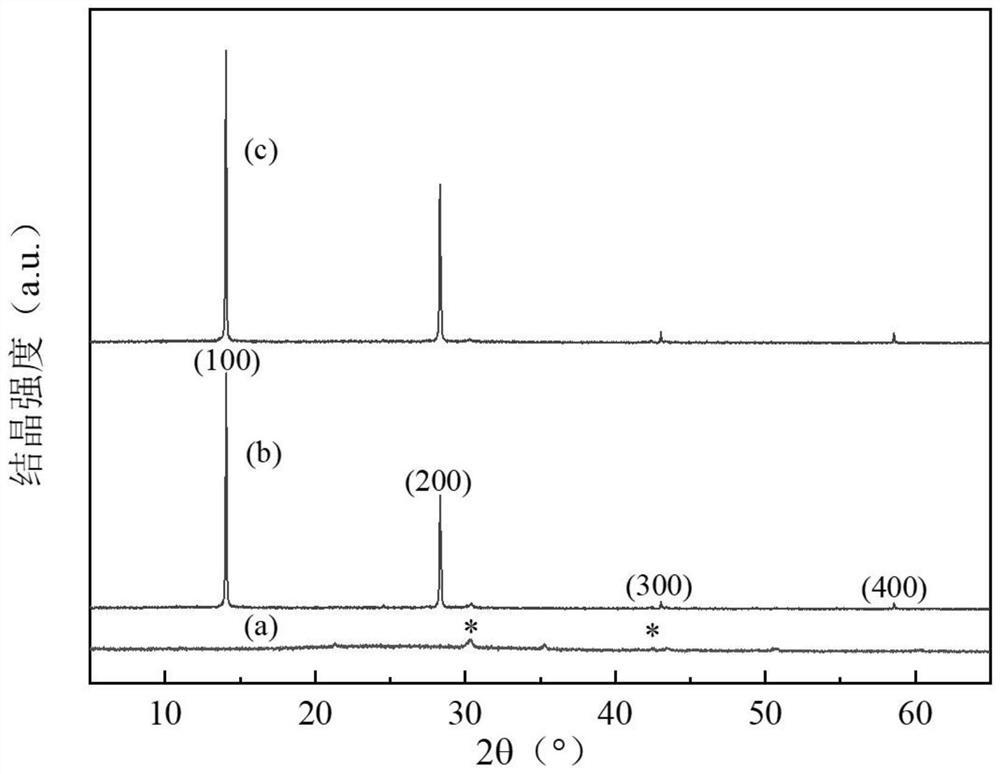

[0086] Figure 8 Among them, the test result (b) is based on the PEDOT:PSS / PEA doped with D-sorbitol 0.2 (FA 0.75 MA 0.25 ) 0.8 SnI 3 The XRD characteristic peaks of the film are significantly enhanced compared with (a), indicating that it is more effective than PEA on pristine PEDOT:PSS 0.2 (FA 0.75 MA 0.25 ) 0.8 SnI 3 The thin film has better crystallinity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com