Brake pad heat-dissipating structure

A technology to improve the structure and make the lining, which is applied in the direction of friction lining, slack adjuster, brake type, etc., can solve the problems of high cost and cumbersome manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

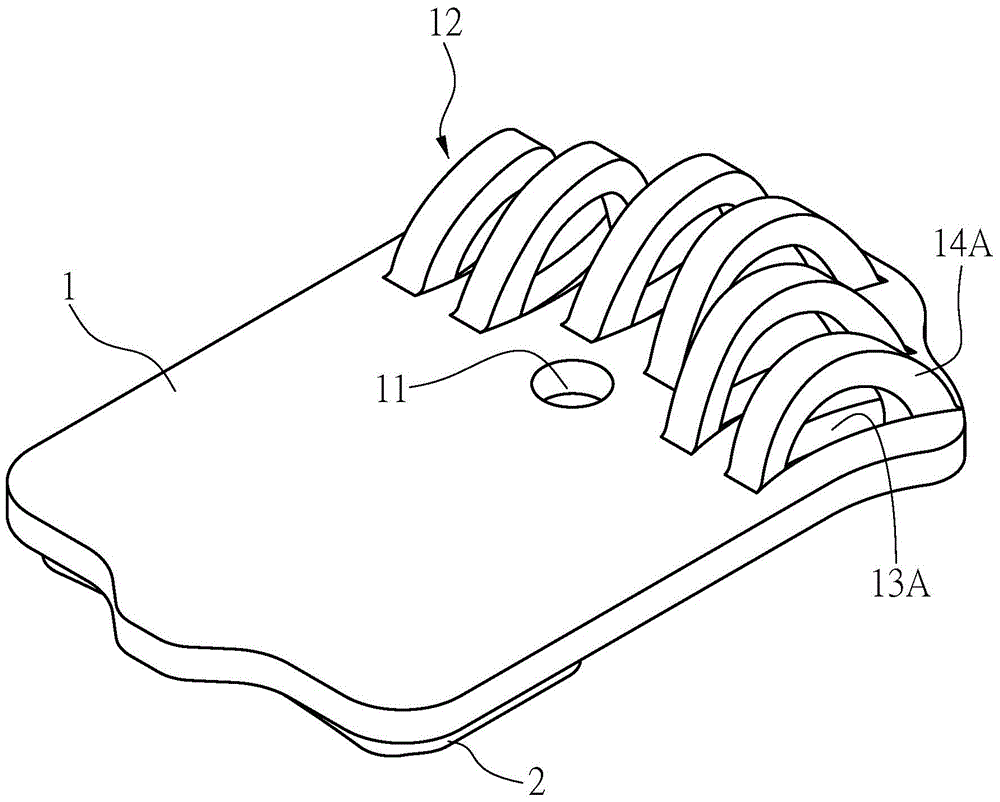

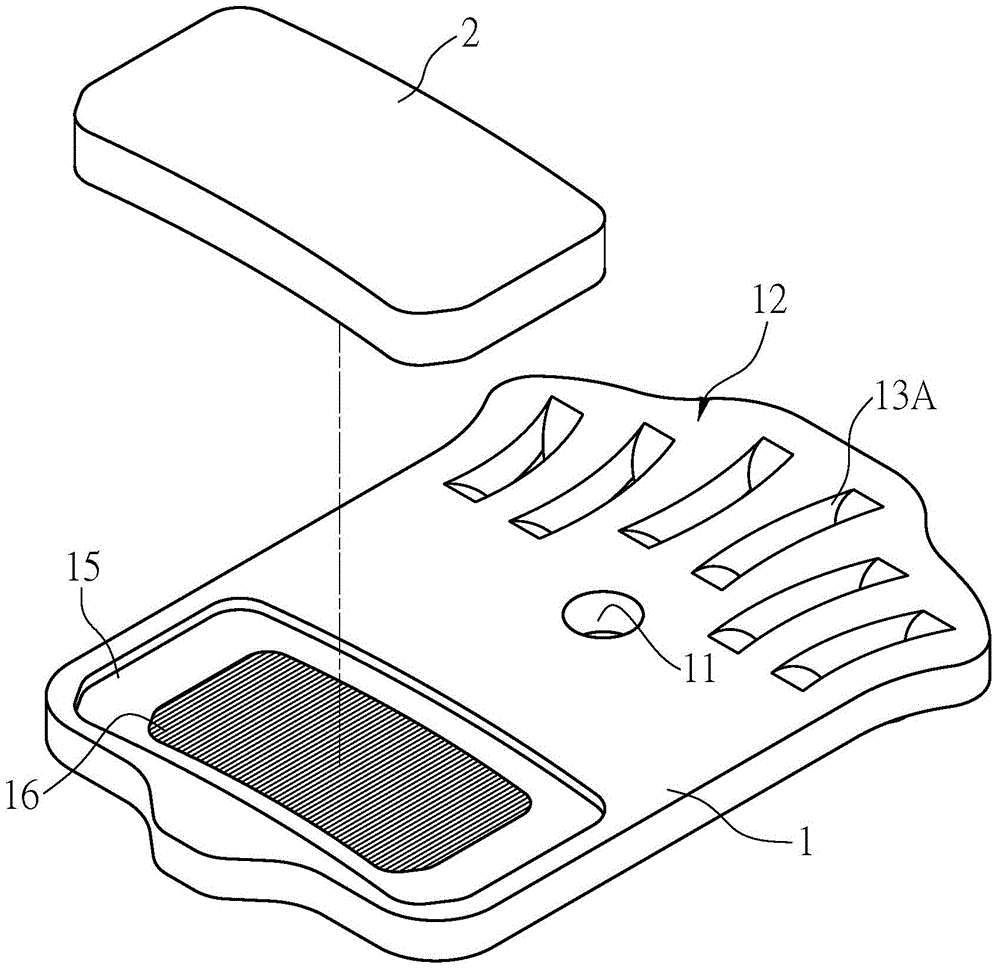

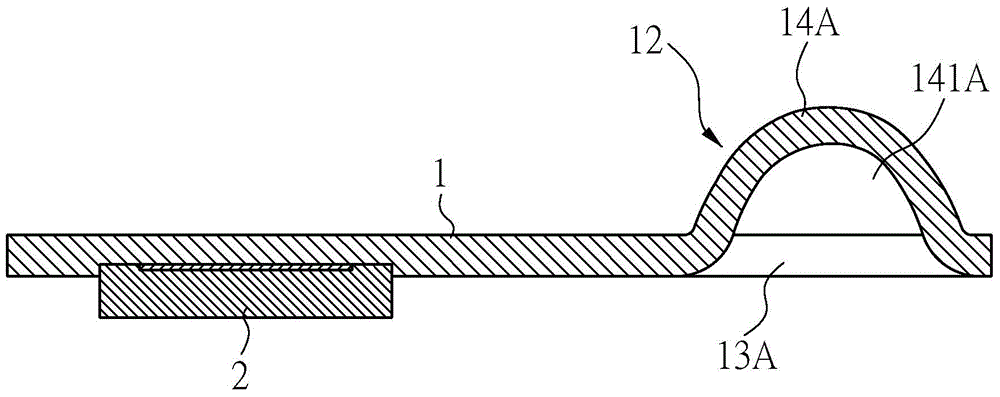

[0016] see figure 1 , figure 2 , the one shown is the first embodiment of the improved structure for heat dissipation of the fins provided by the present invention, which includes a body 1, which is a plate-shaped object and has a positioning hole 11 for fixing with the brake system of the vehicle . The body 1 has a heat dissipation portion 12 and a connection portion for assembling the brake shoe 2 , wherein the heat dissipation portion 12 is disposed at one end of the body 1 , and the connection portion is disposed at the other end of the body 1 . The heat dissipation portion 12 is provided with a plurality of parallel through holes 13A passing through the main body 1 , and each through hole 13A is respectively connected with a fin 14A protruding outward from the main body 1 , and the connecting portion is provided with a brake block 2 .

[0017] In the present embodiment, the above-mentioned radiating portion 12 is, for example, figure 1 As shown, each through-hole 13A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com