Lightweight and high strength and ductility automotive steel using silicon instead of aluminum and preparation method of the steel

A lightweight and tough technology, applied in metal rolling and other directions, can solve problems such as poor weldability and formability, reduce material stiffness, and reduce density, so as to improve toughness, enhance matrix strength, and avoid cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing lightweight high-strength steel for automobiles by substituting silicon for aluminum, comprising the following steps;

[0022] 1) Weigh the alloy composition, and weigh 0.1wt.% of C, 3.5wt.% of Si, 4.0wt.% of Mn, 0.5wt.% of Ni, and 0.01wt.% of Ti according to the weight percentage of the alloy composition, The balance is Fe;

[0023] 2), smelting and casting, vacuum smelting and casting the alloy components weighed in step 1) into a 40mm thick billet;

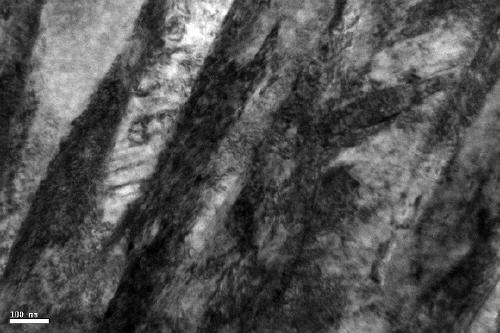

[0024] 3) Hot rolling, keep the 40mm thick cast slab at 1200°C for 2.5h, then hot rolling at 1100°C, the final rolling temperature is 950°C, hot rolling to 3mm, the total reduction rate is 92.5%, air cooling to room temperature Obtain the silicon-substituted aluminum lightweight high-strength steel for automobiles of the present invention; its structure is mainly based on nano-martensitic laths, and high dislocation density, through statistical analysis, the average width of nano-martensitic laths...

Embodiment 2

[0028] A method for preparing lightweight high-strength steel for automobiles by substituting silicon for aluminum, comprising the following steps;

[0029] 1) Weigh the alloy composition, and weigh 0.4wt.% of C, 5.5wt.% of Si, 6.0wt.% of Mn, 1.0wt.% of Ni, and 0.1wt.% of Ti according to the weight percentage of the alloy composition, The balance is Fe;

[0030] 2), smelting and casting, vacuum smelting and casting the alloy components weighed in step 1) into a slab with a thickness of 80 mm;

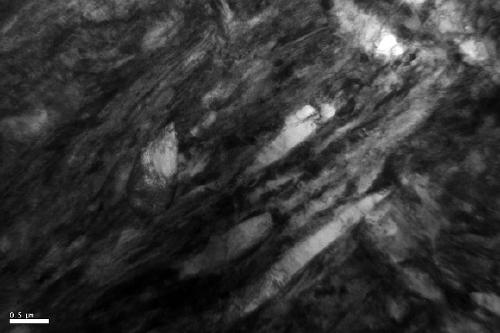

[0031] 3) Hot rolling, keep the 80mm thick casting slab at 1250°C for 2.5h, then hot rolling at 1150°C, the final rolling temperature is 950°C, hot rolling to 4mm, the total reduction rate is 95%, air cooling to room temperature Obtain the silicon-substituted aluminum lightweight high-strength steel for automobiles of the present invention; its structure is mainly based on nano-martensitic laths, and high dislocation density, through statistical analysis, the average width of nano-mart...

Embodiment 3

[0035] A method for preparing lightweight high-strength steel for automobiles by substituting silicon for aluminum, comprising the following steps;

[0036]1) Weigh the alloy composition, and weigh 0.2wt.% of C, 4.8wt.% of Si, 5.2wt.% of Mn, 0.6wt.% of Ni, and 0.07wt.% of Ti according to the weight percentage of the alloy composition, The balance is Fe;

[0037] 2), smelting and casting, the alloy components weighed in step 1) are vacuum smelted and cast into a 60mm thick billet;

[0038] 3) Hot rolling, keep the 60mm thick casting slab at 1230°C for 2.4h, then hot rolling at 1130°C, the final rolling temperature is 950°C, hot rolling to 2.4mm, the total reduction rate is 96%, air cooling to At room temperature, obtain the silicon-substituted aluminum lightweight high-strength automobile steel of the present invention; its structure is mainly based on nano-martensitic laths, and high dislocation density. Through statistical analysis, the average width of nano-martensitic lath...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com