Gearbox with switching support and outage protection

A technology of transmission and shifting shaft, applied in the direction of elements with teeth, transmission control, belt/chain/gear, etc. problems, to achieve the effect of ensuring fail-safety and easy vibration decoupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

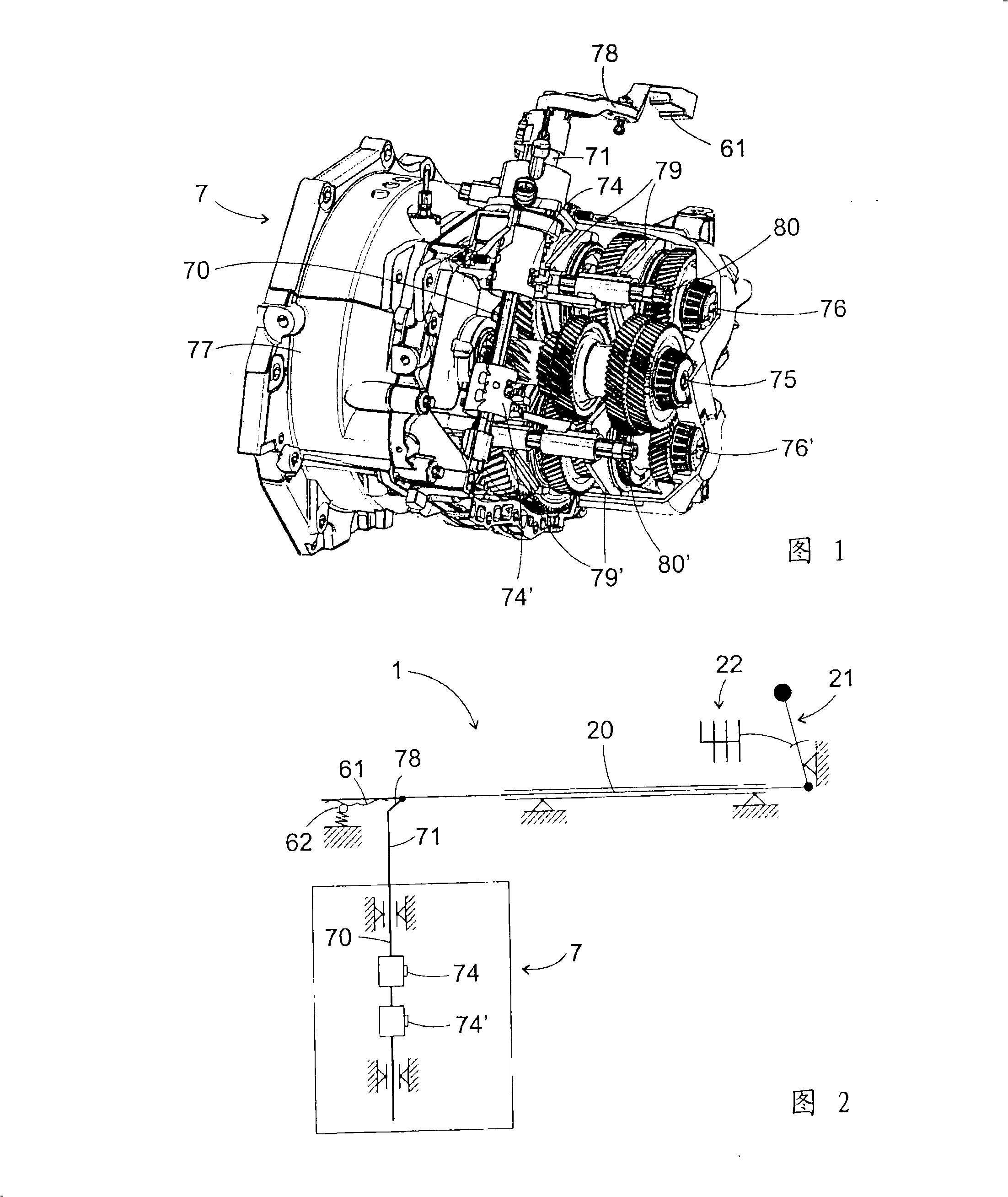

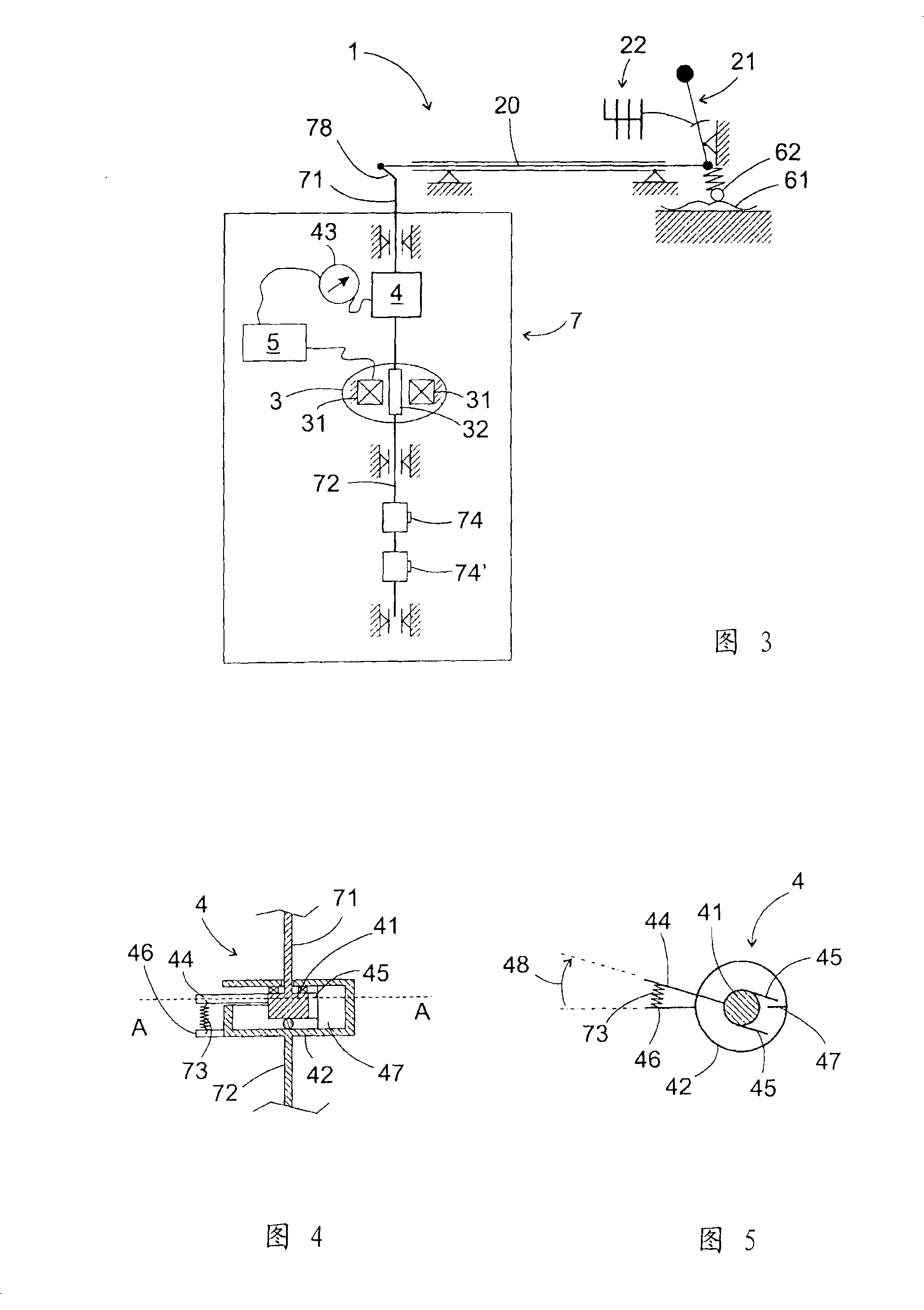

[0031] figure 1 Represents the automobile transmission according to the prior art. The transmission 7 comprises a drive shaft 75 and two output shafts 76, 76', which are arranged parallel to each other and can be coupled to each other in a general manner in order to adjust different transmission ratios in the transmission 7.

[0032] The shift shaft 70 is arranged perpendicular to the drive shaft 75 and the output shaft 76, 76' and has two shift lever fingers 74, 74': the shift shaft is movable along its axis; One of the lever finger 74, 74' is coupled with a shift dog 79, 79' which can move on a lever 80, 80 parallel to the axes 75, 76, 76' so that by means of The synchronized interlocking device couples the different gears rotationally fixedly to the output shafts 76, 76' supporting them, and thereby adjusts the gear ratio of the transmission. Here, axial movement of the shift shaft 70 causes selection of a transmission ratio, and radial rotation of the shift shaft 70 caus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com