Check valve structure

A check valve and cavity technology, applied in the field of liquid check valve structure, can solve the problems of short service life, inconvenient assembly, many parts, etc., and achieve the effect of ingenious structure design, prevention of sewage backflow, and fewer parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

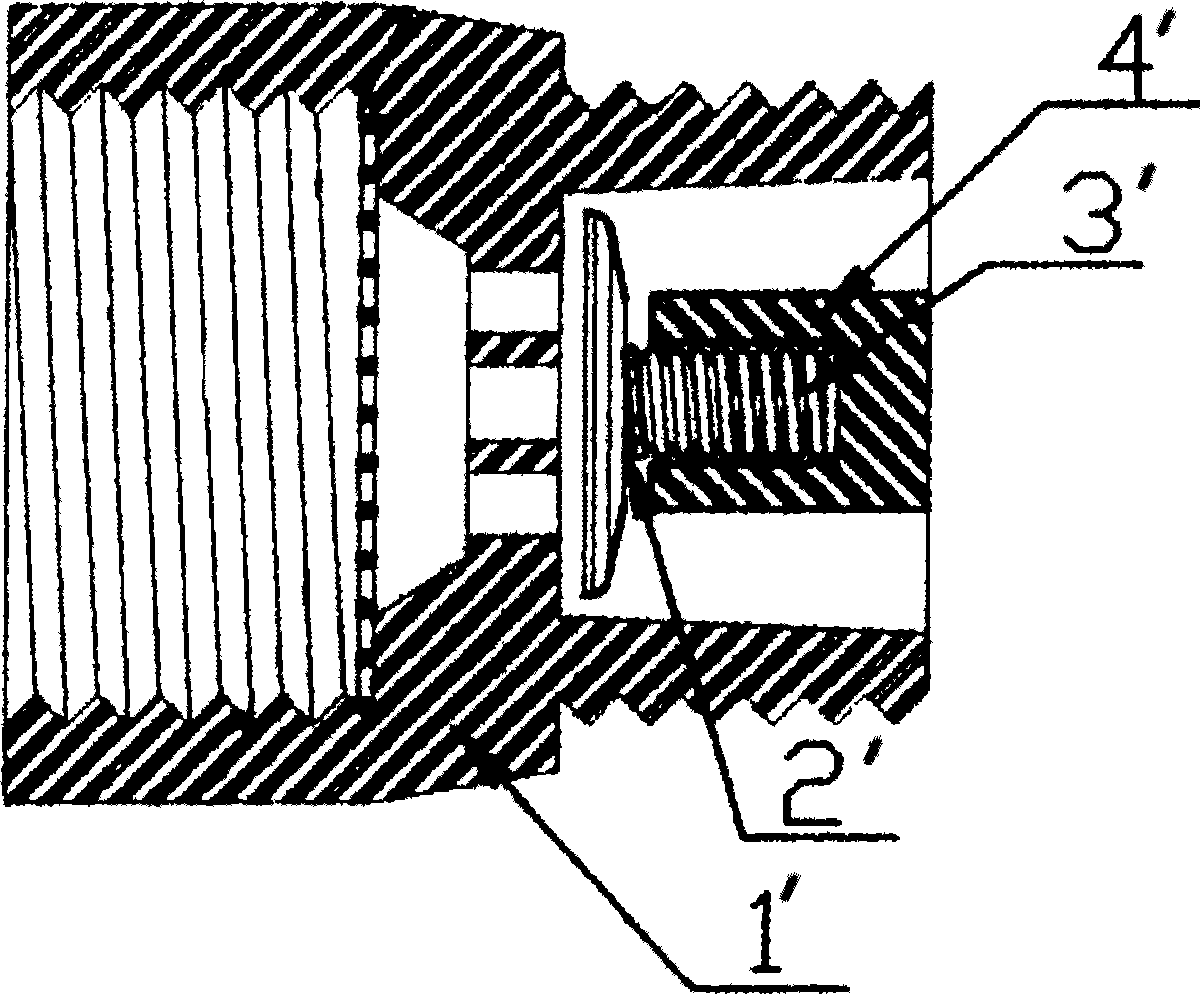

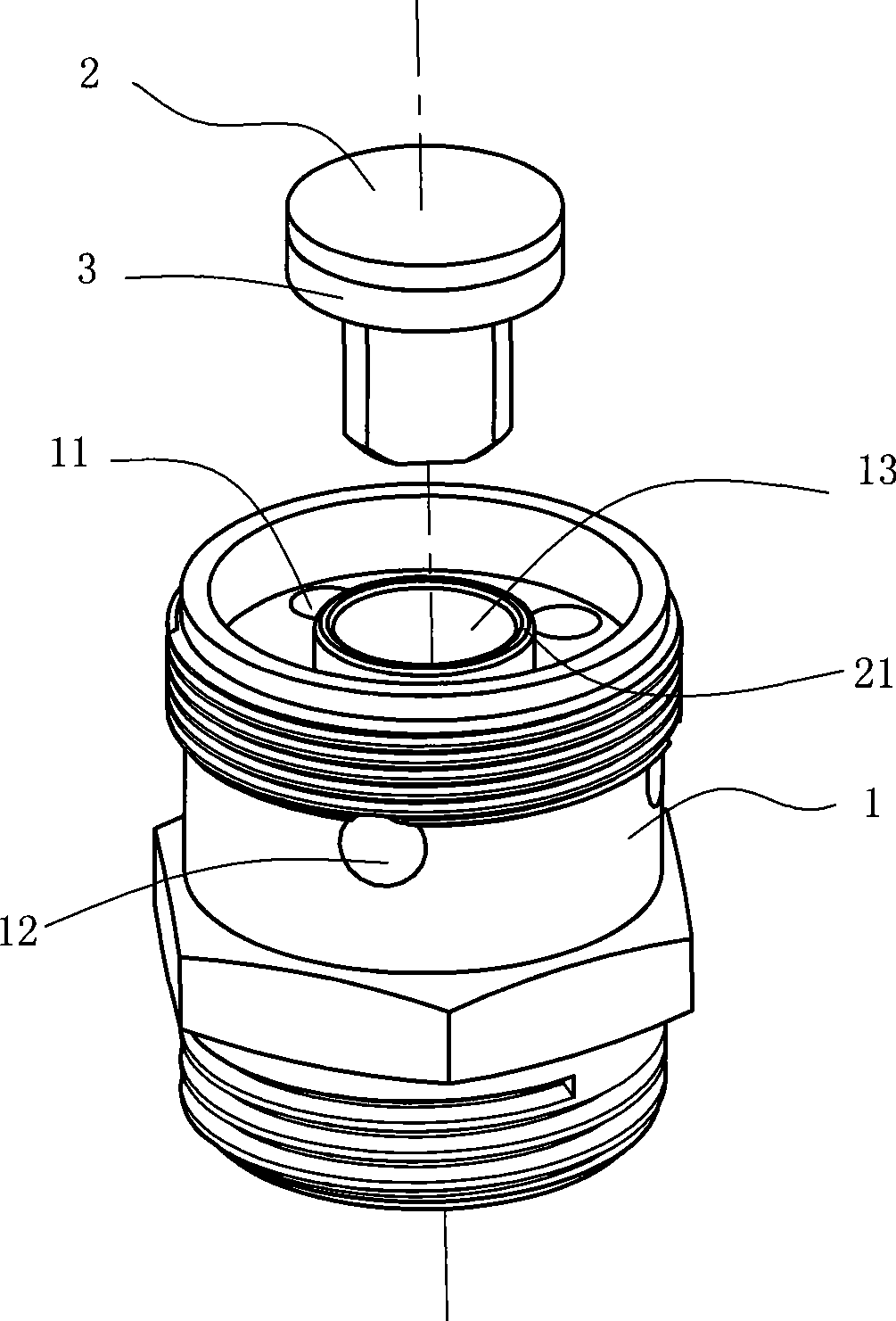

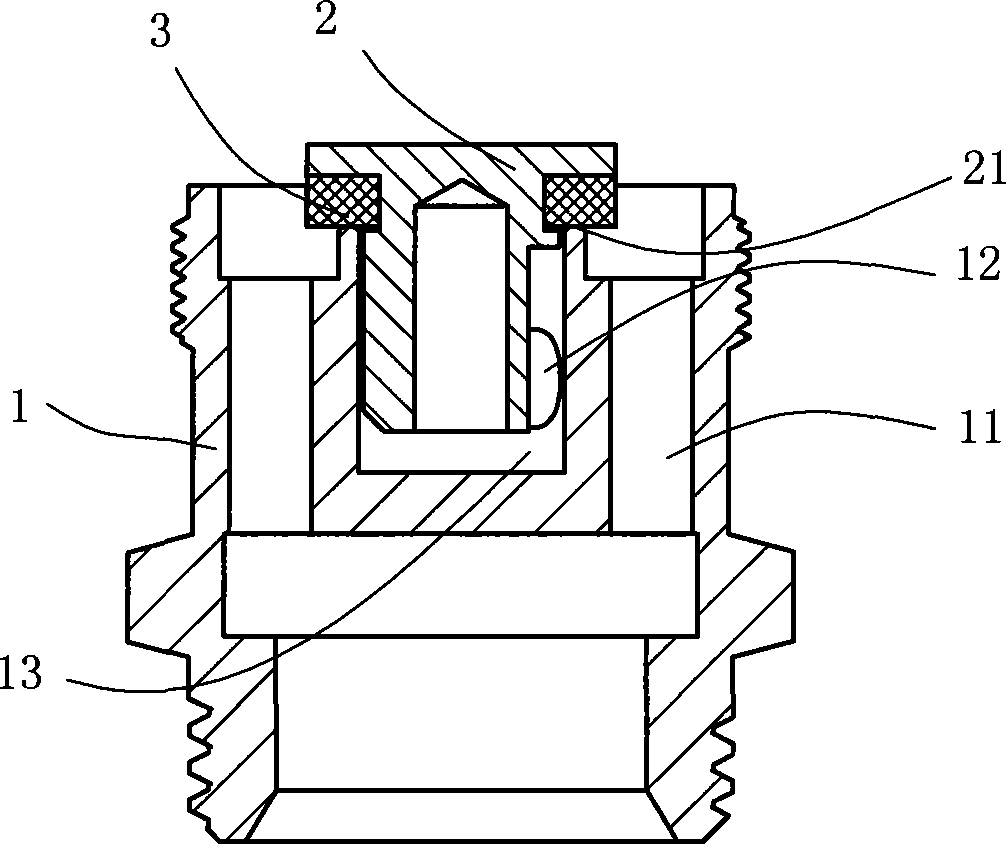

[0024] Such as figure 2 , 3 As shown in and 4, a check valve structure includes a joint body 1, and the joint body is provided with a first cavity 11 communicating up and down. Here, there may be one, two or more through holes. At the same time, the joint body 1 is also provided with a second cavity 12 that directly communicates with the side of the joint body. The second cavity 12 communicates with the first cavity 11 through a connecting hole 13, and the mouth of the connecting hole 13 is movably equipped with a piston 2. The length of the piston 2 placed in the connecting hole 13 is less than the depth of the connecting hole 13. Here, in order to ensure the sealing of the mouth of the piston 2 and the connecting hole 13, a sealing surface 21 is provided at the connection between the two. In this embodiment, the second cavity 12 has a structure of four air holes, which are evenly distributed around the circumference, and here, the number of air holes can also be one, two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com