Particulate filter arrangement

一种颗粒过滤、颗粒过滤器的技术,应用在废气的颗粒过滤装置,废气颗粒过滤装置,颗粒过滤装置领域,能够解决颗粒过滤器满负载或堵塞、满负载、堵塞等问题,达到减少位置需求的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

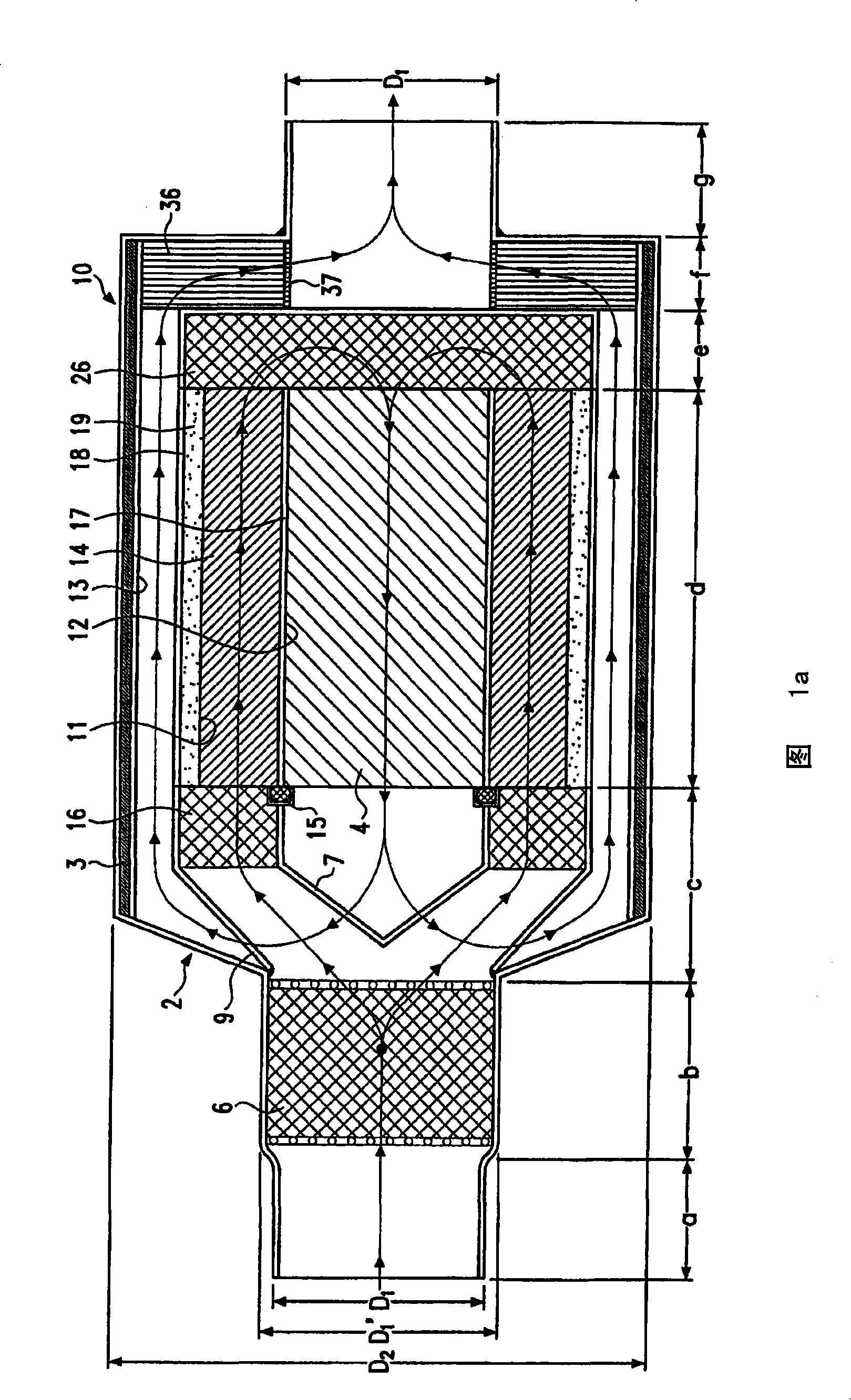

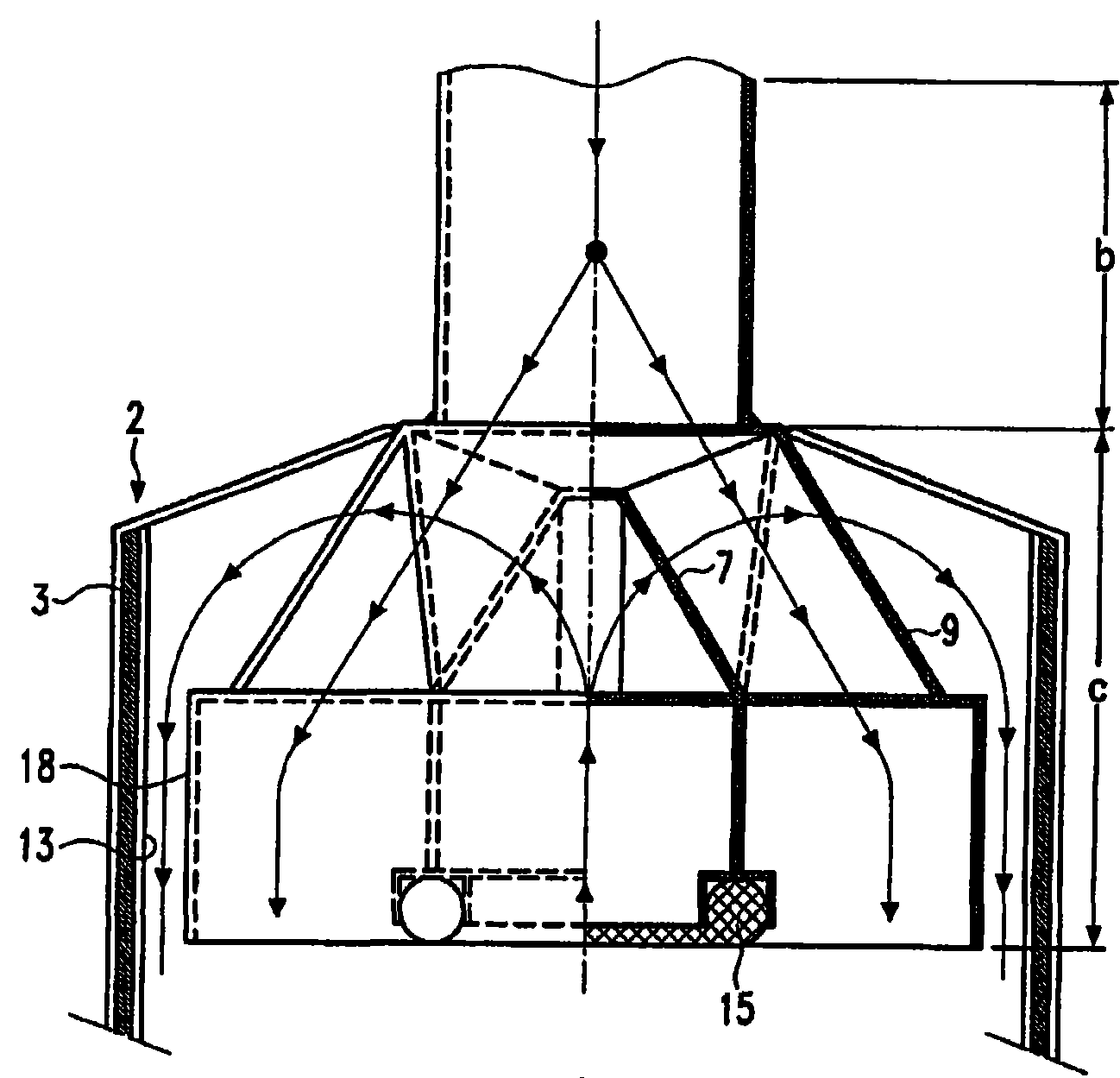

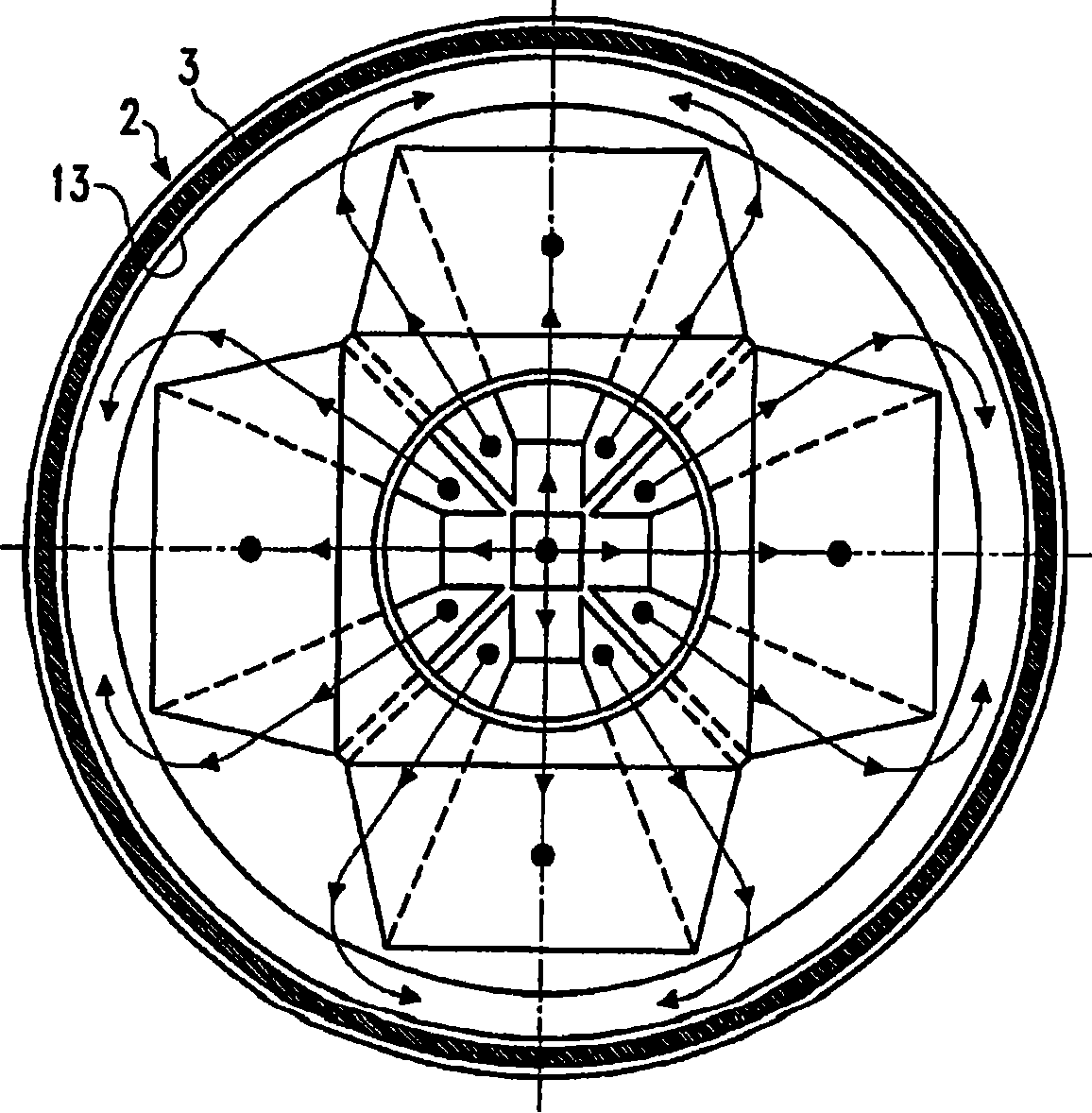

[0039] refer to Figures 1a to 1c A first exemplary embodiment of a particle filter device 10 according to the invention will be described in detail below with regard to its structure and function in the sectional view shown. Figure 1a A largely schematic longitudinal section through a particle filter device 10 according to the invention is shown. The particle filter device 10 according to the invention is located in the main flow direction of the exhaust gas (in the direction from the inlet to the outlet, that is to say in the Figure 1a and 2a from left to right) with an inlet section a, a filter forward section b, a forward diversion section or a first section c (in Figure 1a is very briefly indicated), a filter section or second section d, a rear steering section or third section e, a filter extension section f and an outlet section g, which All designed in a common housing 2 . The particle filter device 10 is connected via an inlet section a, for example, to a motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com