Solid anti-pricked tyre and manufacturing method thereof

A puncture and tire technology, applied in tire parts, non-pneumatic tires, transportation and packaging, etc., to achieve the effect of simple production, low cost, high safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

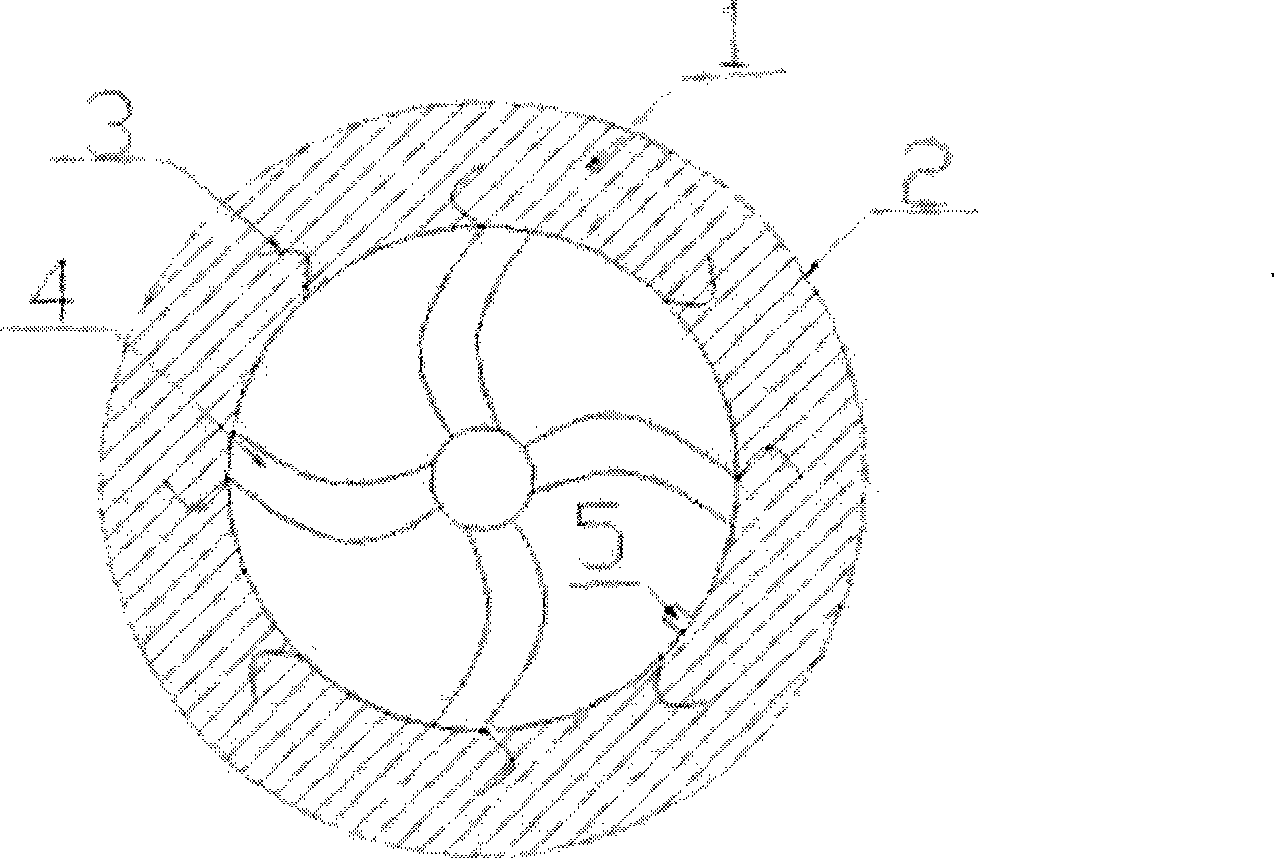

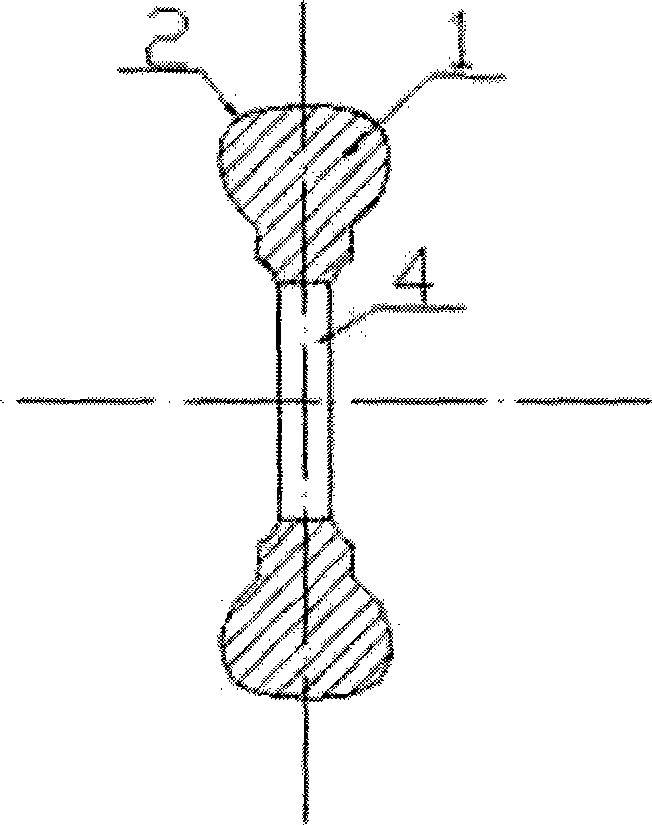

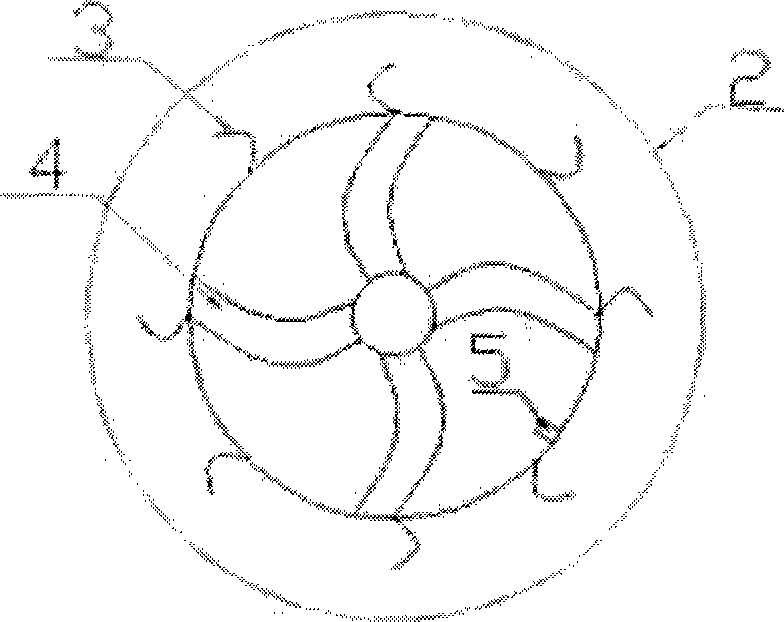

[0038] The solid tire of the present invention is simple in structure, low in manufacturing cost, simple in process, safe and practical, and has a wide range of applications. It solves the shortage of solid tires in the market and the monotony of varieties. The framework 3 mentioned in the present invention not only prevents tires from braking for a long time and slips, but also has the effect of shockproof. Usually, solid tires are filled with the same material. In this way, once the road surface is uneven, it will cause the car body to bump, causing discomfort to the driver or damage to the cargo. After the skeleton 3 is added, a section of glue is fastened between every two adjacent skeletons. The solid tires used by different types of vehicles have different filling pressures. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com