Nano silver filtering carbon core and production method

A nano-silver and carbon core technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of absorption limitation and polar substance absorption limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

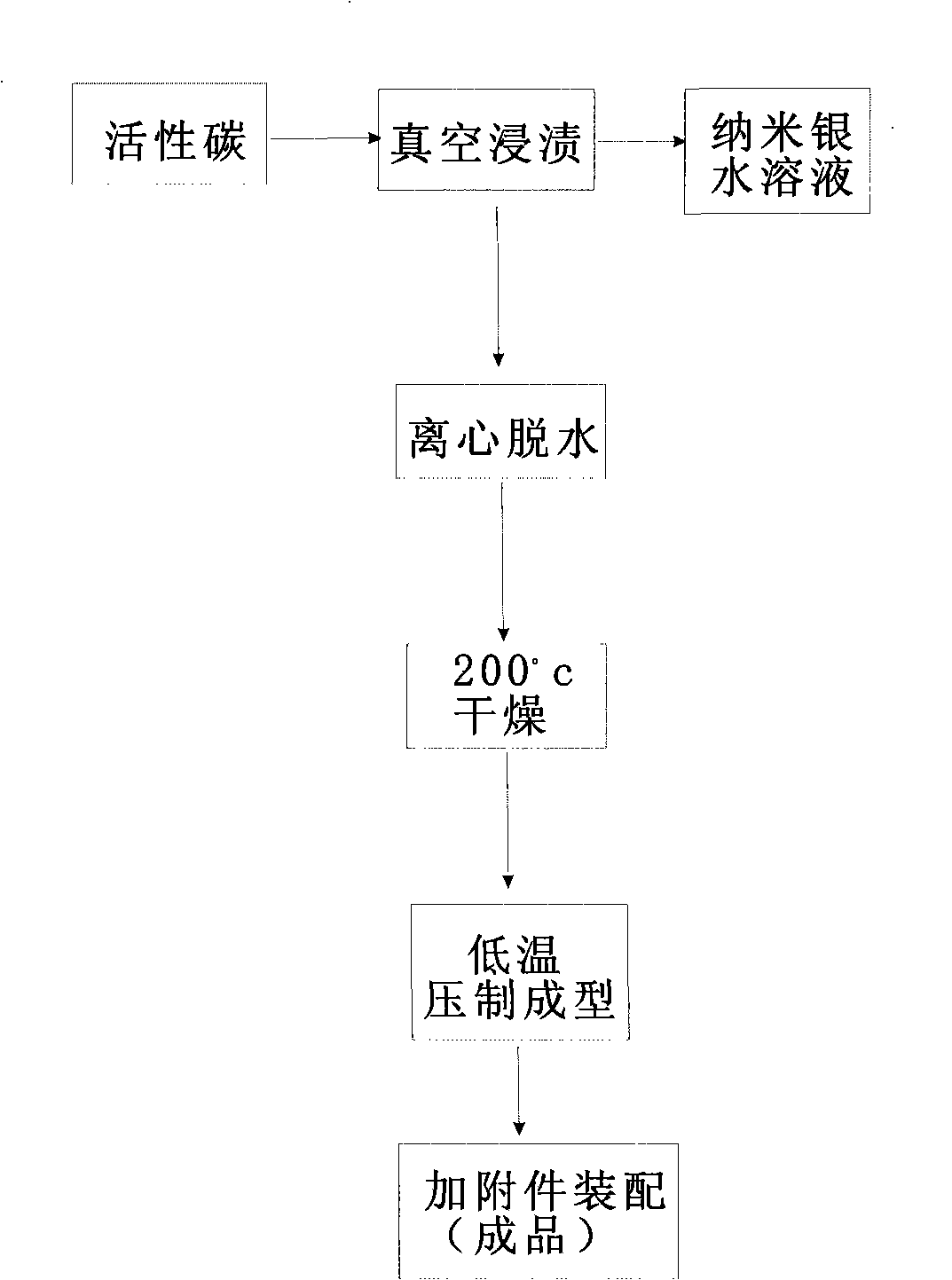

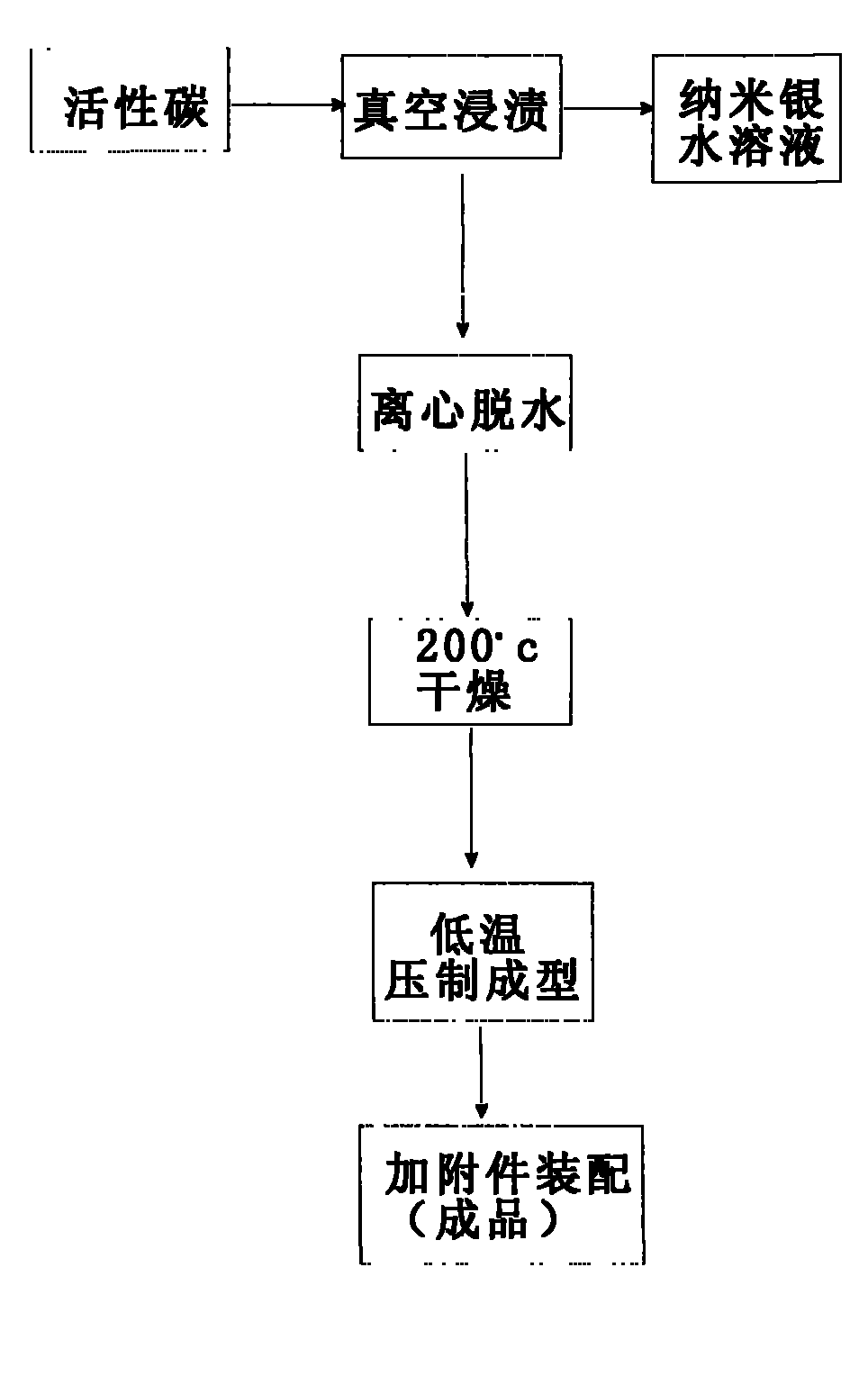

[0017] figure 1 It is a process flow chart of the present invention, and the specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] The nano-silver filter carbon core is composed of activated carbon and nano-silver, and the specific molding process is as follows:

[0019] 1. Material selection:

[0020] The particle size of activated carbon: 50 mesh;

[0021] Nano silver particle size: 20nm;

[0022] 2. The ratio of nano-silver to activated carbon: 4g pure nano-silver / kg of activated carbon.

[0023] 3. Mix the nano-silver with tap water or deionized water first and stir evenly, then pour the activated carbon into the vacuum container, then pour the nano-silver aqueous solution into the vacuum container for vacuum impregnation, pour in the nano-silver aqueous solution to submerge the activated carbon The immersion time shall be based on the fact that there are no bubbles overflowing in the wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com