Van-type semi-trailer

A semi-trailer and fixing hole technology, applied in the direction of tractor-trailer combination, motor vehicle, vehicle parts, etc., can solve the problem of inconvenient fixing of van semi-trailer, and achieve the effect of convenient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

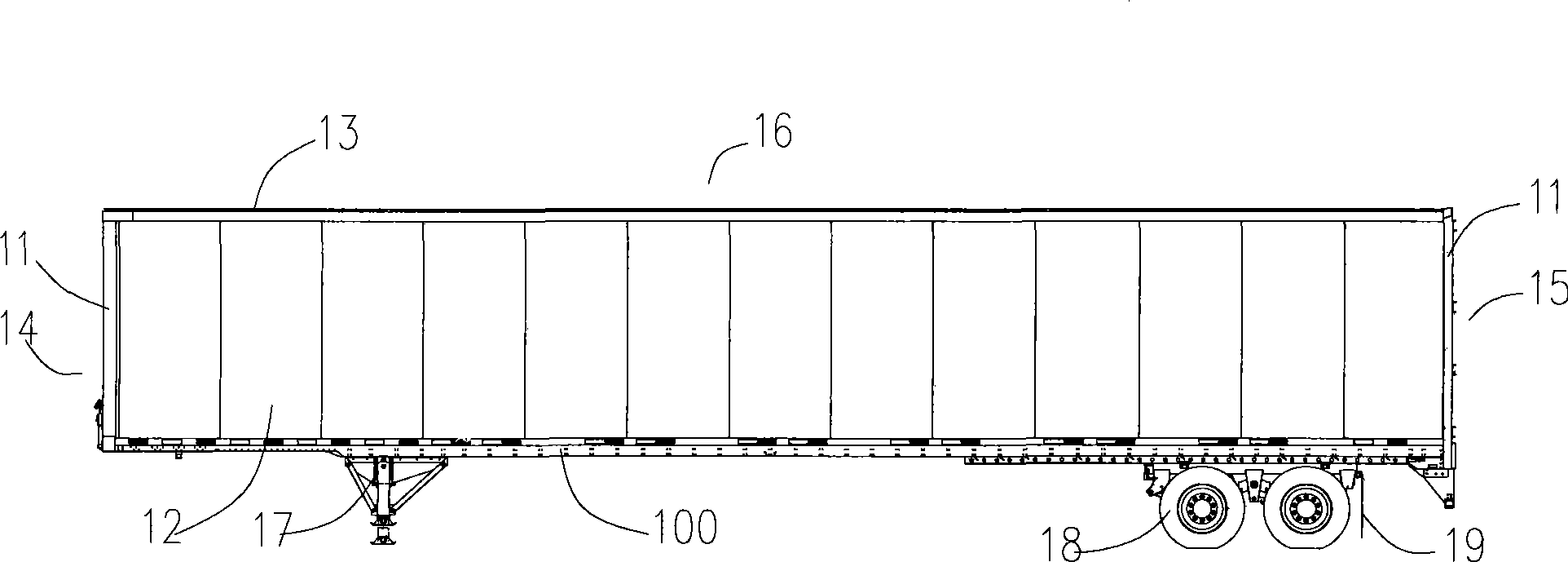

[0032] In the present invention, the van-type semi-trailer includes an underframe, on which parts such as uprights, side panels, and top plates are arranged, and these components together with the underframe constitute a box body. 2-3 pairs of tires are arranged at one end of the bottom frame, and legs are arranged at the other end to support the box body.

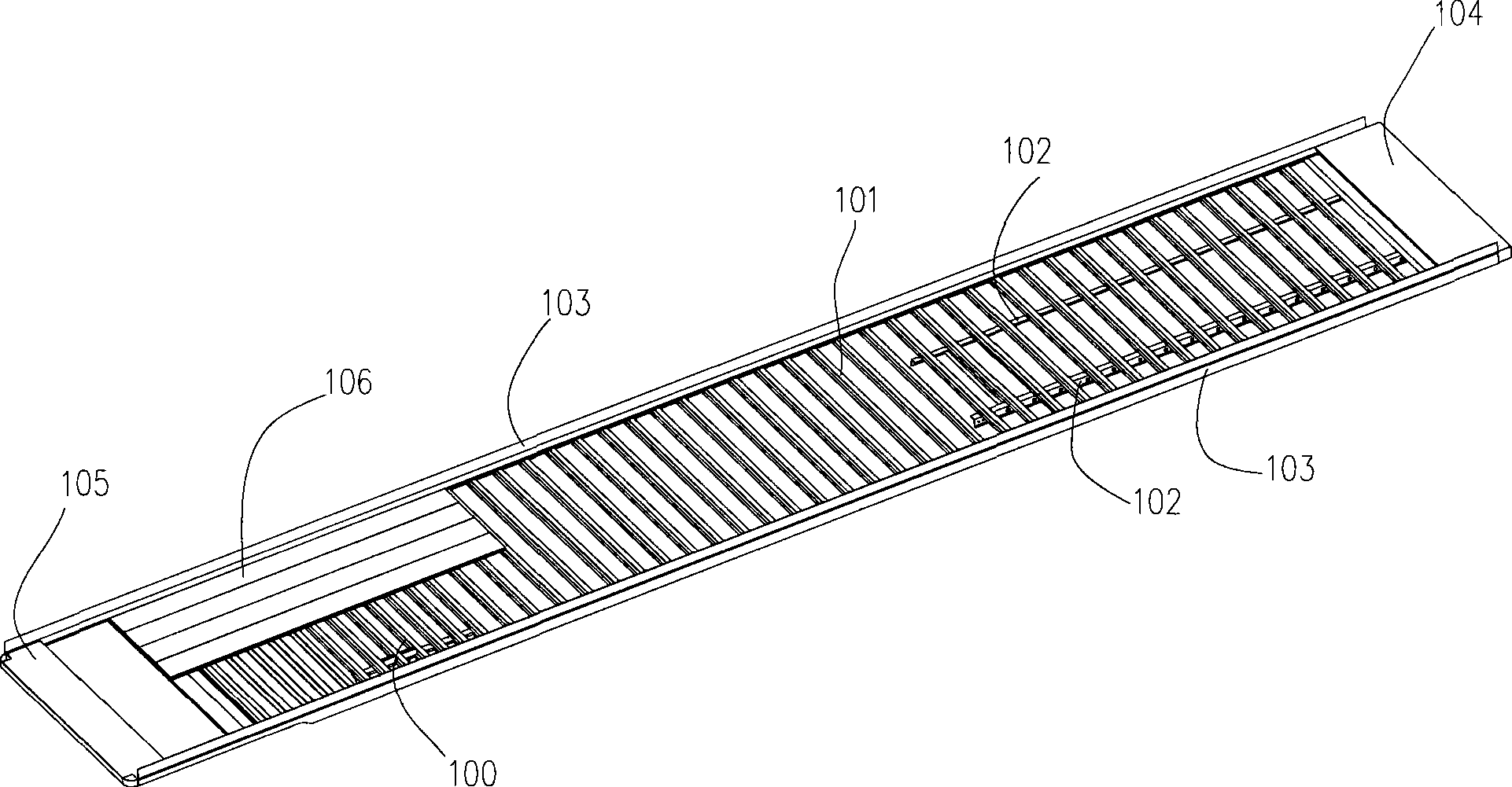

[0033] like figure 2 As shown, the underframe 100 includes two longitudinal beams 103, several bottom cross beams 101 between the two longitudinal beams 103, two slide rail beams 102 connected to the bottom cross beams 101 and used to connect supporting tires, arranged on two longitudinal beams 103 The traction plate 105 at one end of the beam 103 , the rear end beam 104 arranged at the other end of the two longitudinal beams and the wooden floor 106 above the bottom cross beam 101 .

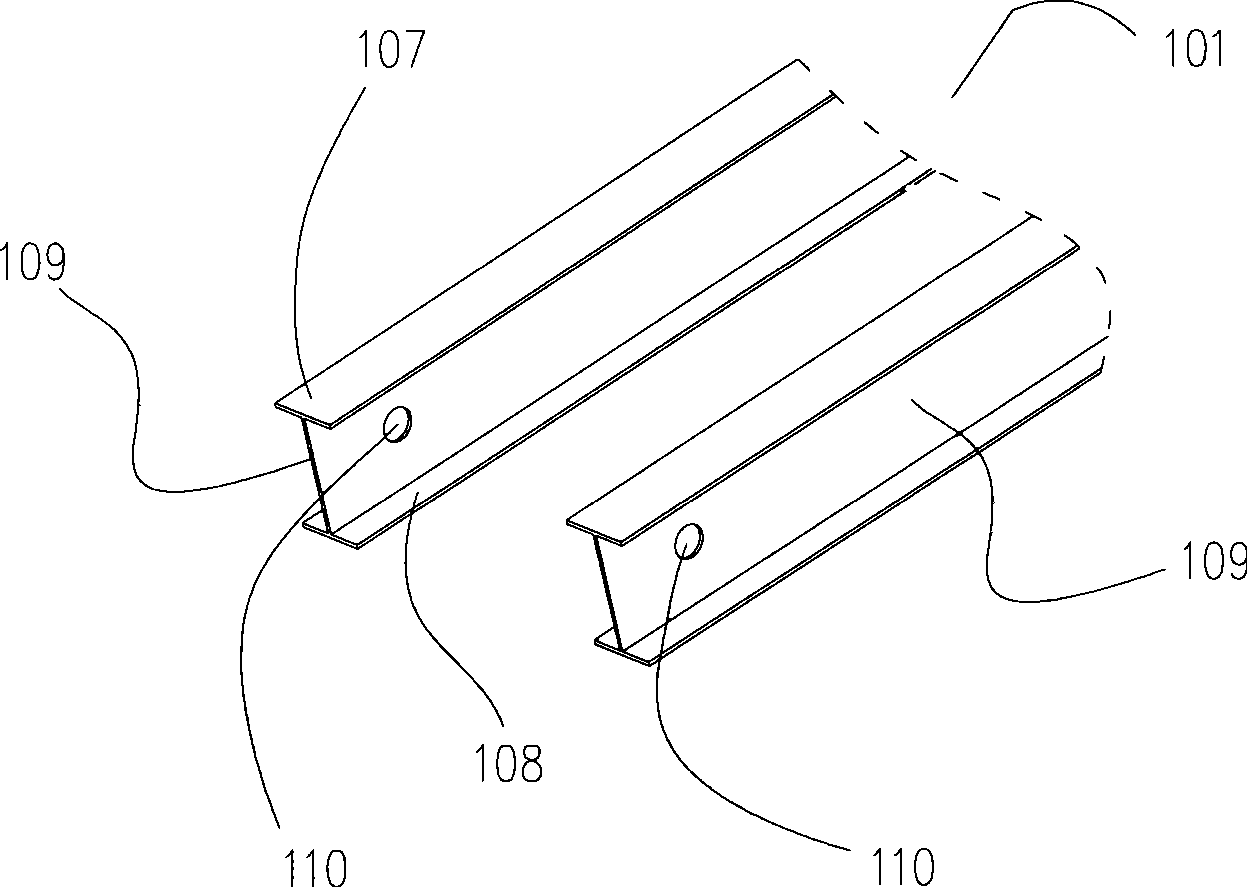

[0034] Considering that the bottom cross beam 101 of the chassis 100 can bear a relatively large load, therefore, when designing and manu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com