Pneumatic tire with cap ply comprising weft inserted warp knit fabric

A technology of pneumatic tires and warp knitted fabrics, which is applied to the reinforcement layer of pneumatic tires, tire parts, wheels, etc., and can solve the problems of not being able to keep the warp yarns at constant intervals, warp yarns not being able to accurately maintain parallel and spacing, yarn displacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

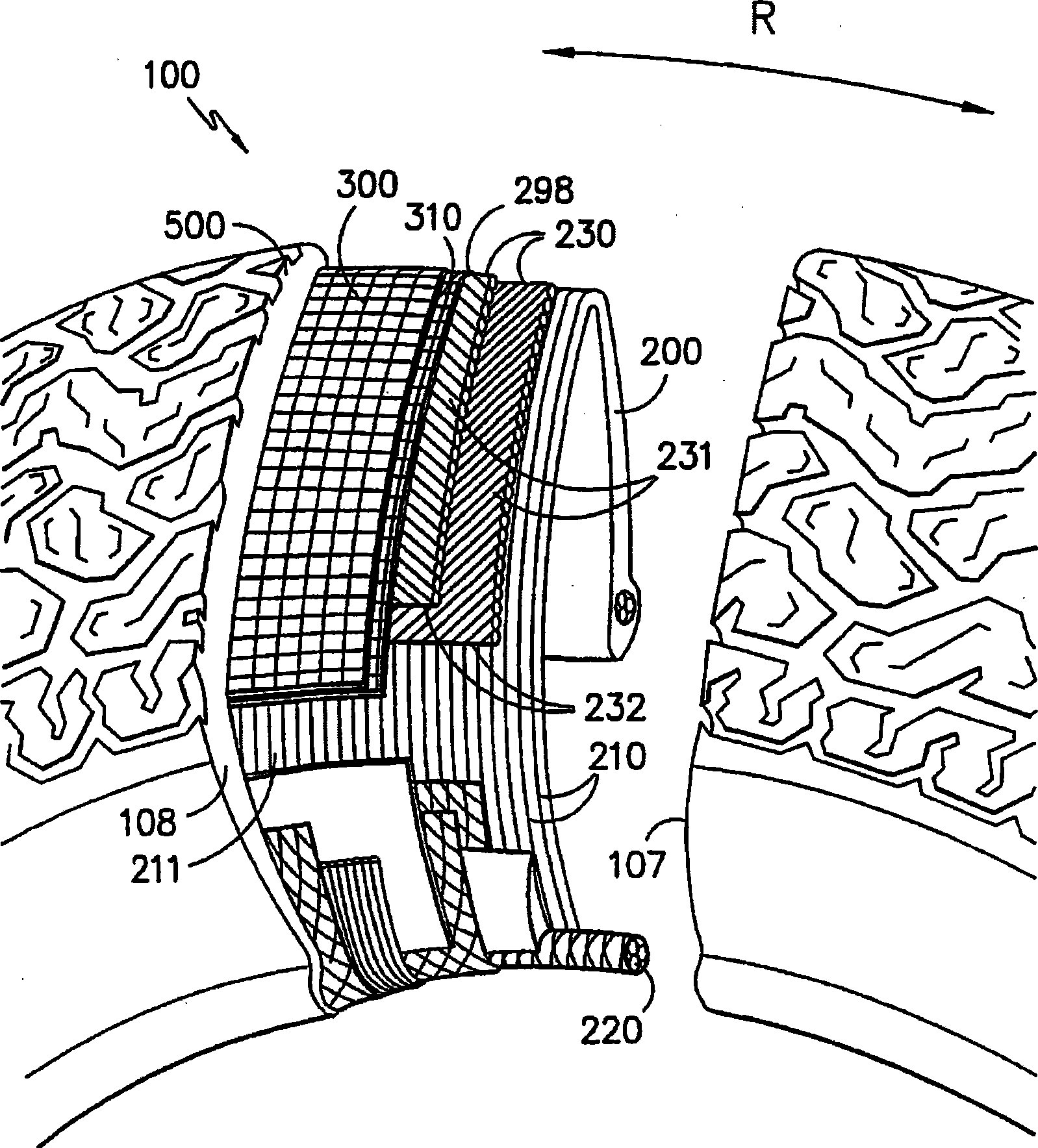

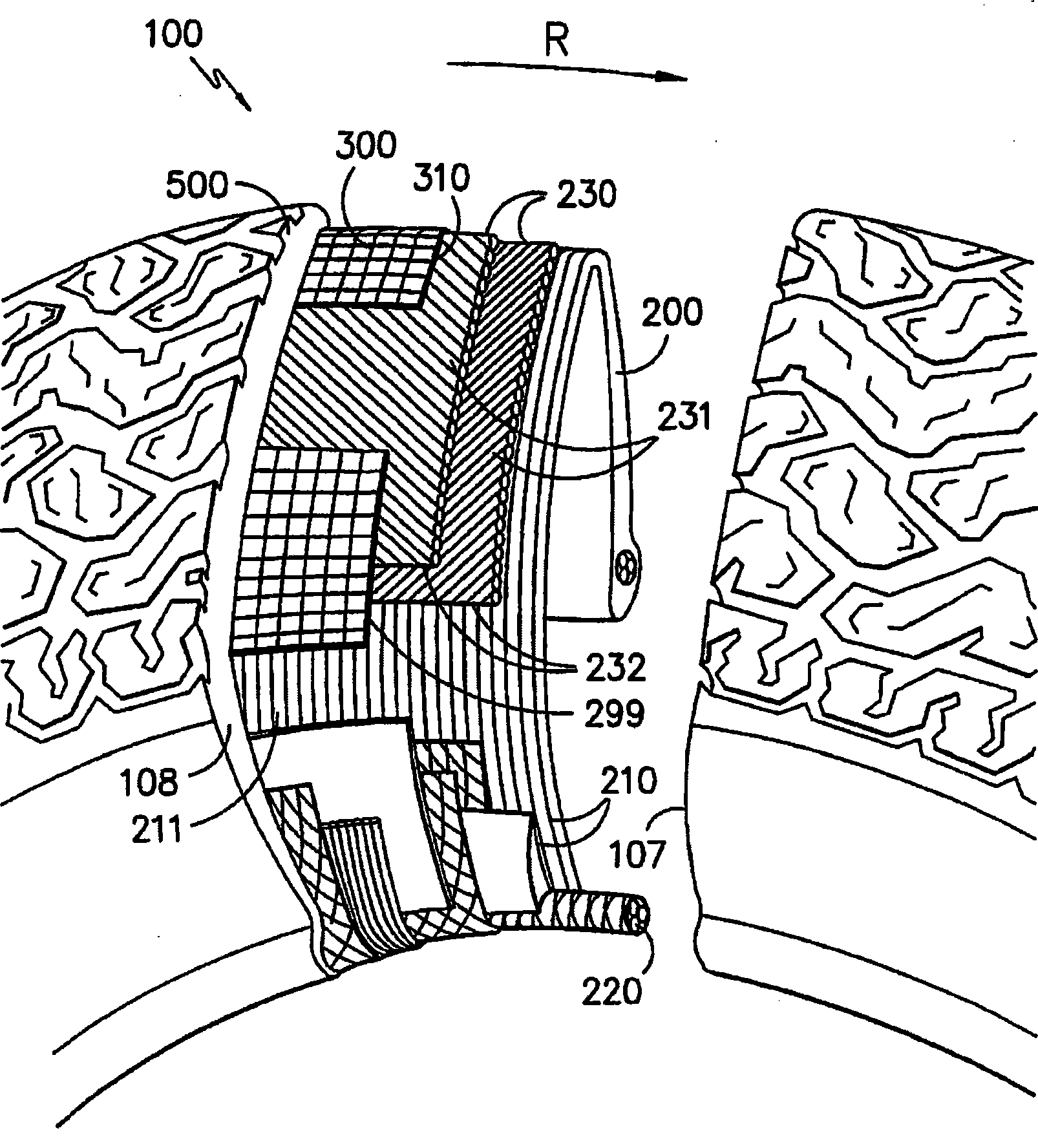

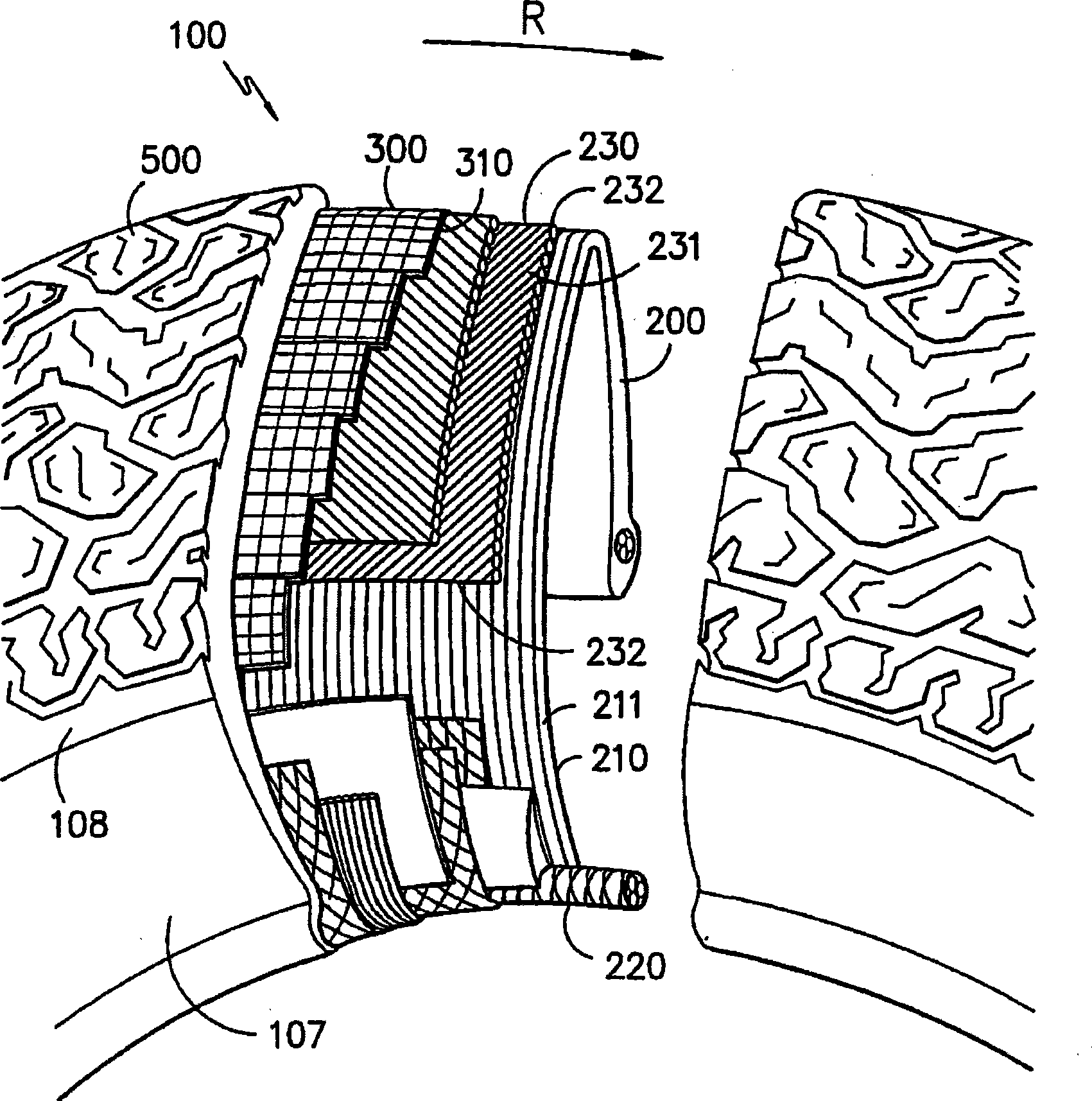

[0031] Referring now to the accompanying drawings, in particular Figures 1A-1C , a tire 100 is shown comprising a sidewall 107 connected to a tread 500 by a shoulder 108 . The tire 100 includes a carcass 200 covered by a tread 500 . exist Figures 1A-1C Among them, the tire 100 is a radial tire. However, the invention is not limited to radial tires, but can also be used in other tire constructions. The carcass 200 is composed of one or more layers of tire cord 210 terminating at a metal bead 220 on the inner periphery of the tire, at least one belt layer 230 arranged circumferentially in the area of the tread 500 tire cord 210 . Tire cord 210 is a rubberized fabric whose warp threads are formed from relatively inextensible reinforcing threads. exist Figure 1A In the tire shown in -C, the carcass 200 is configured such that the reinforcing wire 211 extends substantially in the radial direction of the intended rotation direction R of the tire 100 . Belt ply 230 is form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com