Pneumatic tool with wear resistance

A pneumatic tool, wear resistance technology, applied in the direction of manufacturing tools, portable motorized devices, etc., can solve problems such as wear, cylinder component failure, heat generation, etc., to achieve the effect of improving work efficiency and improving the life of pneumatic tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

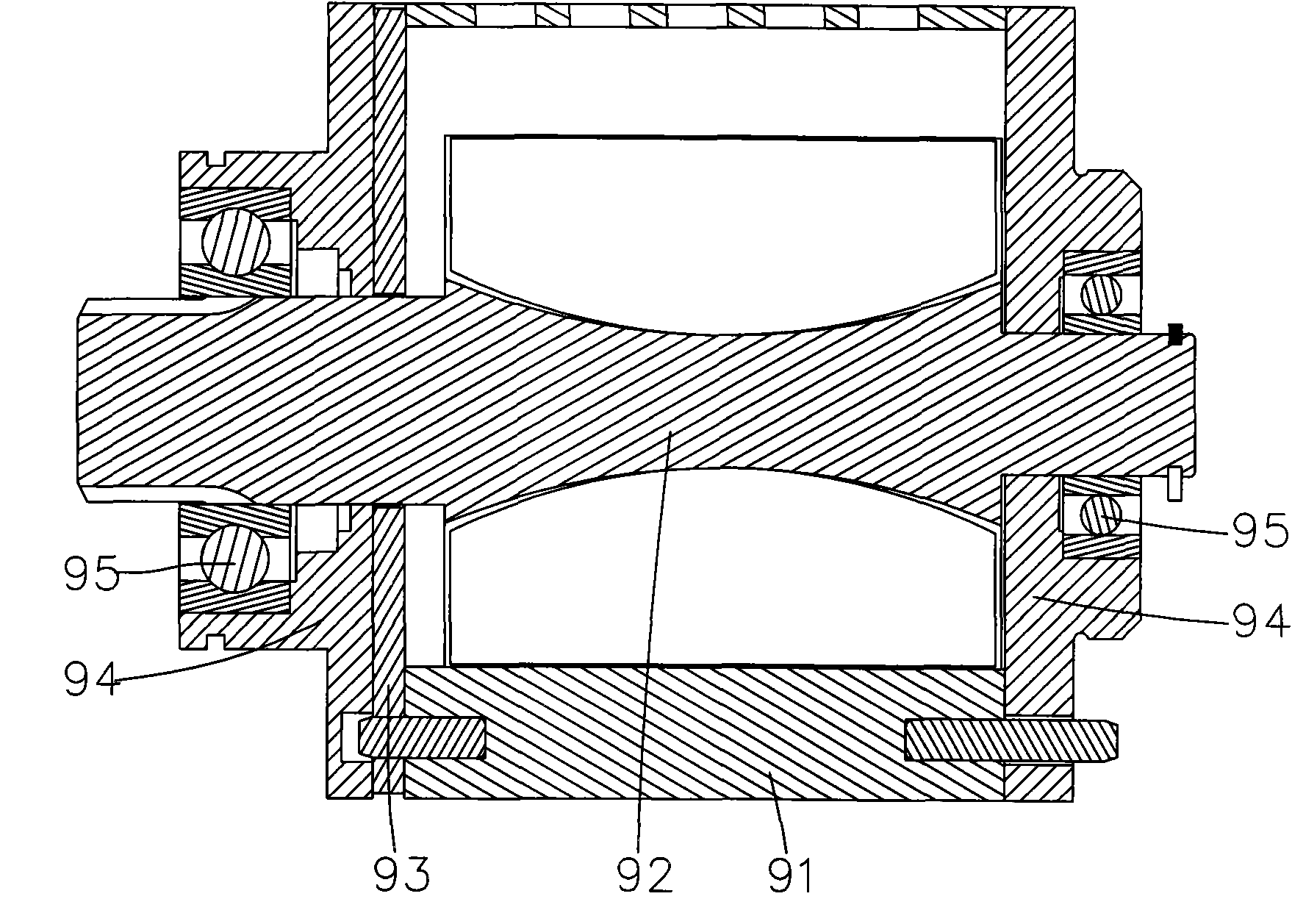

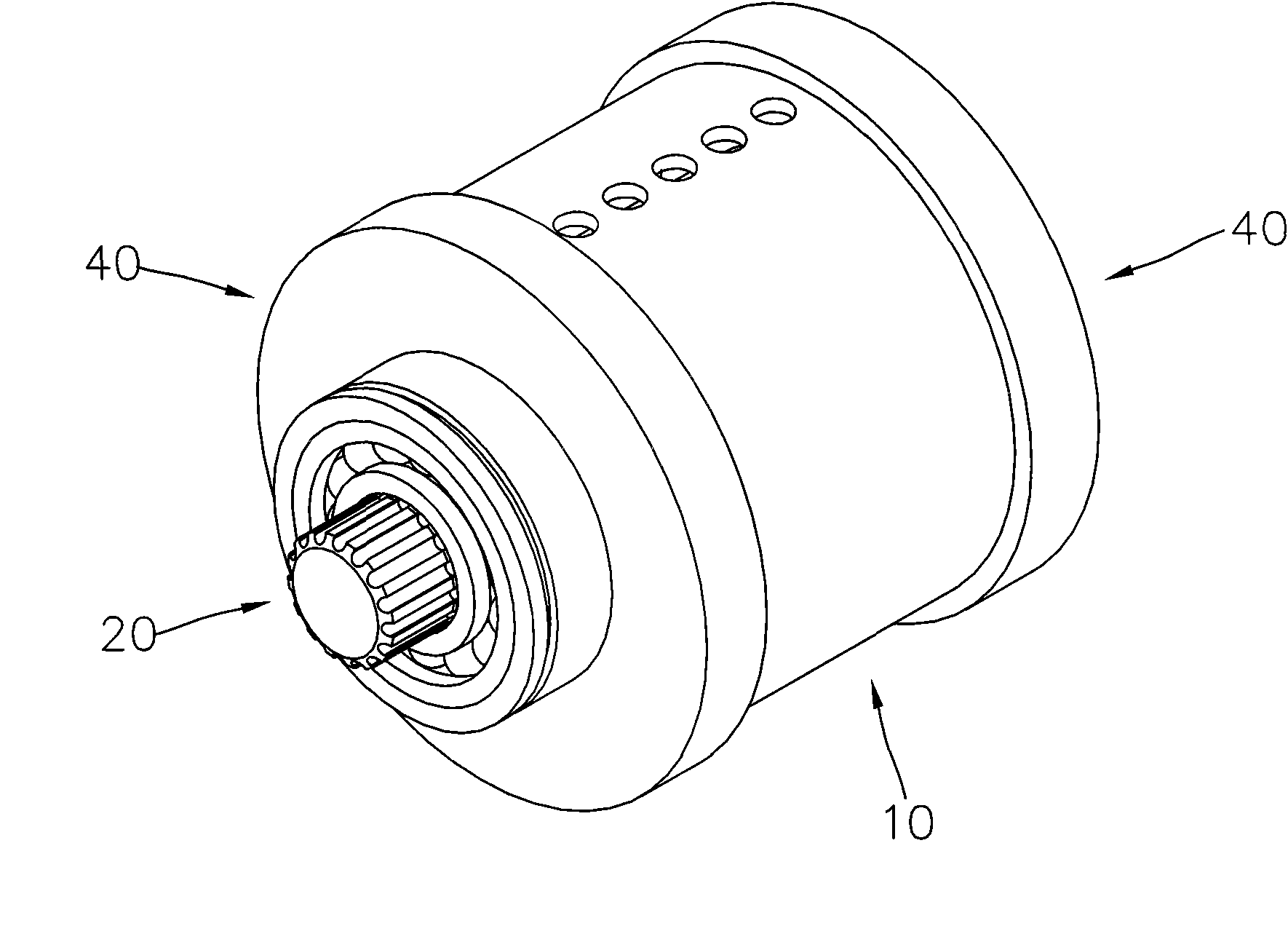

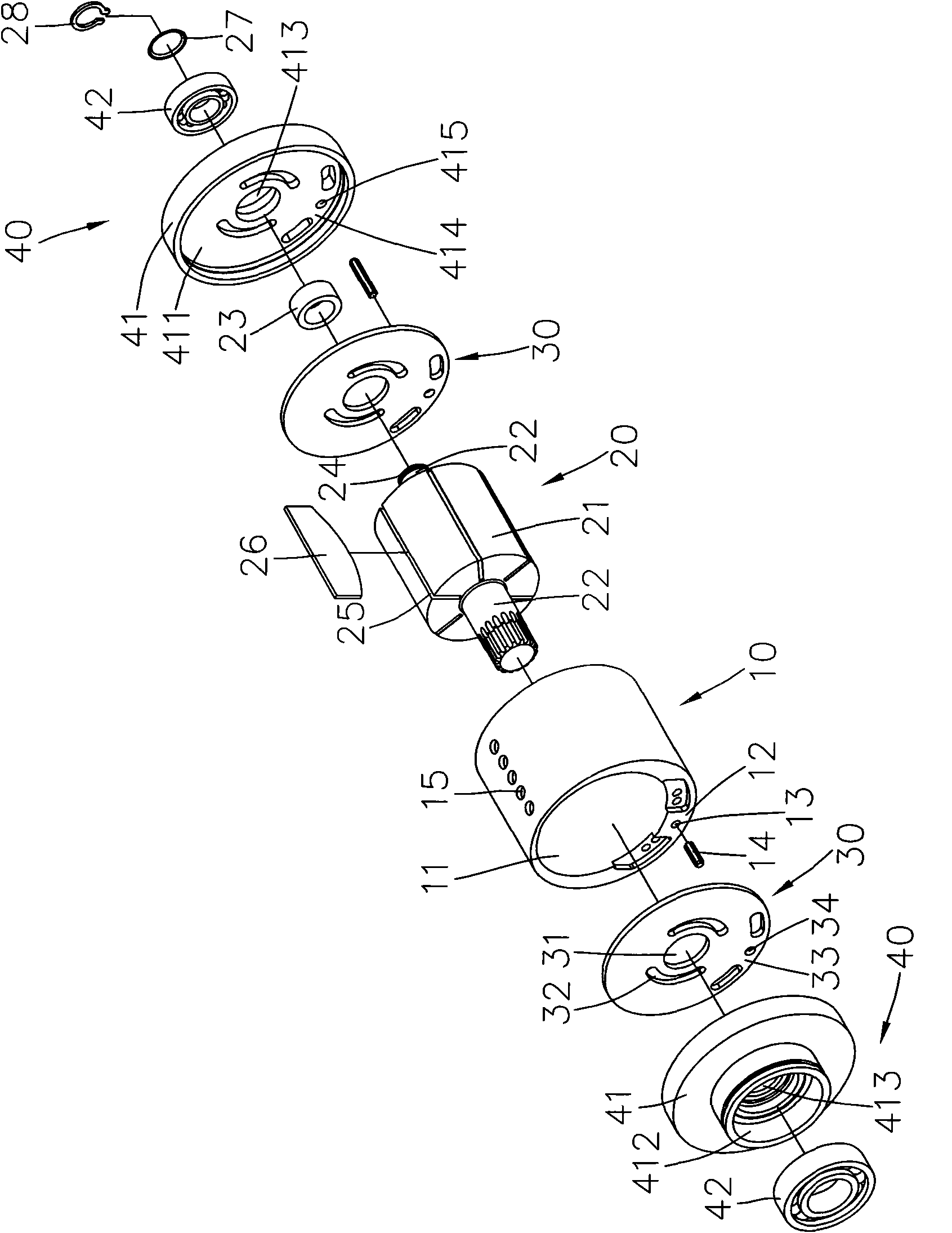

[0025] refer to figure 2 and image 3 , is the three-dimensional appearance view and three-dimensional exploded view of the first embodiment of the wear-resistant pneumatic tool of the present invention. The wear-resistant pneumatic tool of the present invention includes a cylinder 10 , a rotor 20 , two gaskets 30 and two outer cover assemblies 40 .

[0026] The cylinder 10 includes an eccentric cavity 11, one end on both sides of the cylinder 10 is a fixed portion 12, the fixed portion 12 is arranged at the thicker end of the cylinder 10, the fixed portion 12 on both sides is provided with at least one fixed hole 13, At the same time a pin 14 is inserted in the fixing hole 13 . Opposite to the other end of the fixing hole 13 , several air holes 15 are arranged radially on the outer peripheral surface of the cylinder 10 .

[0027] The rotor 20 is accommodated in the cavity 11 of the cylinder 10. The rotor 20 includes a body 21 and an axis 22 extending from two sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com