Broad-amplitude film extrusion calendaring train

A calendering unit and calender technology, applied in the field of wide-width film extrusion and calendering units, can solve the problems of difficult processing and production, low work efficiency, inconvenient use, etc., and achieve the effect of simple structure, high production efficiency and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

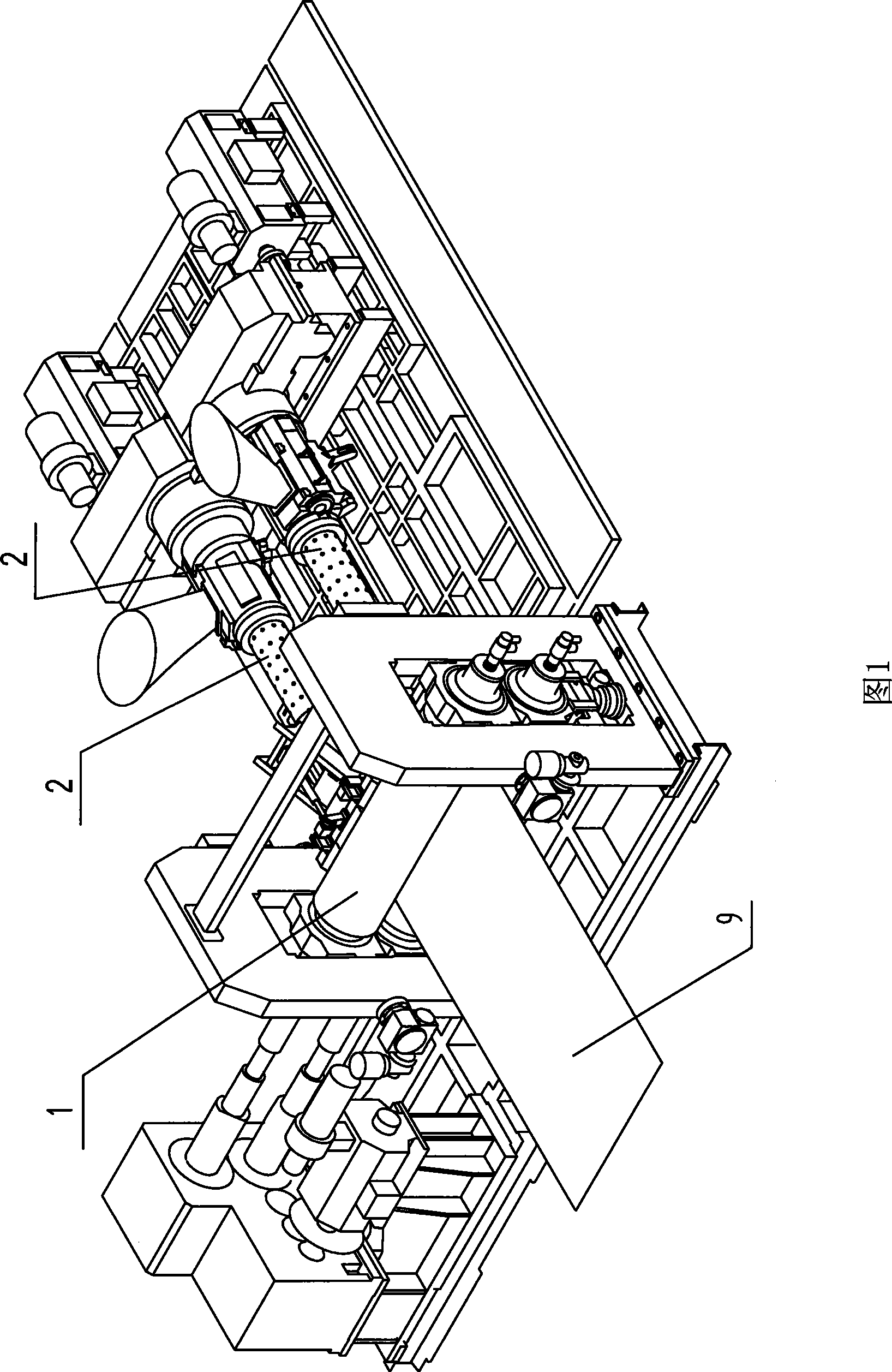

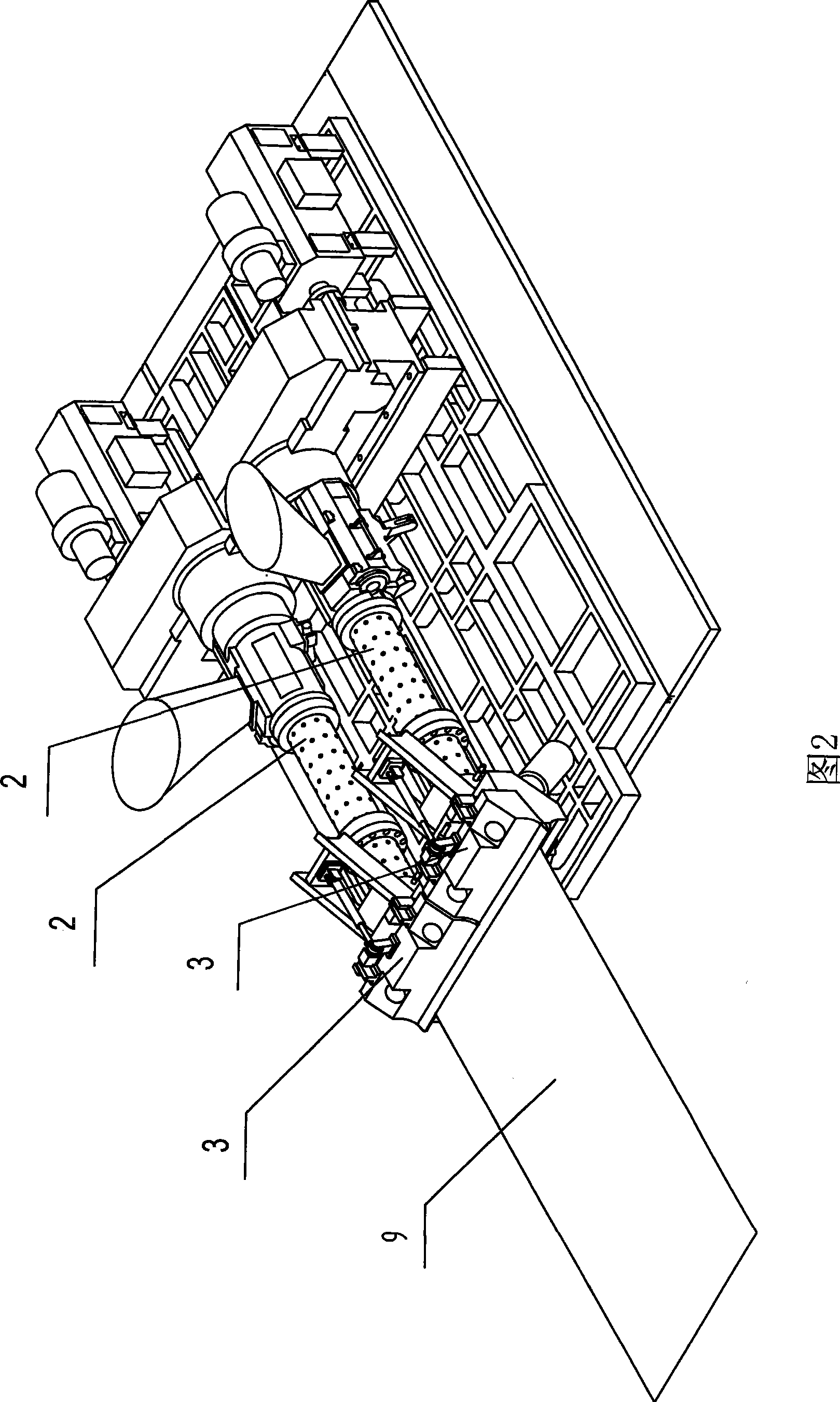

[0029] The wide-width film extrusion and calendering unit of the present invention includes a two-roller calender 1 and a set of extrusion equipment for feeding the calender 1 . Extrusion equipment can be composed of two or more extruders 2 arranged side by side. In Fig. 1, the extrusion equipment is composed of two extruders 2 arranged side by side, each extruder 2 has its own single extruder head 3 respectively, and the single extruder heads 3 are horizontally arranged side by side to form a combination head, and a single extruder The outlets of the extruder head 3 are on the same vertical plane, as shown in FIG. 2 .

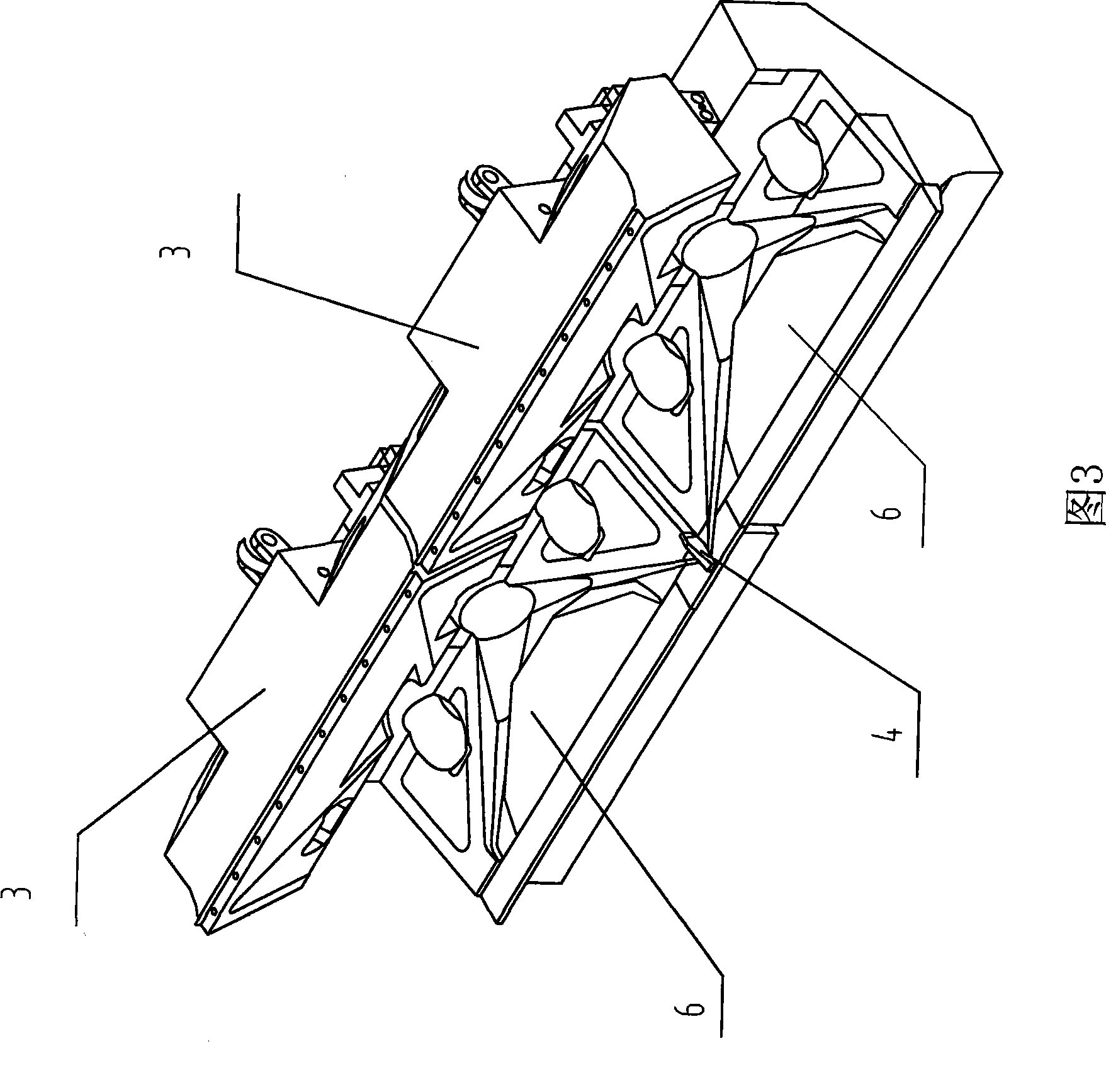

[0030] (1), the individual extrusion heads 3 in the combination head are connected by a flow mixer 4:

[0031] As shown in FIG. 3 , the flow mixer 4 is connected at the junction of the runner cavities 6 in adjacent single extruder heads 3 . When using combined extruder head 3 to extrude materials at the same time, the film 9 with the widest width can be prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com