Fireproofing device of ventilating duct for conveying high greasy dirt/high powder dust fluids

A technology for ventilation pipes and fire prevention devices, which is applied in the direction of pipeline damage/abrasion prevention, pipe protection, pipes/pipe joints/fittings, etc. It can solve the problems of high energy consumption in transportation and easy failure of fire protection functions, so as to ensure fire safety and save energy. The effect of transporting energy consumption and ensuring fire safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

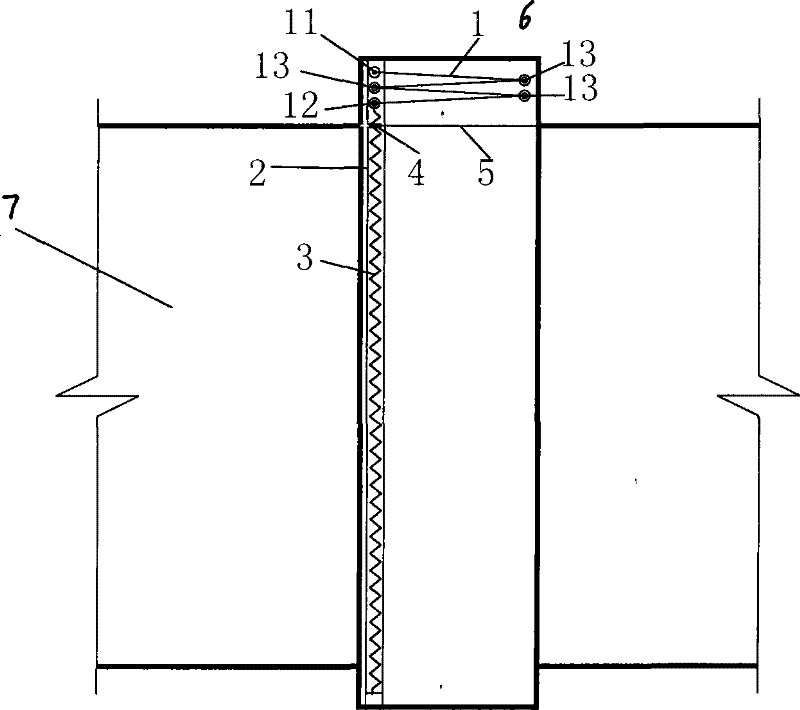

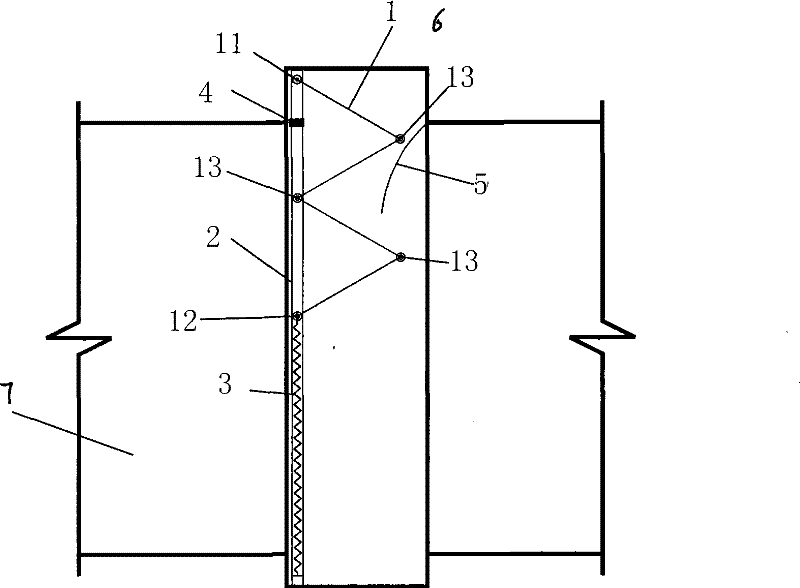

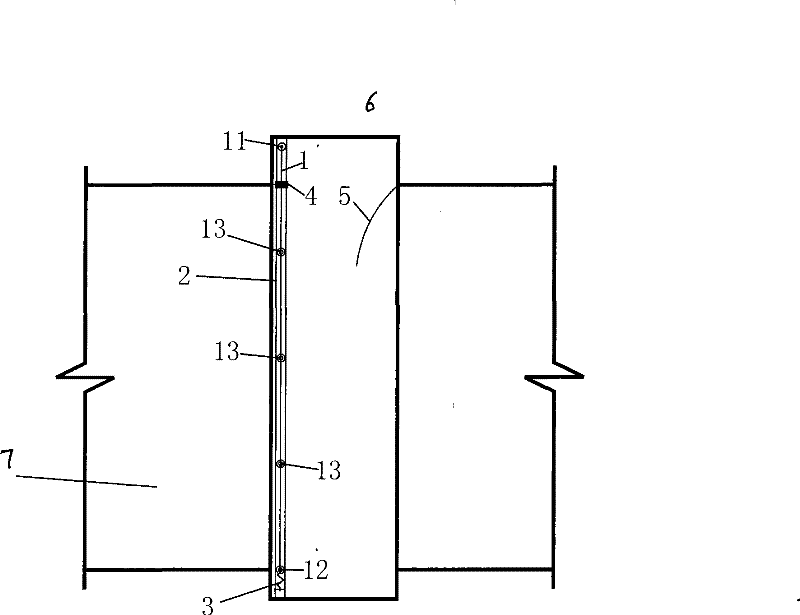

[0018] refer to figure 1 , figure 2 and image 3 , the present embodiment includes a folding blade mechanism 1, a guide rail 2 and a telescopic mechanism 3 fixed in the guide rail 2, the upper end 11 of the folding blade mechanism 1 is fixedly connected with the top end of the guide rail 2, and the lower end 12 of the folding blade mechanism 1 is connected to the The head of the telescopic mechanism 3 is fixedly connected, and the folding blade mechanism 1 is formed by connecting several blades, and a plurality of middle movable ends 13 are formed by end-to-end connections between the blades, and the tail end of the telescopic mechanism 3 is connected to the bottom end of the guide rail 2 Fixed connection; the telescopic mechanism 3 is provided with a temperature sensor 4, and the signal output end of the temperature sensor 4 is connected with the control input end of the telescopic mechanism.

[0019] In this embodiment: the length of the guide rail 2 is greater than the c...

specific Embodiment 2

[0023] The feature of this embodiment is that the folding blade mechanism 1 has an upper end 11 , a lower end 12 and a middle movable end 13 . Others are the same as in Example 1.

specific Embodiment 3

[0024] The feature of this embodiment is: the foldable blade mechanism 1 has an upper end 11 , a lower end 12 and five intermediate movable ends 13 . Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com