Calibrating method and apparatus for touch screen equipment

A calibration method and touch screen technology, applied in the input/output process of data processing, instruments, electrical and digital data processing, etc., can solve the problems of transformation, data inversion, and unusable touch screen equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

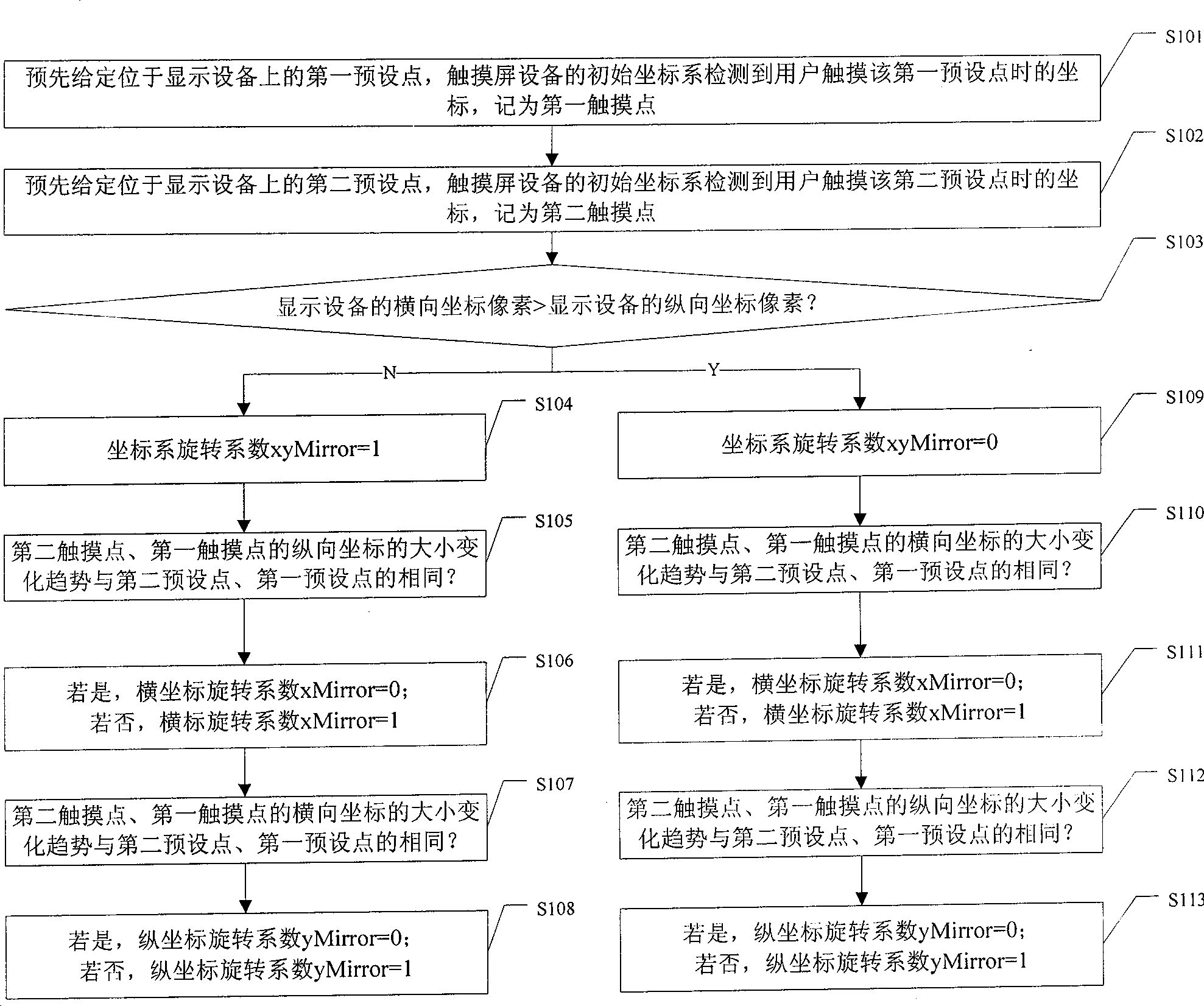

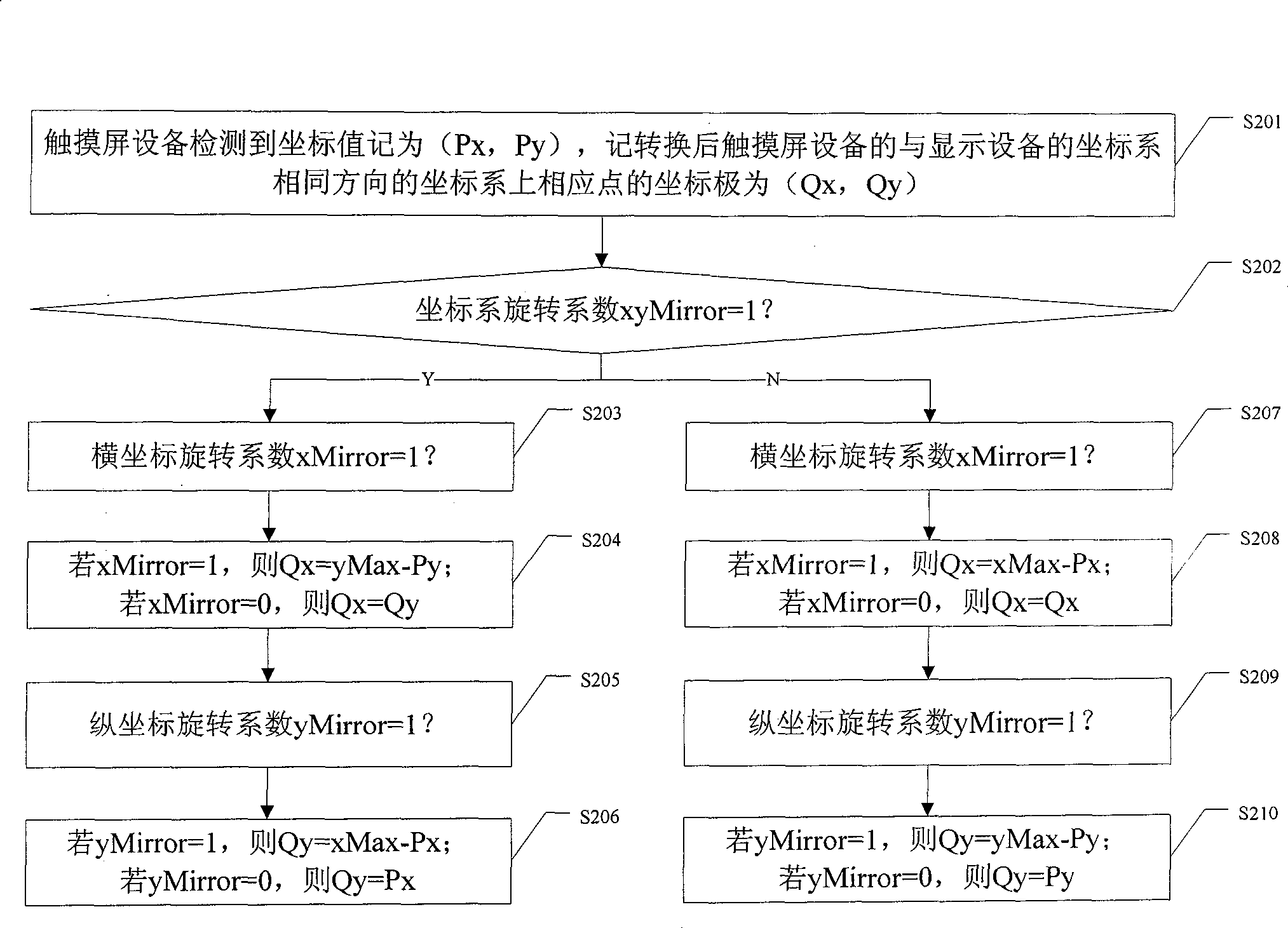

Method used

Image

Examples

Embodiment Construction

[0026] The following describes in detail specific embodiments of the present invention.

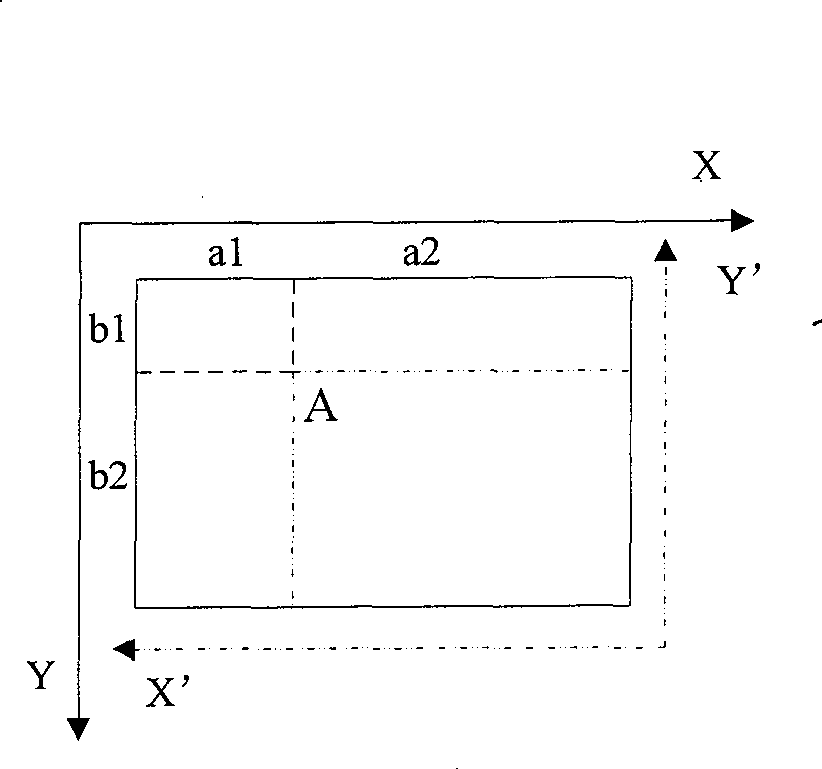

[0027] According to people's usual addressing habits, in the following descriptions, the horizontal coordinate is used as the first coordinate and the vertical coordinate is used as the second coordinate for illustration. Correspondingly, the horizontal coordinate pixel refers to the maximum pixel value of the first coordinate, and the vertical coordinate Pixel refers to the maximum pixel value of the second coordinate, the rotation coefficient of the abscissa refers to the rotation coefficient of the first coordinate, and the rotation coefficient of the ordinate refers to the rotation coefficient of the second coordinate. It should be noted that this example is not used for touch screen devices , the orientation of the display device and the coordinate system used are restricted.

[0028] Because under normal circumstances, touch screen devices use the wider side as the horizontal coordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com