Multi lateral compensation type high power density electromechanical energy convertor

A technology with high power density and electromechanical energy, applied in the direction of electromechanical devices, mechanical energy control, multi-output synchronous motors, etc., can solve the problems of not being able to be adjusted arbitrarily, restricting the application range of the system, and large voltage adjustment rate, etc., to achieve simple structure, high voltage The effect of low adjustment rate and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

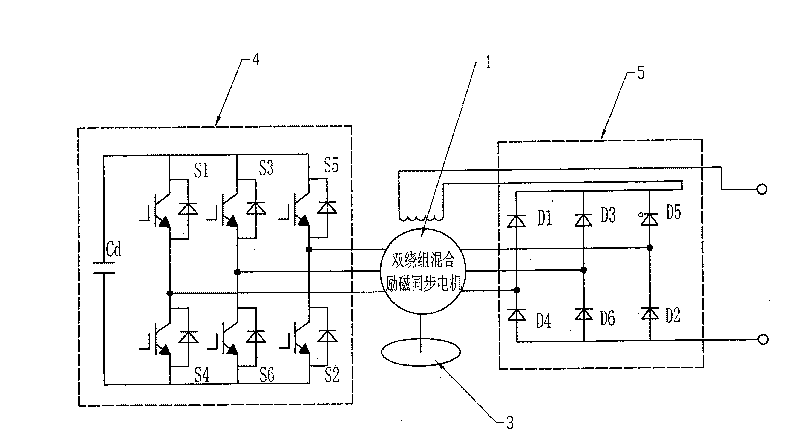

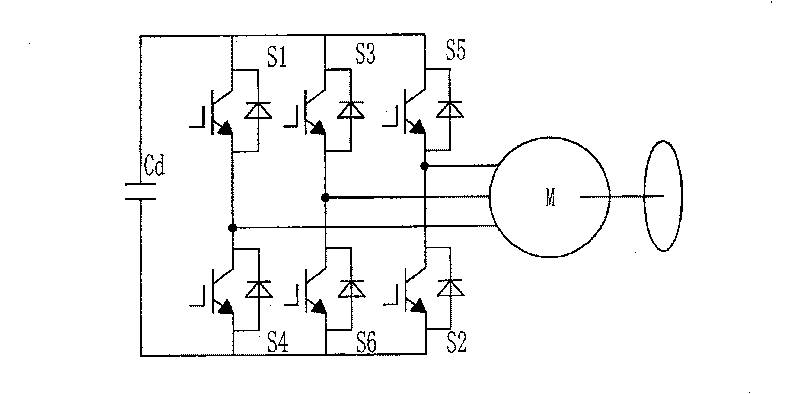

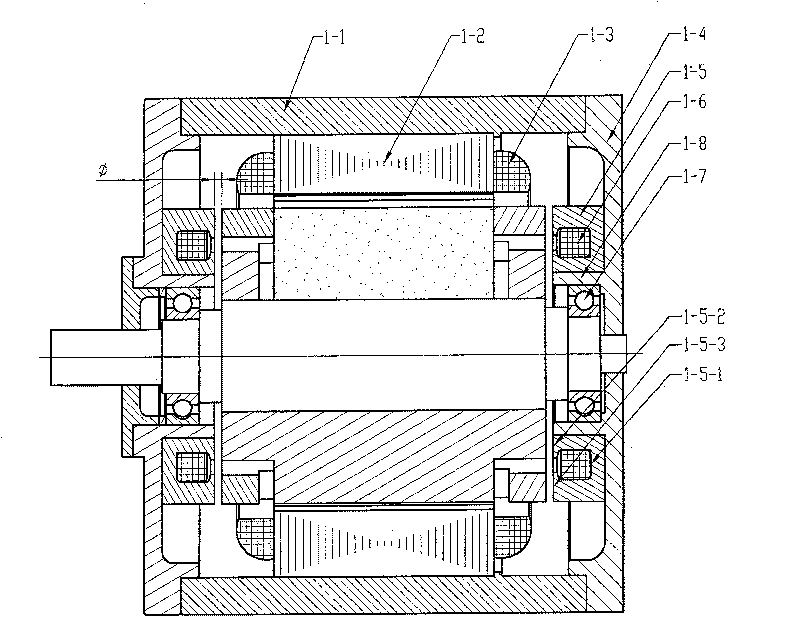

[0009] Specific implementation mode one: as Figure 1 to Figure 18 As shown, this embodiment is composed of a double-winding hybrid excitation synchronous motor 1, an inertial flywheel 3, an inverter 4 and a rectifier 5; -2. Two sets of armature windings 1-3, two end caps 1-4, two magnetic conducting rings 1-5 and two DC excitation windings 1-6; the magnetic conducting rings 1-5 are ring-shaped in the middle The annular structure of the groove 1-5-1, the magnetic conduction ring 1-5 is installed at the axial position of the end cover 1-4, and the annular DC excitation winding 1-6 is embedded in the annular groove 1 of the magnetic conduction ring 1-5 In -5-1; the armature core 1-2 and two sets of armature windings 1-3 are fixed on the inner surface of the casing 1-1; the rotor consists of a permanent magnet, a magnetically conductive yoke, a magnetically conductive end ring and a rotating shaft 2- 6 components; the magnetic yoke is 2p sectors with the same shape and size, the...

specific Embodiment approach 2

[0012] Specific implementation mode two: as Figure 5 with Figure 6 As shown, the difference between this embodiment and the specific embodiment one is that the parallel or radially magnetized permanent magnets 2-1-2 are rectangular flat plates, and the axial direction of the magnetic yoke has a The chord of the arc is parallel to the rectangular hole 2-8, and the parallel or radially magnetized permanent magnet 2-1-2 is embedded in the axial rectangular hole 2 of the N-pole magnetic yoke 2-2 and the S-pole magnetic yoke 2-3 -8 within. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0013] Specific implementation mode three: as Figure 7 with Figure 8As shown, the difference between this embodiment and the specific embodiment is that the parallel or radially magnetized permanent magnet 2-1-2 is an arc-shaped plate, and the N of the parallel or radially magnetized permanent magnet 2-1-2 The pole surface and the S pole surface are pasted on the radially outer surfaces of the N pole magnetic yoke 2-2 and the S pole magnetic yoke 2-3 respectively. Other compositions and connection methods are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com