Circular plate type super-filter

An ultrafilter and circular plate technology, applied in the field of circular plate ultrafiltration membrane devices, can solve the problems of thin membrane filaments, easy to break filaments, difficult cleaning, etc., and achieve the effects of small pressure drop, safe drinking water, and easy cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

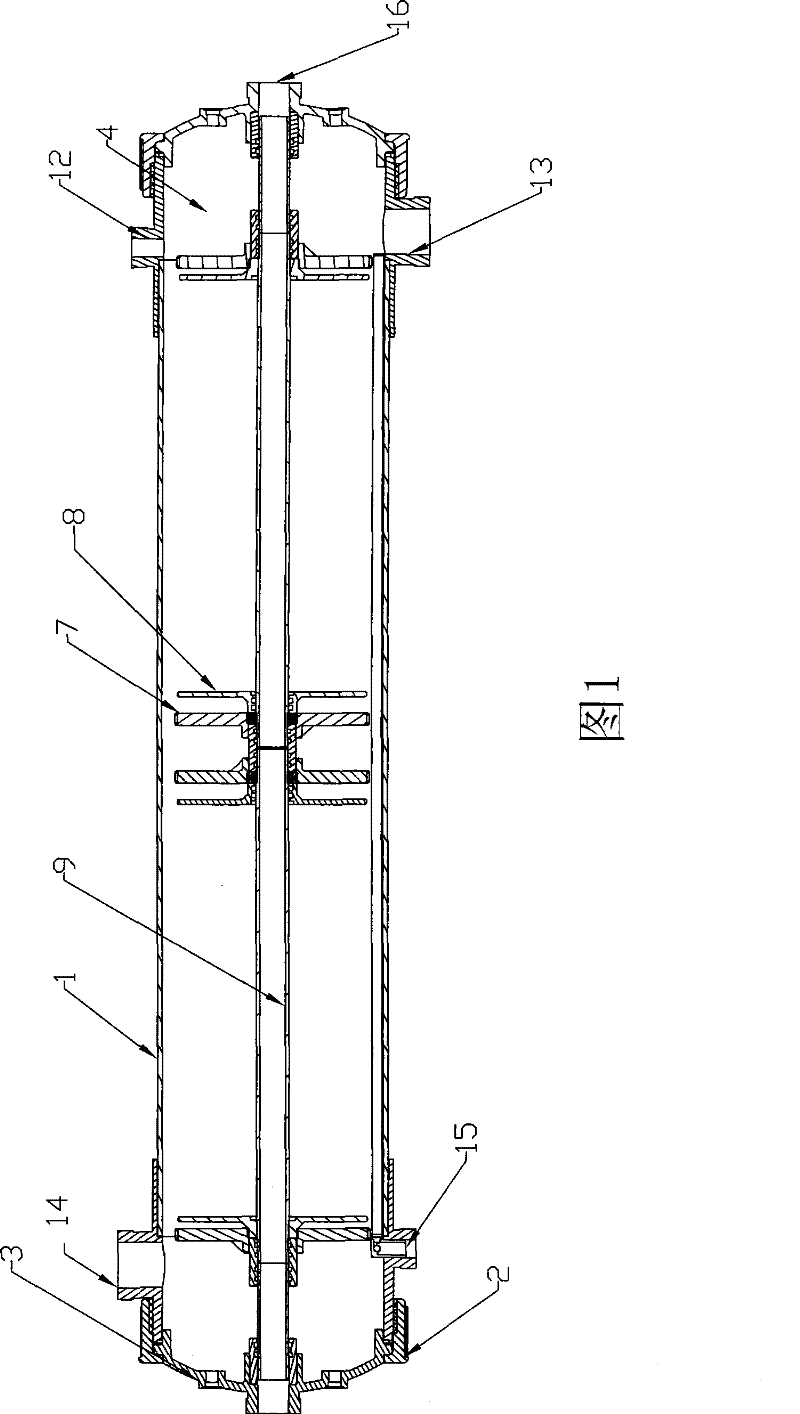

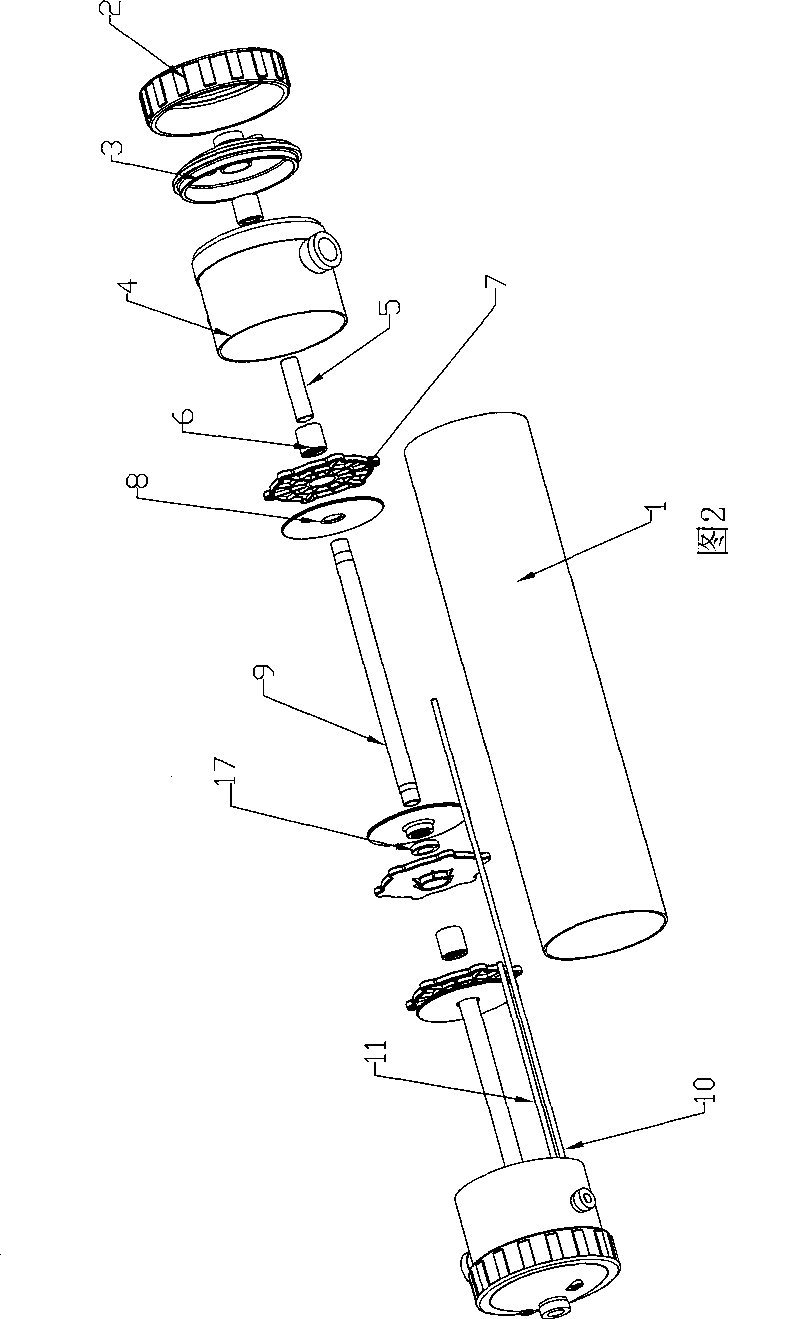

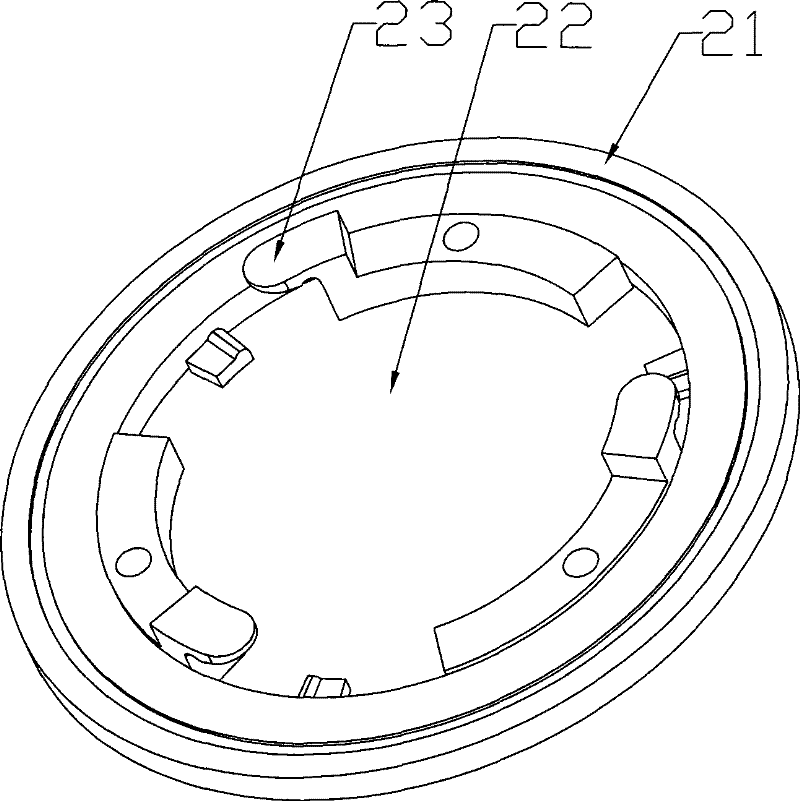

[0021] refer to figure 1 , 2 , 3, 4, 5, 6, the disc type ultrafilter mainly includes a cylinder body 1, a cylinder cover assembly and a disc type ultrafiltration membrane assembly placed in the cylinder body 1, the cylinder body 1 is made of polyethylene (PE) material, Its length can be determined according to the amount of water output. The cylinder cover components at both ends are made of high-strength, corrosion-resistant hard polyvinyl chloride (UPVC) material, and are socket-bonded with the cylinder body 1 . The disc type ultrafiltration membrane module is set on the cylinder body 1, the two ends are connected to the pipe connector 4, and the top cover 3 is used to seal the composition. The disc-type ultrafiltration membrane module is composed of a short water-producing pipe through a threaded connector 17 to form a water-producing pipe 9, and its two ends are connected with a blocking piece 8 and a positioning piece 7 to fix it. Two rows of symmetrical water permeabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com