Clutch arrangement

A clutch device, clutch technology, applied in the direction of clutches, automatic clutches, transmissions, etc., can solve the problems of expensive, complex temperature compensation, etc., to achieve the effect of simple cost, not easy to fail, and reduce temperature correlation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

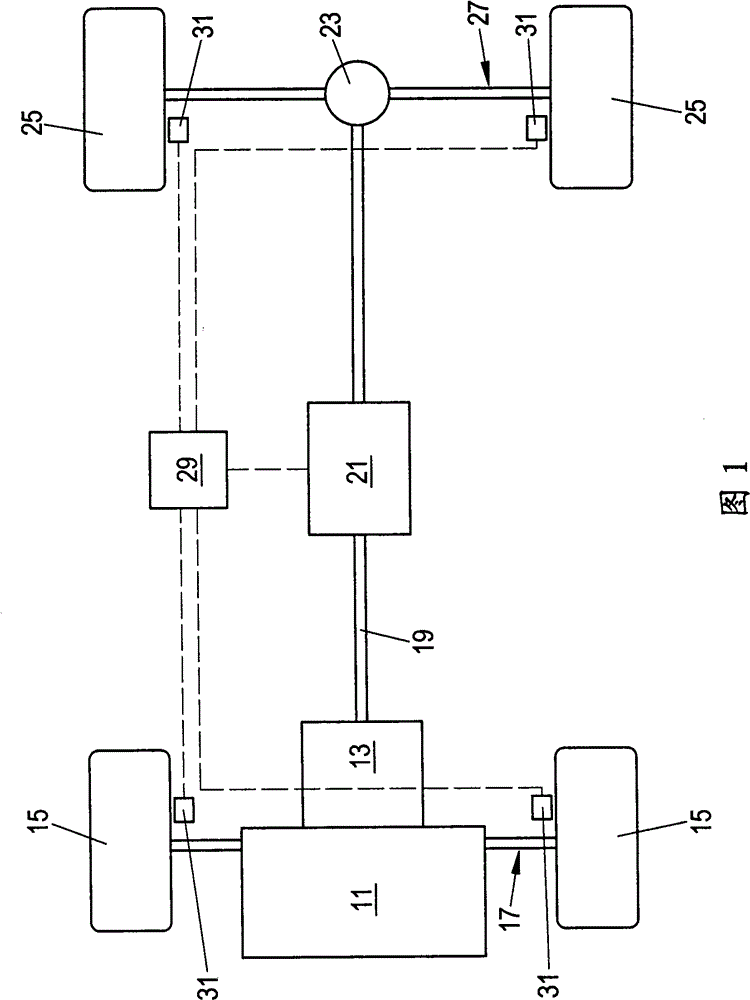

[0036] figure 1 A powertrain of a motor vehicle is shown schematically. The engine 11 drives the two wheels 15 of the front axle 17 through a transmission unit 13 and a front axle differential gear (not shown). Thus, the front axle 17 forms the main axle. Furthermore, the engine 11 drives the two wheels 25 of the rear axle 27 via the transmission unit 13 , the cardan shaft 19 , the clutch device 21 and the rear axle differential gear 23 . In this respect, the rear axle 27 forms the secondary axle of the vehicle. The electronic control unit 29 of the vehicle is connected at the input side to four wheel speed sensors 31 associated with the front wheels 15 and the rear wheels 25 . Optionally, the control unit 29 is connected to other sensors, for example to a steering angle sensor, a yaw rate sensor, etc. (not shown). The control unit 29 is connected to the clutch device 21 at the output side. The clutch device 21 serves to transmit some of the drive torque of the engine 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com