Method and circuit device for determining position of movable armature of electromagnetic actuator

A technology of electromagnetic actuator and circuit device, which is applied in the direction of fluid pressure actuation device, valve operation/release device, circuit, etc., to achieve the effects of improving temperature characteristic curve, interference robustness, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

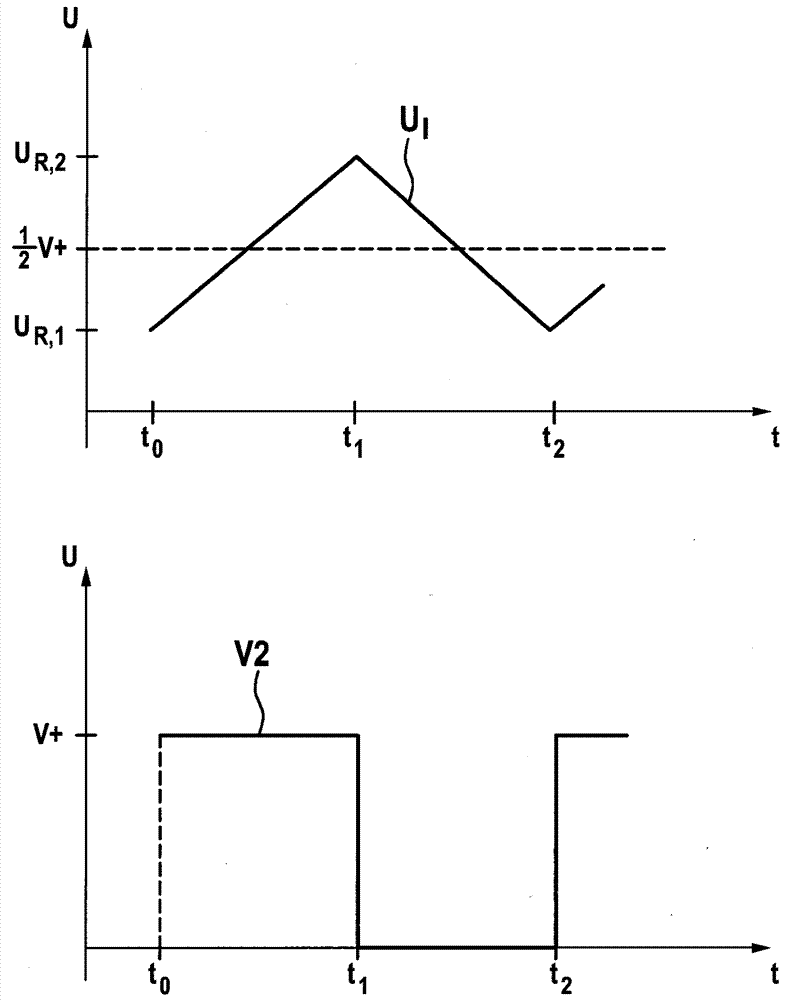

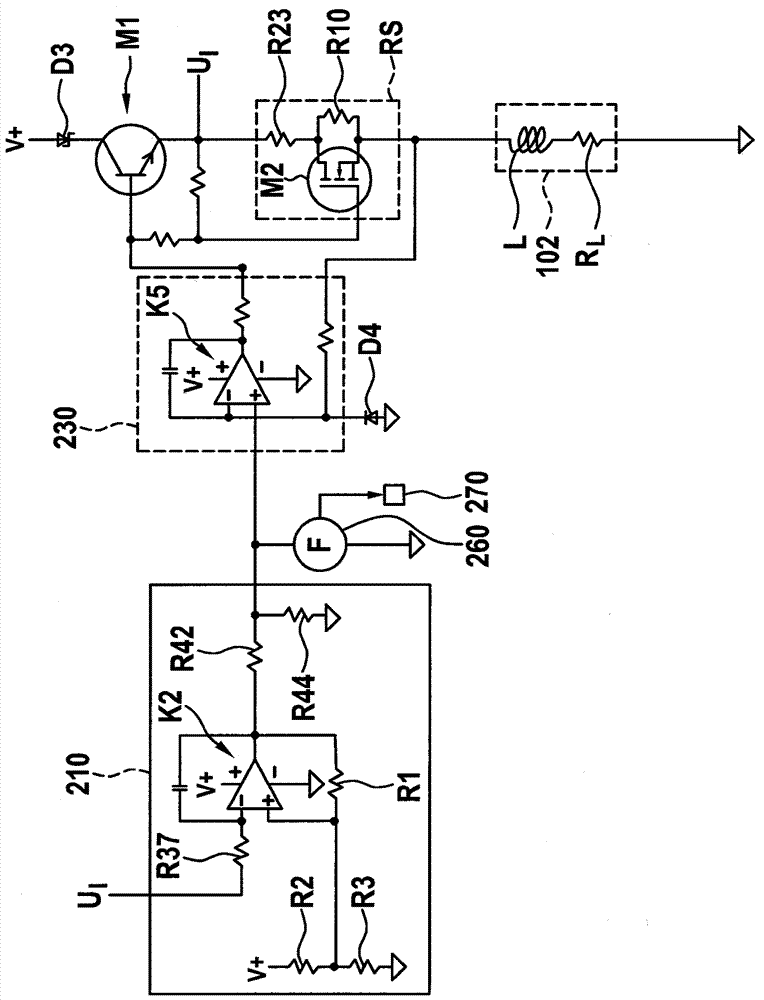

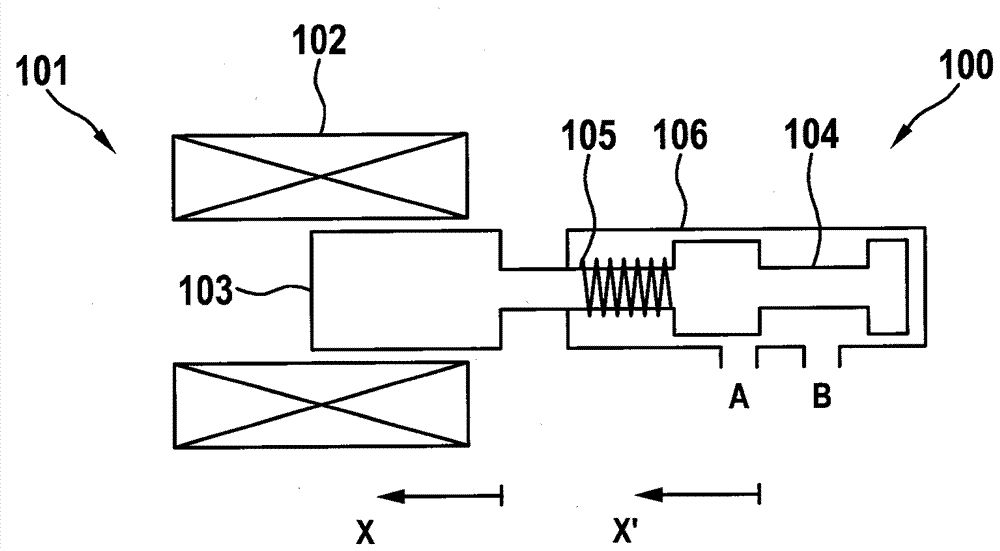

[0031] exist figure 1 A solenoid valve 101 is schematically shown in FIG. 1 , in which the method according to the invention can be carried out. Solenoid valve 101 , which is presently designed as a proportional valve, has a solenoid actuator 101 , which in turn has a coil 102 and an armature 103 movable in this coil.

[0032] Connected to the armature 103 is a control slide valve 104 which can be moved back and forth in a valve housing 106 . The control spool 104 is supported at the end of the valve housing 106 by means of a spring 105 . The armature 103 is moved by controlling the electromagnetic actuator 101 and thus the spool 104 presses against the spring 105 . In this way, the position x of the armature 103 or of the slide valve 104 can be changed. For this purpose, the coil 102 can be controlled, for example (via terminals not shown here) by pulse width modulation.

[0033] Flow from port A to port B through valve housing 106 is regulated by movement of spool valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com