Railway track joint

A technology for rails and railways, applied to the joints of rails, roads, tracks, etc., can solve the problems of increasing the friction between the train wheels and rail joints, and achieve the effects of reducing train noise, increasing driving speed, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, invention is described further:

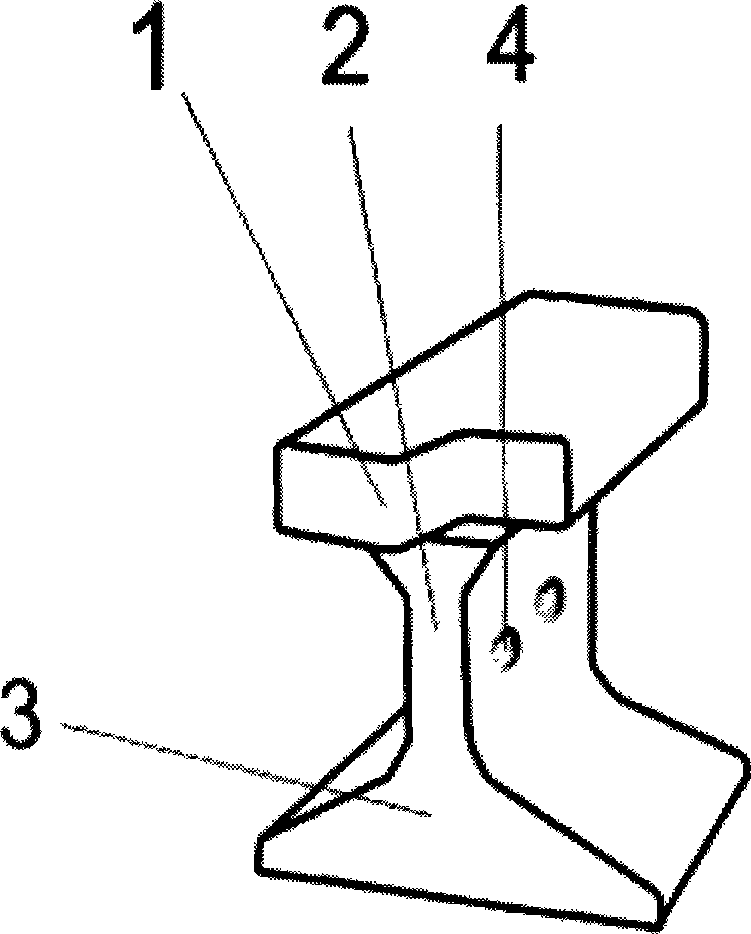

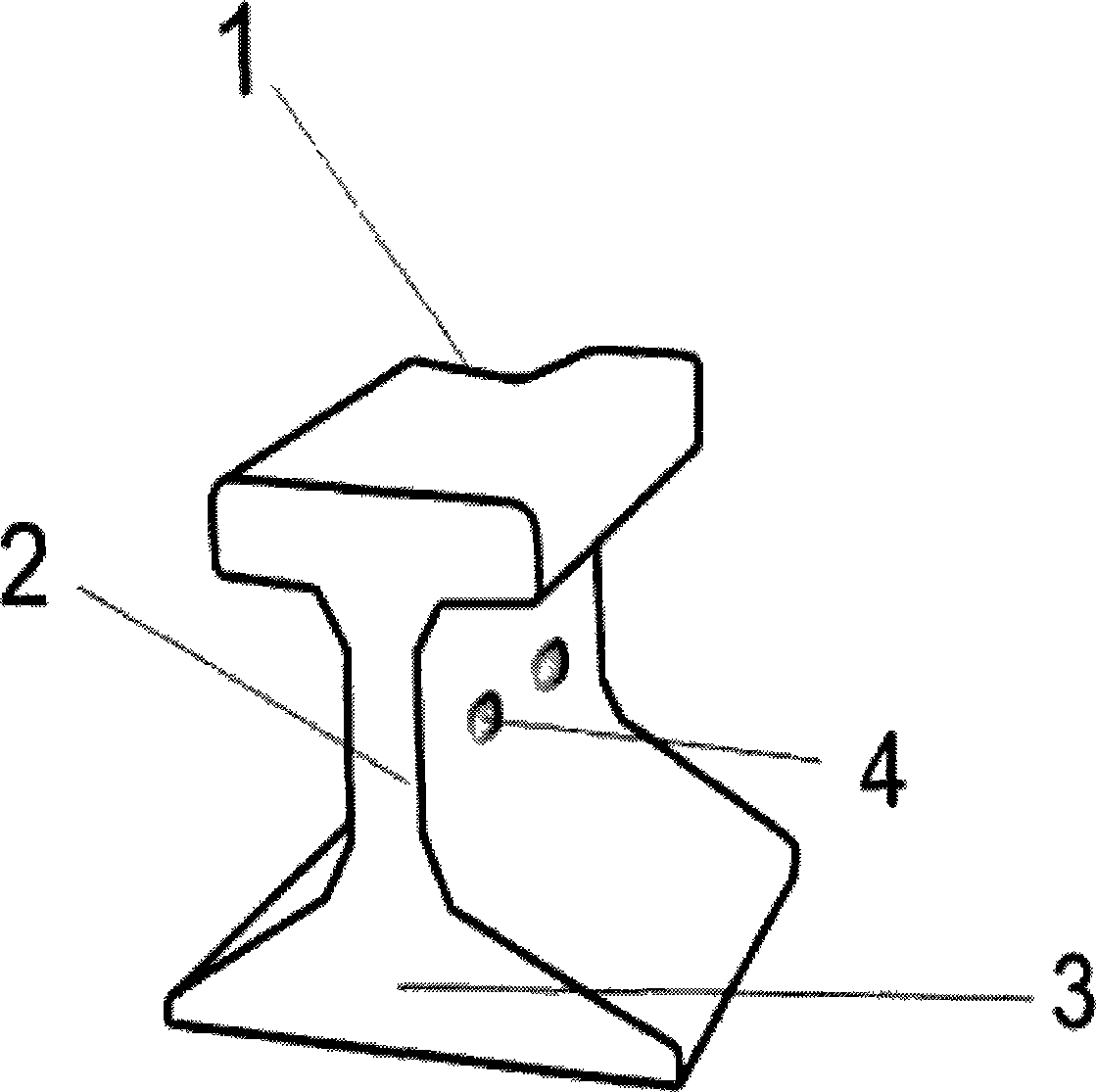

[0014] A new type of railway rail joint, which changes the part of the rail head (1) where the "I"-shaped rail contacts the wheel from a flat surface to two "mortise" shaped joints with half protruding and half recessed, that is, " "The shape of the middle rail waist (2) and the bottom (3) remain unchanged. When laying the rail, align any two joints, put them into the steel plate (5), and fix them with screws (4).

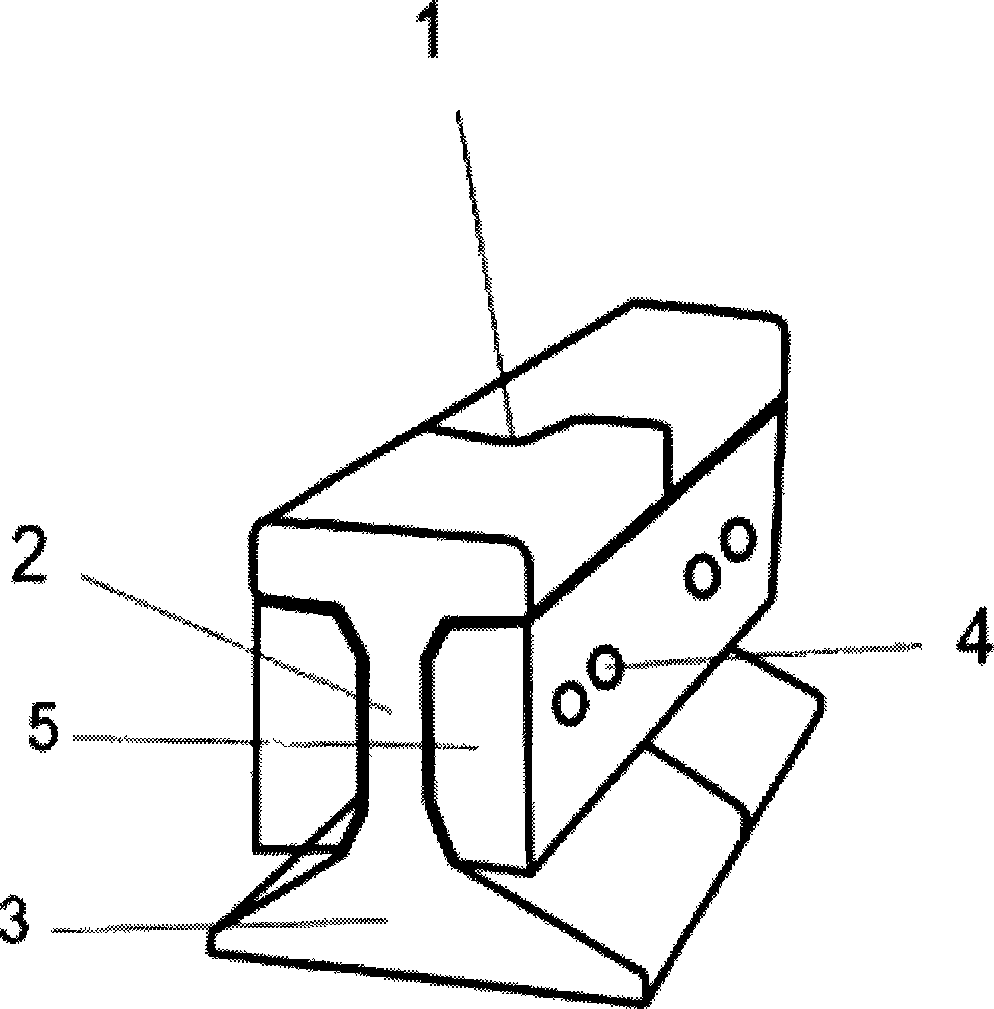

[0015] A new type of railway rail head, which is to change the "I"-shaped rail head (1) in contact with the wheel from a flat surface to a 50° inclined joint. The two ends of the inclined plane are straight lines, and the joint between the straight line and the inclined plane is a straight line. shape, the middle rail waist (2) and the bottom (3) of the rail remain unchanged. For the auxiliary rail, align any two joints, put in the steel plate (5), and fix it with screws (4)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com