Contact type image sensor

An image sensor and contact technology, applied in image communication, instrumentation, optics, etc., can solve the problems of shadows, interference signals, and unequal reading of originals, and achieve the effects of preventing loss, reducing interference signals, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

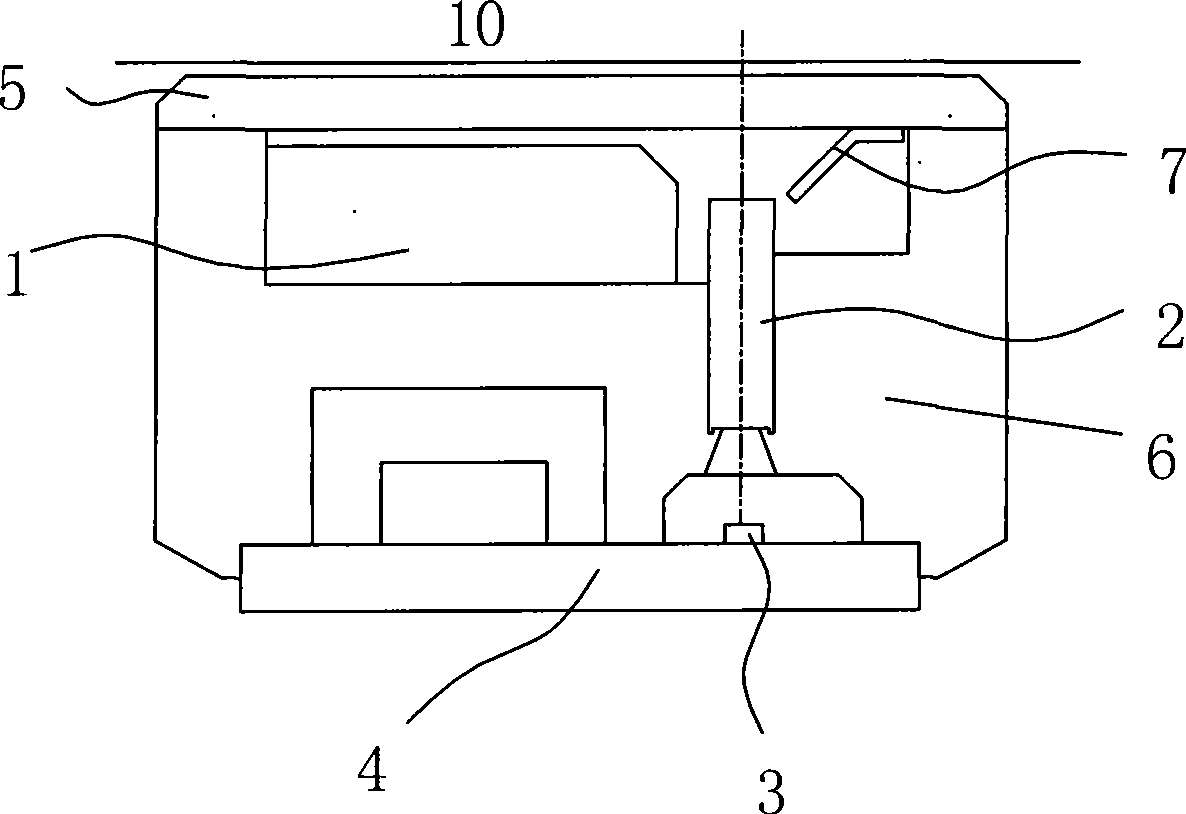

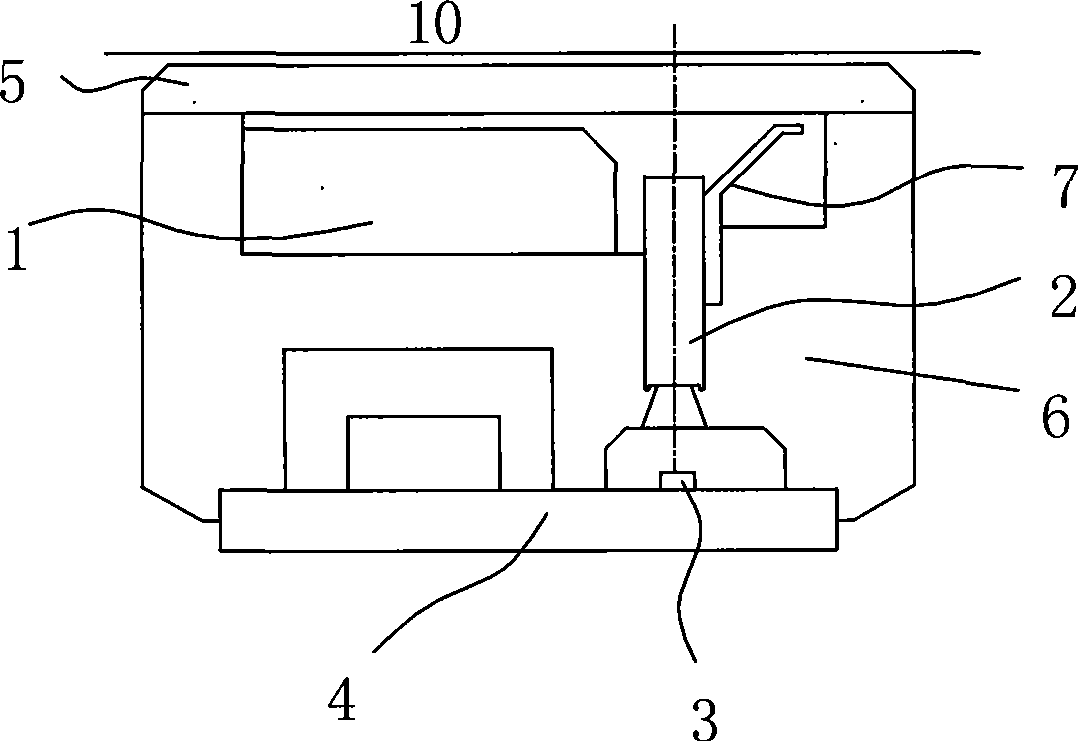

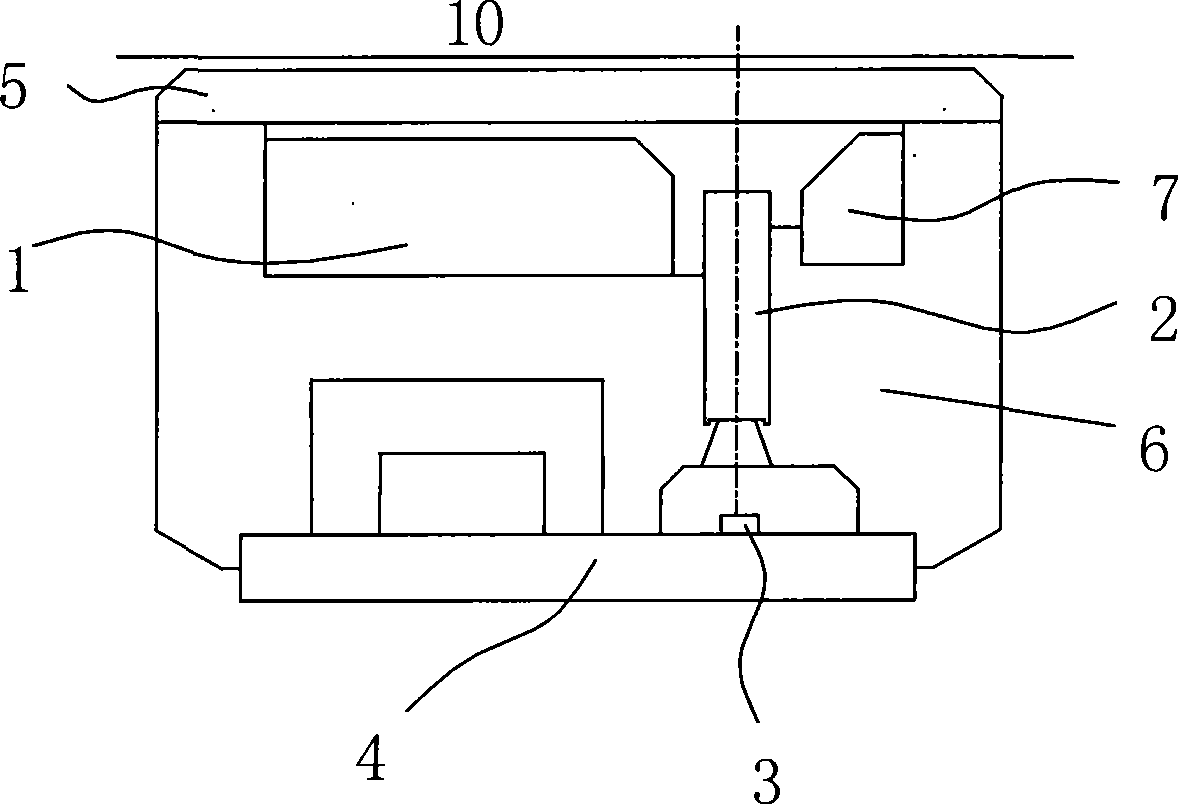

[0019] as attached figure 1 As shown, 1 is a light-emitting light source, 2 is a lens, 3 is a photosensitive part that receives light collected by the lens 2, that is, a photosensitive integrated circuit, 4 is a sensor substrate equipped with photosensitive integrated circuits 3 arranged in a line, and 6 is accommodating the light source 1, The frame of the lens 2 and the sensor substrate 4, 5 is a light-transmitting plate arranged on the top of the frame 6 to carry the original. The structure of the above-mentioned components and the interconnection relationship between them are the same as those of the prior art, and will not be repeated here. In the present invention, 7 is a reflective device arranged on the side of the lens opposite to the light source. The reflective surface of the reflective device is on a vertical direction symmetrical to the light emitting directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com