Bidirectional triangle arm rubber lining for spacing suspension system

A technology of suspension system and rubber bushing, which is applied to the direction of the cantilever mounted on the pivot, the suspension, and the spring made of plastic materials, etc., which can solve the problems of high cost of parts and high cost of installation man-hours, and reduce installation The effect of simple process and structure and ingenious conception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

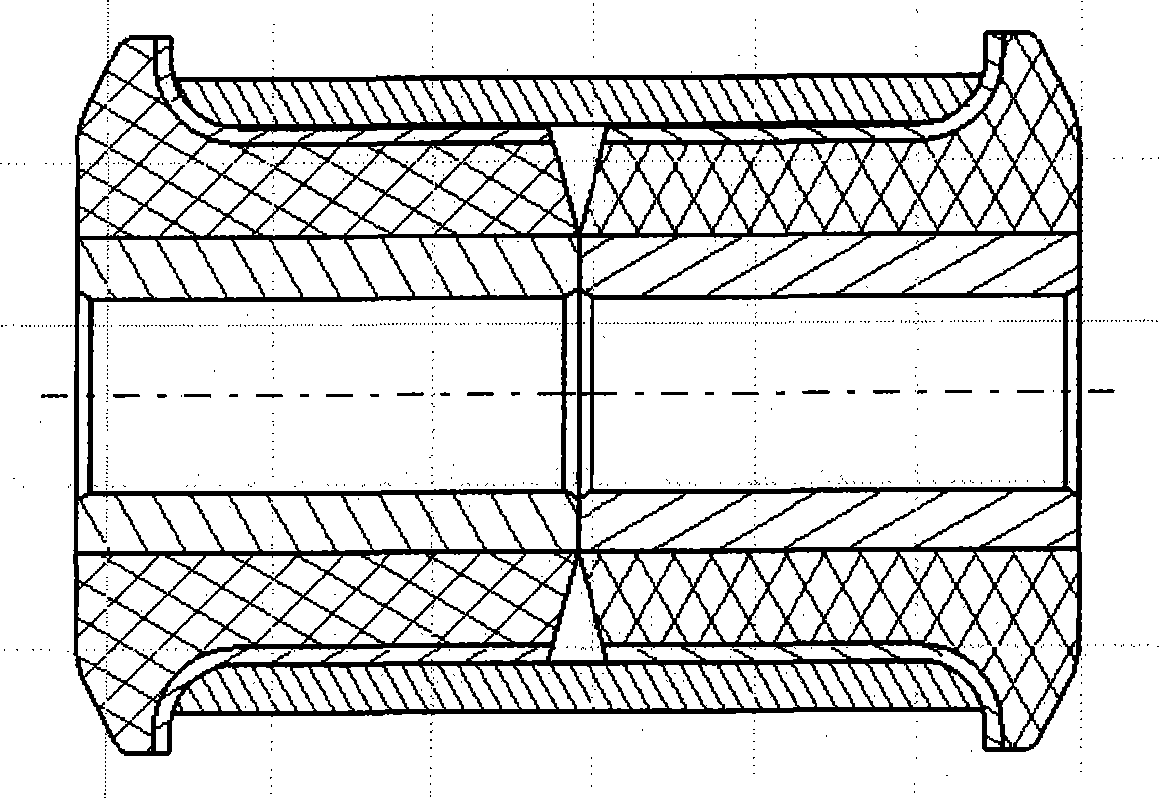

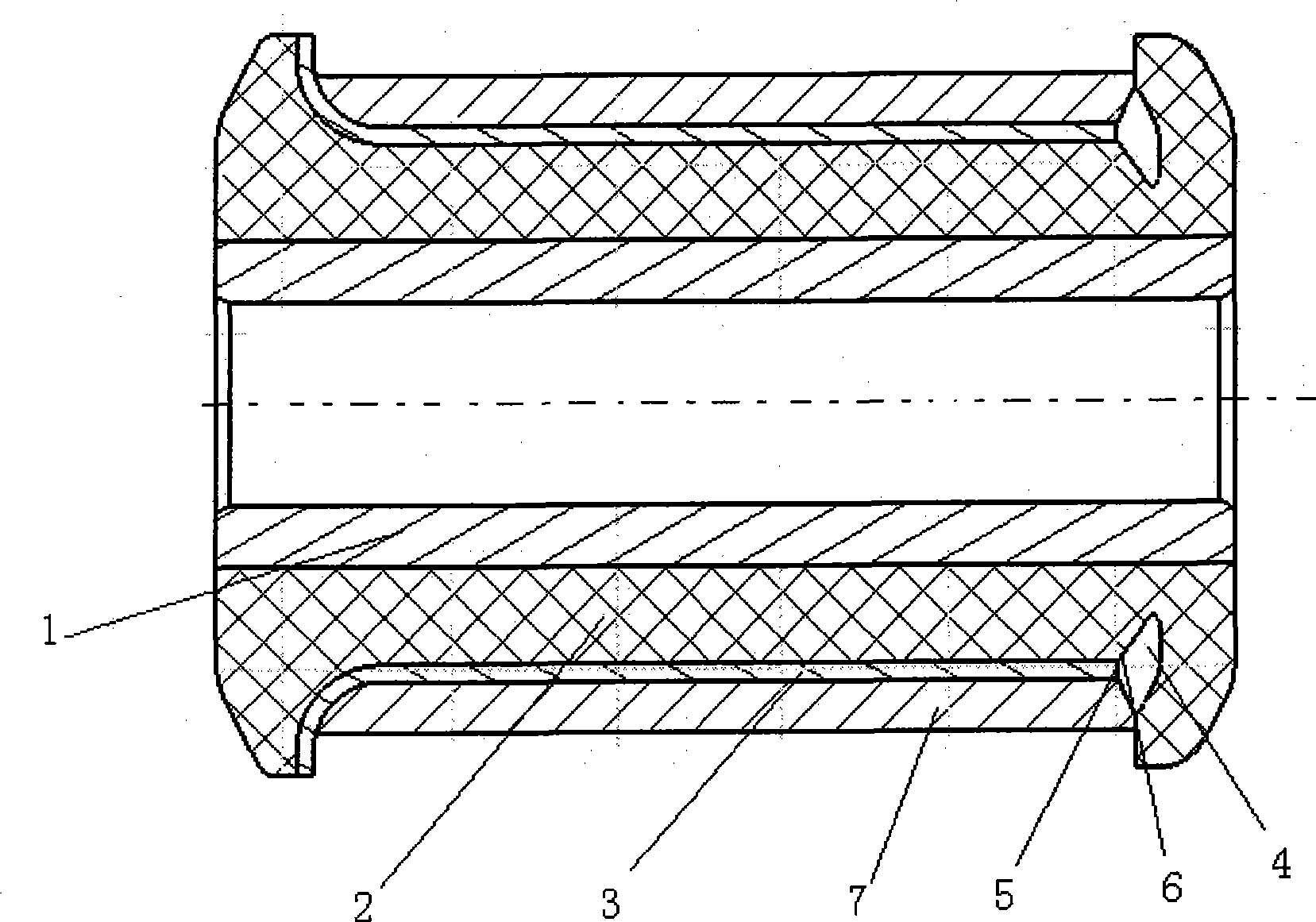

[0008] Such as figure 2 As shown, the bushing inner ring 1 has a rubber ring 2 with an "I"-shaped cross-section on the sleeve shaft, and a rubber deformation groove 4 is provided between the inner bottom of the "I"-shaped convex edge at one end of the rubber ring and the side end of the rubber ring. The notch width of the rubber deformation groove is larger than the groove bottom width, and the section of the rubber deformation groove is "V" shape. The direction of the "V" type rubber deformation groove is not perpendicular to the axis. The angle between the direction of the "V"-shaped rubber deformation groove and the axis is an acute angle, so that the "V"-shaped rubber deformation groove is in the same extrusion deformation direction as the "I"-shaped convex edge, which is beneficial to the "I"-shaped rubber ring " Extrusion deformation and elastic reset of "I"-shaped convex edge.

[0009] The shaft section of the outer ring 3 of the bushing is "T" type and is set on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com