Closed loop cycle electric heater with decompression apparatus

A pressure relief device and electric heater technology, applied in the field of electric heaters, can solve problems such as hidden dangers, explosion venting, and long-term aging, and achieve the effects of good reliability, high accuracy of pressure relief, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

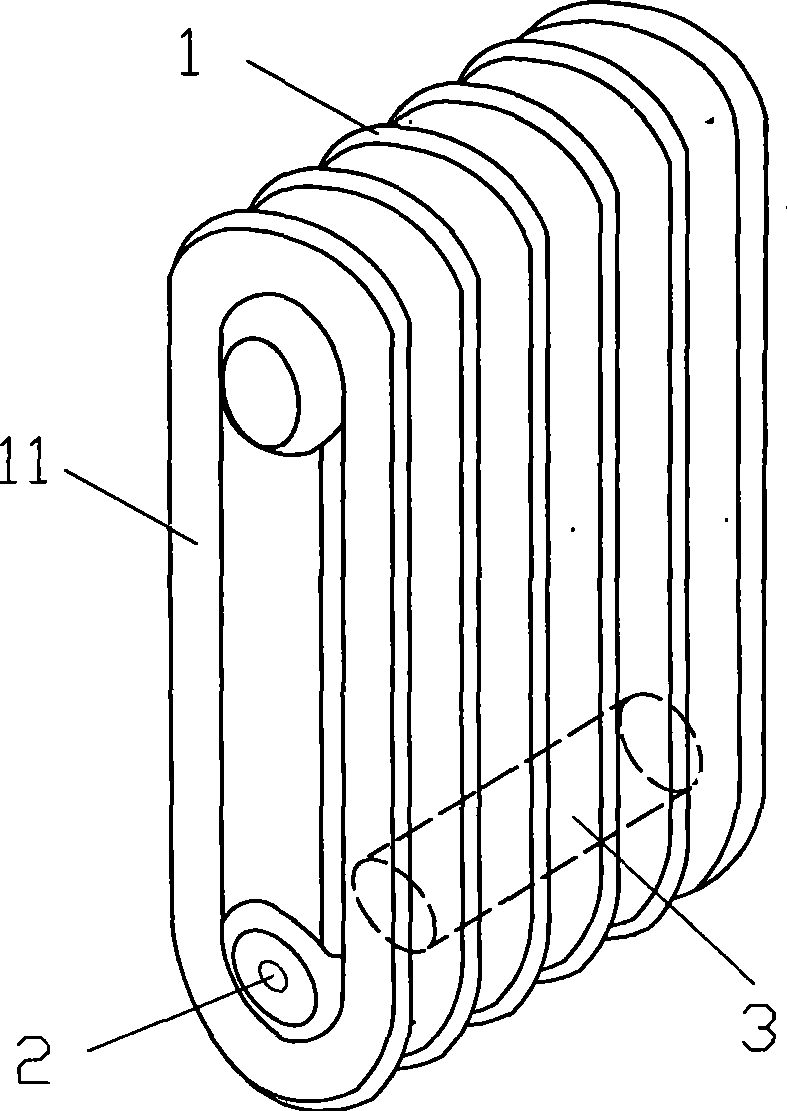

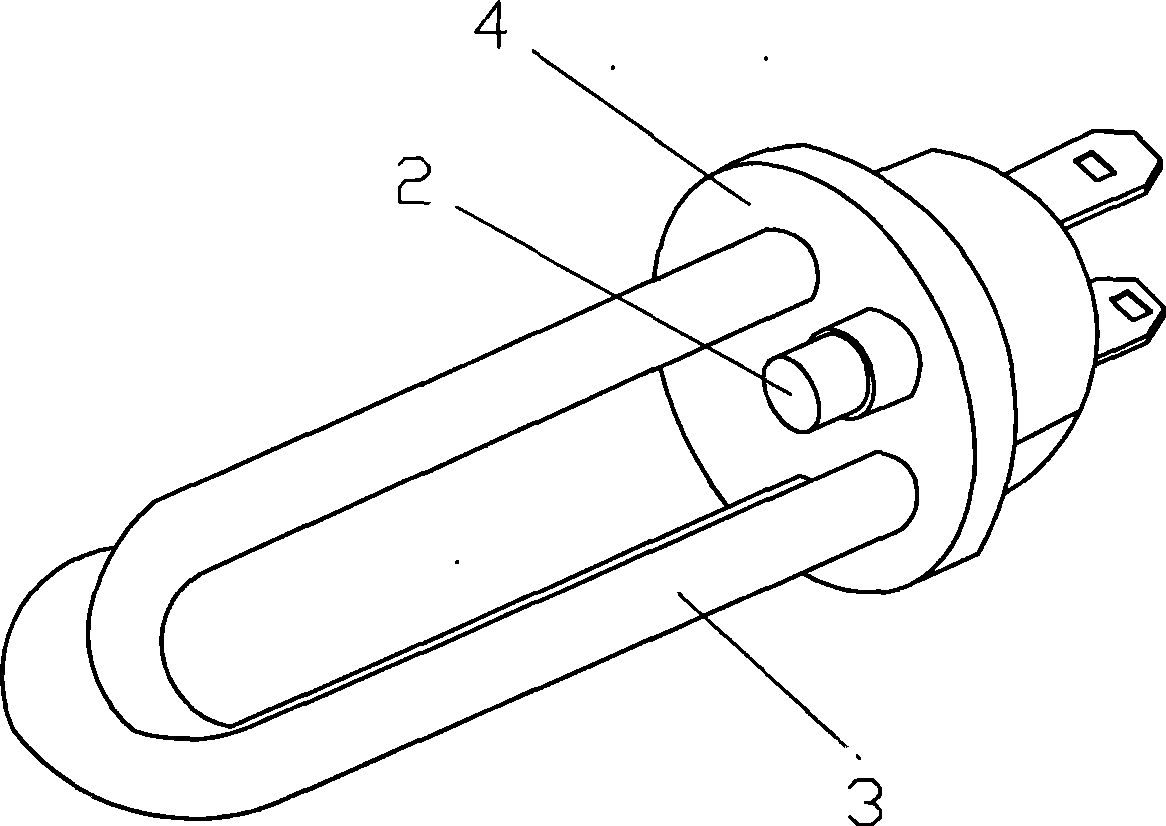

[0013] Refer to figure 1 , figure 2 , A closed-loop circulating electric heater with pressure relief device, comprising an electric heating group 1 composed of heat exchange blades 11, the blades 11 are filled with liquid, and an electric heating tube 3 is arranged below the inside of the electric heating group 1. A pressure relief hole 2 is provided on the heater, and the pressure relief hole 2 is sealed by a low melting point material. The material is a metal alloy with a melting point of 110°C to 180°C. The sealing form can be riveting or welding fusion sealing.

[0014] The pressure relief hole 2 of this product can be arranged at any position of the electric heater, such as: the side wall of the blade 11 or the end seat 4 of the electric heating tube 3 or the electric heating tube 3, in short, as long as it achieves the technology of the present invention by basically the same means The effects should all belong to the protection scope of the present invention.

[0015] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com