Top and bottom board for permatron

A technology of magnetron and yoke, applied in the field of magnetron, can solve the problems of uneven distribution of magnetic field, inability to locate magnets correctly, etc., and achieve the effect of good concentricity and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

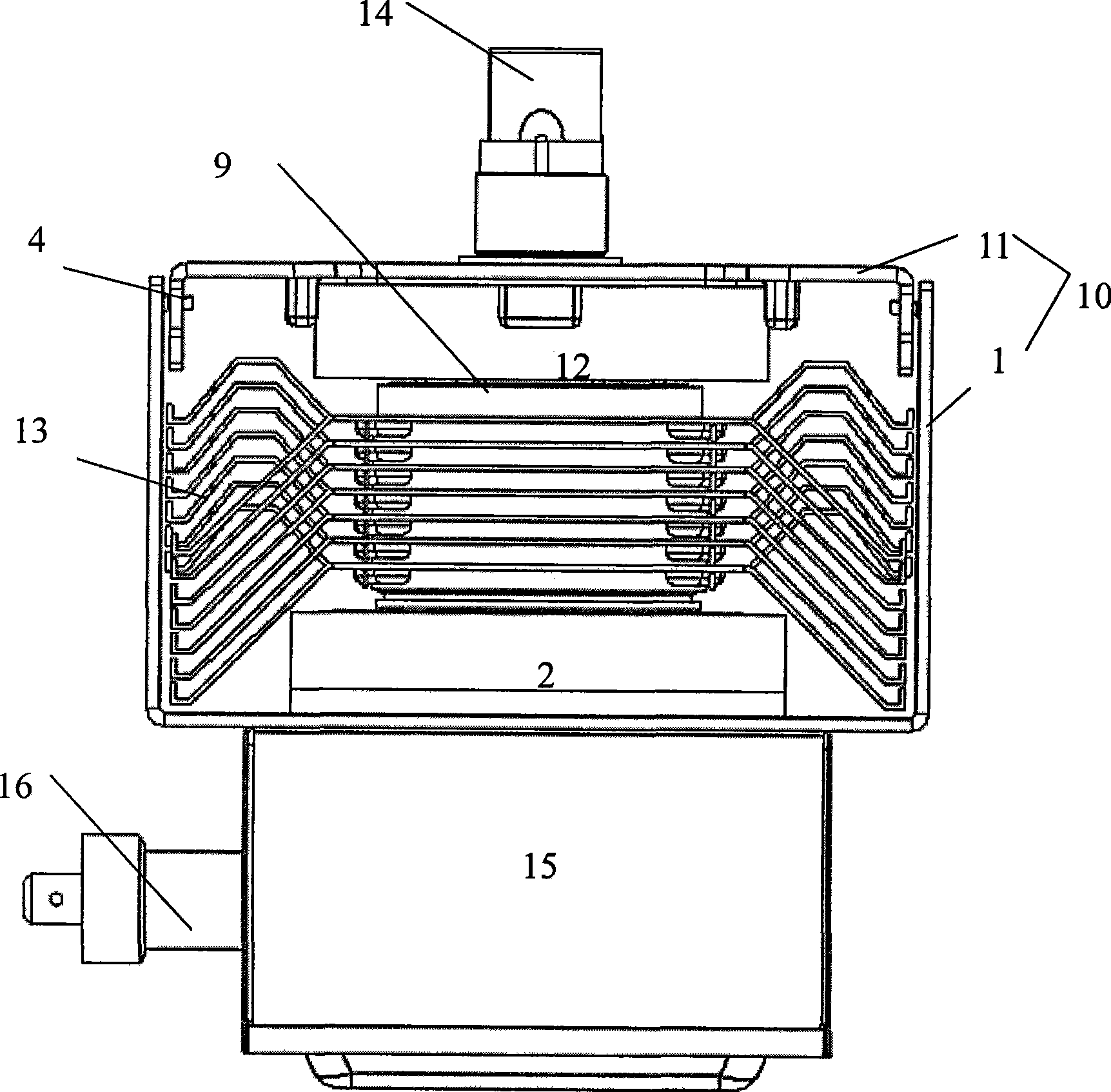

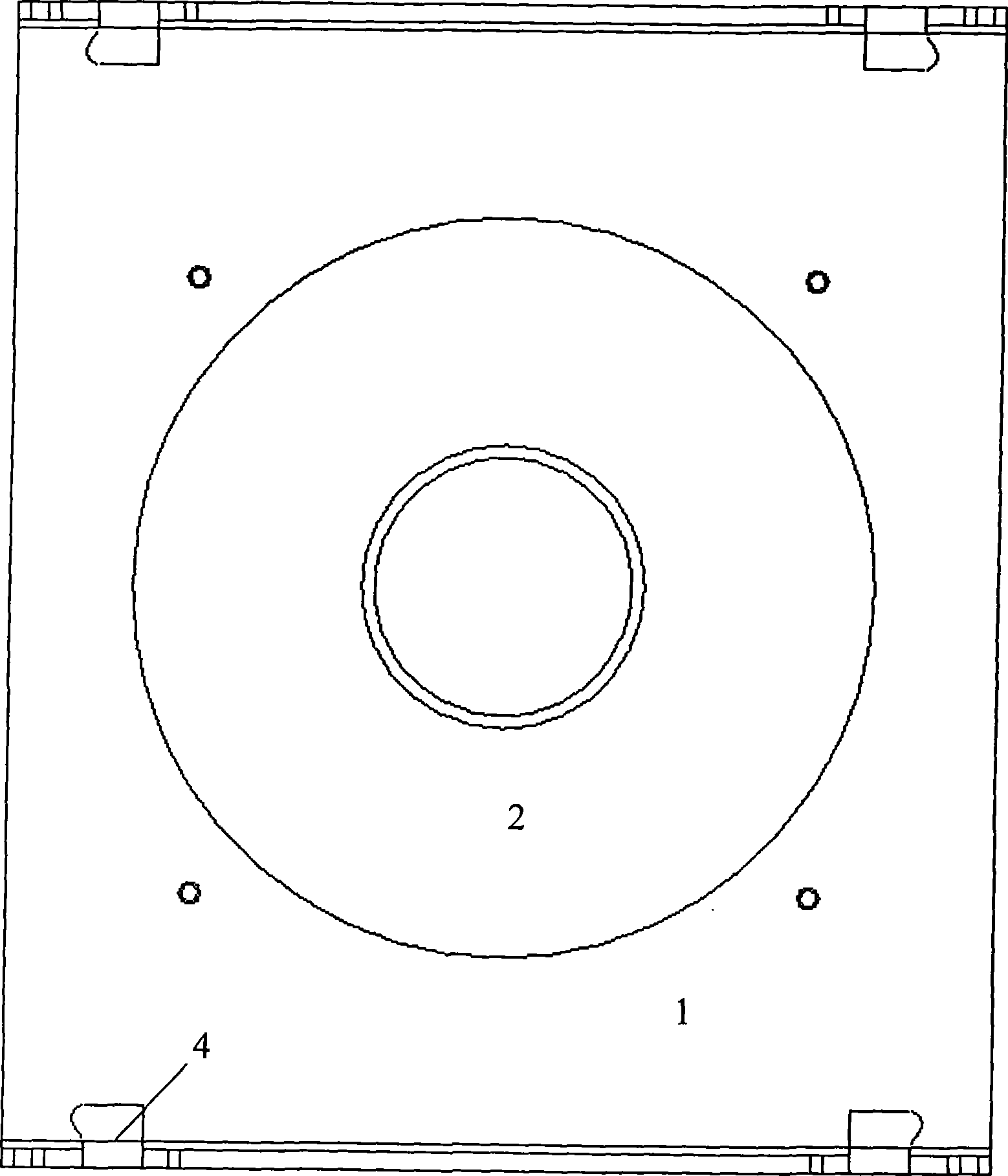

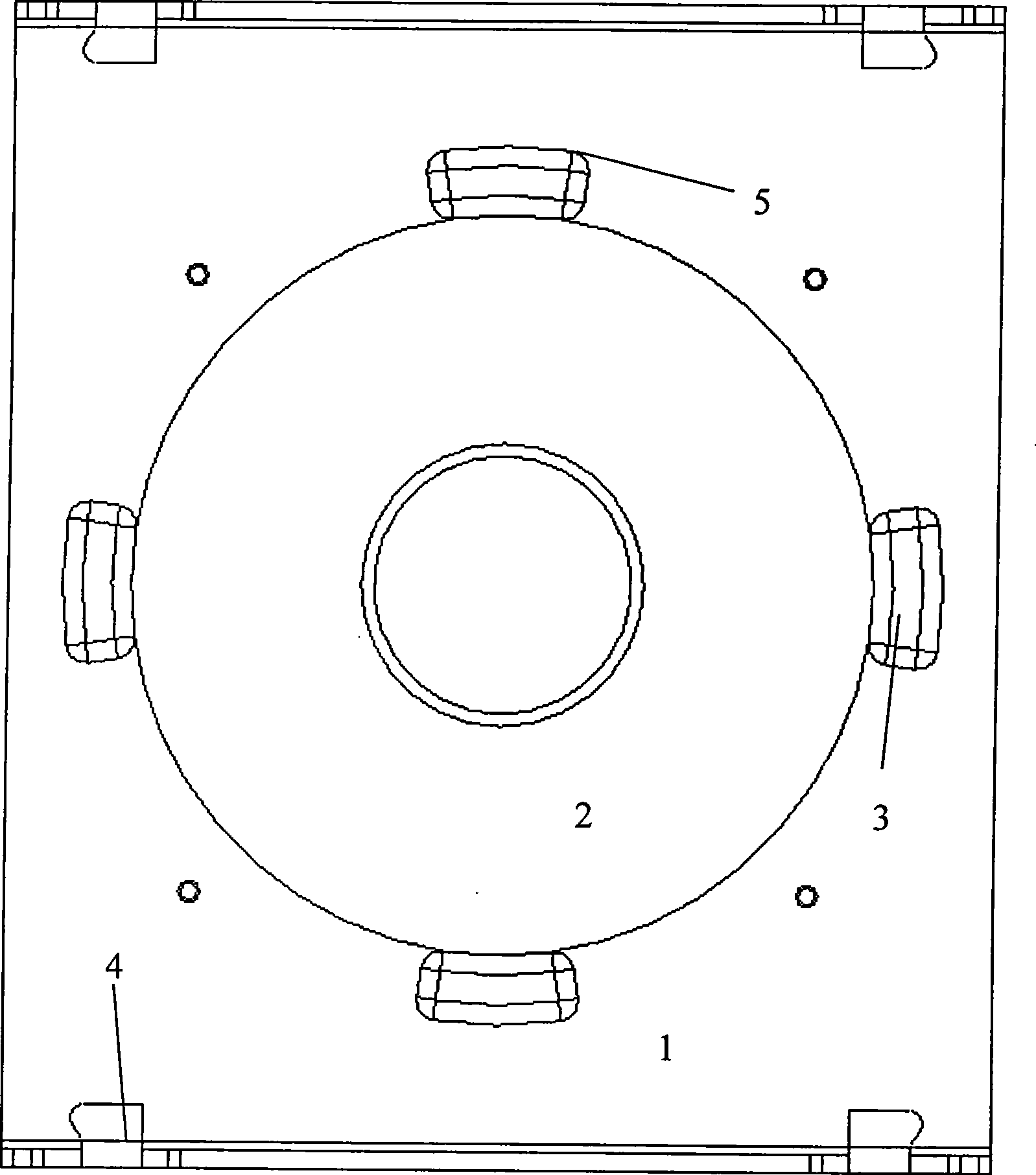

[0022] The upper and lower plates for the magnetron of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments:

[0023] The magnetron where the upper and lower plates are used for the magnetron of the present invention is the same as the prior art. The yoke 10 is formed by connecting the upper plate 11 and the lower plate 1, and is roughly in the shape of a square box with openings on both sides. The top surface of the upper plate 11 All be square with the bottom surface of lower plate 1, the side wall of upper plate 11 is shorter, and the side wall of lower plate 1 is higher, and correspondingly be provided with connecting portion 4 on the side wall of upper and lower plate, connecting portion 4 connects upper, lower plate. The lower plate is combined to form a yoke 10, and the inside of the yoke 10 is equipped with an anode assembly and a cathode assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com