Tobacco carton distributing apparatus capable of pre-sorting

A distribution device and pre-sorting technology, which is applied in the direction of object destacking, transportation and packaging, conveyor objects, etc., can solve the problem of affecting the sorting ability of equipment, and it is difficult to meet the needs of efficient sorting in the automatic logistics system of cigarette sorting , low distribution efficiency and other issues, to achieve the effect of shortening the sorting time, improving the appearance of cigarettes, and shortening the length of orders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

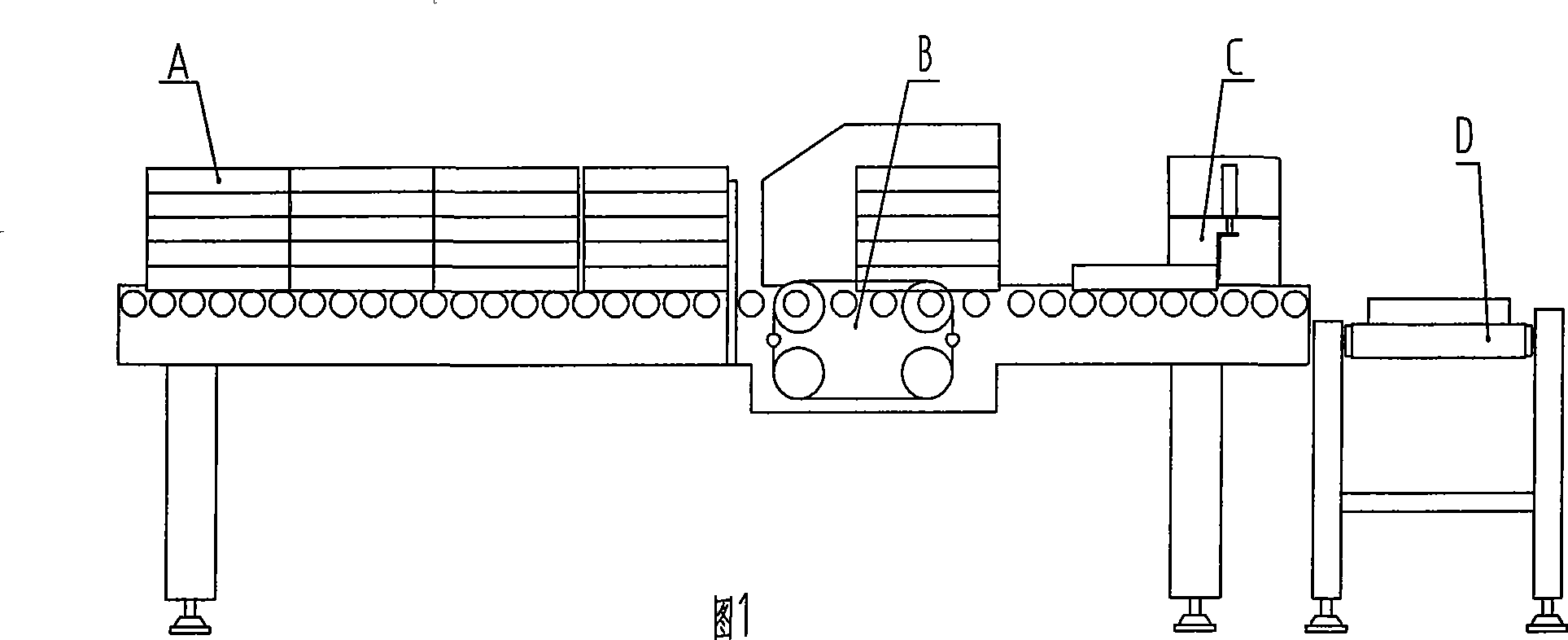

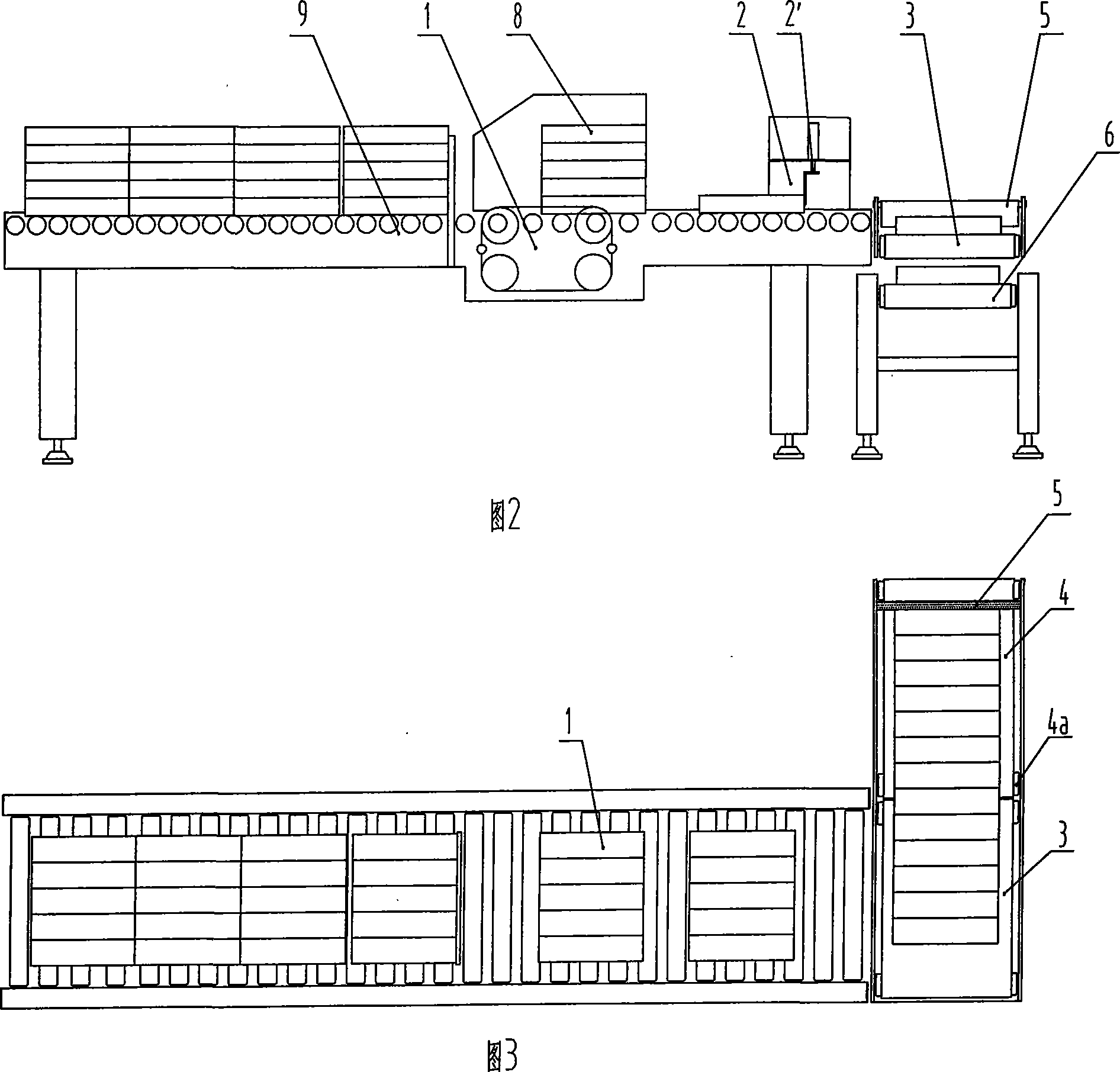

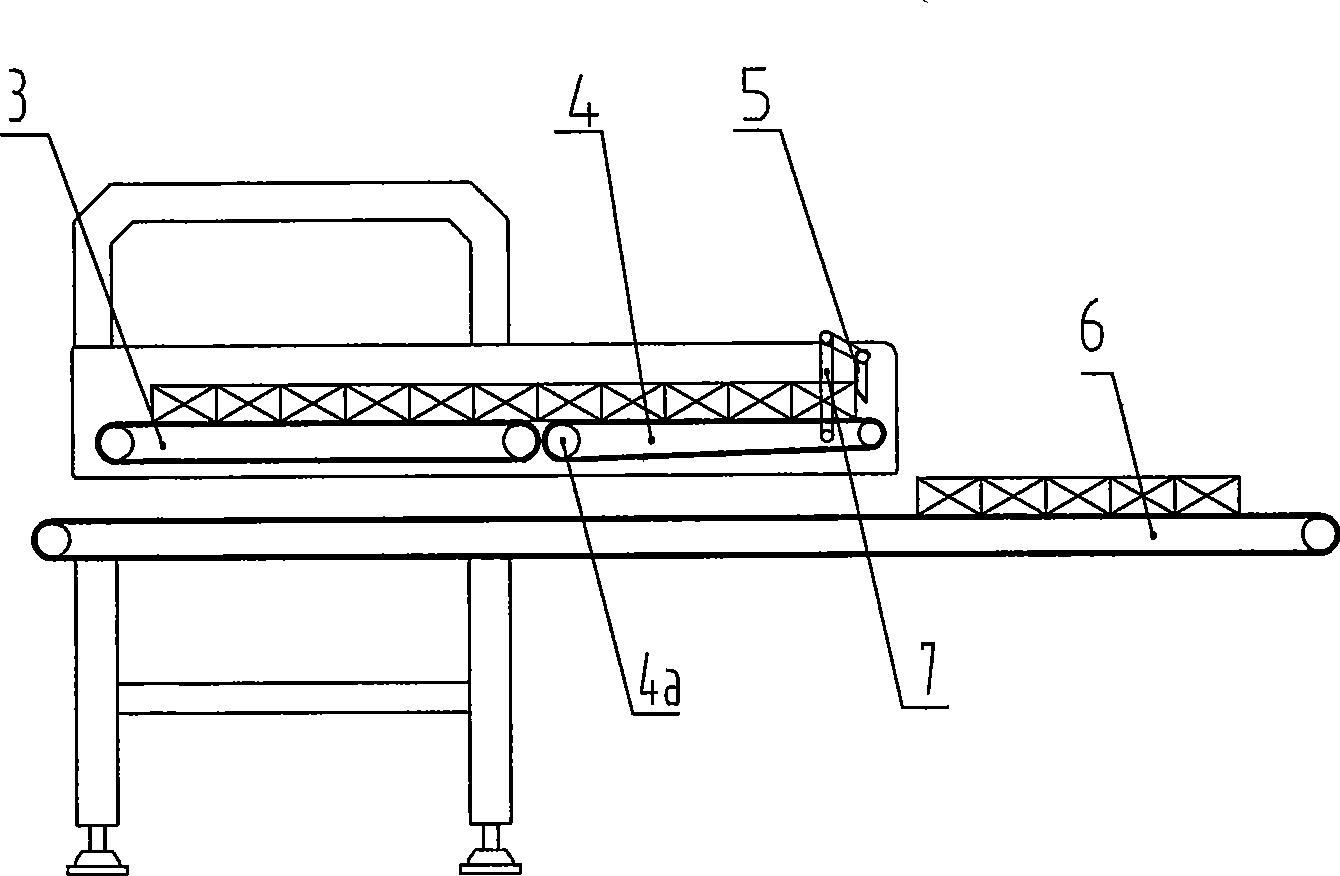

[0013] Such as figure 2 ~As shown in Figure 4, the present invention comprises the layer distributing mechanism 1 that can be distributed layer by layer to the stack of cigarettes installed in sequence, the rod distribution mechanism 2 that can distribute single-layer cigarettes by rods, and at the outlet end of the rod distribution mechanism 2 A pre-sorting buffer conveying mechanism is provided; the pre-sorting buffer conveying mechanism includes a horizontal fixed conveying mechanism 3, a swing conveying mechanism 4 installed behind the fixed conveying mechanism and can swing up and down at the entrance end as a support shaft 4a, A buffer and blocking mechanism 5 is arranged above the outlet end of the swing conveying mechanism 4 . The outlet end of the swing conveying mechanism 4 is connected with the central conveying mechanism 6 . The horizontal position of the central conveying mechanism 6 is lower than the fixed conveying mechanism 3 . The outlet end of the fixed co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com