Electric angle grinder with secondary action unlocking mechanism

An angle grinder and opening mechanism technology, applied in grinding/polishing equipment, grinding machines, portable grinding machines, etc., can solve problems such as misoperation, the two actions of the opening switch are not obvious enough, and the first lock hole is separated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

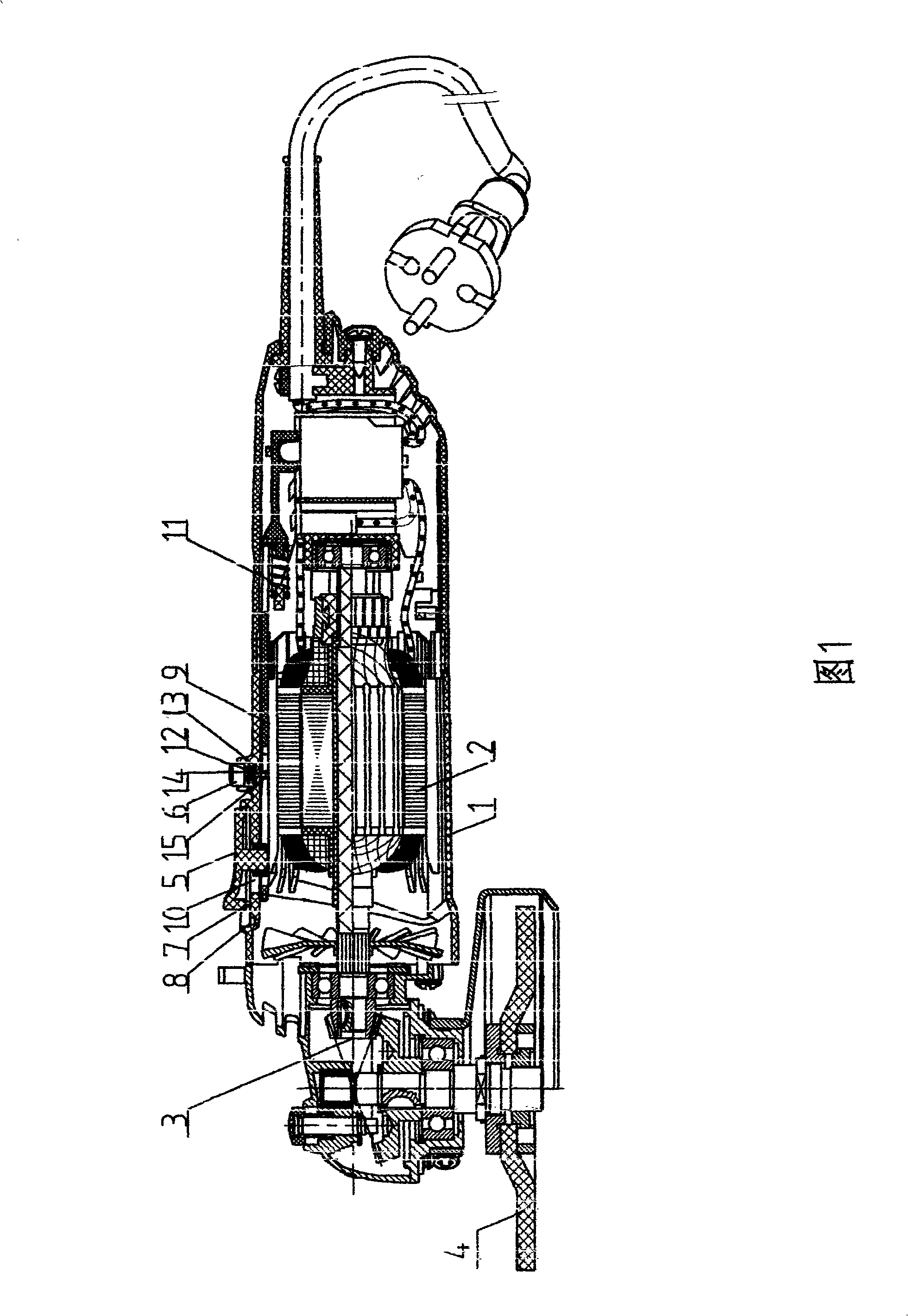

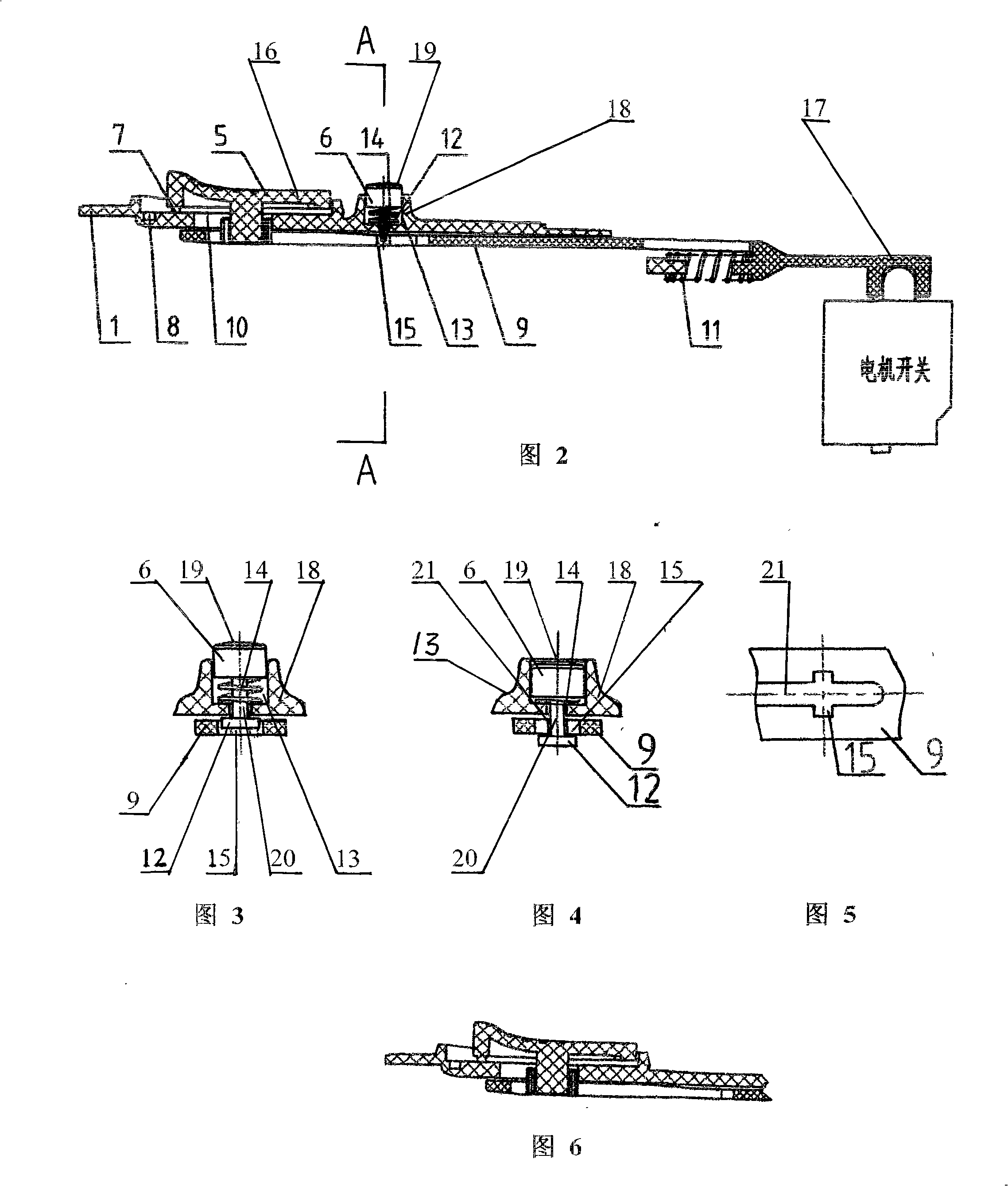

[0015] What is represented by Fig. 1-5 is an embodiment of the present invention, which includes a casing 1, a motor 2, a transmission mechanism 3, a working head 4, a switch mechanism 5, and an anti-mistaken opening mechanism 13, and the switch mechanism 5 includes: the bottom is provided with The bump is used as the push button 16 of the lock catch 7, the lock hole 8 correspondingly matched with the bump of the push button 16 on the casing 1, the chute 10 for the push button 16 to slide back and forth on the casing 1, the inside of the casing 1 and the The pull bar 9 that push button 16 is connected, the first back-moving spring 11 that is connected with pull bar 9, the motor switch that toggles on or off with the shift fork 17 of pull bar 9, the beginning end and the terminal end of stroke at pull bar 9 places are respectively with the closing of push button 16. The position corresponds to the opening position; the anti-mistaken opening mechanism 13 is provided with a button...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com